Electrolyte and technology for preparing ceramic coating formed by plasma micro-arc oxidation on zirconium alloy surface

A technology of surface plasma and micro-arc oxidation, which is applied in the field of improving wear resistance and corrosion resistance of zirconium and its alloys, to achieve the effects of low processing requirements, improved service life, wear performance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

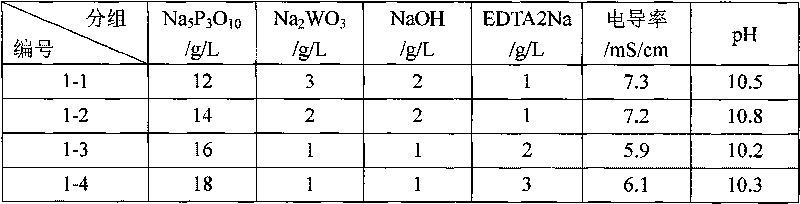

[0026] (1) After dissolving the solute main salt sodium tripolyphosphate, auxiliary salt sodium tungstate, alkali sodium hydroxide and stabilizer edetate disodium in deionized water respectively, according to the main salt, auxiliary salt, The order of stabilizer and alkali is injected into the electrolytic cell in sequence, and deionized water is added to make the electrolyte reach the specified concentration conditions; the concentration of each component, the pH value of the electrolyte at 20°C and the conductivity of the electrolyte are shown in Table 1.

[0027] (2) Zirconium alloy surface treatment: After grinding and cleaning the corrosion products and oil stains on the zirconium alloy surface with sandpaper, rinse the surface of the zirconium alloy with flowing water and absolute ethanol in sequence, test the degreasing effect by water wetting method, and dry the zirconium alloy surface ready for use;

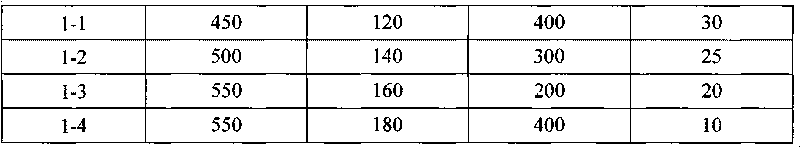

[0028] (3) Micro-arc oxidation process:

[0029] The zirconium al...

Embodiment 2

[0040] (1) After dissolving the solute main salt sodium silicate of the electrolyte, auxiliary salt sodium tungstate, alkali potassium hydroxide and stabilizer ethylenediaminetetraacetic acid with deionized water respectively, according to the main salt, auxiliary salt, stabilizer and The alkali is injected into the electrolytic cell in sequence, and deionized water is added to make the electrolyte meet the specified conditions; the concentration of each component, the pH value of the electrolyte at 20°C and the conductivity of the electrolyte are shown in Table 4.

[0041] (2) Zirconium alloy surface treatment: After grinding and cleaning the corrosion products and oil stains on the zirconium alloy surface with sandpaper, rinse the surface of the zirconium alloy with flowing water and absolute ethanol in sequence, test the degreasing effect by water wetting method, and dry the zirconium alloy surface ready for use;

[0042] (3) Micro-arc oxidation process:

[0043] The zirco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com