Ultraporous ceramic base heat accumulating material and its preparation method

A technology of porous ceramics and heat storage materials, applied in ceramic products, heat exchange materials, chemical instruments and methods, etc., can solve the problems of increasing the thermal resistance of heat transfer medium and phase change material, increasing cost, reducing heat transfer efficiency, etc. , to achieve the effect of high porosity, high heat of solution and high apparent porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation of ultraporous ceramic matrix

[0024] Mix aluminum hydroxide powder and phosphoric acid solution according to the molar ratio of P / Al=23, heat and stir to form a colorless and transparent binder solution, add distilled water to dilute to a concentration of 10% by mass, and mix ceramic fiber and binder The binder solution is mixed, and the ceramic fiber is formed into the required shape by the pressurized drainage method, and after drying, it is fired in a high-temperature electric furnace to form a porous ceramic sintered body. The obtained fiber porous ceramic has a porosity of more than 96%.

Embodiment 2

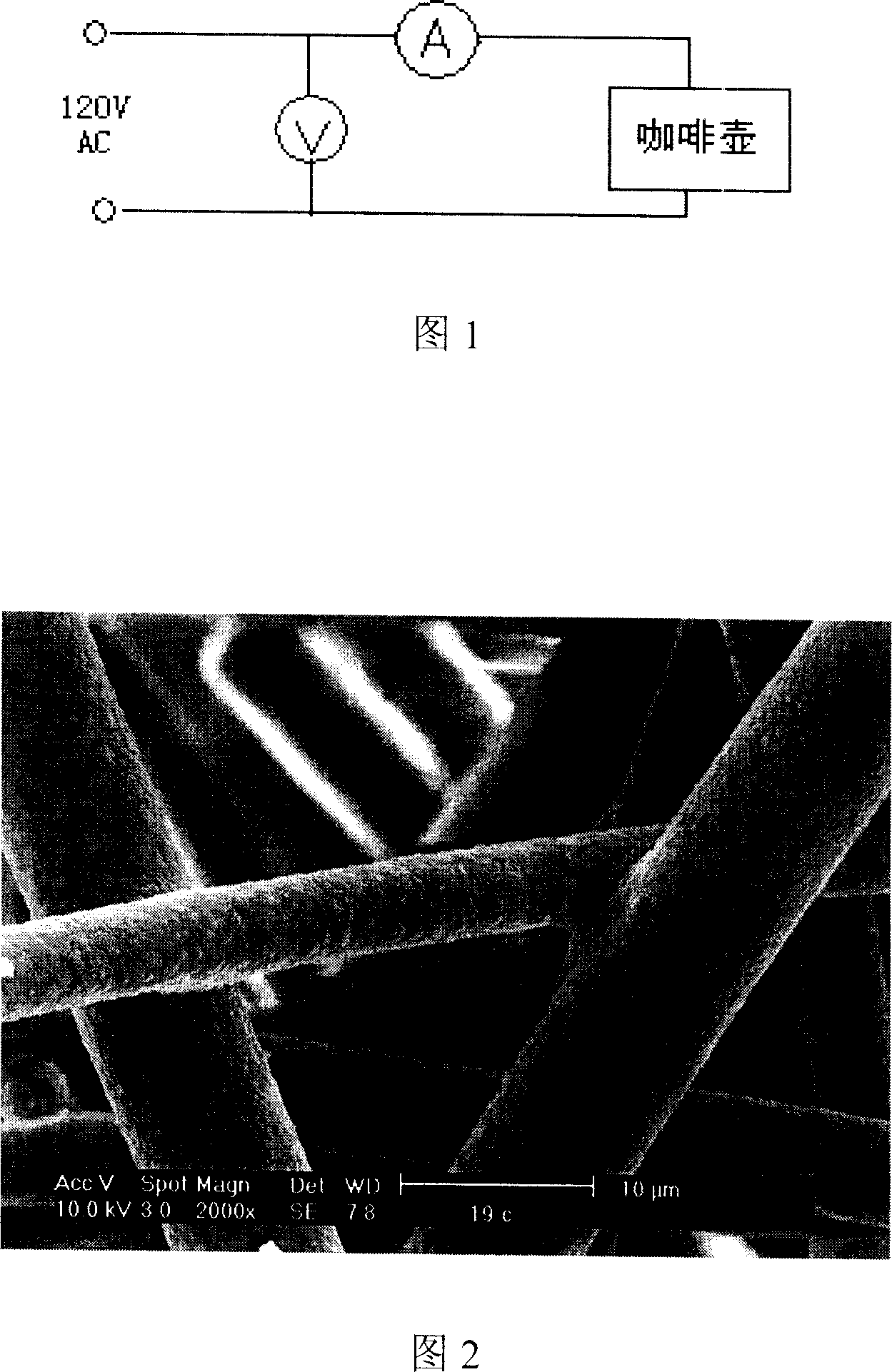

[0026] Take by weighing 150g of alum, one piece (20.6g by weight) of the superporous ceramic substrate prepared in Example 1, cover the alum on the porous ceramic substrate, put it in a container, and heat and dry it in an oven at a drying temperature of 100 to 120°C , and keep warm for 30 minutes, take out the porous ceramic impregnated with the salt solution, cool to room temperature, remove the excess material on the surface, and obtain the phase change heat storage body. The scanning electron microscope picture of the superporous ceramic matrix is shown in Figure 2. From the scanning electron microscope picture magnified 2000 times, it can be seen that the ceramic fibers are interlinked to form a three-dimensional network structure, and the pores formed between the fibers are about a dozen microns . The capillary force formed by such micron-sized pores can keep the molten salt in the ceramic matrix without flowing out.

Embodiment 3

[0028] Weigh 1 g of superfine carbon powder and add it into 40 ml of A23 solution with a concentration of 10% by mass, wherein A23 is configured by aluminum hydroxide powder and phosphoric acid in a molar ratio of 1:23. Because the carbon powder surface is hydrophobic, add 0.1% (by carbon powder mass) titanate coupling agent to carry out surface modification treatment, make it evenly dispersed in the A23 solution, the ultra-porous ceramic matrix prepared in Example 1 is immersed in The mixed solution is dried at about 100-150° C. to obtain a porous ceramic matrix containing carbon powder. Weigh 150g of alum and a piece of super-porous ceramic substrate, cover the alum on the porous ceramic substrate, put it in a container, heat it to 120°C in an oven, and keep it warm for 30 minutes, take out the porous ceramic impregnated with salt solution, cool to room temperature, and remove excess substances on the surface to obtain a phase change heat storage body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com