Process for preparing porous ceramic by water-based gel injection moulding method

A technology of water-based gel injection molding and porous ceramics, which is applied to ceramic products, other household appliances, household appliances, etc., can solve the problem of undiscovered porous bioceramics, etc., and achieve the effect of increasing apparent porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

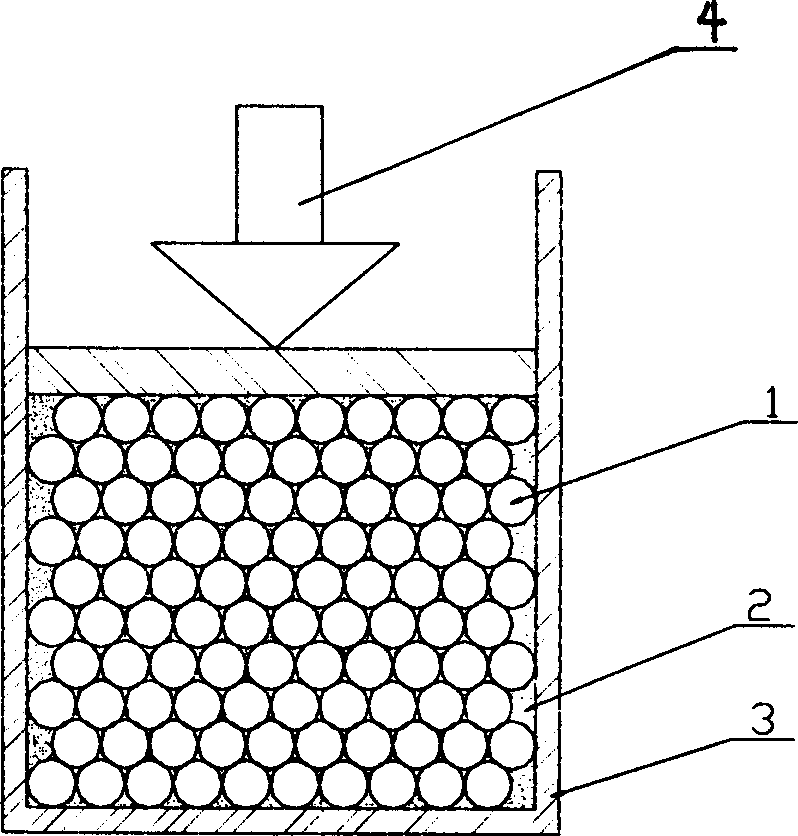

Image

Examples

example

[0021] The β-TCP porous ceramics were successfully prepared by water-based gel injection molding combined with the pore-forming agent method. The apparent porosity of the ceramics can reach more than 80%, and the strength can reach 3-5 MPa. The specific process is as follows:

[0022] 1. Preparation of powder:

[0023] (1) The β-TCP ceramic powder is synthesized by a solid-state reaction method. The powder is ball milled for 24 hours, dried and passed through a 40-mesh sieve for use.

[0024] (2) The high-temperature binder is melted-quenched, and then ground into powder.

[0025] 2. Preparation of β-TCP slurry with low viscosity and high solid content:

[0026] Distilled water is selected as the dispersion medium, and the dispersant is ammonium polyacrylate (PMAA-NH 4 ), mix and dissolve the organic monomer (AM), cross-linking agent (MBAM) and distilled water in a mass ratio of 10:1:50, and then mix and dissolve the β-TCP ceramic powder (β-TCP powder and high-temperature b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com