Polyaspartic acid gel and preparation method thereof

A technology of polyaspartic acid gel and polyaspartic acid, which is applied in the field of polymer water-absorbing materials, can solve the problems of no clear use and no water-absorbing function, and achieve good water-absorbing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

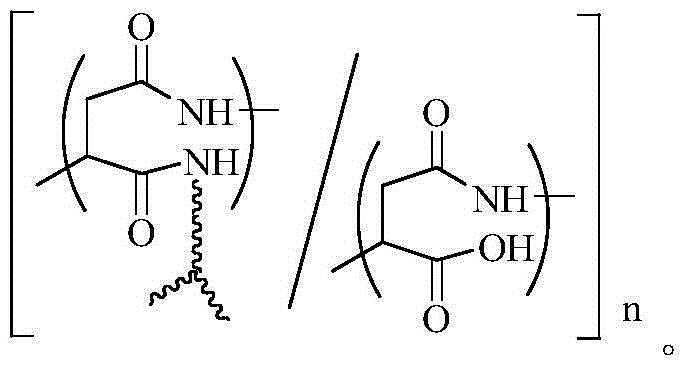

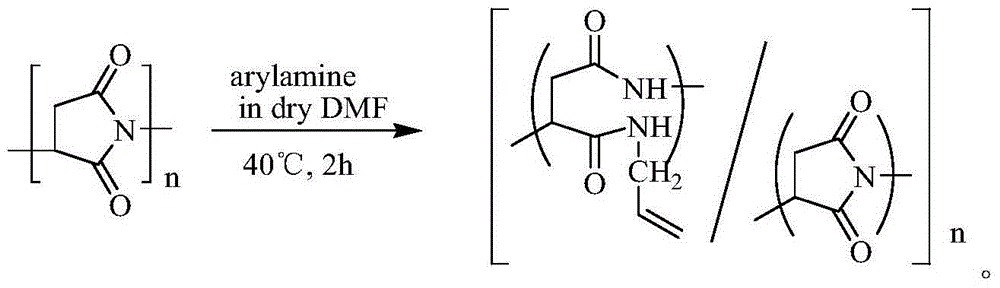

[0010] 1. Synthesis of modified polysuccinimide (t-PSI) by grafting allylamine

[0011] In a protective gas, dissolve polysuccinimide (PSI) in a dry polar solvent, concentrate with allylamine (arylamine) under reduced pressure distillation at 40-45°C, and reprecipitate with methanol to obtain Solid matter; the solid matter is washed with methanol and dried under vacuum at a temperature of 50-60° C. to obtain modified polysuccinimide (t-PSI).

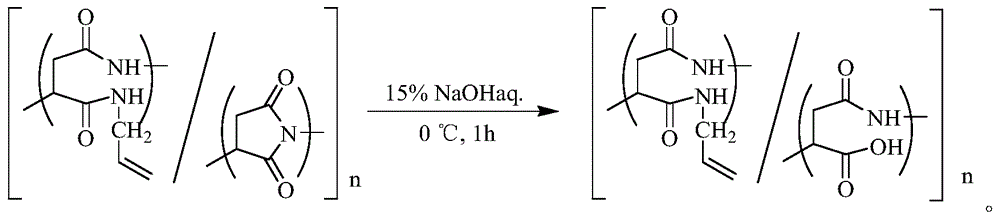

[0012] 2. Synthesis of modified polyaspartic acid (t-PAsp) by hydrolysis of NaOH aqueous solution

[0013] Hydrolyze the modified polysuccinimide (t-PSI) with NaOH aqueous solution (NaOHaq.) in an ice bath, reprecipitate and wash the product with methanol, and dry the obtained solid in vacuum at a temperature of 50-60°C , to obtain modified polyaspartic acid (t-PAsp).

[0014] 3. Synthesis of polyaspartic acid gel (PAspgel)

[0015] Dissolve modified polyaspartic acid (t-PAsp) in water under ice bath, add ammonium persulfate (APS) as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com