Cashew phenolic aldehyde amide epoxy hardener for four-season-general type anticorrosive paint and preparation method of cashew phenolic aldehyde amide epoxy hardener

A technology of epoxy curing agent and anti-corrosion coating, applied in anti-corrosion coating, carboxylic acid amide preparation, chemical instruments and methods, etc., to achieve the effect of high yield, strong low temperature applicability and good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

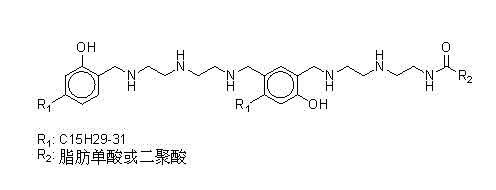

[0032] 1. A cashew nut phenolic amide epoxy curing agent for four-season general-purpose anticorrosion coatings, which is made of the following raw materials in parts by weight: 103g of diethylenetriamine, 280g of dimer acid or 18 carbon unsaturated fatty monoacids, cashew nuts 300g of phenol: 103g of diethylenetriamine, 94g of paraformaldehyde with a purity of 96%.

[0033] 2. The preparation method of the cashew nut phenolic amide epoxy curing agent for the above-mentioned four-season general-purpose anticorrosion coating specifically comprises the following steps:

[0034] (1) First put 103g of diethylenetriamine, 280g of dimer acid or 18-carbon unsaturated fatty monoacid into a 1000mL reactor, heat it to 140oC after stirring evenly, keep it for 2 hours, then heat it to 160oC for 1 hour, then Reheat to 180oC, keep warm for 2 hours, and cool down to 80oC after the water is completely discharged;

[0035] (2) Then put 300g of cardanol and 103g of diethylenetriamine into the ...

Embodiment 2

[0040] 1, a kind of cardanol phenalkamide epoxy curing agent for four seasons universal anticorrosion coating, it is made of the raw material of following parts by weight: diethylenetriamine 103g, unsaturated fatty acid 280g of 18 carbons, cardanol 300g, two Ethylenetriamine 103g, 37% formaldehyde aqueous solution 284g.

[0041] 2, the preparation method of cashew nut phenolic amide epoxy curing agent for the above-mentioned four-season general-purpose anticorrosion coating, it may further comprise the steps:

[0042] (1) First put 103g of diethylenetriamine and 280g of 18-carbon unsaturated fatty monoacid into a 2000mL reactor, stir well, heat to 140 oC, keep it for 2 hours, then heat it to 160oC for 1 hour, and then heat it to 180oC, keep warm for 2 hours, and cool down to 80oC after the water is completely discharged;

[0043] (2) Then put 300g of cardanol and 103g of diethylenetriamine into the reaction kettle of step (1), stir well, then slowly add 284g of 37% formaldehyde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| impact resistance | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com