High solid labour-saving paint

A high-solids, coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of not having high solids, not carrying rust and damp construction, etc., to shorten the construction period, reduce costs, and reduce requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

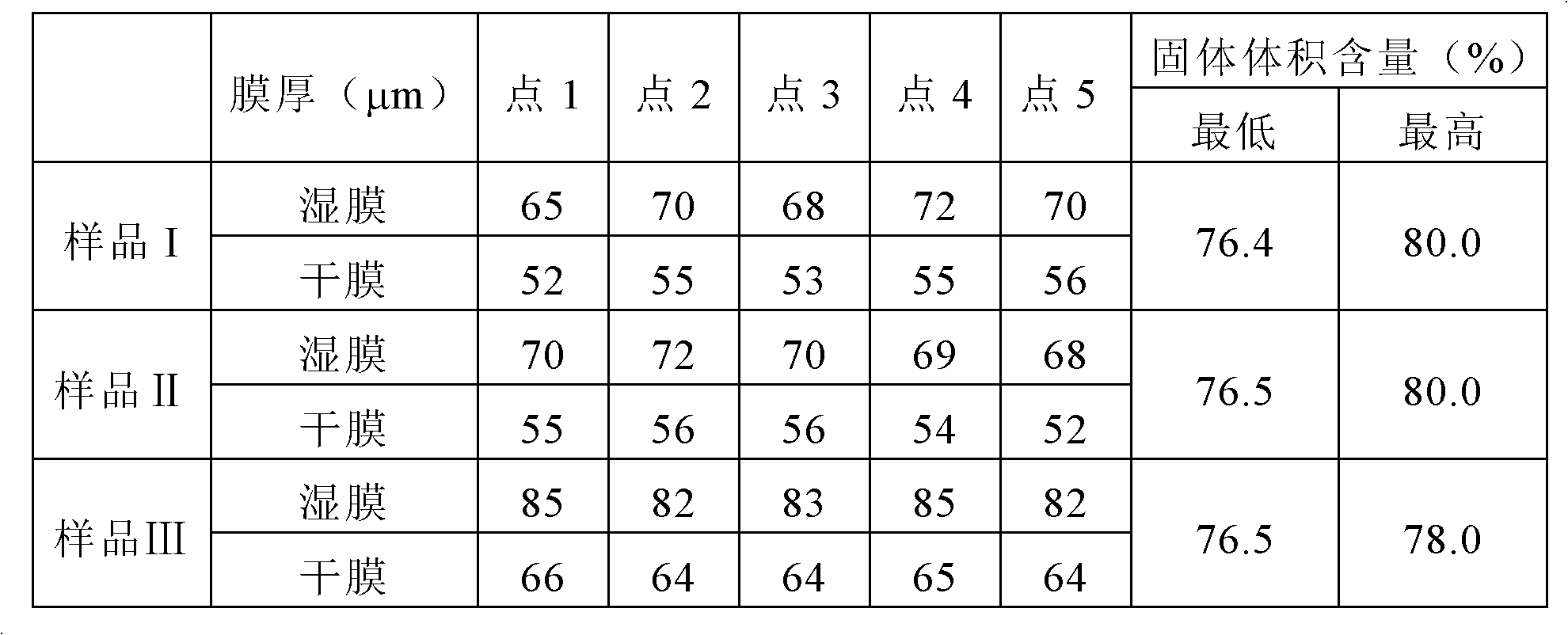

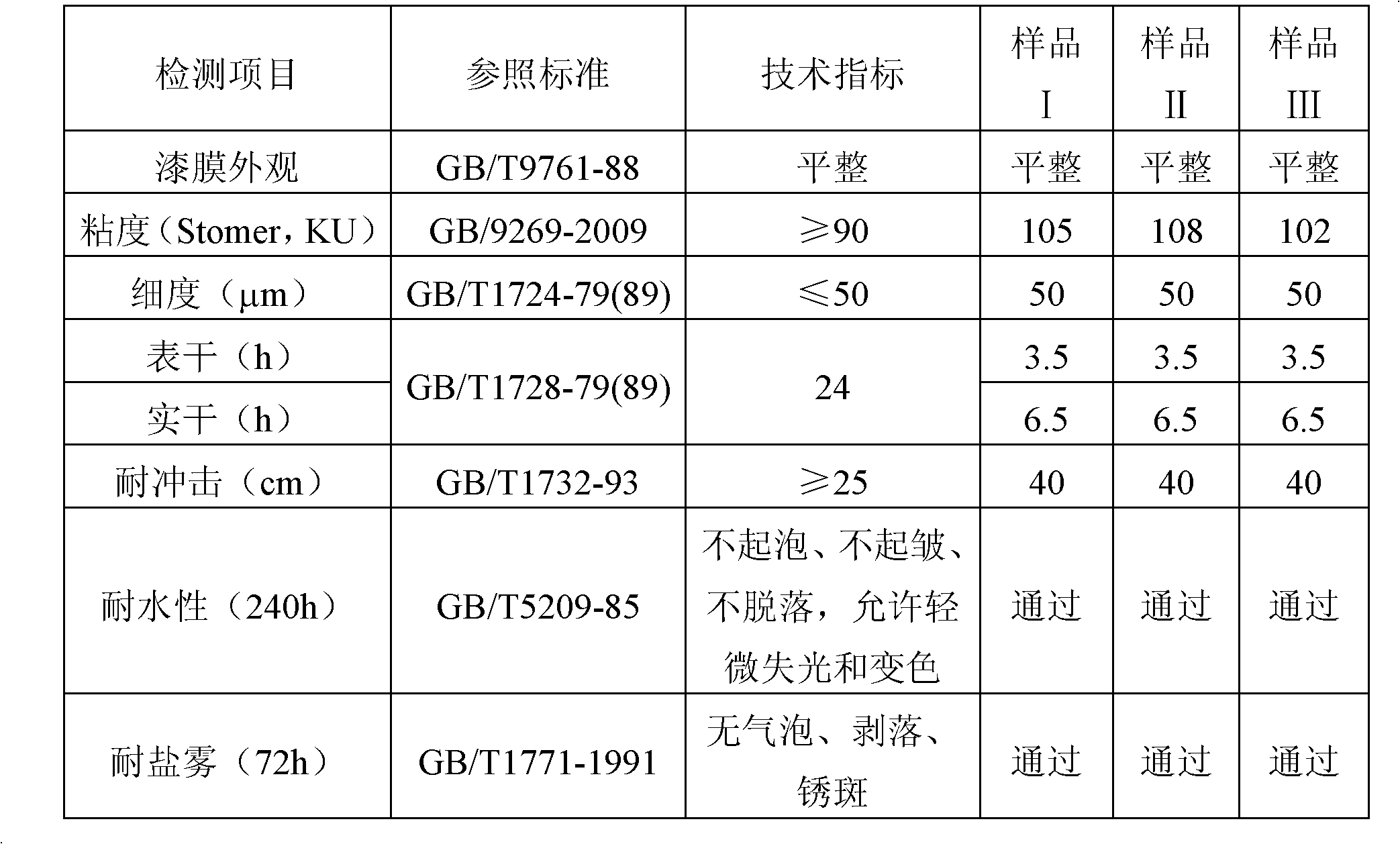

Embodiment 1

[0044] Preparation of Coating Composition I

[0045] Base material A: first add 250g of bisphenol A modified epoxy resin into the container, and then add 10g of wetting agent, 10g of dispersing agent, 10g of leveling agent, 10g of defoaming agent, and 10g of anti-settling agent (respectively Qian 904, soybean lecithin, Deqian 202P, Deqian 435, Dow Corning DC62) 50g coating additive mixture, then add the toughening agent made up of 25g phthalate, 25g adipate, stir and disperse Uniform; Add the pigment and filler mixture consisting of 90g of quartz powder, 90g of talc powder, 90g of titanium dioxide, 90g of alumina powder, 90g of superfine zinc powder, 75g of phosphorus titanium powder, and 75g of phosphorus, iron, zinc and silicon powder to the above mixture. Anti-rust agent: After uniform dispersion, grind to a fineness of 50 μm with a sand mill, and finally add a mixed solvent composed of 25 g of crude toluene and 25 g of n-butanol, adjust the viscosity to 100-110 KU, and fil...

Embodiment 2

[0048] Preparation of Coating Composition II

[0049] Base material A: first add 300g of bisphenol A modified epoxy resin into the container, then add 10g of wetting agent, 10g of dispersant, 10g of leveling agent, 10g of defoamer, and 10g of anti-settling agent (respectively Qian 904, soybean lecithin, Deqian 202P, Deqian 435, Dow Corning DC62) 50g coating additive mixture, then add the toughening agent made up of 25g phthalate, 25g adipate, stir and disperse Uniform; Add the pigment and filler mixture consisting of 80g of quartz powder, 80g of talc powder, 80g of titanium dioxide, 80g of alumina powder, 80g of superfine zinc powder, 75g of phosphorus titanium powder, and 75g of phosphorus, iron, zinc and silicon powder to the above mixture. Anti-rust agent: After uniform dispersion, grind to a fineness of 50 μm with a sand mill, and finally add a mixed solvent composed of 25 g of crude toluene and 25 g of n-butanol, adjust the viscosity to 100-110 KU, and filter to obtain th...

Embodiment 3

[0052] Preparation of Coating Composition III

[0053] Base material A: first add 300g of bisphenol A modified epoxy resin into the container, then add 10g of wetting agent, 10g of dispersant, 10g of leveling agent, 10g of defoamer, and 10g of anti-settling agent (respectively Qian 904, soybean lecithin, Deqian 202P, Deqian 435, Dow Corning DC62) 50g coating additive mixture, then add the toughening agent made up of 25g phthalate, 25g adipate, stir and disperse Uniform; Add the filler mixture consisting of 90g of quartz powder, 90g of talc powder, 90g of titanium dioxide, 90g of alumina powder, 90g of superfine zinc powder, 50g of phosphorus titanium powder, and 50g of phosphorus, iron, zinc and silicon powder into the above mixture. Rust agent: After uniform dispersion, grind to a fineness of 50 μm with a sand mill, and finally add a mixed solvent consisting of 25 g of crude toluene and 25 g of n-butanol, adjust the viscosity to 100-110 KU, and filter to obtain the finished b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com