Method for preparing ferric acetylacetonate-containing silicon carbonitride ceramic by precursor conversion method

A technology of iron acetylacetonate and precursors, applied in the field of inorganic non-metallic materials, can solve the problems of limiting the application of SiCN ceramics and poor microwave absorption performance, and achieve the effects of improving microwave absorption performance, increasing apparent porosity, and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

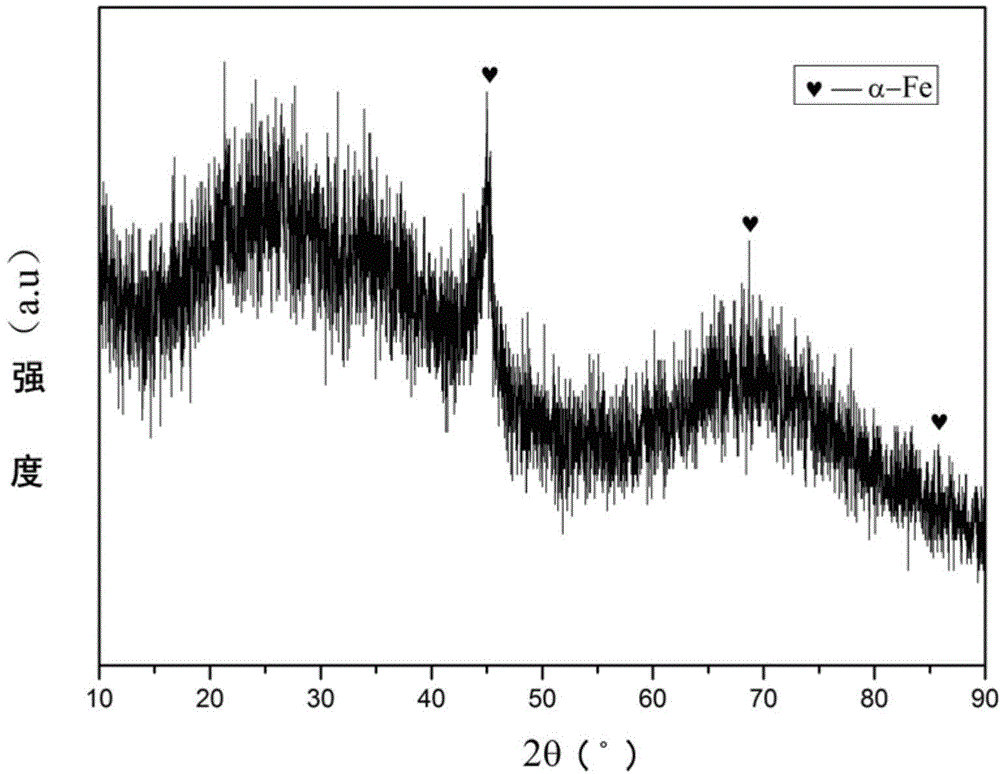

Image

Examples

Embodiment 1

[0034] A kind of precursor method prepares SiCN ceramic method containing iron acetylacetonate, comprises steps as follows:

[0035] (1) Mixing: in N 2 Under the atmosphere, weigh 9.6g of polysilazane, 1g of α-methacrylic acid, and 0.4g of dicumyl peroxide, and stir on a constant temperature magnetic stirrer for 1h to obtain a mixed solution;

[0036] In the mixed solution, polysilazane: dicumyl peroxide is formulated according to the mass ratio of 96%: 4%, and α-methacrylic acid is 10% of the total mass of polysilazane and dicumyl peroxide;

[0037] (2) Cross-linking curing: the mixed solution obtained in step (1) is cured at a heating rate of 3°C / min from room temperature to 400°C for 2 hours;

[0038] (3) Pulverizing and ball milling: the solidified material obtained in step (2) is pulverized and ball milled in a vibrating ball mill, and crosses a 100-mesh sieve;

[0039] (4) Mixing: Weigh 0.1 g of iron acetylacetonate and 0.5 g of the powder obtained in step (3) and mix ...

Embodiment 2

[0046] A kind of precursor method prepares SiCN ceramic method containing iron acetylacetonate, the steps are as follows:

[0047] (1) Mixing: in N 2 Under the atmosphere, weigh 9.6g of polysilazane, 1g of α-methacrylic acid, and 0.4g of dicumyl peroxide, and stir on a constant temperature magnetic stirrer for 1h to obtain a mixed solution;

[0048] In the mixed solution, polysilazane: dicumyl peroxide is formulated according to the mass ratio of 96%: 4%, and α-methacrylic acid is 10% of the total mass of polysilazane and dicumyl peroxide;

[0049] (2) Cross-linking curing: the mixed solution obtained in step (1) is cured at a heating rate of 5°C / min from room temperature to 600°C for 4 hours;

[0050] (3) Pulverizing and ball milling: the solidified material obtained in step (2) is pulverized and ball milled in a vibrating ball mill, and crosses a 100-mesh sieve;

[0051] (4) Mixing: Weigh 0.1 g of iron acetylacetonate and 0.5 g of the powder obtained in step (3) and mix th...

Embodiment 3

[0056] A kind of precursor method prepares the magnetic SiCN ceramic method containing iron acetylacetonate, and the steps are as follows:

[0057] (1) Mixing: in N 2 Under the atmosphere, weigh 9.8g of polysilazane, 1g of α-methacrylic acid, and 0.2g of dicumyl peroxide, and stir on a constant temperature magnetic stirrer for 1h to obtain a mixed solution;

[0058] In the mixed solution, polysilazane: dicumyl peroxide is formulated according to the mass ratio of 98%: 2%, and α-methacrylic acid is 10% of the total mass of polysilazane and dicumyl peroxide;

[0059] (2) Cross-linking curing: the mixed solution obtained in step (1) is cured at a heating rate of 5° C. / min from room temperature to 400° C. for 6 hours;

[0060] (3) Pulverizing and ball milling: the solidified material obtained in step (2) is pulverized and ball milled in a vibration ball mill, and crosses a 200-mesh sieve;

[0061] (4) Mixing: Weigh 0.25 g of iron acetylacetonate and 0.5 g of the powder obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com