Al2O3-Cr2O3 refractory product and preparation method thereof

A technology of al2o3-cr2o3 and refractory products, which is applied in the field of Al2O3-Cr2O3 refractory products and its preparation, and can solve the problems of reduced performance of refractory materials, inability to shape bricks, and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

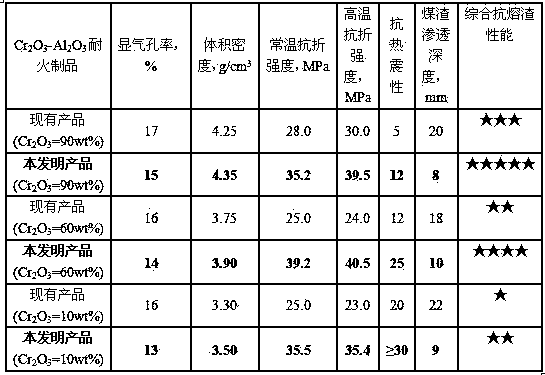

Method used

Image

Examples

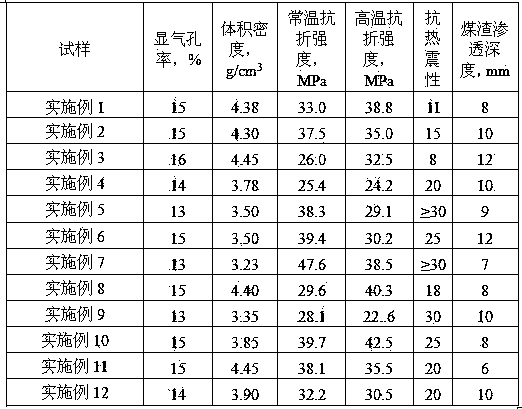

Embodiment 1

[0026] Weigh Cr with a grain size greater than 0.043 mm and less than or equal to 0.15 mm 2 O 3 -Al 2 O 3 Fine powder (Cr 2 O 3 ≈99%) 15 kg, 320 mesh chromium oxide green fine powder (Cr 2 O 3 ≥99.5%) 10 kg, alumina powder 10 kg, red phosphorus with a particle size greater than 0.01mm and less than or equal to 0.05mm (P≈99.0%) 0.35 kg are fully premixed by a ball mill to prepare a matrix fine powder; weigh the particle size to be greater than 0.15 mm less than or equal to 5 mm fused Cr 2 O 3 -Al 2 O 3 Particles (Cr 2 O 3 ≈99%) 65 kg, add it to the roller-type sand mixer and mix well; add about 3 kg of PVA aqueous solution with a mass fraction of 5% to the pellets, add the pre-mixed matrix fine powder after stirring, and mix well, The material is trapped; the body of the friction brick press is dried at 110 ℃, and then loaded into the normal pressure shuttle gas kiln at 1800 ℃ for sintering. The sintering process is from 200 ℃ to 1000 ℃ and the heating rate is 5 ℃ / s. Cr 2 O 3 -Al...

Embodiment 2

[0028] Weigh Cr with a grain size greater than 0.043 mm and less than or equal to 0.15 mm 2 O 3 -Al 2 O 3 Fine powder (Cr 2 O 3 ≈99%) 15 kg, 320 mesh chromium oxide green fine powder (Cr 2 O 3 ≥99.5%) 10 kg, alumina powder 7 kg, monoclinic zirconia powder 6 kg, red phosphorus with a particle size greater than 0.01 mm and less than or equal to 0.1 mm (P≈99.5%) 2.2 kg, fully premixed by a ball mill, and prepared into a matrix fine powder ; Weigh fused Cr with a grain size greater than 0.15 mm and less than or equal to 5 mm 2 O 3 -Al 2 O 3 Particles (Cr 2 O 3 ≈99%) 60kg, add it to the roller-type sand mixer and mix well; add about 3.5 kg of PVA aqueous solution with a mass fraction of 5% to the pellets, add the pre-mixed matrix fine powder after stirring, and mix well. Material; the body formed by friction brick press, after drying at 110 ℃, it is put into normal pressure shuttle gas kiln for firing at 1700 ℃, the firing process is from 200 ℃ to 1000 ℃, the heating rate is 15 ℃ / s, t...

Embodiment 3

[0030] Weigh Cr with a grain size greater than 0.043 mm and less than or equal to 0.15 mm 2 O 3 -Al 2 O 3 Fine powder (Cr 2 O 3 ≈99%) 15 kg, 320 mesh chromium oxide green fine powder (Cr 2 O 3 ≥99.5%) 10.7 kg, alumina powder 3.5 kg, red phosphorus with a particle size greater than 0.01mm and less than or equal to 0.15mm (P≈99.9%) 0.88 kg is fully premixed by a ball mill to prepare a matrix fine powder; weigh the particle size to be greater than 0.15 mm less than or equal to 5 mm fused Cr 2 O 3 -Al 2 O 3 Particles (Cr 2 O 3 ≈99%) 70kg, add it to the roller-type sand mixer and mix well; add about 3.5 kg of PVA aqueous solution with a mass fraction of 5% to the pellets, add the pre-mixed matrix fine powder after stirring, and mix well. Material; the body formed by friction brick press, after drying at 110 ℃, it is put into atmospheric shuttle gas kiln for sintering at 1500 ℃, the sintering process is from 200 ℃ to 1000 ℃, the heating rate is 15 ℃ / s, then Cr is obtained 2 O 3 -Al 2 O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com