A kind of ceramic protective layer for c/zrc-sic composite material and preparation method thereof

A technology for composite materials and protective layers, which is applied in the field of ceramic protective layers and its preparation, can solve the problems of general high-temperature oxidation resistance, high cost, and easy peeling off of coatings, and achieve high-temperature oxidation resistance. Improve the oxidation resistance temperature, Effect of improving thermal compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

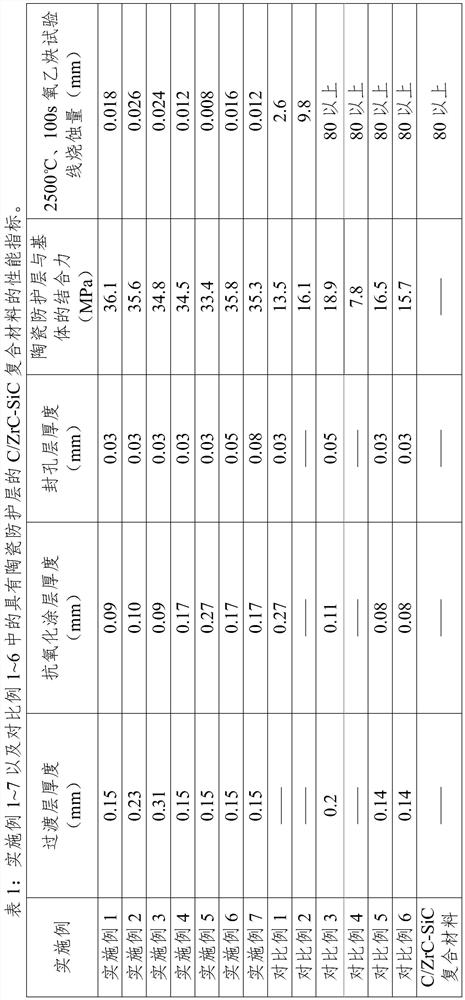

Examples

preparation example Construction

[0029] The present invention provides the preparation method of the ceramic protective layer for C / ZrC-SiC composite material described in the first aspect of the present invention in the second aspect, described method comprises the following steps:

[0030] (1) impregnate the C / ZrC-SiC composite material with the Ti-Zr-Hf-Ta-Si integrated ceramic precursor solution, and then perform the steps of solidification and high-temperature cracking sequentially, on the surface of the C / ZrC-SiC composite material Prepared (TiZrHfTa)C x -SiC transition layer; the Ti-Zr-Hf-Ta-Si integrated ceramic precursor solution is prepared by Ti-Zr-Hf-Ta high-entropy ceramic precursor resin, polycarbosilane, allyl phenolic resin and xylene made;

[0031] (2) Coat the Ti-Zr-Hf-Ta high-entropy ceramic precursor solution with the (TiZrHfTa)C obtained in step (1) x - the surface of the SiC transition layer, followed by the steps of solidification and pyrolysis, in the (TiZrHfTa)C x -SiC transition l...

Embodiment 1

[0054] A kind of preparation method for the ceramic protective layer of C / ZrC-SiC composite material, its specific steps are:

[0055] ①(TiZrHfTa)C x -Preparation of SiC transition layer: in parts by weight, add 1 part of Ti-Zr-Hf-Ta high-entropy ceramic precursor resin, 1 part of polycarbosilane, and 3 parts of allyl phenolic resin to 4 parts of xylene , stirred at 90°C for 6 hours to prepare a Ti-Zr-Hf-Ta-Si integrated ceramic precursor solution; put the C / ZrC-SiC composite material in the Ti-Zr-Hf-Ta-Si integrated ceramic In the precursor solution, vacuum impregnated for 5 hours, and then cured at 2 MPa pressure and 300 °C for 10 hours; after impregnation and curing, the C / ZrC-SiC composite material was placed in a high-temperature cracking furnace and pyrolyzed at 1400 °C for 5 hours to obtain With (TiZrHfTa)C x - C / ZrC-SiC composite material with SiC transition layer.

[0056] ②(TiZrHfTa)C x Preparation of anti-oxidation coating: in parts by weight, add 1 part of Ti-Zr-...

Embodiment 2

[0059] A kind of preparation method for the ceramic protective layer of C / ZrC-SiC composite material, its specific steps are:

[0060] ①(TiZrHfTa)C x -Preparation of SiC transition layer: In parts by weight, add 2 parts of Ti-Zr-Hf-Ta high-entropy ceramic precursor resin, 1 part of polycarbosilane, and 3 parts of allyl phenolic resin to 4 parts of xylene , stirred at 90°C for 6 hours to prepare a Ti-Zr-Hf-Ta-Si integrated ceramic precursor solution; put the C / ZrC-SiC composite material in the Ti-Zr-Hf-Ta-Si integrated ceramic In the precursor solution, vacuum impregnated for 5 hours, and then cured at 2 MPa pressure and 300 °C for 10 hours; after impregnation and curing, the C / ZrC-SiC composite material was placed in a high-temperature cracking furnace and pyrolyzed at 1400 °C for 5 hours to obtain With (TiZrHfTa)C x - C / ZrC-SiC composite material with SiC transition layer.

[0061] ②(TiZrHfTa)C x Preparation of anti-oxidation coating: in parts by weight, add 1 part of Ti-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com