Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Improve thermal compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and preparation method thereof

The invention relates to a high-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and a preparation method thereof. The preparation method comprises the following steps of: by taking a two-dimensional cloth paving layer and 2.5D woven or orthogonally three-dimensional woven continuous aluminum oxide fiber preform as an enhancer, preparing a matrix through a double nano composite impregnation liquid where silicon dioxide and aluminum oxide are uniformly mixed; and finally obtaining the aluminum oxide fiber enhanced composite material through the process of vacuum pressure impregnation, micro-positive pressure medium and low temperature pre-curing, micro-positive pressure curing and atmosphere temperature programming sub-sectional thermal treatment, wherein the mass ratio of silicon dioxide to aluminum oxide in the composite material is (19:1)-(12:8), and the volume content of the aluminum oxide fibers is 30-60%. The prepared composite material has a high-temperature-resistant property and a high-temperature mechanical property, and is high in compactness; the room temperature tensile strength of the material reaches 310+ / -30MPa, the tensile strength at 1100 DEG C reaches 135+ / -20MPa, and the tensile strength at 1200 DEG C reaches 90+ / -10MPa; and compared with a similar quartz fiber enhanced silicon dioxide oxide / oxide composite material, the performance is improved by 4-5 times.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Novel ultrahigh-temperature ceramic integrally-modified anti-ablation carbon/carbon composite material and preparation method thereof

ActiveCN107021773AImprove anti-ablation performanceExhibits high melting point propertiesCarbon compositesCarbon fibers

The invention discloses a novel ultrahigh-temperature ceramic (Zr0.8Ti0.2C0.74B0.26) integrally-modified anti-ablation carbon / carbon composite material and a preparation method thereof. The preparation method comprises the following steps: (1) performing high-temperature thermal treatment on a carbon fiber preform, and depositing pyrolytic carbon in a chemical gas phase permeation furnace to prepare a porous carbon / carbon composite material; (2) placing the carbon / carbon composite material on which the pyrolytic carbon is deposited on zirconium-titanium mixed powder, and preparing a zirconium-titanium carbide modified carbon / carbon composite material in a non-stoichiometric ratio through a high-temperature infiltration reaction method; (3) placing the composite material in mixed powder of C, B4C, SiC, Si and a penetration enhancer, and forming an integral ultrahigh-temperature ceramic modified carbon / carbon composite material by adopting an embedding method. The method is simple, is convenient to operate, can be used for preparing large-sized components, and is suitable for integrally modifying substrates and coatings of anti-ablation carbon / carbon composite materials in heat-resistant components of hypersonic aircrafts.

Owner:CENT SOUTH UNIV

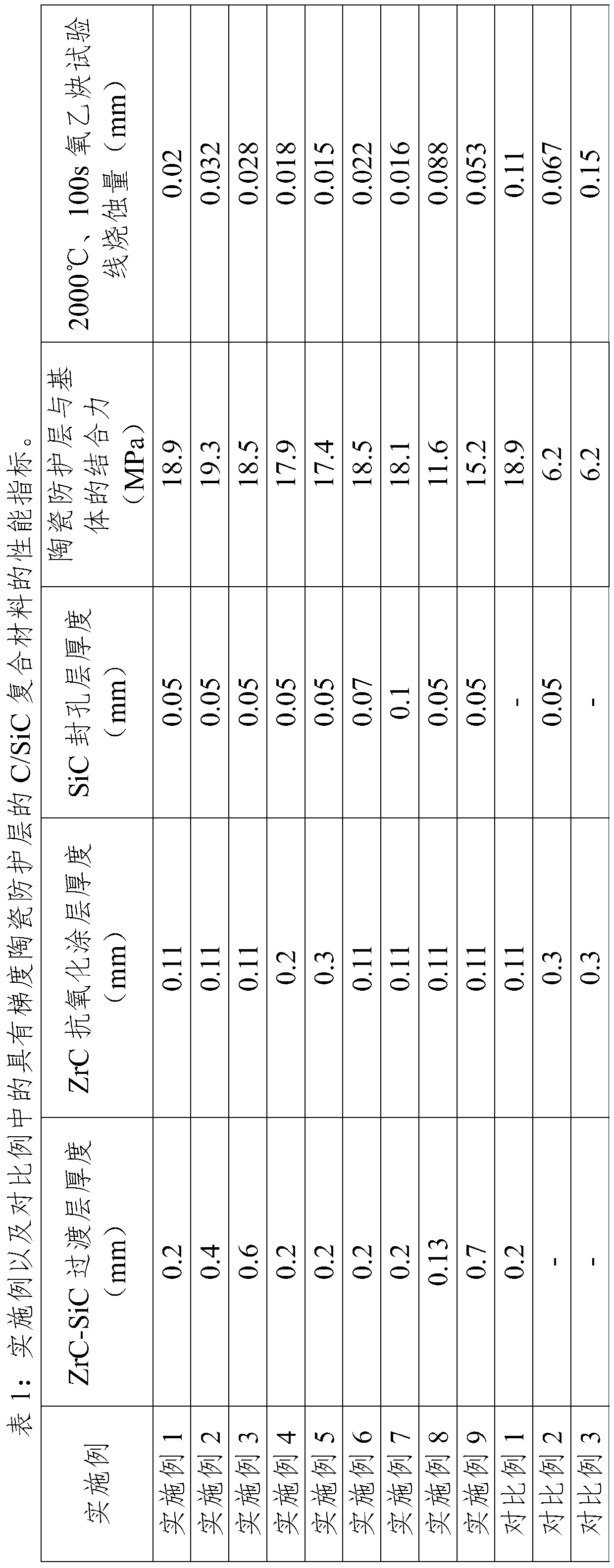

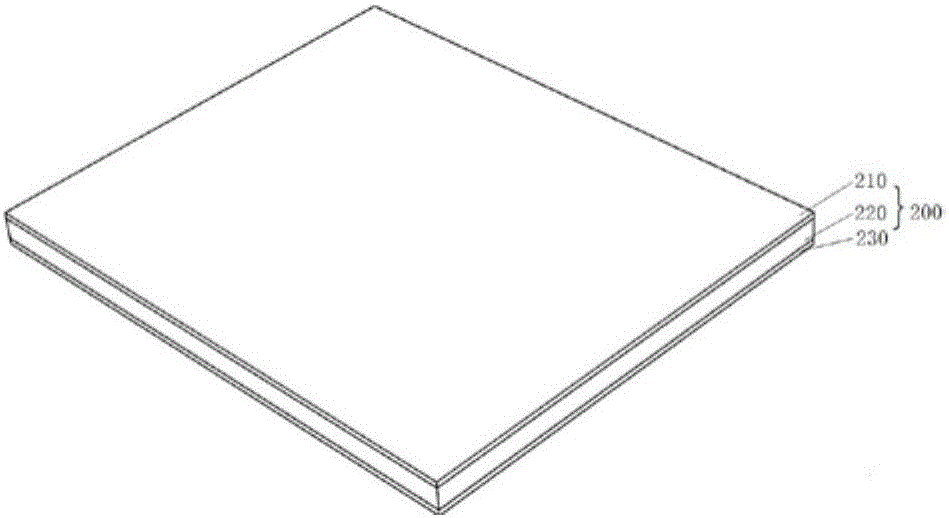

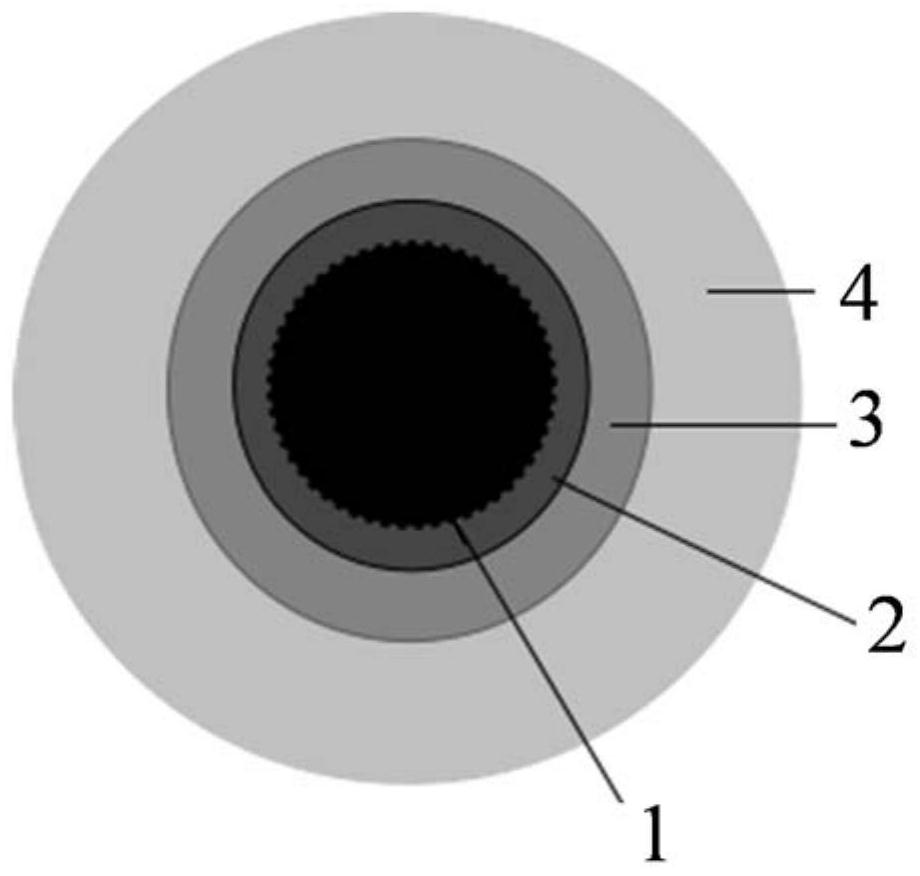

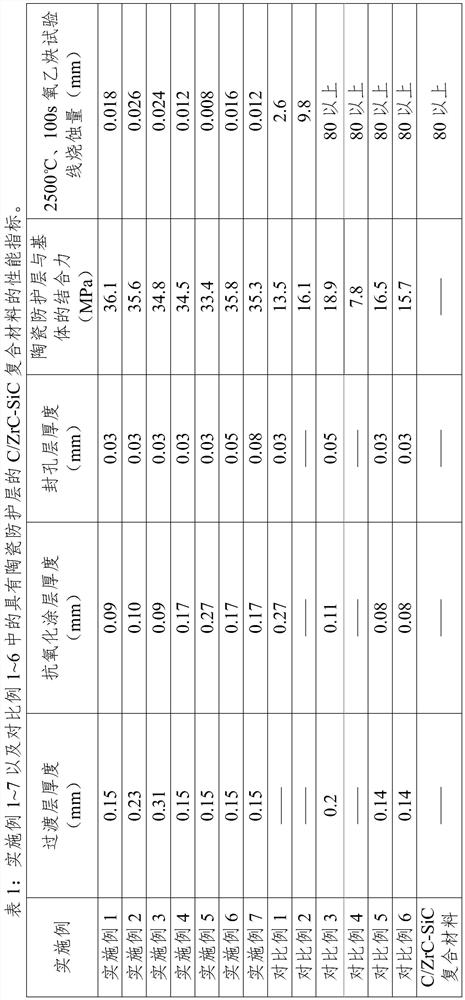

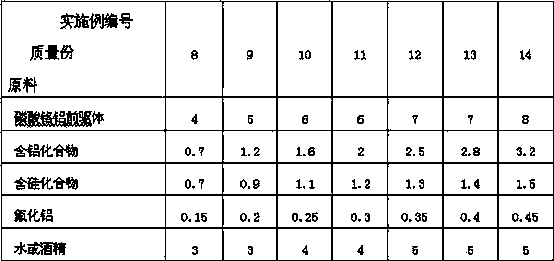

Method for preparing ceramic protection layer on C/SiC composite material, and ceramic protection layer prepared therethrough

ActiveCN110835273AImprove high temperature oxidation resistanceImprove thermal compatibilityLeading edgeFlight vehicle

The invention relates to a method for preparing a ceramic protection layer on a C / SiC composite material, and the ceramic protection layer prepared therethrough. The method comprises the following steps: preparing a ZrC-SiC transition layer on the surface of the C / SiC composite material through an impregnation-solidification-high temperature cracking process by using an impregnation solution beinga zirconium-silicon integrated ceramic precursor solution containing zirconium and silicon according to a weight ratio of (1-8):1; preparing a ZrC anti-oxidation coating layer on the basis of the ZrC-SiC transition layer through a brush coating process; and depositing a SiC hole sealing layer on the surface of the obtained ZrC antioxidant coating through a chemical vapor deposition technology toprepare the ceramic protection layer on the C / SiC composite material. The prepared ceramic protection layer has excellent oxidation resistance at a temperature of 2000 DEG C or above, has high bindingforce with a substrate, and has wide application prospects in structural parts such as a wing rudder, a leading edge, an end and an engine of a novel hypersonic aircraft.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

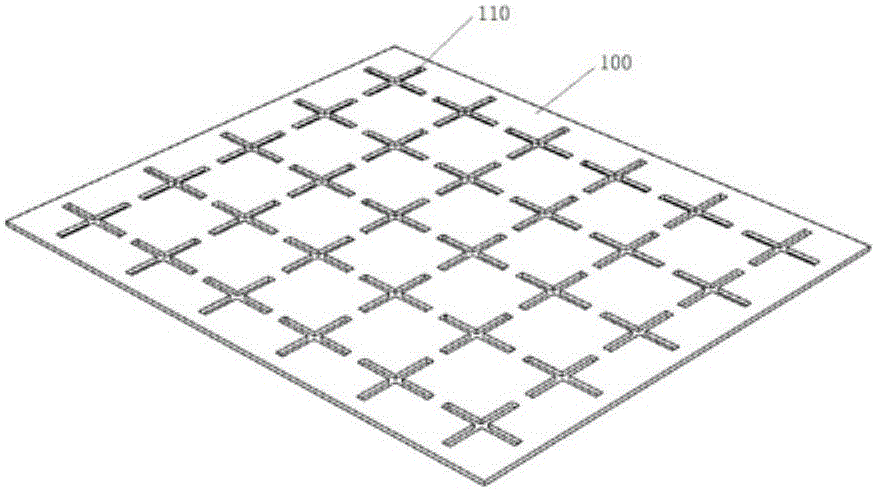

Graphene film frequency selective surface

ActiveCN105161803AImprove adaptabilityReduce Thermal MismatchSynthetic resin layered productsWaveguide type devicesCvd grapheneResin composite

The invention discloses a graphene film frequency selective surface comprising a substrate and a graphene film layer disposed on the substrate. The substrate is prepared from fiber reinforced polymer composite material. The graphene film layer comprises a graphene film with periodically-arranged holes or graphene film chips arranged periodically. The graphene film frequency selective surface is simple in technique implementation, well matches the fiber reinforced resins composite material substrate, is low in weight increment, resistant to corrosion, and can be widely applied to devices such as composite material radomes or filters.

Owner:NAT UNIV OF DEFENSE TECH

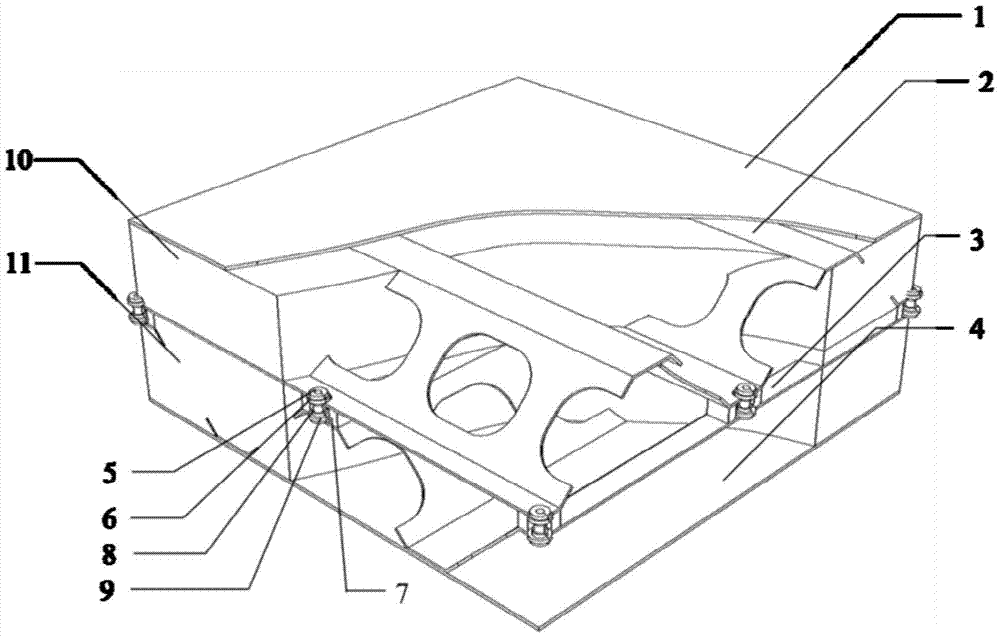

Thermal protection device

ActiveCN105083528AImprove structural resistanceImprove thermal compatibilityFuselage insulationBolt connectionThermal protection

The invention discloses a thermal protection device which comprises an upper panel, a bottom panel, an upper corrugated plate layer and a lower corrugated plate layer, wherein the upper corrugated plate layer comprises a plurality of upper corrugated plates which are arranged in sequence; the lower corrugated plate layer comprises a plurality of lower corrugated plates which are arranged in sequence; the upper corrugated plate layer is arranged above the lower corrugated plate layer; the upper and lower corrugated plate layers are arranged in a staggered manner; the lower ends of the at the upper part corrugated plates and the upper ends of the lower corrugated plates are connected with one another through a heat insulation and bearing bolt connection structure; the heat insulation and bearing bolt connection structure comprises joint bolts, upper heat insulation gaskets, middle heat insulation spacers, lower heat insulation gaskets, and connecting nuts; the gap between the upper panel and the lower ends of the upper corrugated plates is filled with a high-temperature resistant insulating material; the gap between the bottom panel and the upper ends of the lower corrugated plates is filled with a middle-temperature resistant insulating material. Due to the adoption of the thermal protection device provided by the invention, the problems of thermal short-circuiting of the connection structure and thermal mismatch of a cold-hot structure of the thermal protection device can be solved.

Owner:HARBIN INST OF TECH

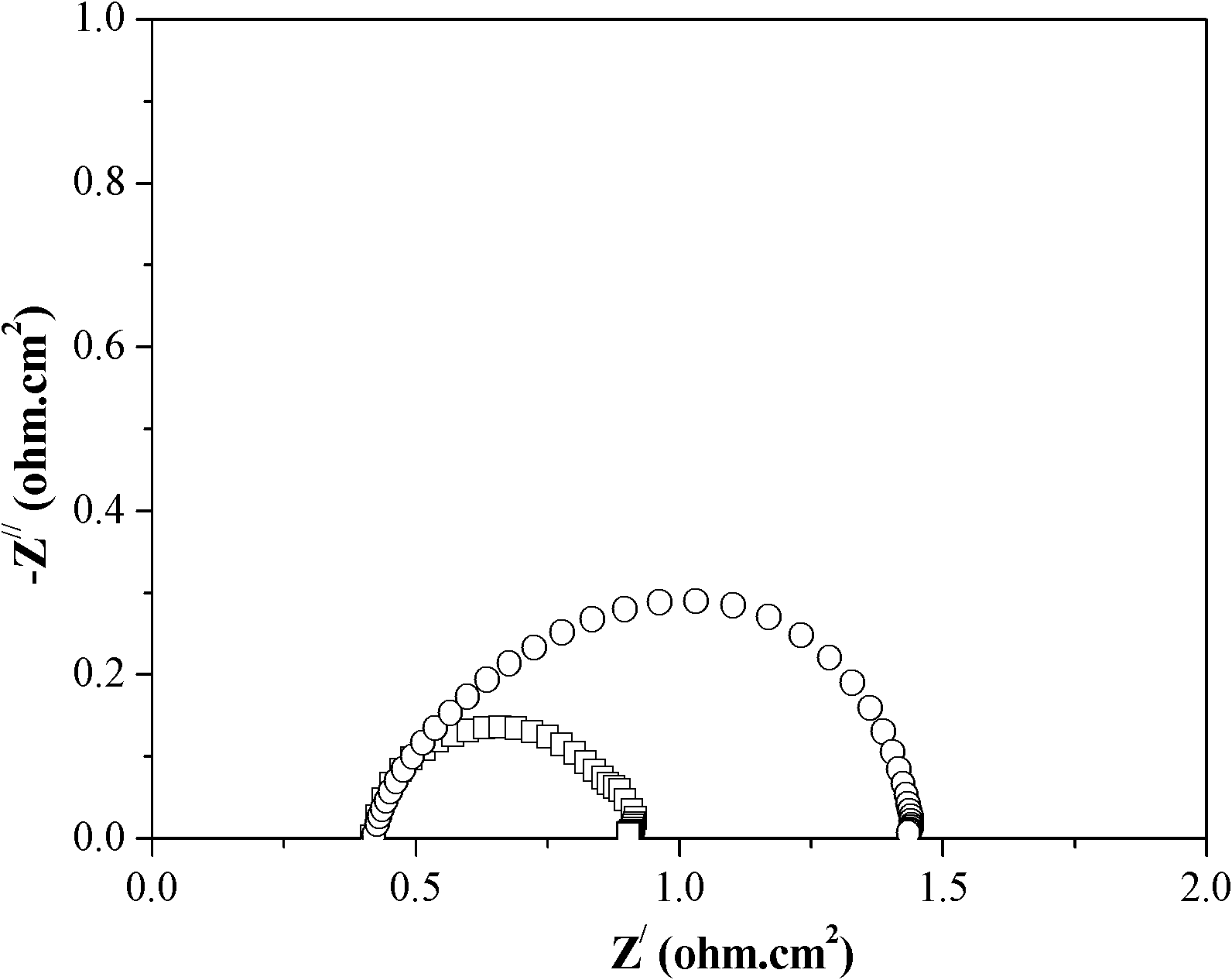

Solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 and preparation method thereof

InactiveCN103151533AImprove electrochemical performanceIncreased mixed conductivityCell electrodesComposite cathodeFuel cells

The invention relates to a solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 and a preparation method thereof. The invention relates to a cell composite cathode material and a preparation method thereof, aiming at solving the problem that the catalytic activity and electro-chemical property of the cathode material are pool. The solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 is made of Ln2CuO4 and solid electrolyte Ce0.9Gd0.1O1.95; the method comprises the steps of: I. weighing; II. preparing mixed stock; III. preparing a prefabricated body; and IV. preparing the solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95. According to the solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 and the preparation method thereof, the reaction active site of the cathode is extended into the overall cathode material, the active region of the oxygen reduction reaction can be enlarged, and the electrochemical property of the cathode can be improved. The preparation method is used for preparing solid oxide fuel cell composite cathode.

Owner:HEILONGJIANG UNIV

Fiber-reinforced ceramic matrix composite surface antioxidant/infrared stealth coating capable of resisting temperature of 1650 DEG C and preparation method thereof

ActiveCN111732457AGood compatibilityMinimizes differences in thermal expansion coefficientsLiquid surface applicatorsMolten spray coatingLayered structureOxidation resistant

The invention relates to the technical field of high-temperature infrared stealth materials and particularly discloses a fiber-reinforced ceramic matrix composite surface antioxidant / infrared stealthcoating capable of resisting the temperature of 1650 DEG C. The infrared stealth coating is of a layered structure and comprises a ceramic inner layer, a ceramic middle layer, a ceramic outer layer and a low-infrared-emissivity functional layer from bottom to top, wherein the ceramic inner layer is a mullite layer, the ceramic middle layer is a rare earth silicate layer, the ceramic outer layer isan 8YSZ layer, and the low-infrared-emissivity functional layer is a coating with Pt as a conductive phase and Bi2O3 as a binding phase. The invention further provides a preparation method of the fiber-reinforced ceramic matrix composite surface antioxidant / infrared stealth coating capable of resisting the temperature of 1650 DEG C. According to the infrared stealth coating, the oxidation resistance and the high-temperature stability of the composite material are improved, the infrared radiation intensity of a base material can be remarkably reduced, and the infrared stealth coating has excellent oxidation resistance and an infrared stealth function.

Owner:NAT UNIV OF DEFENSE TECH

High-strength vibration-reduction epoxy mortar with nano improver

The invention discloses high-strength vibration-reduction epoxy mortar with a nano improver. The high-strength vibration-reduction epoxy mortar consists of three components A, B and C, wherein the component A is a substrate mixture; the component B is an auxiliary mixture; the component C is a curing mixture; the component A consists of the following various raw materials in parts by weight: 80-100 parts of modified epoxy resin, 45-70 parts of cement and 100-300 parts of quartz sand; the component B consists of the following various raw materials in parts by weight: 10-50 parts of a nano improver, 3-5 parts of a silane coupling, 0-1 part of a defoaming agent and 10-15 parts of a diluent; the component C consists of the following various raw materials in parts by weight: 40-55 parts of a curing agent and 1-5 parts of a toughening agent; the weight ratio of the component A, the component B to the component C is (80-100):(5-100):(50-600). The high-strength vibration-reduction epoxy mortar disclosed by the invention has the advantages of being high in strength, good in vibration reduction effect, good in binding force with a concrete substrate, good in compatibility and the like, and can be used as a secondary grouting material of complex industrial vibration equipment.

Owner:SINOPEC PETROLEUM ENG & CONSTR ZHONGYUAN

Antioxidant coating for C/ZrC-SiC composite material, and preparation method thereof

ActiveCN110776339AStop the spreadImprove antioxidant capacityOxidation resistantPhenol formaldehyde resin

The invention relates to an antioxidant coating for a C / ZrC-SiC composite material, and a preparation method thereof. The antioxidant coating comprises an HfC-HfB2 coating and a SiC coating which arealternately formed on the C / ZrC-SiC composite material. The preparation method comprises the following steps: the surface of the C / ZrC-SiC composite material is coated with a ceramic slurry containingHf powder, B powder, ethyl alcohol and phenolic resin, the HfC-HfB2 coating is formed after cracking, and then the SiC coating is deposited; and the above step is repeated (N-2) / 2 times so as to formthe antioxidant coating on the surface of the C / ZrC-SiC composite material. The method has the advantages of simple process, low preparation cost, solving of the problems of uniform distribution of HfC-HfB2 and SiC and combination with a matrix, remarkable improvement of the ablation resistance and oxidation resistance of the C / ZrC-SiC composite material, and further improvement of the use temperature of the C / ZrC-SiC composite material.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Carbon fiber reinforced carbon-tantalum hafnium carbide solid solution composite material and preparation method thereof

ActiveCN110655414AImprove thermal compatibilityImprove mechanical propertiesOxidation resistantChemical vapor infiltration

The invention relates to a carbon fiber reinforced carbon-tantalum hafnium carbide solid solution composite material and a preparation method thereof. The preparation method comprises the following steps: preparing a pyrolytic carbon interface layer on a carbon fiber preform by utilizing a chemical vapor infiltration technology, preparing a C matrix by using a pyrolysis technology or a precursor infiltration and pyrolysis technology, then preparing a C-TaxHfC transition matrix from a tantalum hafnium carbide ceramic by using the precursor infiltration and pyrolysis technology, and finally preparing a TaxHfC matrix from the tantalum hafnium carbide by using the infiltration and pyrolysis technology. The Cf / C-TaxHfC composite material contains the C-TaxHfC transition matrix which is uniformly distributed, so that the thermal matching property of the first C matrix and the antioxidant TaxHfC matrix can be improved, and the mechanical properties of the composite material are enhanced; andthe Cf / C-TaxHfC composite material has a high TaxHfC content, so the oxidation resistance of the composite material can be obviously enhanced.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

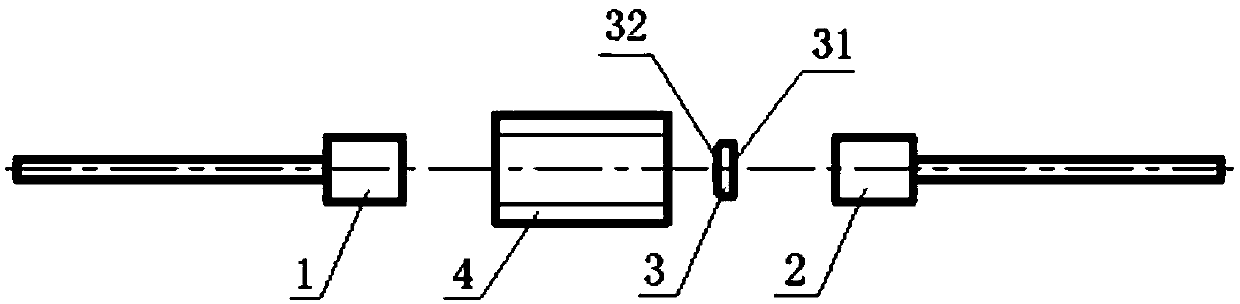

Supporting truss rod and space truss structure

PendingCN111255989AImprove thermal compatibilityReduce the internal stress of the connectionMaterial analysis by optical meansStands/trestlesStructural engineeringFiber

The invention relates to a supporting truss rod and a space truss structure. The problems that according to an existing space truss structure, the glue joint position is large in stress, and the bonding technology is poor in reliability are solved. The supporting truss rod comprises a truss rod body and connecting assemblies arranged at the two ends of the truss rod body. The truss rod body is a hollow rod formed through winding of carbon fiber materials. Each connecting assembly comprises an embedded piece and a metal bottom plate, wherein the material of the embedded piece is a carbon fiberenhanced SiC ceramic composite material and comprises a tubular embedded end and a connecting flange located at one end portion of the embedded end, the embedded end is embedded in the rod wall of thetruss rod body, the outer wall diameter of the embedded end is smaller than the outer diameter of the truss rod body, the inner wall diameter of the embedded end is larger than the inner diameter ofthe truss rod body, and the metal bottom plate is an annular metal plate adaptive to the connecting flange and is bonded and fixed to the connecting flange. The low-stress embedding manner is adopted,assembling stress and heat stress possibly generated during truss rod and metal piece bonding are relieved, and the truss structure assembling technology is simplified.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Solid oxide fuel cell gradient porosity anode and solid oxide fuel cell

ActiveCN108598493AHigh strength propertiesImprove performanceCell electrodesFuel cellsPorosityFuel cells

The invention discloses a solid oxide fuel cell gradient porosity anode and a solid oxide fuel cell. The solid oxide fuel cell gradient porosity anode comprises an anode function layer, an anode transition layer and an anode support layer which are connected in sequence from top to bottom. The opening porosity of the anode transition layer is greater than or equal to the opening porosity of the anode function layer. The opening porosity of the anode transition layer is smaller than or equal to the opening porosity of the anode support layer. The opening porosity of the anode function layer, the opening porosity of the anode transition layer and the opening porosity of the anode support layer are in gradient gradual decrease along a horizontal direction, or the opening porosity of the anodefunction layer, the opening porosity of the anode transition layer and the opening porosity of the anode support layer are in gradient gradual increase. The anode is characterized by relatively low activation polarization, concentration polarization and ohm polarization loss. The fuel cell is characterized by high output electrical property and high intensity.

Owner:XI AN JIAOTONG UNIV

Intermediate temperature solid oxide fuel battery composite cathode and preparation method thereof

InactiveCN101944617AIncreased mixed conductivityIncrease active areaCell electrodesDielectricComposite cathode

The invention discloses an intermediate temperature solid oxide fuel battery composite cathode and a preparation method thereof, and belongs to the field of chemical power solid oxide fuel battery materials. The invention solves the problem that the conventional cathode materials are not suitable for working under the condition of intermediate temperature. The composite cathode material is composed of Ca2Fe1.4Co0.6O5 and a solid dielectric which is Ce0.8Gd0.2O1.95 or Ce0.8Sm0.2O1.95. The method comprises the following steps of: 1, mixing the Ca2Fe1.4Co0.6O5 and the solid dielectric, adding terpilenol and uniformly mixing the three materials to obtain a mixed material; 2, coating the mixed material on the surface of the dielectric, and placing the dielectric in an oven for drying; and 3, sintering the dielectric to obtain the intermediate temperature solid oxide fuel battery composite cathode material on the surface of the dielectric. The cathode has the advantages of high electro-catalytic activity and low polarization resistance in the temperature range of 500 to 700 DEG C.

Owner:HEILONGJIANG UNIV

Gradient porosity anode for solid oxide fuel cell and fuel cell

ActiveCN108598493BHigh strength propertiesImprove performanceCell electrodesFuel cellsFuel cellsConcentration polarization

The invention discloses a solid oxide fuel cell gradient porosity anode and a solid oxide fuel cell. The solid oxide fuel cell gradient porosity anode comprises an anode function layer, an anode transition layer and an anode support layer which are connected in sequence from top to bottom. The opening porosity of the anode transition layer is greater than or equal to the opening porosity of the anode function layer. The opening porosity of the anode transition layer is smaller than or equal to the opening porosity of the anode support layer. The opening porosity of the anode function layer, the opening porosity of the anode transition layer and the opening porosity of the anode support layer are in gradient gradual decrease along a horizontal direction, or the opening porosity of the anodefunction layer, the opening porosity of the anode transition layer and the opening porosity of the anode support layer are in gradient gradual increase. The anode is characterized by relatively low activation polarization, concentration polarization and ohm polarization loss. The fuel cell is characterized by high output electrical property and high intensity.

Owner:XI AN JIAOTONG UNIV

A kind of carbon fiber reinforced carbon-hafnium tantalum carbon solid solution composite material and preparation method thereof

The invention relates to a carbon fiber reinforced carbon-hafnium-tantalum-carbon solid solution composite material and a preparation method thereof. The preparation method includes preparing a pyrolytic carbon interface layer on a carbon fiber preform by chemical vapor infiltration, preparing a C matrix by using a pyrolysis method or a precursor impregnation cracking method, and then preparing a C matrix by impregnating a hafnium-tantalum carbon ceramic precursor. Ta x HfC transition matrix, and finally Ta x HfC matrix. C prepared by the present invention f / C‑Ta x HfC composites contain uniformly distributed C‑Ta x HfC transition matrix, can increase the first C matrix and anti-oxidation Ta x The thermal matching of HfC matrix enhances the mechanical properties of composite materials; the C prepared by the present invention f / C‑Ta x Ta in HfC composites x The high content of HfC can significantly enhance the oxidation resistance of the composite.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A high-temperature-resistant high-strength alumina fiber-reinforced composite material and its preparation method

The invention relates to a high-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and a preparation method thereof. The preparation method comprises the following steps of: by taking a two-dimensional cloth paving layer and 2.5D woven or orthogonally three-dimensional woven continuous aluminum oxide fiber preform as an enhancer, preparing a matrix through a double nano composite impregnation liquid where silicon dioxide and aluminum oxide are uniformly mixed; and finally obtaining the aluminum oxide fiber enhanced composite material through the process of vacuum pressure impregnation, micro-positive pressure medium and low temperature pre-curing, micro-positive pressure curing and atmosphere temperature programming sub-sectional thermal treatment, wherein the mass ratio of silicon dioxide to aluminum oxide in the composite material is (19:1)-(12:8), and the volume content of the aluminum oxide fibers is 30-60%. The prepared composite material has a high-temperature-resistant property and a high-temperature mechanical property, and is high in compactness; the room temperature tensile strength of the material reaches 310+ / -30MPa, the tensile strength at 1100 DEG C reaches 135+ / -20MPa, and the tensile strength at 1200 DEG C reaches 90+ / -10MPa; and compared with a similar quartz fiber enhanced silicon dioxide oxide / oxide composite material, the performance is improved by 4-5 times.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Multilayer structure environmental barrier coating for silicon carbide ceramic matrix composite material and preparation method thereof

PendingCN112939629AImprove thermal protection performanceEffective protectionMolten spray coatingCarbide siliconSand blasting

The invention relates to a multilayer structure environmental barrier coating for a silicon carbide ceramic matrix composite material and a preparation method of the multilayer structure environmental barrier coating. The method comprises the following steps: carrying out sand blasting, polishing, ultrasonic cleaning and drying on the silicon carbide ceramic matrix composite material; sequentially preparing a bonding layer Si, a middle first layer Yb2O3-2SiO2, a middle second layer Yb2O3-SiO2 and an outer layer La2O3-2MgO-11Al2O3 on the surface of a pretreated silicon carbide ceramic matrix composite material by using an atmospheric plasma spraying method. The multilayer structure environmental barrier coating prepared by the method is compactly combined with the silicon carbide ceramic matrix composite material, can provide effective protection for the composite material in an oxygen-enriched high-temperature environment, and can be used at the temperature of 1350 DEG C for more than 500 hours.

Owner:WUHAN UNIV OF TECH

A method for preparing a ceramic protective layer on a c/sic composite material and the ceramic protective layer prepared thereby

ActiveCN110835273BImprove high temperature oxidation resistanceImprove thermal compatibilityLeading edgeFlight vehicle

The invention relates to a method for preparing a ceramic protective layer on a C / SiC composite material and the prepared ceramic protective layer. The method is as follows: a ZrC-SiC transition layer is prepared on the surface of the C / SiC composite material through an impregnation-curing-pyrolysis process, and the impregnating solution is zirconium-silicon containing zirconium and silicon with a weight ratio of (1-8):1 An integrated ceramic precursor solution; a ZrC oxidation-resistant coating is obtained on the basis of the ZrC-SiC transition layer by a brushing process; a SiC sealing layer is deposited on the surface of the ZrC oxidation-resistant coating obtained by chemical vapor deposition , thus making a ceramic protective layer on the C / SiC composite. The ceramic protective layer prepared by the present invention can have excellent oxidation resistance at a temperature above 2000°C, and also has a high bonding force with the substrate. with broadly application foreground.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A kind of anti-oxidation coating for c/zrc-sic composite material and preparation method thereof

ActiveCN110776339BStop the spreadImprove antioxidant capacityOxidation resistantPhenol formaldehyde resin

The invention relates to an anti-oxidation coating for a C / ZrC-SiC composite material and a preparation method thereof. The anti-oxidation coating consists of HfC‑HfB sequentially formed alternately on the C / ZrC‑SiC composite 2 coating and SiC coating. The preparation method includes brushing the ceramic slurry containing Hf powder, B powder, ethanol and phenolic resin on the surface of the C / ZrC-SiC composite material, forming HfC-HfB after cracking 2 coating, and then depositing a SiC coating; repeating the above steps (N-2) / 2 times, thereby forming an anti-oxidation coating on the surface of the C / ZrC-SiC composite material. The method of the invention has simple process and low preparation cost, and solves the problem of HfC-HfB 2 , the uniform distribution of SiC and the combination with the matrix significantly improve the ablation resistance and oxidation resistance of the C / ZrC-SiC composite material, and further increase the service temperature of the C / ZrC-SiC composite material.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A graphene film frequency selective surface

ActiveCN105161803BReduce failureReduce weightSynthetic resin layered productsWaveguide type devicesThin layerGraphite

The invention discloses a graphene film frequency selective surface, the surface comprises a substrate and a graphene film layer arranged on the substrate, the substrate is a fiber reinforced resin composite material; the graphene film layer is graphite with periodic openings ene films or periodically arranged graphene film patches. The frequency selective surface technology of the graphene film of the invention is simple to implement, has good compatibility with the fiber reinforced resin composite material substrate, has small weight gain and corrosion resistance, and can be widely used in devices such as composite material radomes or filters.

Owner:NAT UNIV OF DEFENSE TECH

Intermediate temperature solid oxide fuel battery composite cathode and preparation method thereof

InactiveCN101944617BIncreased mixed conductivityIncrease active areaCell electrodesDielectricComposite cathode

The invention discloses an intermediate temperature solid oxide fuel battery composite cathode and a preparation method thereof, and belongs to the field of chemical power solid oxide fuel battery materials. The invention solves the problem that the conventional cathode materials are not suitable for working under the condition of intermediate temperature. The composite cathode material is composed of Ca2Fe1.4Co0.6O5 and a solid dielectric which is Ce0.8Gd0.2O1.95 or Ce0.8Sm0.2O1.95. The method comprises the following steps of: 1, mixing the Ca2Fe1.4Co0.6O5 and the solid dielectric, adding terpilenol and uniformly mixing the three materials to obtain a mixed material; 2, coating the mixed material on the surface of the dielectric, and placing the dielectric in an oven for drying; and 3, sintering the dielectric to obtain the intermediate temperature solid oxide fuel battery composite cathode material on the surface of the dielectric. The cathode has the advantages of high electro-catalytic activity and low polarization resistance in the temperature range of 500 to 700 DEG C.

Owner:HEILONGJIANG UNIV

A temperature-resistant 1650°C fiber-reinforced ceramic matrix composite material surface oxidation resistance/infrared stealth coating and its preparation method

ActiveCN111732457BImprove antioxidant capacityImprove high temperature stabilityLiquid surface applicatorsMolten spray coatingEmissivityMullite

The invention relates to the technical field of high-temperature infrared stealth materials, and specifically discloses an anti-oxidation / infrared stealth coating on the surface of a fiber-reinforced ceramic matrix composite material with a temperature resistance of 1650°C. The infrared stealth coating has a layered structure, which consists of A ceramic inner layer, a ceramic middle layer, a ceramic outer layer and a low infrared emissivity functional layer, the ceramic inner layer is a mullite layer, the ceramic middle layer is a rare earth silicate layer, and the ceramic outer layer is an 8YSZ layer , the low infrared emissivity functional layer is based on Pt as the conductive phase, Bi 2 o 3 coating for the binder phase. The invention also provides a preparation method for the anti-oxidation / infrared stealth coating on the surface of the fiber-reinforced ceramic matrix composite material with a temperature resistance of 1650°C. The infrared stealth coating of the invention improves the oxidation resistance and high temperature stability of the composite material, can significantly reduce the infrared radiation intensity of the base material, and has excellent oxidation resistance and infrared stealth function.

Owner:NAT UNIV OF DEFENSE TECH

A kind of ceramic protective layer for c/zrc-sic composite material and preparation method thereof

ActiveCN112374916BImprove high temperature oxidation resistanceAnti-oxidation temperature is highFlight vehicleOxidation resistant

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for manufacturing ultra-high temperature ceramic matrix composite material ablation head radome body

ActiveCN105742810BImprove high temperature resistanceEasy to useRadiating element housingsCarbon fibersComposite ceramic

The invention discloses a fabrication method for a cover body of a superhigh temperature ceramic matrix composite material ablation head antenna cover. The method comprises the following steps of weaving an ablation head flat plate fabric by a carbon fiber three-phase orthogonal mode to obtain an ablation head woven fabric; immersing and compounding to obtain C / SiC-ZrC composite ceramic ablation head rough blank, and carrying out profiling weaving on the cover body fabric by a needling mode to obtain a cover body woven fabric; mechanically processing the cover body woven fabric to required product sizes to obtain an ablation head and the cover body; and connecting and forming the ablation head and the cover body by nuts, thereby obtaining the cover body of the ablation head antenna cover. According to the method, the C / SiC-ZrC composite material and a C / SiC-HfC composite material which have excellent temperature resistance reaching 2,000 DEG C and ablation resistance are used; and through optimal design on a prefabricated element of the ablation head and control on volume content of annular fibers, zero expansion of the ablation head composite material in an annular direction can be achieved, and thus, the obtained cover body of the antenna cover can be applied to intermediate and remote land attack cruise missiles with high mach (greater than 10Ma), long endurance (greater than 1,000 seconds) and high accuracy.

Owner:湖北三江航天江北机械工程有限公司

Low thermal expansion cathode material for solid oxide fuel cell and preparation method thereof

ActiveCN107394213BWeakened electrical propertiesImprove thermal compatibilityCell electrodesOxygen vacancyLattice oxygen

The invention discloses a low thermal expansion cathode material for a solid oxide fuel cell. The low thermal expansion cathode material is prepared from barium, strontium, cobalt, iron and manganese, wherein Mn partially replaces Co in a Ba0.5Sr0.5Co0.8Fe0.2O3-delta-based cathode material; replacement is carried out in a position B of a perovskite structure; the content of manganese in a cathode is not greater than 15%, and the proportion of Co and Mn in a chemical formula is (0.8-x):x; and a cathode composition is expressed as Ba0.5Sr0.5Co0.8-xFe0.2MnxO3-delta, wherein x is greater than 0 and less than 0.3. The cathode material releases lattice oxygen at a slower speed, oxygen vacancy concentration in lattices is controlled, and thermal expansion changes slowly along with rise of the temperature, so that the thermal matching performance of the cathode and an electrolyte is improved; further the electrical property of the cathode is not weakened; and the preparation method is simple, uses simple equipment, is low-cost, has high repeatability, and is easy for industrial production.

Owner:HUAIBEI NORMAL UNIVERSITY

Preparation method of mullite whisker in-situ toughened chromium phosphate aluminum wave-transmitting material

The invention discloses a preparation method of a mullite whisker in-situ toughened chromium phosphate aluminum wave-transmitting material. The method is characterized by the following steps of: dissolving a phosphorus-containing compound into absolute ethyl alcohol or water, adding an aluminum-containing compound and a chromium-containing compound at the temperature of 50-100 DEG C while stirring for reacting, and adding ammonia water, citric acid or methanol for reacting to obtain a chromium phosphate aluminum precursor; putting the chromium phosphate aluminum precursor, the aluminum-containing compound, a silicon-containing compound, aluminum fluoride and water or alcohol into a ball milling device for performing ball milling to obtain a mixture; and drying the mixture, grinding, sieving, performing press forming on the minus sieve, i.e., sintering precursor powder, and calcining in an enclosed container at the temperature of 1,200-1,500 DEG C for 1-24 hours to obtain the mullite whisker in-situ toughened chromium phosphate aluminum wave-transmitting material. The method has the advantages of in-situ growth of mullite whiskers, uniform distribution of the whiskers, dense substrate sintering, good toughening effect, high performance of the wave-transmitting material, applicability of the wave-transmitting material to antenna covers of flying vehicles, radar antenna covers and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

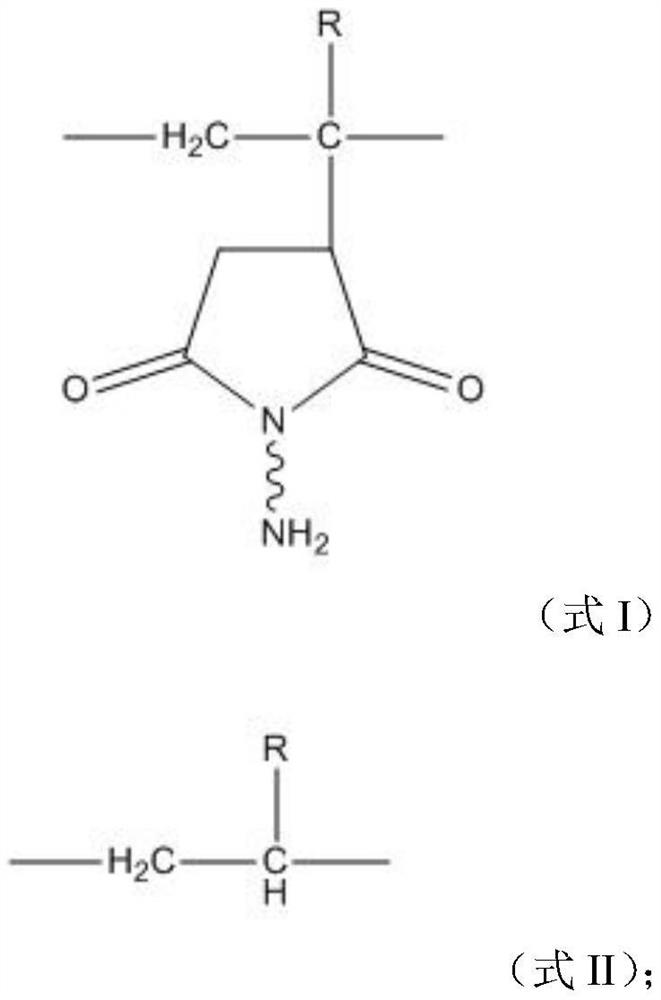

Polyurethane elastic fiber with ultrasonic bonding performance and preparation method thereof

PendingCN113897703AGood unwinding and spinning stabilityExcellent unwinding propertyMonocomponent synthetic polymer artificial filamentArtifical filament manufacturePolymer scienceNonwoven fabric

The invention relates to a polyurethane elastic fiber with an ultrasonic bonding performance. The polyurethane elastic fiber contains a polymer A, wherein the polymer A contains a structural formula I and a structural formula II of the following units, wherein R in the formula I and the formula II is independently selected from hydrogen group, alkyl group, alkoxy group, hydroxyl group, halogen, amino group, amino group, nitro group or sulfonic acid group; in the formula I, a saturated or unsaturated aliphatic hydrocarbon group of C2-C18 is used; the mass of the structure in the formula I accounts for 1 to 25 percent of the total mass of the polymer A; the balance is the mass of the structure shown in the formula II, and the polymer A accounts for 0.5 to 15 percent of the mass of the polyurethane elastic fiber; and the thermal compatibility and the adhesiveness of the polyurethane elastic fiber and non-woven fabrics or other textiles are improved under the condition of an ultrasonic welding process and on the premise that no glue is used.

Owner:ZHEJIANG HUAFENG SPANDEX +1

A carbon nanotube film frequency selective surface and its preparation method, radome

The invention discloses a carbon nanotube film frequency selective surface, a preparation method thereof and a radome. The surface includes a substrate and a carbon nanotube thin film layer arranged on the substrate, the substrate is a fiber-reinforced resin composite material; the carbon nanotube thin film layer is a carbon nanotube thin film with periodic openings. The frequency selective surface technology of the carbon nanotube thin film of the invention is simple to implement, has good matching with the substrate of the fiber-reinforced resin composite material, has small weight gain, and is corrosion-resistant, and can be widely used in devices such as composite material radomes or filters.

Owner:NAT UNIV OF DEFENSE TECH

Metallurgical bonding glass-encapsulated diode structure and production method

ActiveCN105845740BSimple structureReduce dosageSemiconductor/solid-state device manufacturingSemiconductor devicesState of artElectrical connection

The invention discloses a metallurgical bonding glass-sealed diode structure and a production method thereof. The metallurgical bonding glass-sealed diode structure comprises an electrode A, an electrode B, a chip and a glass tube, wherein the electrode A, the electrode B and the chip are arranged in the glass tube; electrical connection is achieved through diffusion welding between the chip and the electrode A and the electrode B; transition layer materials for diffusion welding are an upper surface metallization layer and a lower surface metallization layer of the chip respectively; and diffusion welding between the chip and the electrode A and the electrode B and sealing of the glass tube are synchronously finished to form a whole. The method comprises component assembling and sintering steps. The metallurgical bonding is achieved between the electrodes and the chip in a high-temperature process; the metallurgical bonding glass-sealed diode structure has the advantages of good heat dissipation performance, high current impact resistance and the like; the working range can be -55 DEG C to 175 DEG C; and the shortages that a metallurgical bonding glass-sealed diode product produced by the prior art is low in positive surge current resistance, reverse transient power resistance and the like are overcome.

Owner:张路非

a heat protection device

ActiveCN105083528BImprove structural resistanceImprove thermal compatibilityFuselage insulationEngineeringBoard structure

The invention discloses a heat protection device, comprising: an upper panel, a bottom panel, an upper corrugated board layer composed of a plurality of upper corrugated boards arranged in sequence, and a lower corrugated board layer composed of a plurality of lower corrugated boards arranged in sequence layer; the upper corrugated board layer is set above the lower corrugated board layer, and the upper corrugated board layer and the lower corrugated board layer are arranged alternately; the lower end of the upper corrugated board and the upper end of the lower corrugated board are connected through heat insulation and load-bearing cooperative bolt connection structure ; Heat insulation and load-bearing collaborative bolt connection structure includes: connecting bolts, upper heat insulation gasket, middle heat insulation gasket, lower heat insulation gasket, connecting nut; the gap between the upper panel and the lower end of the upper corrugated plate is filled with resistant High temperature heat insulation material; the gap between the bottom panel and the upper end of the lower corrugated plate is filled with medium temperature heat insulation material. By using the thermal protection device of the present invention, the problem of thermal short circuit of the connecting structure and thermal mismatch of the hot and cold structures in the thermal protection device can be solved.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com