Repair assembly for corrosion-resistant layer of buried pipeline and construction method

A technology of buried pipeline and construction method, applied in the direction of coating, can solve the problems of difficulty in ensuring the quality of anti-corrosion layer, construction efficiency, and inability to carry water, and achieve the effect of low surface treatment requirements and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

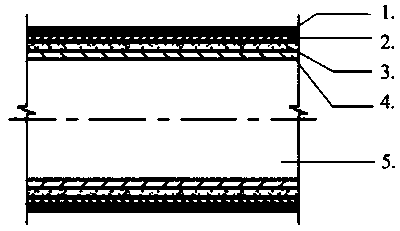

[0034] Such as figure 1 As shown, a buried pipeline anticorrosion layer repair kit, the repair kit is coated on the outside of the pipe body 5, the repair kit is a layered structure, oily petrolatum primer 4, oily petrolatum tape from the inside to the outside 3. Outer protective tape 2 and armored outer protective tape 1.

[0035] Described oily petrolatum primer 4 selects STACprime primer for use. Anti-corrosion primer is an important part of the preliminary treatment of the surface of the workpiece before winding the anti-corrosion oil tape. good combination.

[0036] The oily petrolatum tape 3 is selected from STACwrap oil tape. Anti-corrosion oil tape is a long-term anti-corrosion, sealing and waterproof protection tape for metal surfaces, pipes and fittings under industrial atmospheric conditions. It has excellent flexibility and hydrophobici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com