Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109results about How to "High apparent porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

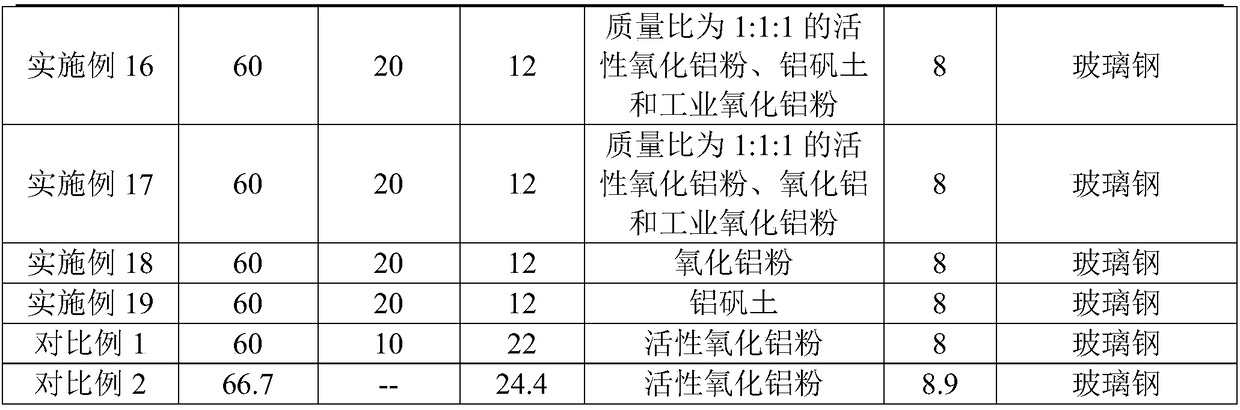

Process for preparing porous ceramic by water-based gel injection moulding method

InactiveCN1456535AHigh apparent porosityControllable pore structureCeramicwareWater basedPolymer science

An injection moulding process for preparing porous ceramics from water-base gel includes such steps as preparing the stable suspension from organic monomer, cross-linking agent, trigger, disperser and ceramic powder, proportionally adding surface treated pore-forming agent while applying pressure, proportionally adding catalyst, slowly heating to 60-80 deg.C holding the temp for at least 30 min for solidifying, demoulding, drying and sintering.

Owner:WUHAN UNIV OF TECH

Alumina-magnesia refractory brick containing light porous aggregate and its making process

The present invention relates to one kind of alumina-magnesia refractory brick containing light porous aggregate and its production process. The technological scheme is that the alumina-silica refractory brick is produced with light porous Al2O3-MgO refractory material 30-70 wt%, compact Al2O3-MgO refractory material 0-35 wt%, fine magnesia powder 5-30 wt%, fine alpha-Al2O3 powder 3-10 wt%, fine corundum powder 0-25 wt% and fine spinel powder 0-25 wt%, and through mixture, adding waste pulp liquid in 3-7 wt% as binding agent, stirring, pressing to form adobe, drying at 100-150 deg.c for 12-48 hr, sintering at 1400-1600 deg.c for 2-5 hr and naturally cooling. The alumina-magnesia refractory brick has high macro porosity, small average pore size, low heat conductivity and high medium erosion resistance, and may be used in the permanent layer or work layer in high temperature kiln, furnace and container.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of biological active glass/chitosan composite porous support material

The invention discloses a preparation method of biological active glass / chitosan composite porous support material, which adopts a perfusion method to compound chitosan and sol-gel biological glass porous support material prepared by a foam impregnation method. The invention comprises the steps of preparing pure biological active glass support material through the foam impregnation method, preparing chitosan solution and compounding biological active glass / chitosan composite support through the perfusion method, wherein the preparation of pure biological active glass support material through the foam impregnation method comprises preparation of size of the biological active glass, selection, impregnation and desiccation of polyurethane foam template.. During the preparation process of theinvention, shape, porosity and distribution of aperture are easy to be regulated and controlled. The prepared support material is provided with three-dimensional reticulate backbone structure, and themechanical intensity, biocompatibility and bioactivity thereof are excellent and degradable; the pressure strength thereof can achieve 1.15-1.30 MPa; apparent porosity can achieve 70%-80%. The support material is capable of meeting the requirements of providing support for defective parts of tissue. The invention has simple and practical method, thus being easy for large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

Aluminum-magnesium lightweight refractory material and preparation method thereof

The invention relates to an aluminum-magnesium lightweight refractory material and a preparation method thereof. The technical scheme comprises the following steps of: taking 60-85wt% of microporous corundum particles as an aggregate, taking 5-30wt% of fine corundum powder, and taking 2-10% of magnesium oxide micropowder and 4-9wt% of alpha-alumina micropowder as matrix materials; adding the matrix materials into the aggregate, additionally adding an adhesive which is 3-10wt% of the sum of the aggregate and the matrix materials, stirring uniformly and then mixing and milling for 15-30 minutes by a mixing mill, and molding by a brick pressing machine; and thermally processing the molded green body for 12-24 hours at 100-220 DEG C to obtain the aluminum-magnesium lightweight refractory material. The product prepared by the preparation method has the characteristics of small volume density, low apparent porosity, small average aperture, high refractoriness, large high-temperature strength, low thermal conductivity, good thermal shock resistance and strong capability resistant against the corrosion of media such as steel slag; and the prepared product is applicable to a working lining of a high-temperature industrial furnace.

Owner:WUHAN UNIV OF SCI & TECH

Micropore ceramic and preparation method and atomizing core thereof

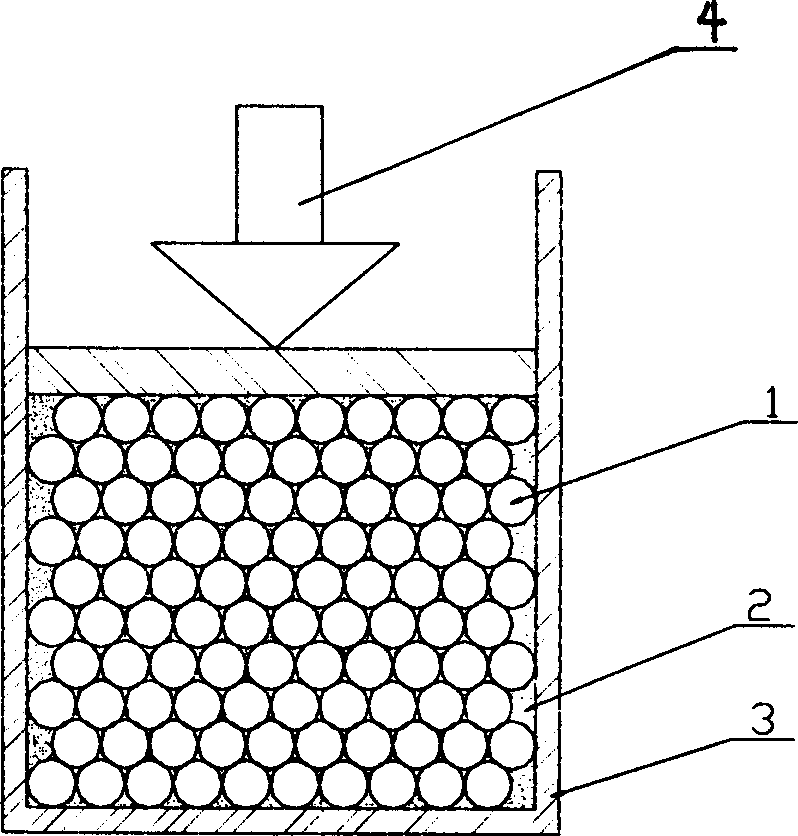

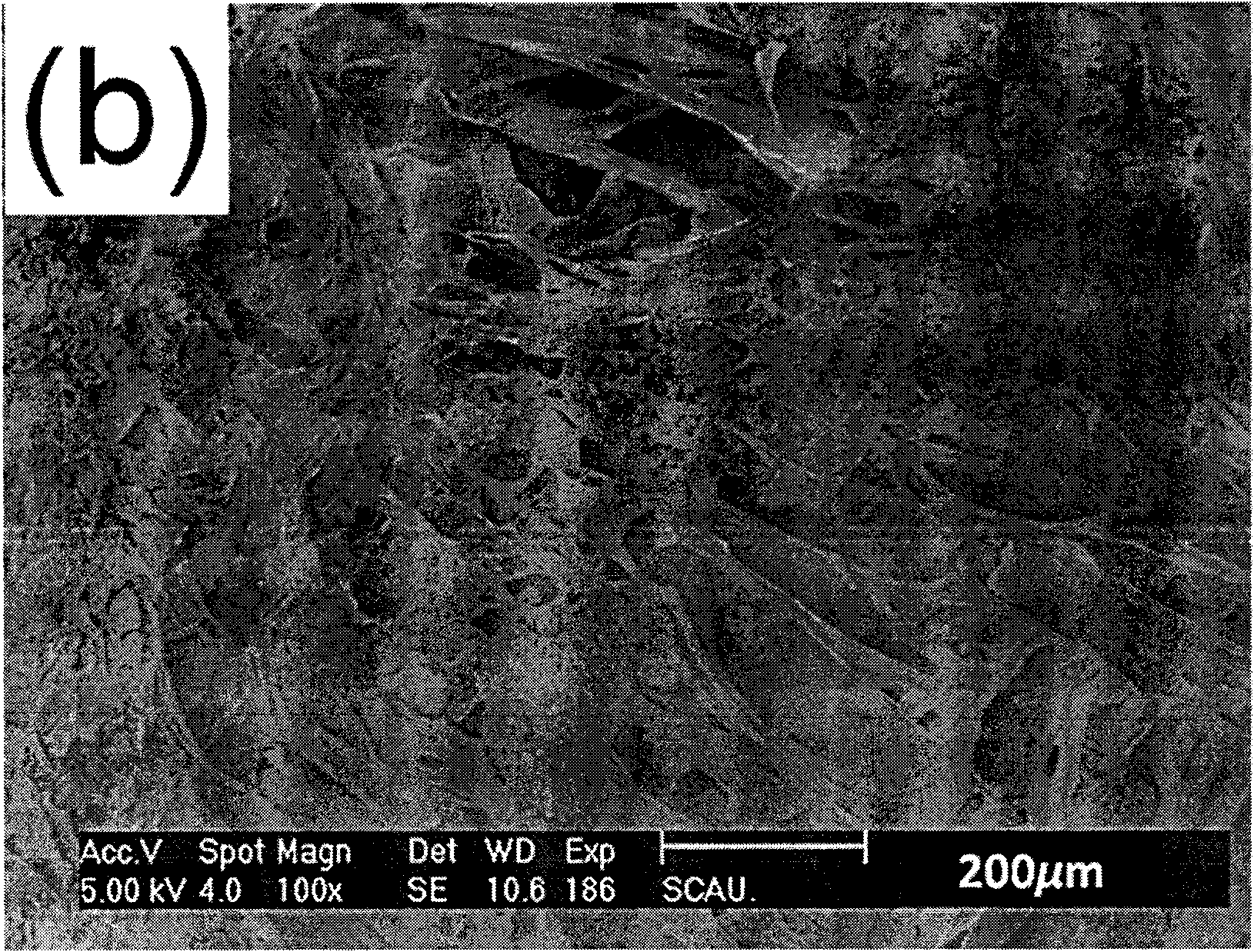

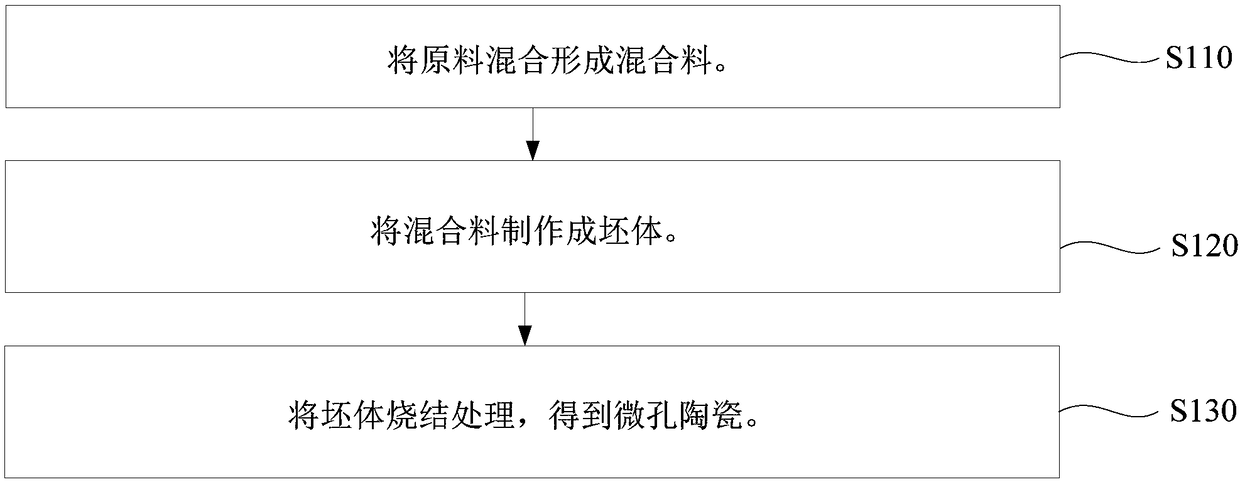

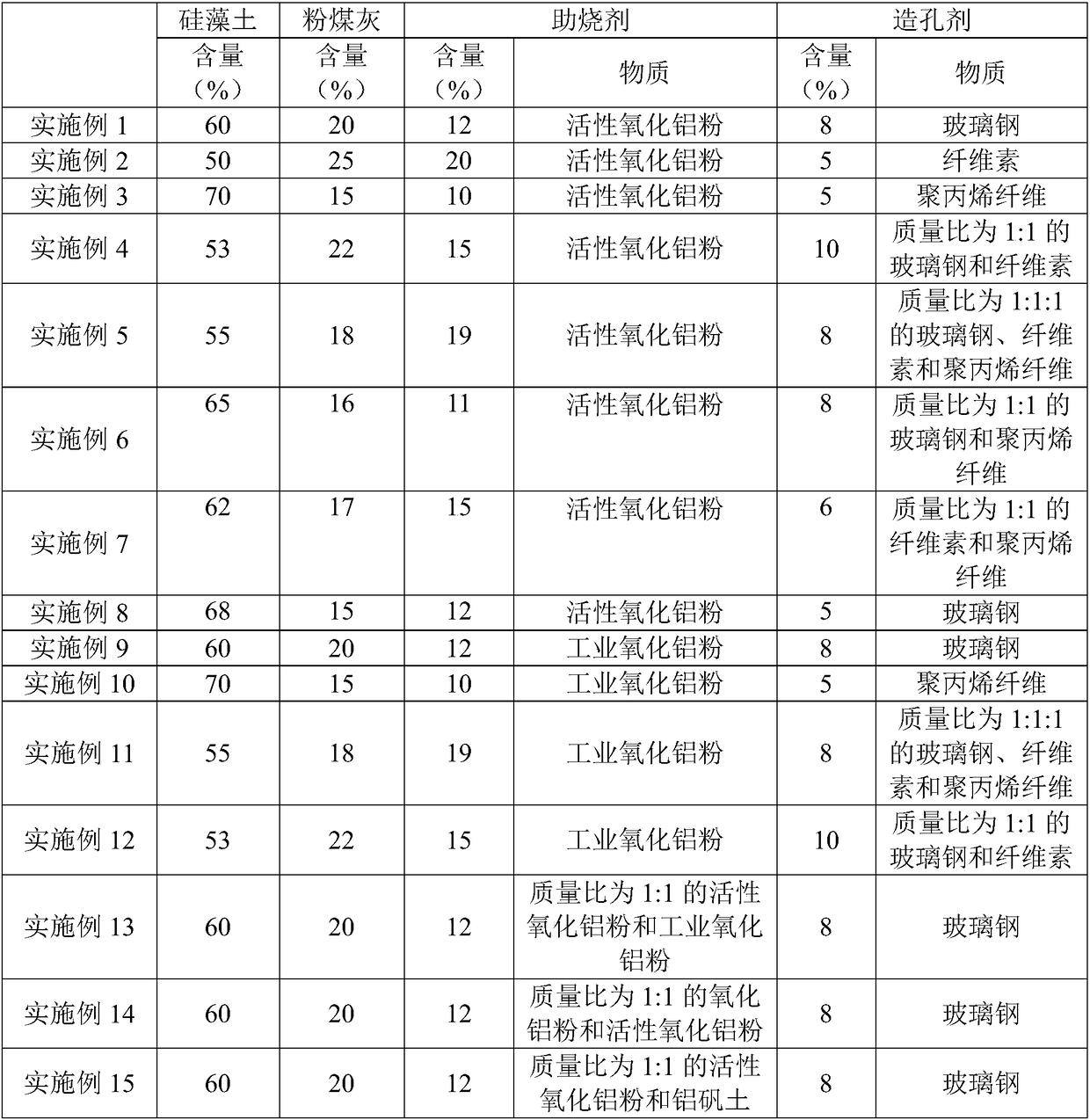

The invention relates to micropore ceramic and a preparation method and an atomizing core thereof. The preparation method for the micropore ceramic comprises the following steps: mixing raw materialsto form a mixture, according to a mass percent, wherein the raw materials comprise 50%-70% of kieselguhr, 15%-25% of coal ash, 10%-20% of a sintering agent and 5%-10% of a pore-forming agent, and thesintering agent comprises aluminum oxide; enabling the mixture to be prepared as a blank body; and sintering the blank body, to obtain the micropore ceramic. The micropore ceramic prepared by the above method has the higher apparent porosity and the higher strength.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

Lightweight corundum-mullite castable and preparation method thereof

The invention relates to a lightweight corundum-mullite castable and a preparation method thereof. The the technical scheme is that the preparation method comprises the following raw materials of 40-70wt% of porous corundum-mullite ceramic particles, 10-25wt% of porous corundum-mullite ceramic fine powder, 10-20wt% of corundum fine powder, 1-3wt% of silicon oxide micro powder, 2-4wt% of active alpha aluminum oxide micro powder, 1-5wt% of calcium aluminate cement and 1-5wt% of rho aluminum oxide fine powder; water and a water reducing agent are taken as additives, wherein the weight of the water is 8-20wt% of that of the raw materials, and the weight of the water reducing agent is 0.02-1wt% of that of the raw materials; and the method comprises the steps of: evenly stirring, casting for molding, naturally drying a molded green body for 24h, and finally, drying the product for 8-48h at the temperature of 110 DEG C. The prepared product not only has the performances of high apparent porosity, high strength, low heat conductivity, high medium erosion resistance and the like, but also has the advantages of being convenient to construct, environment-friendly, controllable in apparent porosity and pore size, small in volume change after being burnt, and the like, thus being suitable for a working layer or a permanent layer of a high-temperature kiln or container with the working temperature lower than 1600 DEG C.

Owner:WUHAN UNIV OF SCI & TECH

Method for improving high-temperature performance of alumina-base ceramic core

InactiveCN101955353AHigh apparent porosityGuaranteed impregnation effectTurbine bladeRoom temperature

The invention discloses a method for improving the high-temperature performance of an alumina-base ceramic core, which comprises the following steps of: firstly, preparing an alumina-base ceramic core blank by adopting a gel casting molding process; secondly, preparing an alumina-base ceramic core prefabricated body with a plurality of holes and certain room-temperature anti-bending strength by freezing, drying and pre-sintering; thirdly, allowing penetrating fluid to seep into the alumina-base ceramic core prefabricated body under the conditions of vacuum and external pressure, drying, removing gel and soaking under vacuum and at pressure for three times; and finally, sintering at a high temperature to obtain the required alumina-base ceramic core. The alumina-base ceramic core prepared by the invention has high high-temperature performance and high core-removing property, can meet the process requirements of a hollow turbine blade on directional casting and single-crystal casting and guarantees the qualification rate of blade castings.

Owner:XI AN JIAOTONG UNIV +1

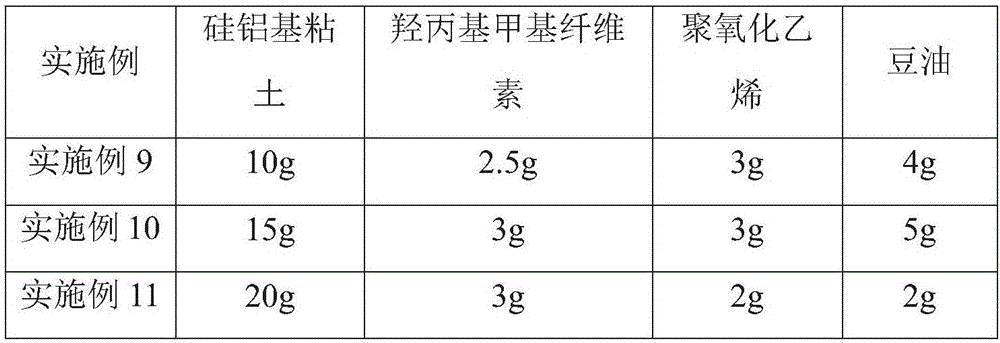

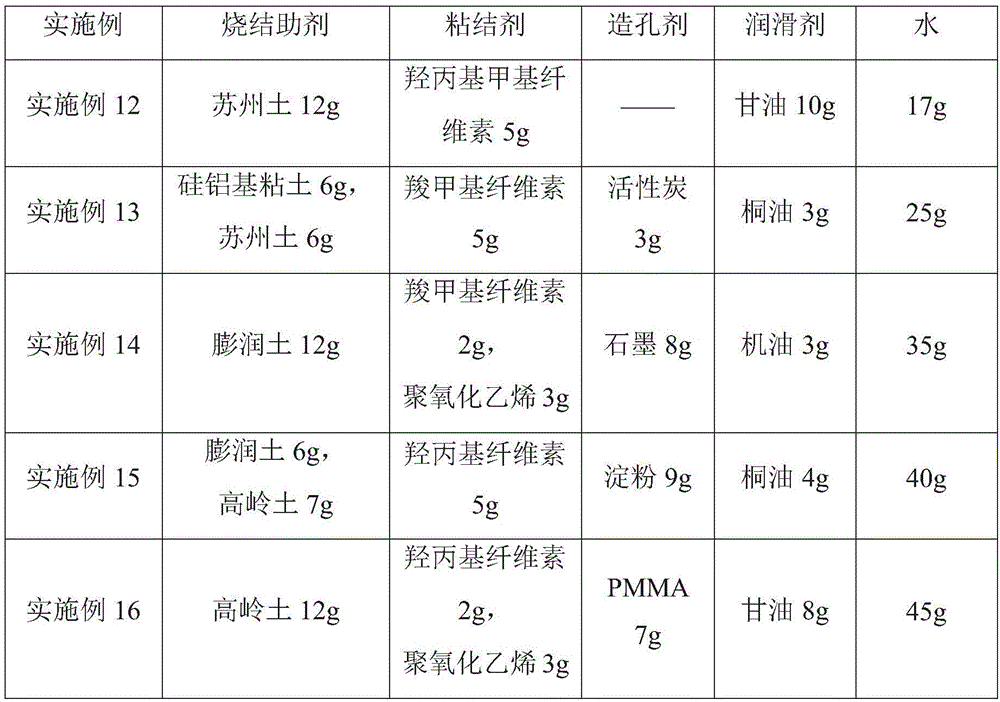

Honeycomb-shaped silicon carbide ceramic carrier, and preparation method and application thereof

ActiveCN106631123AGood water absorptionImprove water absorptionCatalyst carriersCeramicwareChemical industryWater content

The invention relates to a honeycomb-shaped silicon carbide ceramic carrier, and a preparation method and an application thereof. The preparation method comprises the following steps: mixing of raw materials: a step of mixing main materials and auxiliary materials so as to obtain a mixed material, wherein the main materials comprise a first silicon carbide powder material with a particle size of 50 to 65 [mu]m and a second silicon carbide powder material with a particle size of 10 to 40 [mu]m, and the auxiliary materials comprise a sintering auxiliary agent, an adhesive and a pore-forming agent; preparation of a green body; and sintering. The honeycomb-shaped silicon carbide ceramic carrier prepared by using the method provided by the invention can be applied to the fields of metallurgy, environmental protection, chemical industry, energy, biology, food and medicine. According to the invention, the use of two silicon carbide powder materials with different particle sizes increases the water content of a clay material and facilitates extrusion of the clay material, so a ceramic carrier with smooth surface is obtained; meanwhile, the ceramic carrier prepared by using the method provided by the invention has the advantages of high porosity, high strength and more applicability to practical application.

Owner:CHINA BUILDING MATERIALS ACAD

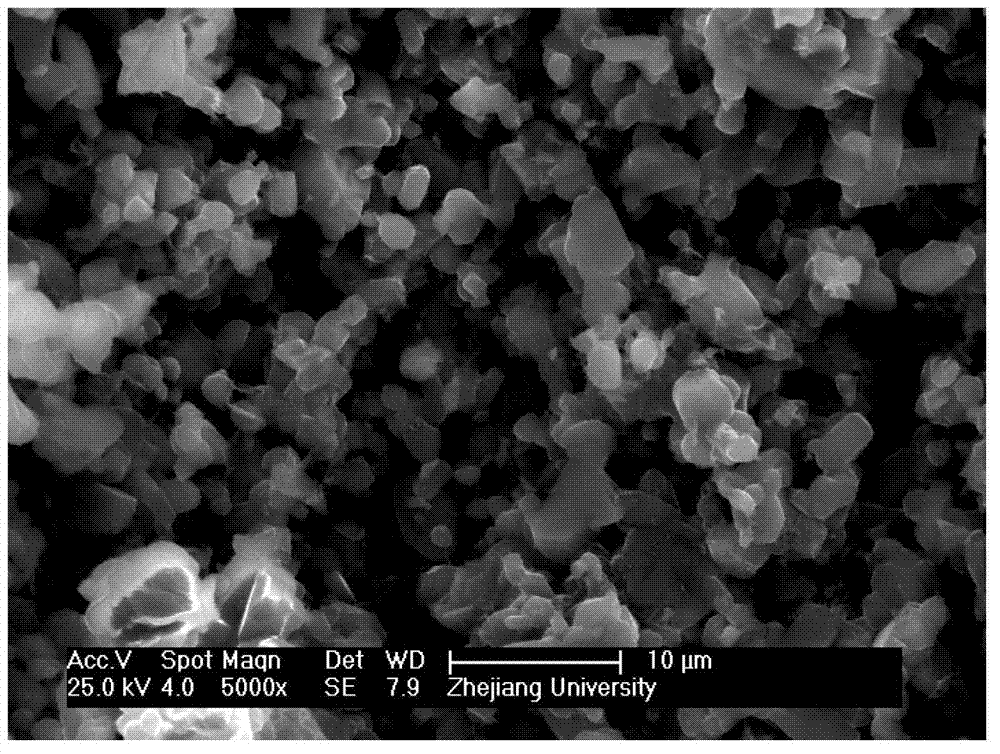

Preparation method of high-porosity silicon-carbide porous ceramics

ActiveCN102807384ALow raw material costHomogeneous microstructureCeramicwareSpray GranulationPolyvinyl alcohol

The invention discloses a preparation method of high-porosity silicon-carbide porous ceramics. According to the preparation method, 60 to 80% of silicon-carbide powder, 10% of boron carbide, 5 to 25% of iron oxide and 5% of polyvinyl alcohol by weight are adopted as raw materials, and the steps of mixing, spray granulation, extrusion forming, drying and sintering are sequentially carried out, wherein the technical conditions for sintering are as follows: a dried biscuit is sintered for 10 to 15 hours at 2100 to 2200 DEG C through pressureless sintering technology so as to obtain the high-porosity silicon-carbide porous ceramics. The silicon-carbide porous ceramics prepared by the method disclosed by the invention has the characteristics of controllable aperture size, high apparent porosity, and relatively large specific surface area, and strength of the silicon-carbide porous ceramics meets the application requirement.

Owner:ZHEJIANG UNIV

Ultraporous ceramic base heat accumulating material and its preparation method

InactiveCN100999414AHigh porosityHigh apparent porosityHeat-exchange elementsCeramicwareFiberNetwork structure

This invention relates to a porous ceramic thermal storage material and preparation method. This material composed by the ceramic matrix and phase change material; ceramic matrix composed of ceramic fibers, with three-dimensional network structure, porosity of 96% or more; Phase change materials is inorganic hydrated salt, including alum, and mixture of alum and six hydrated magnesium chloride, heat of fusion more than 220J / g. Their preparation methods including: ultra-porous ceramic matrix preparation; Phase change salt modification; melt Phase change salt, imbibe in ceramic matrix. The porosity of porous ceramic matrix is high (up to 96%), far higher than the traditional porous ceramic (porosity is generally 40 to 80%); the material can be used in home heating and other energy-saving areas.

Owner:SOUTH CHINA UNIV OF TECH

Method for firing porous filtering ceramic tiles with ceramic polishing scrap

InactiveCN101709001AIncrease contentIncrease the number ofSolid waste disposalCeramicwareCordieriteMaterials processing

The invention discloses a method for firing porous filtering ceramic tiles with ceramics polishing scrap. The method is implemented through raw materials processing, powder preparation, pressing molding, sintering and other processes performed on 50 to 70 percent of building ceramics polishing scrap mixed with 18 to 22 percent of calcined alumina, 0 to 10 percent of fired talc and 28 to 35 percent of light magnesium oxide. The porous filtering ceramic tiles prepared by the method not only have the function of protecting and purifying environment, but also have high modulus of rupture and good filtration performance. The method can effectively solve the problem of dealing with the building ceramics polishing scrap, can save natural ceramic raw materials, is simple in technological process of utilizing the ceramics polishing scrap to fire cordierite porous filtering ceramic tiles and low in cost, and has good application prospects in the fields of liquid pollution treatment, precise filtration and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of zircon corundum brick containing chromic oxide

The invention belongs to the technical field of a refractory material, and in particular relates to a preparation method of a zircon corundum brick containing chromic oxide. The preparation method comprises the following steps: taking fused zircon corundum particles and chromic oxide particles as aggregate, adding chromic oxide fine powder, chromic oxide powder, alpha-Al2O3 powder and white corundum fine powder as a matrix, adding a binding agent, mixing materials, molding and drying, adding the obtained mixture to a nitrogen kiln, regulating the oxygen partial pressure of a firing atmosphere and carrying out low-temperature firing so as to obtain the zircon corundum brick. The brick disclosed by the invention is applicable to such parts as the burner sidewall, burner crown, burner slope and regenerative chamber wall of a horseshoe flame furnace as well as the flue of an alkali-free glass fiber tank furnace; the zircon corundum brick has the characteristics of being excellent in thermal shock resistance, slag corrosion resistance and the like, and the brick is relatively high in industrial application and popularization values.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

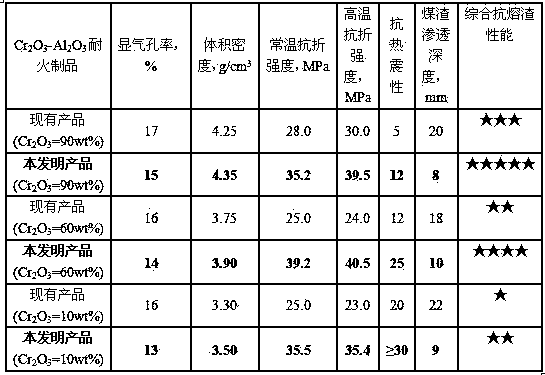

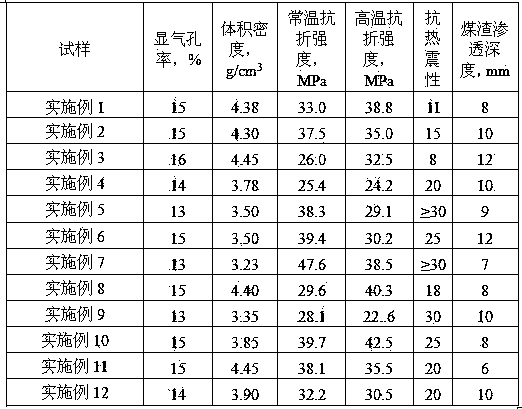

Al2O3-Cr2O3 refractory product and preparation method thereof

The invention belongs to the field of refractory materials, and mainly relates to a Al2O3-Cr2O3 refractory product and a preparation method thereof. The total mass percent of Al2O3 and Cr2O3 in the product is at least 90%, wherein the mass percent of Cr2O3 in the product is 5-95%. The product is prepared by mixing Al2O3-containing and Cr2O3-containing refractory raw particles and fine powders with a binder into a billet and firing the billet at high temperature. The invention is characterized in that the Al2O3-Cr2O3 refractory product contains P2O5 which accounts for 0.8-5 wt% of the product. In the Al2O3-Cr2O3 refractory product, the P element is added in the form of a raw material in the billet manufacturing process; and the P element is simple substance phosphorus. The simple substance phosphorus is powdery red phosphorus of which the purity is not lower than 99.0%. The Al2O3-Cr2O3 refractory product is fired under normal pressure in an oxidizing atmosphere.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

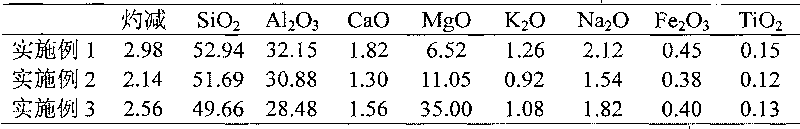

Environment-friendly cordierite-mullite kiln furniture and preparation method thereof

Environment-friendly cordierite-mullite kiln furniture is prepared from the following raw materials in parts by weight: 25 to 35 parts of waste ceramics, 12 to 22 parts of cordierite-mullite clinker,30 to 45 parts of washing ball clay, 10 to 15 parts of andalusite, 8 to 13 parts of talcum powder, 5 to 15 parts of kyanite, 5 to 12 parts of industrial-alpha-alumina powder. According to the environment-friendly cordierite-mullite kiln furniture disclosed by the invention, a solid matter of a composite material of the environment-friendly cordierite-mullite kiln furniture is prepared by taking the waste ceramics, the cordierite-mullite clinker and the andalusite as aggregates and introducing the washing ball clay, the talcum powder, the kyanite and the industrial-alpha-alumina powder as matrix materials, so that the utilization rate of the waste ceramics is up to 25 to 35 percent, waste of resources is reduced, and the production cost of kiln furniture materials is also reduced; a prepared environment-friendly cordierite-mullite kiln furniture product has the advantages of low density, light weight, high bending strength under a normal temperature, high apparent porosity, good thermalshock stability and good energy-saving performance.

Owner:福建省德化县创捷窑具有限公司

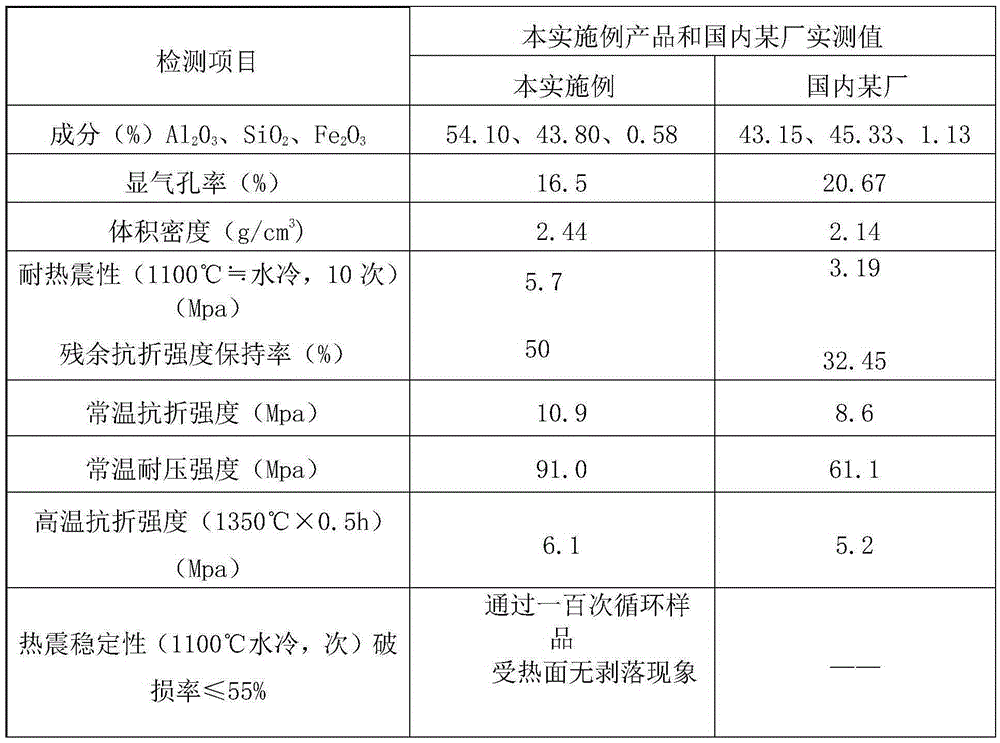

Al2O3-SiO2 tundish permeable brick and preparation method thereof

InactiveCN102320845AAvoid room temperature decompositionGuaranteed decentralizationAluminum fluorideBrick

The invention relates to an Al2O3-SiO2 tundish permeable brick and a preparation method thereof. 65-78 wt% of tabular corundum particles, 7-20 wt% of mullite particles, 2-10 wt% of white corundum fine powder, 1-4 wt% of rho-Al2O3 fine powder, and 1-3 wt% of silicon micropowder are used as raw materials; 0.10-0.20 wt% of mixtures of sodium hexametaphosphate and sodium tripolyphosphate, 0.05-0.20 wt% of yellow dextrin, 0.01-0.20 wt% of azodicarbonamide, 1-4 wt% of Al2O3-SiO2 gel powder, and 0.20-1.0 wt% of aluminium fluoride are used as additives. The preparation method comprises the following steps: premixing the additives and silicon micropowder uniformly according to the contents, adding the tabular corundum particles and the mullite particles, mixing and grinding, adding the white corundum fine powder and rho-Al2O3 fine powder, mixing and grinding, adding 5-7 wt% of water, stirring, casting, molding, performing heat preservation at 110-200 DEG C for 12-48 hours, and finally sintering at 1200-1500 DEG C for 3 hours. The prepared permeable brick has good permeability and high strength, and is erosion-resistant and environment-friendly.

Owner:WUHAN UNIV OF SCI & TECH

Light-weight cordierite castable and preparation method thereof

The invention relates to a light-weight cordierite castable and a preparation method thereof. The technical scheme includes that the preparation method includes: using 40-70wt% of porous cordierite ceramic grains, 20-48wt% of cordierite ceramic fine powder, 2-10wt% of calcium aluminate cement, 2-4wt% of talcum fine powder, 2-4wt% of silicon oxide micro powder and 2-4wt% of active alpha alumina micro powder as raw materials, additionally adding water accounting for 8-20wt% of the raw materials and 0.02-1wt% of water reducers, uniformly stirring and molding by casting; and naturally drying molded green bodies for 24 hours and then drying the dried green bodies for 8-48 hours at the temperature of 110 DEG C. The light-weight cordierite castable prepared by the method not only has the advantages of high apparent porosity, small average pore size, high strength, low thermal conductivity, good thermal shock stability and high medium erosion resistance, but also has the advantages of convenience to construct, environmental friendliness, controllability in apparent porosity and pore size and small volume change after firing, and is applicable to backing layers or working layers of high-temperature kilns or containers at the working temperature lower than 1340 DEG C.

Owner:WUHAN UNIV OF SCI & TECH

High strength thermal shock resistance push plate

The invention discloses a high strength thermal shock resistance push plate, which comprises components with parts by weight: 3-0.5mm mullite particles 20-30 parts, 1-0.5mm alundum particles 15-20 parts, 0.5-0.1mm quartz particles 10-15 parts, 320 meshes andalusite fine powder 15-20 parts, 220 meshes mullite fine powder 25-30 parts, 2Mumalumina micro powder 8-12 parts, 320 meshes alundum fine powder 5-10 parts, silica powder 5-15 parts, zirconite 5-10 parts, cerium oxide 0.5-2 parts, cerium oxide 2-10 parts, aluminum 5-10 parts, silicon 10-15 parts, white mud 10-15 parts and external binders 1-3 parts. The invention further discloses a method for preparing the high strength thermal shock resistance push plate. The high strength thermal shock resistance push plate is excellent in thermal shock resistance, high in mechanical strength, simple in preparation method and convenient for actual operation.

Owner:ANHUI NINGHUO NEW MATERIAL

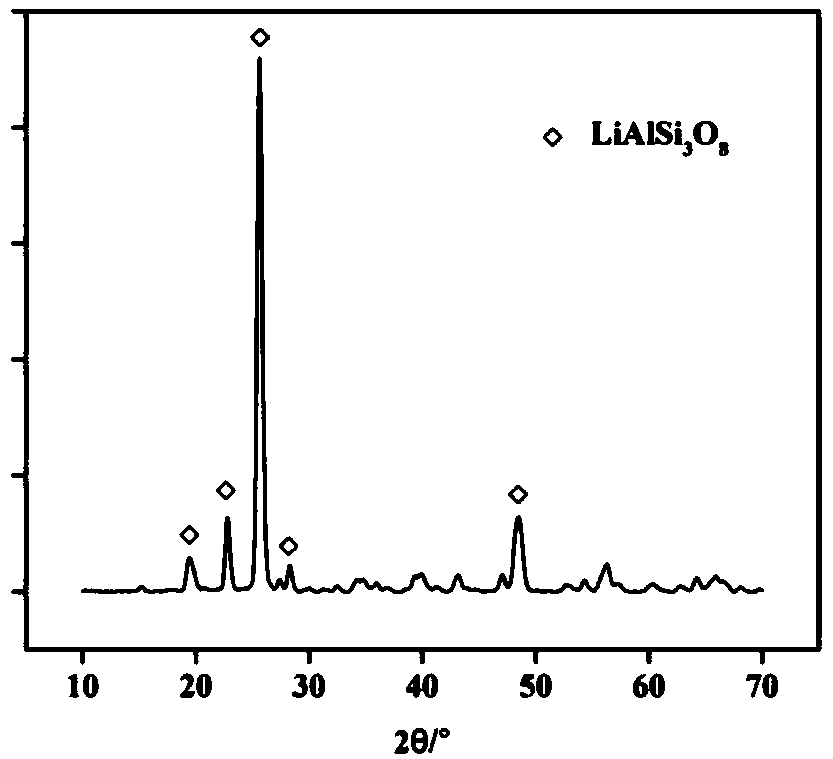

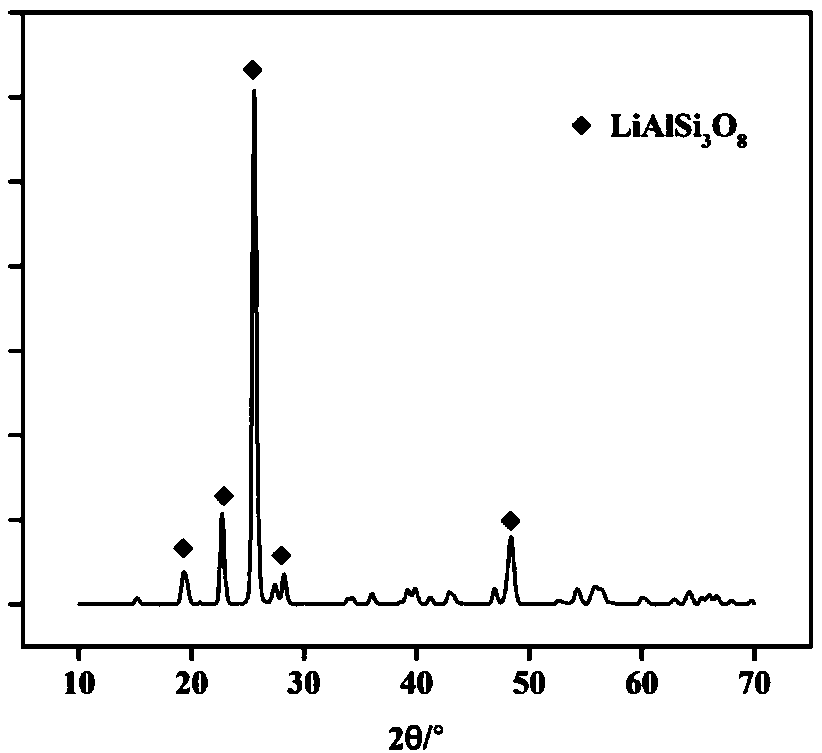

Formula, preparation method and application of LAS-series glass ceramic abrasive binding agent

ActiveCN109015419AImprove flexural strengthMeet low temperature sintering requirementsAbrasion apparatusPorosityBreaking strength

The invention discloses a formula, preparation method and application of an LAS-series glass ceramic abrasive binding agent and belongs to the field of glass ceramic abrasive tools. The LAS-series glass ceramic abrasive binding agent is prepared from, by mass, 4-9% of Li2O, 14-20% of Al2O3, 48-58% of SiO2, 8-16% of B2O3, 0.8-2.2% of Na2O, 0.8-1.2% of K2O, 1-4.5% of MgO, 1-3% of ZnO, 0.5-1.5% of BaO and 3.5-4.5% of TiO2. The melting temperature is 1200-1300 DEG C, the sintering temperature is 600-780 DEG C, the coefficient of thermal expansion is small, the adjustable characteristic is achieved, the wettability is good, the agent is suitable for preparing abrasive tools with abrasives such as white corundum, green silicon carbide and artificial diamond, and the tools are moderate in density, low in water absorption rate and high in apparent porosity and breaking strength, have a good chip containing space and good abrasive holding force and are not prone to falling off in the machiningprocess.

Owner:DALIAN POLYTECHNIC UNIVERSITY

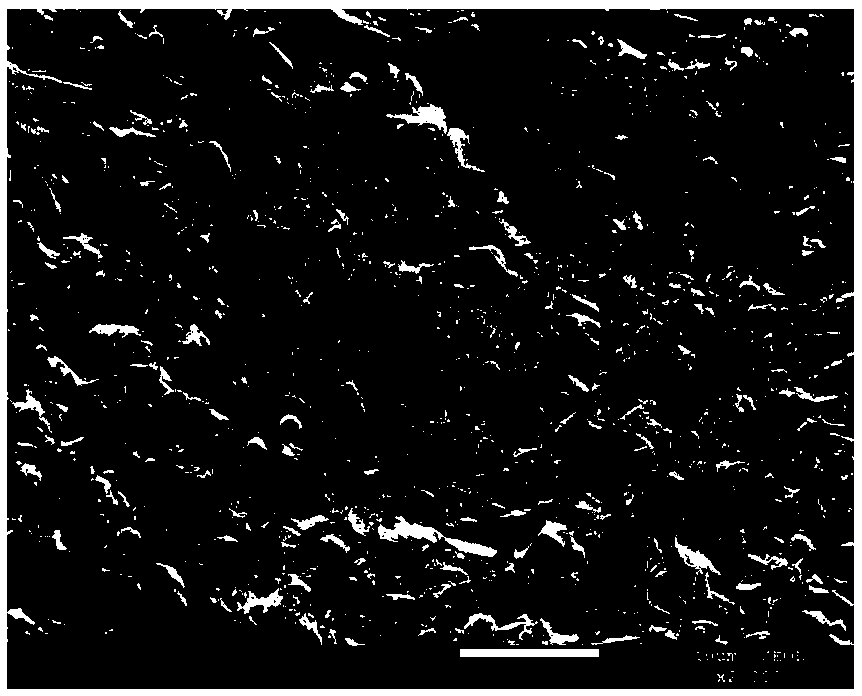

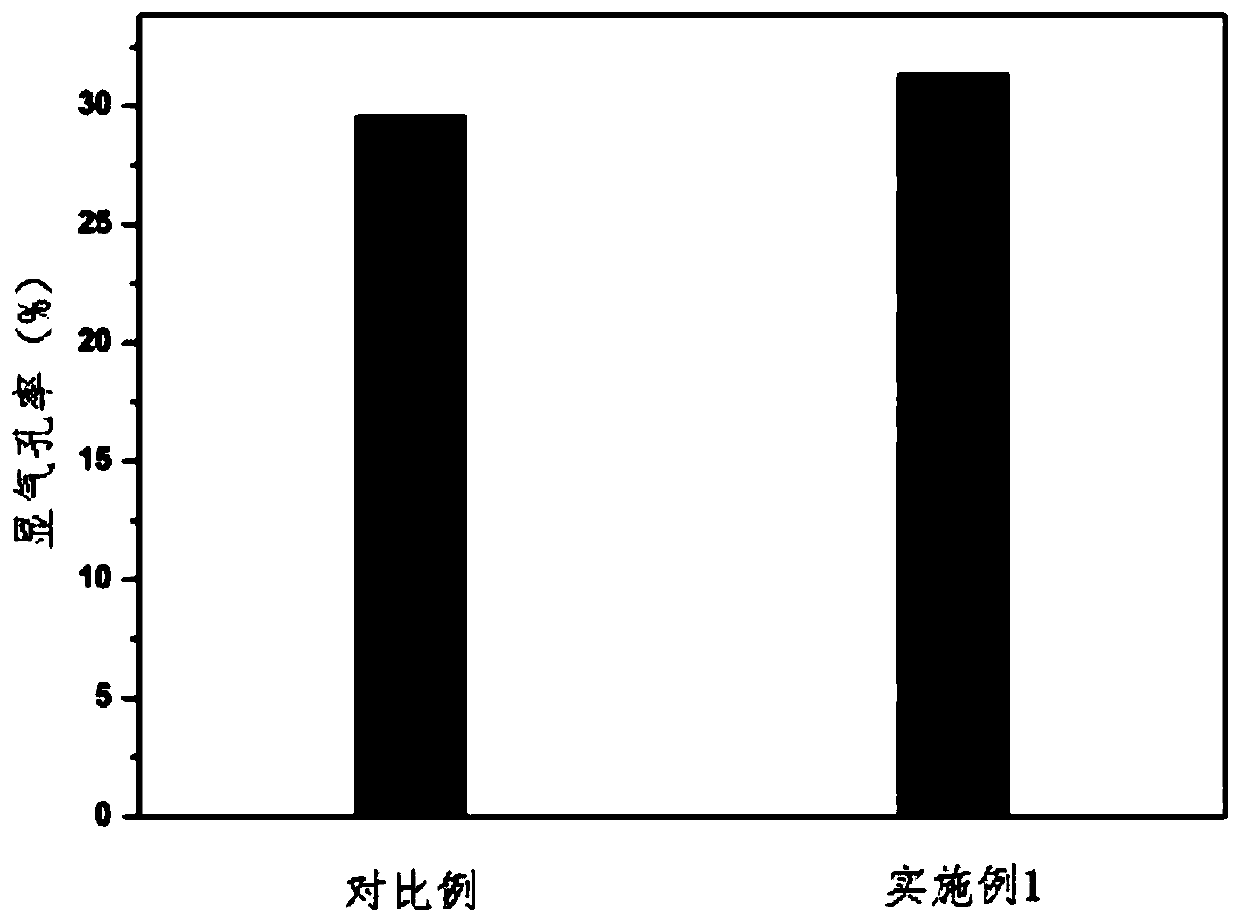

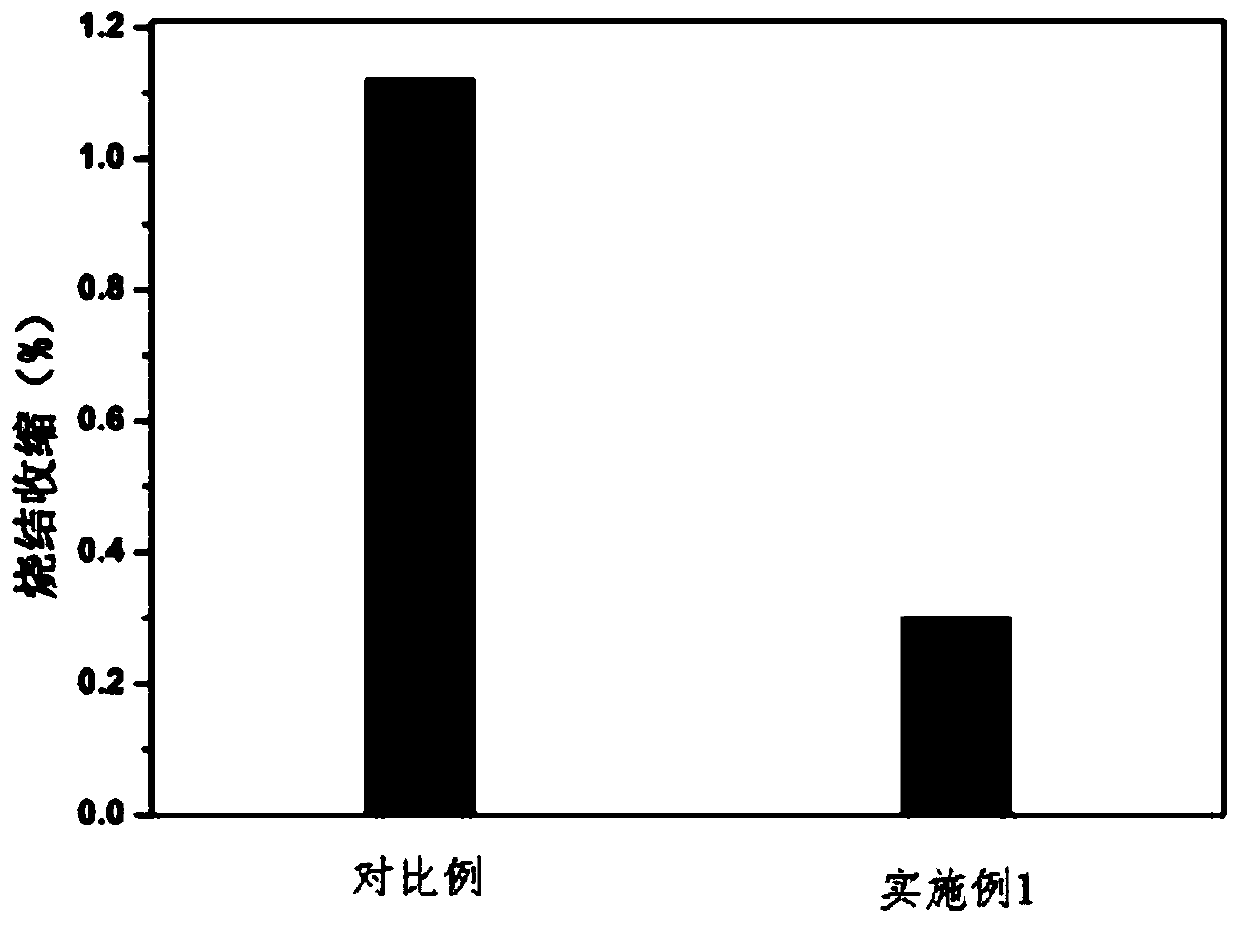

Porous silicon-based ceramic core suitable for double-wall blades and preparation method of core

InactiveCN109734430AImprove high temperature performanceReduce Shrinkage ProblemsFoundry mouldsFoundry coresWaxPlasticizer

The invention relates to the technical field of precision casting, and provides a porous silicon-based ceramic core suitable for double-wall blades. The core is prepared from ceramic powder and a plasticizer, wherein the ceramic powder comprises quartz glass powder, fused mullite powder and zirconium silicate powder; the plasticizer is ceramic core casting wax; and the mass ratio of the quartz glass powder, the fused mullite powder and the zirconium silicate powder is (70-80): (10-20): (10-20). The high-temperature performance of the porous silicon-based ceramic core is improved through the selection of raw materials and the control of the content, the shrinkage and deformation of the ceramic core in the sintering and pouring processes are reduced, and the application requirements of the increasingly-complex double-wall blade ceramic core can be met. The invention provides a porous silicon-based ceramic core preparation method, which has the advantages of simple operation, high moldingrate of the ceramic core, short production time and low production cost.

Owner:SHANGHAI UNIV

Preparation method of tundish air brick

InactiveCN103787670AHigh Durability Thermal Shock ResistantExcellent thermal shock resistanceAzodicarbonamideCorundum

The invention discloses a preparation method of a tundish air brick. The preparation method comprises the following steps of: (1) placing 45-55 parts by weight of tabular corundum granules, 10-14 parts by weight of mullite granules and 5-8 parts by weight of chromic oxide granules into a mixer, and mixing for 5-8 minutes; (2) placing 4-6 parts by weight of white corundum fine powder, 2-3 parts by weight of alpha-Al2O3 fine powder and 1.5-3.5 parts by weight of silica micropowder into the mixer, and mixing for 10-15 minutes; (3) adding a mixture prepared from the step (1) to the mixer used in the step (2), mixing for 10-15 minute again, adding 0.4-0.6 part by weight of sodium hexametaphosphate, 0.3-0.5 part by weight of yellow dextrin, 0.1-0.3 part by weight of azodicarbonamide, 0.2-0.4 part by weight of boric acid and 0.1-0.3 part by weight of aluminum fluoride, and then mixing for 10-15 minutes again; (4) ageing for 1-2 hours, pressing for forming by using a press machine, and drying into a drying kiln at 200 DEG C for 24 hours; (5) firing under the condition of 1250-1350 DEG C for 2-3 hours.

Owner:WUXI CHENGBO SCI & TECH DEV

Light cordierite-spinel castable and preparation method thereof

The invention relates to a light cordierite-spinel castable and a preparation method thereof. The technical scheme includes that 40wt. %-70wt. % of porous cordierite ceramic particles, 5wt. %-15wt. % of magnesium oxide fine powders, 11wt. %-30wt. % of industrial alumina fine powders, 2wt. %-8wt. % of active Al2O3 fine powders, 2wt. %-10wt. % of silicon oxide micro powders and 1wt. %-14wt. % of silica fine powders are used as raw materials, and water and water reducing agents are added for being uniformly stirred and molded by casting, wherein the water is 8wt. %-20wt. % of the raw materials, and the water reducing agents is 0.02wt. %-1wt. % of the raw materials; a molded green body is naturally dried for 24 hours and then dried for 8-48 hours under the condition of 110 DEG C to prepare the light cordierite-spinel castable. The preparation method is simple, and the light cordierite-spinel castable has the advantages of being convenient to construct, environment-friendly, controllable and high in apparent porosity, controllable in pore sizes and burnt volume, small in average pore sizes, low in heat conductivity, high in strength, good in thermal shock stability, high in medium corrosion resistance capability, high in using temperatures and applicable to a permanent layer or a work layer of a high temperature kiln or a container with working temperatures lower than 1410 DEG C.

Owner:WUHAN UNIV OF SCI & TECH

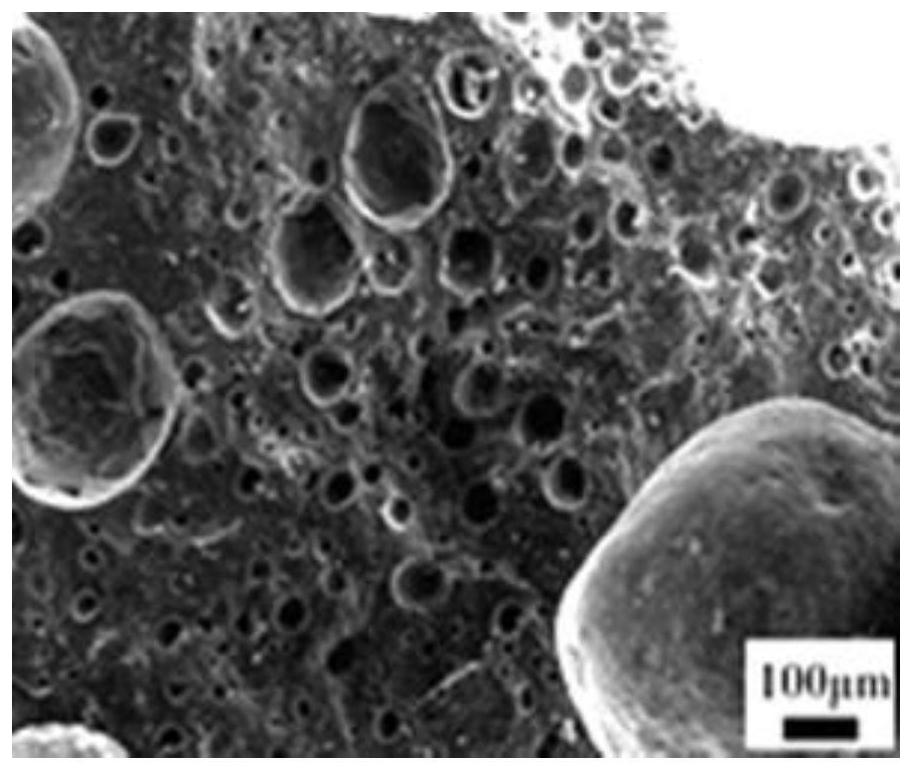

Moulding olivine nickel-loaded catalyst and preparation method thereof

InactiveCN101332429ASuitable chemical compositionMeet the areaGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsLanthanideOlivine

The invention relates to a molded olivine supported nickel catalyst and a preparation method thereof. The catalyst is composed of a molded olivine carrier supported nickel as a main active component and lanthanide metal oxide adjuvant components, wherein, the Nio content is 3 - 28wt%, and the content of lanthanide metal oxide adjuvant such as La2O3 or CeO2 is 0 - 5wt%. The catalyst is prepared by adopting carrier presintering and immersion method, and the molded carrier is prepared by the processes of mixing, molding, curing, and calcining the mixture consisting of olivine powder, a cement binder, adjuvant magnesia, graphite powder or carbon powder, and then the molded carrier is immersed in a nickel nitrate aqueous solution or mixed aqueous solution of nickel nitrate and lanthanum nitrate or mixed aqueous solution of nickel nitrate and cerous nitrate, thus the catalyst is obtained. The catalyst prepared by the method is characterized by good strength, high efficiency of carbon conversion and strong carbon deposition resistance.

Owner:DALIAN UNIV OF TECH

Preparation method of low-zirconium mullite cast steel brick

The invention relates to a preparation method of a low-zirconium mullite cast steel brick, and belongs to the field of preparation of refractory materials. The raw material formula of the low-zirconium mullite cast steel brick provided by the invention comprises electrically smelted mullite, zirconium oxide, Guangxi white clay, andalusite, kyanite and lignin. According to the method provided by the invention, type and grain size of the raw materials are selected to be matched with the sintering temperature and time provided by the invention, so that the prepared low-zirconium mullite cast steel brick has the characteristics of excellent scouring resistance, high temperature resistance, small creep deformation, high compression strength, good thermal stability and the like, and is suitable for being used in large steel ingot casting in nuclear power products.

Owner:四川锦圆耐材有限公司

Cold-pressing one-step forming method for disc brake pad

The invention relates to a cold-pressing one-step forming method for a disc brake pad. The cold-pressing one-step forming method is characterized by comprising a step 1, dry-method material mixing; a step 2, gluing of a steel back; a step 3, cold-pressing forming; a step 4, heat treating; and a step 5, surface grounding and spraying. The cold-pressing one-step forming method for the disc brake pad omits hot pressing, a material directly enters a baking oven to be treated, accordingly, a hot pressing working procedure is omitted, investment for staffs, equipment and electricity is reduced, andproduction efficiency is improved. In addition, liquid resin can be sufficiently adhered on a reinforcement material when mixed with the reinforcement material, stability of performances of the brakepad is guaranteed, flowing of the resin is reduced due to omission of the hot pressing working procedure, materials are distributed sufficiently, a manufactured product is stable in quality, loose insurface, high in apparent porosity, and good in high-temperature performance, and is noise-free, production efficiency of integral process is high, the quality of the manufactured product is good, and cost is low.

Owner:江阴市利港第二化工有限公司

Modified red mud porous ceramic, preparation method and application thereof

PendingCN111825475AAchieve removalAvoid leachingWater contaminantsCeramic materials productionRed mudExpanded clay aggregate

The invention belongs to the technical field of ceramics, particularly relates to modified red mud porous ceramic, a preparation method and application thereof, and provides modified red mud porous ceramic, which comprises porous structure ceramic particles and modified element compounds fixed on the surfaces and the internal pore channels of the porous structure ceramic particles. According to the invention, modified element compounds in modified red mud porous ceramic are fixed on the surface of red mud porous ceramsite and the surfaces of the internal pore channels, so that fluorine ions inF-containing wastewater are removed; and the porous and granular red mud ceramic adsorption filter material is convenient for separation of the adsorption filter material from the water body, and canbe adsorbed and recycled again after desorption; and experimental data show that the modified red mud porous ceramic provided by the invention has a porous structure, the apparent porosity reaches 44.1%, the crushing strength reaches 637.486 N / particle, and the removal rate of fluorine ions in F-containing wastewater can reach 72.5%.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for manufacturing silicon mullite brick by adopting bauxite tailings

The present invention particularly relates to a method for manufacturing a silicon mullite brick by adopting bauxite tailings so as to solve a problem of high raw material cost of the existing silicon mullite brick. According to the method for manufacturing the silicon mullite brick by adopting bauxite tailings, bauxite tailings is adopted to replace mullite with expensive cost to be adopted as a main raw material, and is matched with silicon carbide and other materials, and high-pressure molding and medium temperature firing are performed to obtain the silicon mullite brick. The method has characteristics of comprehensive resource utilization, energy saving and environmental protection. The obtained silicon mullite brick has advantages of high compressive strength at a room temperature and low cost, wherein a compressive strength of the product achieves 115-137 MPa, thermal shock resistance under a 1100 DEG C water cooling condition achieves 60-110 times, room temperature wear resistance achieves 9-13 cm<3>, and content, bulk density, apparent porosity, and refractoriness under load of alumina are higher than the national standards.

Owner:孝义市和中兴矿产有限公司

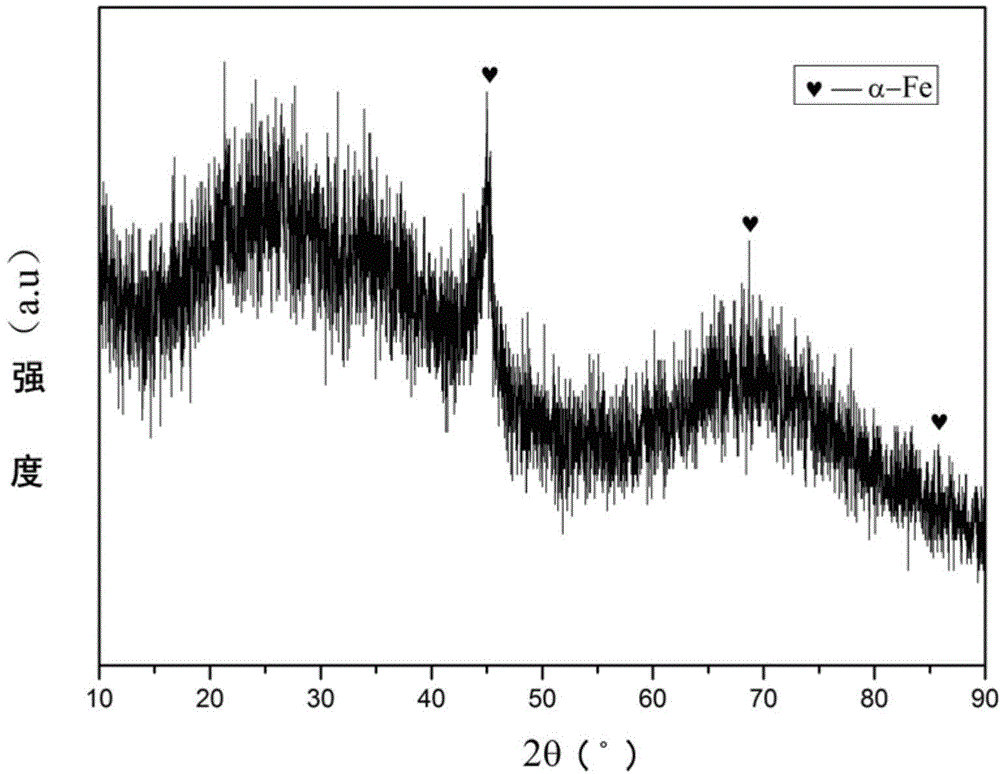

Method for preparing ferric acetylacetonate-containing silicon carbonitride ceramic by precursor conversion method

The invention relates to a method for preparing ferric acetylacetonate-containing silicon carbonitride ceramic by a precursor conversion method. The method comprises the following steps: (1) uniformly mixing polysilazane, alpha-methacrylic acid and dicumyl peroxide to obtain mixed solution; (2) solidifying the mixed solution; (3) crushing and ball-milling the solidified material; (4) uniformly mixing the powder and ferric acetylacetonate; (5) prepressing and shaping the uniformly mixed powder to obtain a green body; (6) pyrolyzing / sintering the green body at a temperature of 1000-1400 DEG C, and insulating to obtain the ferric acetylacetonate-containing silicon carbonitride ceramic. The material obtained by the method disclosed by the invention is good in high-temperature performance, and the introduced ferric acetylacetonate increases the apparent porosity of SiCN ceramic, reduces the volume density of the SiCN ceramic, remarkably improves the microwave absorption performance of the SiCN ceramic, and increases the electromagnetic wave attenuation coefficient.

Owner:SHANDONG UNIV

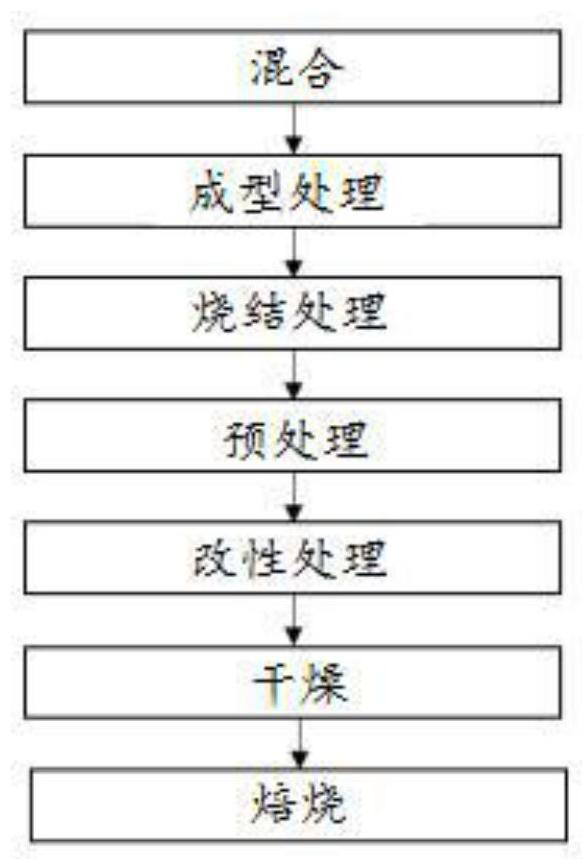

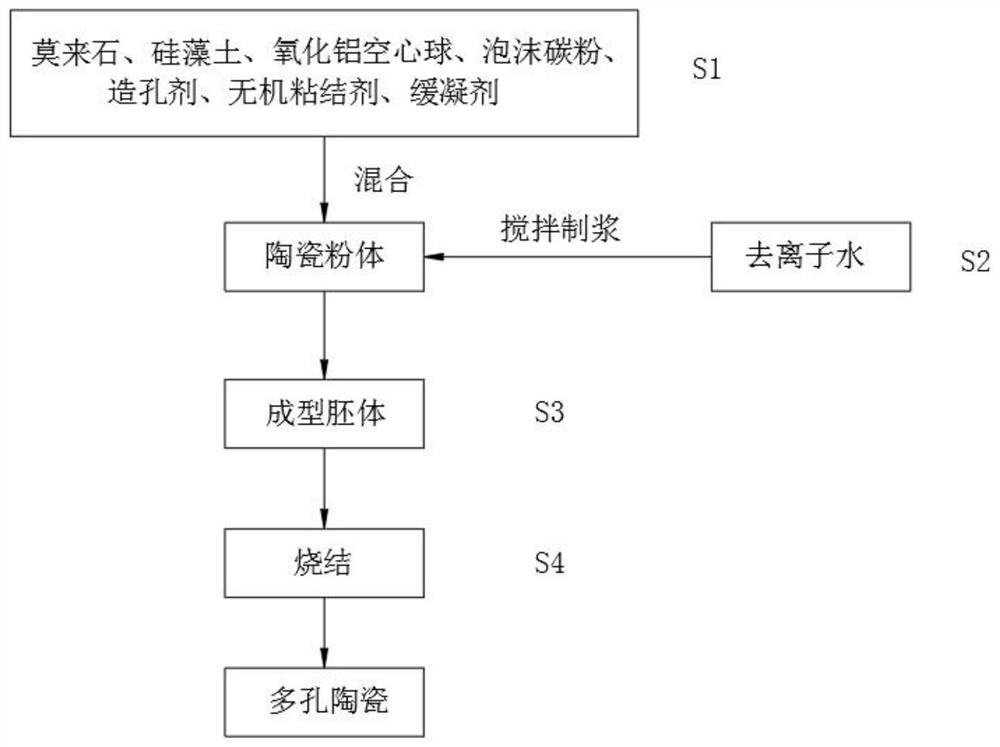

Porous ceramic for electronic cigarette atomization core with low thermal conductivity and high porosity and preparation method of porous ceramic

PendingCN113105260APlay the role of aggregateHigh strengthTobacco devicesCeramicwareThermal conductivityElectronic cigarette

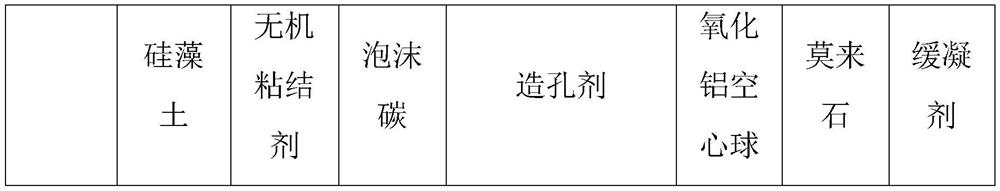

The invention discloses porous ceramic for an electronic cigarette atomization core with low thermal conductivity and high porosity and a preparation method of the porous ceramic, and particularly relates to the field of ceramic materials. Raw materials used in the invention comprise, by mass, 1%-15% of mullite, 40%-60% of diatomite, 5%-25% of alumina hollow spheres, 1%-5% of foamy carbon powder, 10%-15% of a pore-forming agent, 1%-8% of an inorganic binder and 0.1%-0.5% of a retarder. The diatomite, mullite and dense foam carbon in the raw materials are of a porous structure, the aluminum oxide hollow spheres are of a hollow structure, the pore-forming agent can be used for forming pores in the porous ceramic, meanwhile, mullite can also play a role of aggregate, and through reasonable matching according to the proportion, the prepared porous ceramic atomizing core has relatively low thermal conductivity and relatively high apparent porosity.

Owner:江西一创新材料有限公司

Porous forsterite and akermanite composite ceramic material and preparation method thereof

InactiveCN104140246AAvoid secondary pollutionConducive to environmental protectionÅkermaniteComposite ceramic

The invention relates to a porous forsterite and akermanite composite ceramic material and a preparation method of the porous forsterite and akermanite composite ceramic material. According to the technical scheme, 60-70 wt% of dolomite powder, 25-28 wt% of silica powder and 5-15 wt% of magnesite powder serve as raw materials and are mixed, pulp liquid waste 5-8 wt% of the raw materials is added, and the mixture is stirred to be even and is mechanically pressed and formed; then a formed green body is aired for 16-24 hours under the condition of 110 DEG C, the temperature is kept for 3-8 hours under the condition of 1300-1450 DEG C, and then the porous forsterite and akermanite composite ceramic material is obtained. The particle sizes of the dolomite powder, the silica powder and the magnesite powder are smaller than 88 micrometers, and the pressure of mechanical pressing and forming is 30-100 MPa. The porous forsterite and akermanite composite ceramic material has the advantages of being environmentally friendly, being composed of dual phases, and being controllable in phase composition, pore size and size. The prepared porous forsterite and akermanite composite ceramic material is high in apparent porosity, high in intensity and good in high temperature performance, and can be used in the working environment lower than 1400 DEG C as a heat preservation material.

Owner:WUHAN UNIV OF SCI & TECH

Energy-saving cordierite zircon multiphase material and preparation method thereof

InactiveCN110204323ARealize comprehensive utilizationTo achieve the purpose of resource utilizationSpray GranulationPolyvinyl alcohol

The invention relates to an energy-saving cordierite zircon multiphase material and a preparation method thereof. According to the technical scheme, firstly, 40-60 wt% of zircon tailings, 35-50 wt% offine talc powder and 5-15 wt% of fine aluminium oxide powder are taken as raw materials, the raw materials of 40-50 wt% of water, 2-4 wt% of polyvinyl alcohol and 0.4-0.8 wt% of fine cerium oxide powder are additionally added, mixing is carried out, and ball-milling is carried out for 6-8 hours to obtain pulp; then the pup is subjected to spray granulation to obtain granular powder, then the granular powder is press-formed, heat preservation is carried out for 8-10 hours at 1350-1420 DEG C, natural cooling is carried out, and the energy-saving cordierite zircon multiphase material is obtained. The preparation method of the energy-saving cordierite zircon multiphase material has the advantages that the production cost is low, the method is green and environmentally friendly, and the scaleproduction is facilitated; the prepared energy-saving cordierite zircon multiphase material not only has high strength, an obvious energy-saving effect and good thermal shock resistance, but also hasa wide application range.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com