Solvent-free type heavy anti-corrosion coating based on secondary doped polyaniline nanometer material

A secondary doping, nanomaterial technology, applied in anti-corrosion coatings, polyamide coatings, epoxy resin coatings, etc., can solve problems affecting coating quality, high surface treatment requirements, general impact resistance, etc., and achieve impact resistance. Improved performance and bending resistance, low surface treatment requirements, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

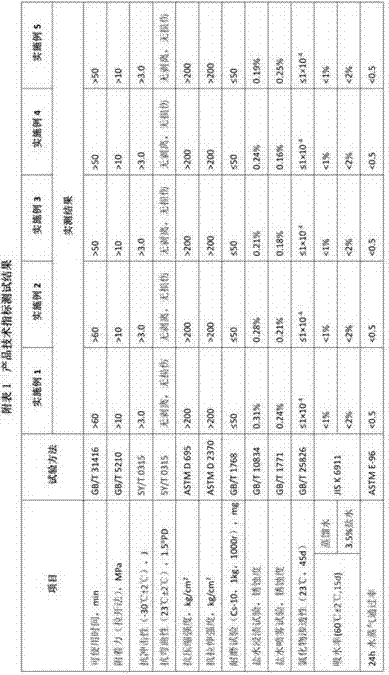

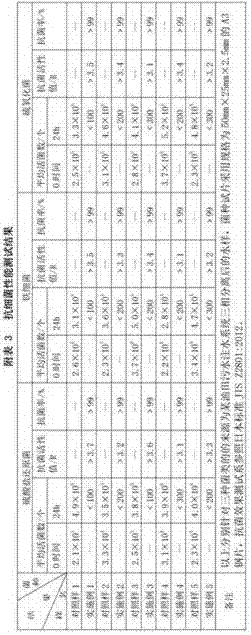

Embodiment 1

[0034] Component A: 32% liquid epoxy resin (epoxy equivalent 190), 7% core-shell rubber toughening agent (MX125, Kaneka, Japan), 6% reactive diluent, silane coupling agent (A-1120, United Carbon ) 0.6%, dispersant (BYK2152, BYK) 2.5%, defoamer (BYK A530, BYK) 0.3%, sterilant (Metatin 4208, ACIMA Buchs, Switzerland) 1.5%, thixotropic agent (BYK410, BYK chemical) 0.6%, leveling agent (BYK361N, BYK chemical) 2.5%, zinc phosphate 12%, mica powder 8%, superfine talc powder 20%, titanium dioxide (rutile type) 7%.

[0035] Component B: phenalkamine (NX-6019, Cardolite Chemicals) 56%, modified polyamide (Aradur 450, Huntsman) 20%, dispersant (BYK2152, BYK Chemicals) 2.4%, defoamer ( BYK A530 (byk chemical) 0.2%, nano graphite powder 6%, polyaniline (prepared by patent CN103819667A method) 15%, thixotropic agent (BYK410, byk chemical) 0.8%.

[0036] A preparation method of a solvent-free heavy-duty anti-corrosion coating based on secondary doped polyaniline material is as follows:

...

Embodiment 2

[0041] Component A: liquid epoxy resin (epoxy equivalent 190) 34%, core-shell rubber toughening agent (MX156, Kaneka, Japan) 9%, reactive diluent 7.3%, silane coupling agent (Z-6020, Dow Corning) 0.8 %, dispersant (EFKA6230, BASF Chemical) 2.2%, defoamer (EFKA2723, BASF Chemical) 0.4%, sterilizer (Rozone 2000, Rohm and Haas, USA) 1.8%, thixotropic agent (Tech-9010, Shanghai Tiger) 0.8%, leveling agent (EFKA3277, BASF chemical) 2.2%, zinc phosphate 10%, mica powder 7%, superfine talc powder 16%, titanium dioxide (rutile type) 8.5%. Component B: phenalkamine (NX-6019, Cardolite Chemicals) 53%, modified polyamide (Aradur 450, Huntsman) 26%, dispersant (EFKA6230, BASF Chemicals) 2.2%, defoamer (EFKA2723 , BASF chemical) 0.3%, nano graphite powder 5%, polyaniline (prepared by patent CN103819667A method) 13%, thixotropic agent (Tech-9010, Shanghai Tigermed) 0.5%.

[0042] A preparation method of a solvent-free heavy-duty anti-corrosion coating based on secondary doped polyaniline m...

Embodiment 3

[0047] Component A: liquid epoxy resin (epoxy equivalent 190) 36%, core-shell rubber toughening agent (MX960, Kaneka, Japan) 12%, reactive diluent 8%, silane coupling agent (KBM-603, Shin-Etsu Japan) 1%, dispersant (EFKA6230, BASF chemical) 2%, defoamer (BYK A530, BYK chemical) 0.5%, sterilant (Metatin 4208, ACIMA Buchs, Switzerland) 2%, thixotropic agent (BYK410, BYK Chemical) 1%, leveling agent (EFKA3277, BASF chemical) 2%, zinc phosphate 8%, mica powder 6%, superfine talc powder 12%, titanium dioxide (rutile type) 9.5%. Component B: phenalkamine (NX-6019, Cardolite Chemicals) 50%, modified polyamide (Aradur 450, Huntsman) 32%, dispersant (EFKA6230, BASF Chemicals) 2%, defoamer (BYK A530, BYK) 0.4%, nano graphite powder 4%, polyaniline (prepared by patent CN103819667A method) 11%, thixotropic agent (BYK410, BYK) 0.6%.

[0048] A preparation method of a solvent-free heavy-duty anti-corrosion coating based on secondary doped polyaniline material is as follows:

[0049] 1) Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com