Honeycomb-shaped silicon carbide ceramic carrier, and preparation method and application thereof

A technology of silicon carbide ceramics and the first silicon carbide powder, which is applied in the direction of ceramic products, catalyst carriers, chemical instruments and methods, etc., can solve the problems of small water absorption performance of silicon carbide, low porosity, and less catalytic tail gas, etc., and achieve increased Water absorption performance, good water absorption performance, beneficial to the load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

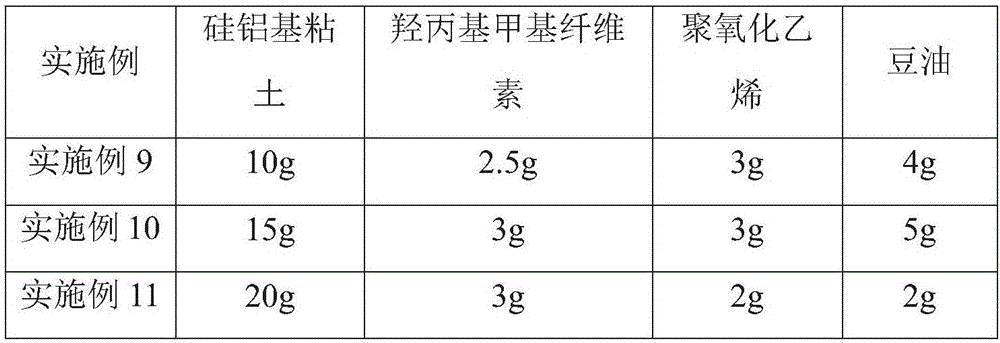

[0042] (1) Weigh 90 g of silicon carbide powder with a particle size of 50-65 μm, 10 g of silicon carbide powder with a particle size of 10-40 μm, 12 g of silicon-aluminum-based clay, 2 g of hydroxypropyl methylcellulose, and 3 g of polyethylene oxide. The prepared honeycomb ceramic powder was placed in a mixer, and dry mixed for 0.5 hours.

[0043] (2) Mix 3g of soybean oil and 30g of water, and stir evenly to obtain a solution; pour the solution into the stirred ceramic powder, and fully knead in a mixer for 0.5 hour to obtain plastic clay. The mud material is put into the extruder for extrusion molding after mud refining and vacuuming to obtain a honeycomb silicon carbide green body. The size and shape of the green body are controlled by the mold in the extrusion molding equipment.

[0044] (3) Place the green body in a cool and dry environment for 2 days, then place the shade-dried honeycomb green body at 60°C for 6 hours, and then raise the temperature to 105°C for 8 hour...

Embodiment 2

[0047] The ratio of silicon carbide powder in this example is shown in Table 1, and other preparation methods are the same as in Example 1.

[0048] After testing, the apparent porosity of the honeycomb silicon carbide ceramics prepared in this embodiment is 43%, and the porosity is 69%; the compressive strength A is 44Mpa, and the compressive strength B is 12Mpa; the thermal shock resistance is detected with 6 ℃ / min to 650 ℃, keep warm for 30 minutes, take it out and cool it naturally in the air to the greenhouse for one cycle, a total of 3 cycles, and the test results show that there are no cracks or damages in the 3 times.

Embodiment 3

[0050] The ratio of silicon carbide powder in this example is shown in Table 1, and other preparation methods are the same as in Example 1.

[0051] After testing, the apparent porosity of the honeycomb silicon carbide ceramics prepared in this embodiment is 43%, and the porosity is 68%; the axial compressive strength is 42Mpa, and the compressive strength radially is 13Mpa; thermal shock resistance is detected with 6 ℃ / min to 650 ℃, keep warm for 30 minutes, take it out and cool it naturally in the air to the greenhouse for one cycle, a total of 3 cycles, and the test results show that there are no cracks or damages in the 3 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com