Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Good water and alkali resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

External wall putty powder and preparation method thereof

The invention relates to external wall putty powder and a preparation method thereof and aims at providing the external wall putty powder with good weather resistance and strong adhesion force and a preparation method thereof. The external wall putty powder comprises the following components in parts by weight: 300-500 parts of white cement, 50-200 parts of organic calcium, 300-500 parts of heavy calcium carbonate powder, 20-40 parts of emulsion powder, 2-5 parts of a water-retaining agent, 2-5 parts of wood fiber, 2-5 parts of a thixotropic agent, 1-3 parts of a water reducing agent and 0.5-1.5 parts of starch ether. The preparation method of the external wall putty powder comprises the following steps of: adding the heavy calcium carbonate powder into a stirrer to be uniformly stirred, then adding the white cement, the organic calcium, the emulsion powder, the water-retaining agent, the wood fiber, the thixotropic agent, the water reducing agent and the starch ether into the stirrer, and uniformly and evenly stirring to obtain the external wall putty powder. The external wall putty powder can be used just by adding an appropriate amount of water and uniformly stirring. The preparation method is simple; and the external wall putty powder prepared by using the preparation method has the advantages of water resistance, alkali resistance, high adhesion force, good filling property and good air permeability, and is easy to shave.

Owner:CHONGQING BAISHIDE BUILDING MATERIALS

Waterborne two-component quick-drying polymer cement waterproof mortar

The invention discloses a waterborne two-component quick-drying polymer cement waterproof mortar. The waterborne two-component quick-drying polymer cement waterproof mortar includes a powder materialand a liquid material, wherein the powder material is composed of the following components by mass percent: 35%-55% of Portland cement, 3%-12% of sulfur aluminum cement, 5%-25% of active filler, 25%-50% of ordinary filler, 0.2%-1.5% of anti-cracking fiber, and 0.1%-1.5% of an assistant; and the liquid material is composed of the following components by mass percent: 30%-50% of a polymer emulsion,0.1%-2% of an assistant, and the balance water; and the powder material and liquid material are mixed in a ratio of 2.5-4:1. Compared with the prior art, the invention realizes one-time thick coatingof polymer cement waterproof mortar, which can dry quickly, does not crack, and has good impermeability. The construction and maintenance time can be shortened to 4h, and the construction period is greatly shortened. The waterborne two-component quick-drying polymer cement waterproof mortar provided by the invention has the characteristics of high bonding strength, good resistance to water and alkali, and good weatherability, can be directly applied to construction on base planes without open water, and can be widely applied to basement, kitchen, toilet, bathroom, swimming pool, balcony, garden waterscape, interior and exterior wall integral waterproofing and seepage prevention, and other waterproofing projects.

Owner:KESHUN WATERPROOF TECH CO LTD

Environment-friendly anticorrosive and antibacterial inner wall negative ion paint

InactiveCN107936660AGood antibacterial and antifungal effectHigh contrast ratioAntifouling/underwater paintsPaints with biocidesEmulsionDeodorant

The invention provides an environment-friendly anti-corrosion and anti-bacterial interior wall anion coating, which is composed of the following components in parts by weight: 200-250 parts of synthetic resin emulsion, 50-150 parts of anion powder, 15-30 parts of anti-corrosion and anti-bacterial agent, filler 220-280 parts, 3-6 parts of defoamer, 5-9 parts of dispersant, 6-10 parts of film-forming aid, 6-10 parts of thickener, 10-18 parts of leveling agent, 200-250 parts of pigment , 250-300 parts of water. The object of the present invention is to provide an environment-friendly anti-corrosion and anti-bacterial interior with good and long-lasting antibacterial and anti-mildew effects, good performance, non-toxic and harmless to the human body, green environmental protection, good safety, containing negative ions, and capable of inhibiting bacteria and deodorizing. Negative ion paint for walls.

Owner:清远市思彤新材料科技有限公司

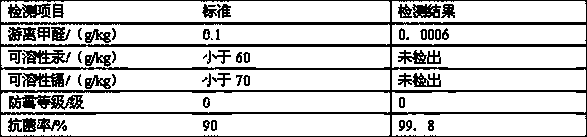

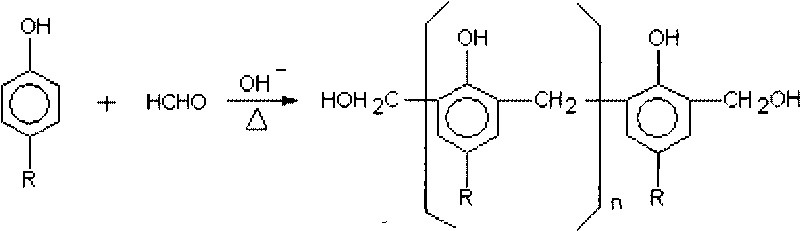

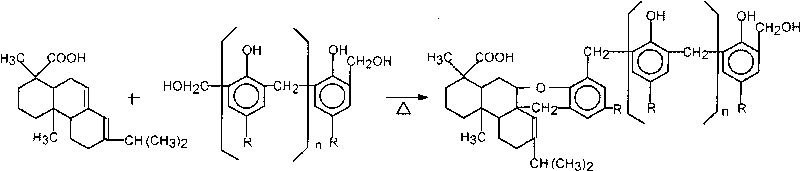

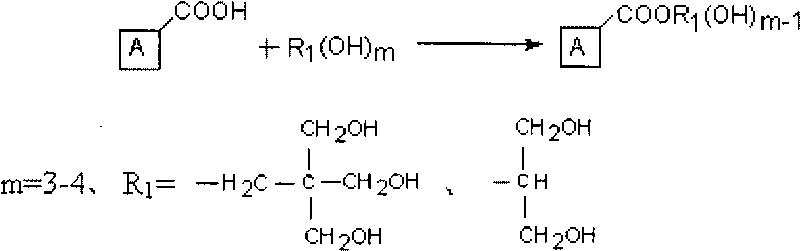

Preparation method of rosin modified phenolic resin

The invention relates to a preparation method of a rosin modified phenolic resin. The method comprises the following three steps of reactions: 1. performing condensation of tert-butylphenol, bisphenol A, tung oil and solid formaldehyde under the action of catalyst magnesium acetate and lime to generate polymer of hydroxymethyl tert-butylphenol; 2. performing an addition reaction with rosin to generate an addition product; and 3. performing esterification of the addition product, pentaerythritol and glycerin under the action of catalyst zinc chloride to generate the rosin modified phenolic resin. The preparation method adopts proper raw material proportioning, reaction temperature, reaction time, catalyst and other technical conditions, thus during the production process, the resin viscosity can be effectively controlled, and the operation is simple and flexible and has good effect. The quality of the product is increased, the oil solubility of resin is good, the oil medium viscosity is high, the normal heptane capacity is 4.5ml / g or more; and the prepared paint film ink has good water resistance and alkali resistance, high hardness, excellent anti-after-binding performance, quick-drying performance, lightness and strong adhesive force. Therefore, the preparation method of the invention is applicable to industrial production.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Stain-resistant white emulsion paint and preparation method thereof

ActiveCN105219199AStrong resistanceContinuous scrubbingAntifouling/underwater paintsPaints with biocidesWaxEmulsion

The invention relates to the field of emulsion paints, and particularly relates to a stain-resistant white emulsion paint. The emulsion paint mainly comprises the following raw materials in percentage by weight: 20-40% of water, 1-4% of water-borne wax, 5-30% of organosilicon acrylic polymer emulsion, 0-25% of second emulsion, 5-10% of additives, 10-30% of pigments, and 5-20% of packing. The emulsion paint is preferably prepared from various raw materials by blending, and rich in water-borne wax and organosilicon emulsion, so that various stains can be easily scrubbed away, and the paint can be kept fresh. The invention also provides a preparation method of the stain-resistant white emulsion paint, and the method is simple and feasible, convenient to operate, and easy to master.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Water-based self-cleaning finish-coat paint and preparation method thereof

InactiveCN105419504AImprove stain resistanceExcellent weather resistance and color retentionAntifouling/underwater paintsPaints with biocidesWater basedEmulsion

The invention relates to a water-based self-cleaning finish-coat paint, which is prepared from the following components in parts by weight: 30-40 parts of water, 0.1-0.2 part of an antibacterial preservative, 0.1-0.2 part of a mildew preventive, 0.1-0.3 part of a pH modifier, 0.1-0.2 part of a defoaming agent, 0.5-0.7 part of an antifreezing agent, 3.3-3.9 parts of a coalescing agent, 55-65 parts of a styrene-acrylic emulsion, 0.1-0.3 part of a water-based hydrophobic agent, 0.1-0.2 part of nano zinc oxide and 0.1-0.3 part of a thickener. The water-based self-cleaning finish-coat paint has the advantages that the water-based self-cleaning finish-coat paint prepared by combination of the components and the proportions has excellent stain resistance, weather-proof color retention property, water and alkali resistance and adhesiveness, and is safe, nontoxic, environmentally friendly and free of pollution.

Owner:SKSHU PAINT

Acrylate tile back glue emulsion and preparation method thereof

InactiveCN106590477AImprove stabilityHigh monomer conversion rateEster polymer adhesivesFunctional monomerWeather resistance

The invention relates to an acrylate tile back glue emulsion and a preparation method thereof. The preparation method comprises preparation of a base material liquid A, preparation of a monomer solution B, preparation of an initiator solution C, preparation of a later added initiator solution D, pre-emulsification semi-continuous dropwise addtion, and later treatment processes. The emulsion comprises, by weight, 100 to 500 parts of an alkyl acrylate monomer, 20 to 100 parts of an alkyl methacrylate monomer, 0.1 to 10 parts of alkyl carboxylic acid, 1 to 10 parts of a functional monomer, 0.1 to 10 parts of vinyltrioxysilane, 1 to 30 parts of an emulsifier, 0.1 to 5 parts of an initiator, 0.1 to 5 parts of a buffering agent, and 100 to 150 parts of deionized water. The preparation method has the advantages of simple processes, low cost and safety. The emulsion has characteristics of good gloss, good water resistance, good weather resistance, high peel strength, high adhesion and instant-coating and instant-pasting of a single component.

Owner:佛山市顺德区巴德富实业有限公司

Heat-insulating heat-preserving coating and preparation method thereof

The invention provides a heat-insulating heat-preserving coating and a preparation method thereof. The heat-insulating heat-preserving coating comprises the following components in parts by weight: 20-25 parts of water, 20-35 parts of film-forming emulsions, 20-40 parts of powdery fillers, 2-8 parts of reflective pigments, 0.5-1 part of paraffin microcapsules and the balance of auxiliary agents, wherein the film-forming emulsions are pure acrylic emulsions and / or styrene-acrylate emulsions. The preparation method comprises the following steps: mixing water and a part of auxiliary agents, and stirring in a dispersing way; then adding the powdery fillers and the reflective pigments, and stirring in the dispersing way; then adding the paraffin microcapsules, and stirring in a dispersing way; then adding the film-forming emulsions, and stirring in a dispersing way; and then adding the balance of auxiliary agents, and stirring in the dispersing way to obtain a product. The heat-insulating heat-preserving coating provided by the invention can be used for enhancing the heat-preserving effect of the coating on two aspects of heat insulation and energy accumulation and has high solar reflectance, hemispherical emittance and inside and outside temperature difference.

Owner:重庆索利特涂料有限公司

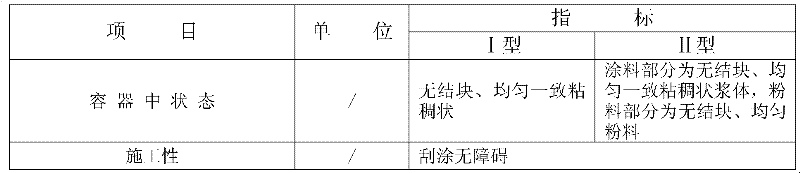

Microhollow super-fibre heat insulation coatings for building insulation and method of use thereof

InactiveCN101381546ACreate pollutionHealth hazardFireproof paintsCovering/liningsNoise removalThermal coefficient

The invention provides a micro hollow fiber thermal insulating coating for buildings and an application method thereof. The micro hollow fiber thermal insulating coating for buildings is divided into a I-type single-component micro hollow fiber thermal insulating coating for buildings and a II-type double-component micro hollow fiber thermal insulating coating for buildings, and is used as an exterior wall thermal insulating coating or used to pipes and other various places needing coating the thermal insulating coating. The coating is added with super hollow fibers and aramid fibers with high-temperature resistance, acid and alkali resistance and light weight, so that the coating has the advantages of low thermal coefficient and heat storage coefficient, obvious heat retaining effect, nontoxic formula, environmental protection, excellent fire resistance, super-strong chemical stability, high cohesional strength, noise removal, high cost performance, long service life, wide application, simple and easy construction, good effect, labor and physical resource conservation, and obvious economic and environment-friendly benefits.

Owner:FUJIAN OUNUO PAINT TECH

Acrylic emulsion for waterborne multicolor paint and preparation technique thereof

ActiveCN106084139AReduced stabilityAvoid premature hydrolysisMulticolor effect coatingsEmulsionPolymer science

The invention discloses an acrylic emulsion for a waterborne multicolor paint and a preparation technique thereof and belongs to the technical field of research and development of architectural coating. The technical process comprises the steps of preparing a core layer emulsion, preparing a shell layer emulsion and an initiator, and then synthesizing the multicolor acrylic emulsion by utilizing the prepared core layer emulsion, shell layer emulsion and initiator. The redox initiator is applied to the technical synthetic process at low temperature; an alkyl polyoxyethylene ether anionic emulsifier containing an EO chain section is taken as the surface active agent; the structure of design emulsion is arranged as a core shell structure; the water tolerance of the waterborne multicolor paint prepared by the invention is greatly increased; the storage stability is excellent; the viscosity of the paint in the storage process is not thick and the performance is excellent.

Owner:HENGSHUI XINGUANG CHEM

High-performance microscopic microfiber building heat insulation and heat preservation slurry and using method thereof

ActiveCN102531465AReduce volumeLow thermal conductivityClimate change adaptationHeat proofingSlurrySilicon dioxide

The invention provides high-performance microscopic microfiber building heat insulation and heat preservation slurry with high tensile strength, compressive strength, heat insulation performance and tear resistance, and a using method thereof. The slurry comprises the following components of crylic synthetic resin, fluorinated silicone synthetic resin, a water retention thickening agent solution,a sepiolite fiber, a vermiculite fiber, a mullite fiber, powdered silicon dioxide, pearlife, a rock wool fiber, hollow ceramic microballs, a defoaming agent, a mildewproof bacteriacide and water; andfurthermore, white portland cement, a reinforcing agent and water which is 20 to 30 weight percent of a component A can be added.

Owner:FUJIAN OUNUOCHUANGNENG NEW MATERIAL TECH CO LTD

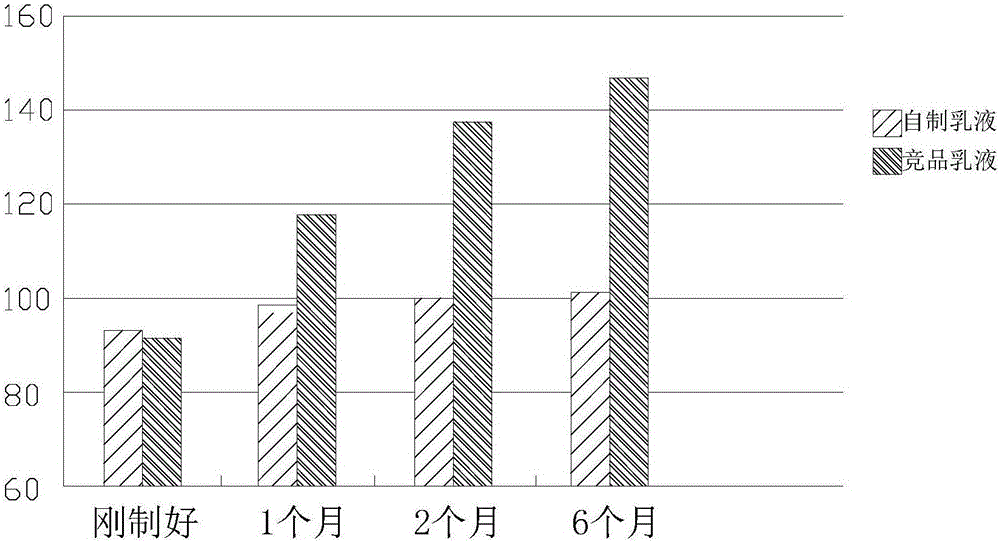

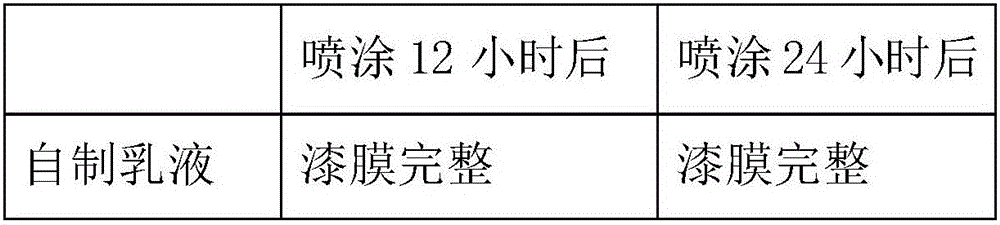

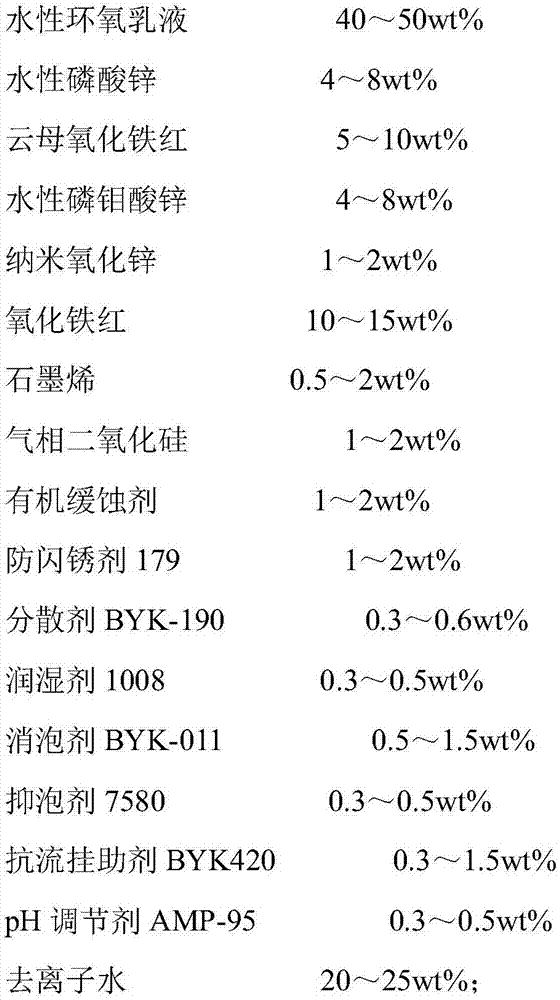

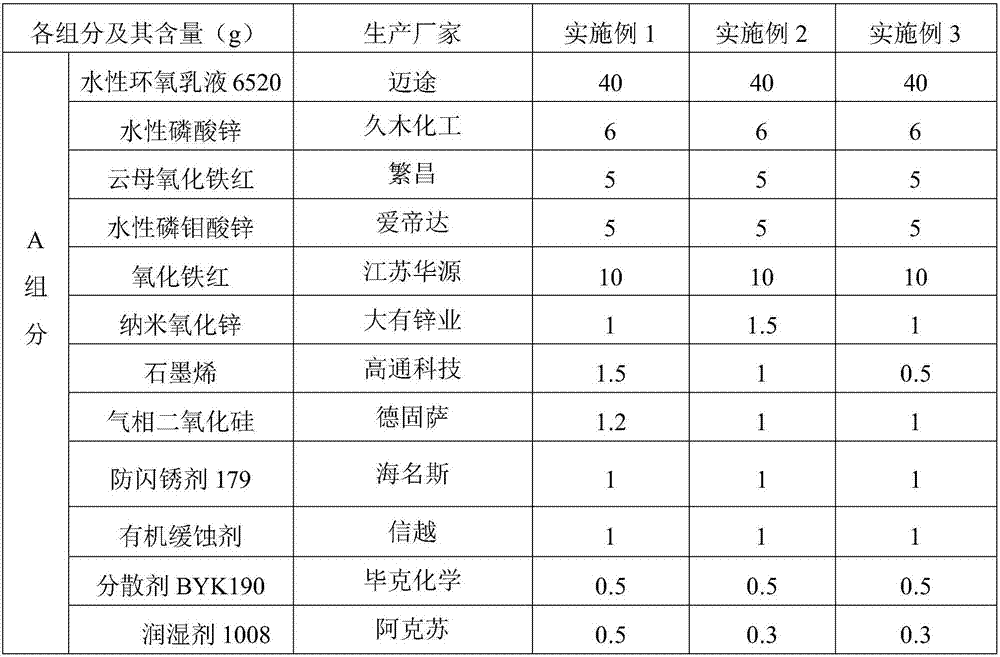

Graphene modified aqueous epoxy heavy anti-corrosion coating and detection method thereof

InactiveCN107400442AChemically stableFirm textureAnti-corrosive paintsEpoxy resin coatingsGas phaseWear resistant

The invention discloses a graphene modified aqueous epoxy heavy anti-corrosion coating which is prepared by mixing a component A and a component B in a weight ratio of 4:1, wherein the component A comprises 40-50 parts of a bisphenol A aqueous epoxy emulsion, 0.5-2 parts of graphene, 4-8 parts of aqueous zinc phosphate, 4-8 parts of aqueous zinc molybdate, 10-15 parts of iron oxide red, 1-2 parts of fumed silica, 1-2 parts of nano zinc oxide, 5-10 parts of mica iron oxide red, 1-2 parts of an organic corrosion inhibitor, 1-2 parts of a 179 anti-flash rust agent, 0.3-0.6 part of a 190 dispersant, 0.3-0.5 part of a 1008 wetting agent, 0.5-1.5 parts of a BYK-011 defoamer, 0.3-0.5 part of a 7580 foam inhibitor, 0.1-1.5 parts of a BYK420 anti-sagging auxiliary agent, 0.3-0.5 part of an AMP-95 pH regulator and some deionized water; the component B is a polyamine addition product aqueous epoxy curing agent. The coating disclosed by the invention has excellent physical property and excellent chemical resistance, in particular salt fog resistance; a film with the coating is firm and tenacious and wear-resistant, is high in adhesive force and construction adaptability and has very good environment-friendliness.

Owner:江苏纽克莱涂料有限公司

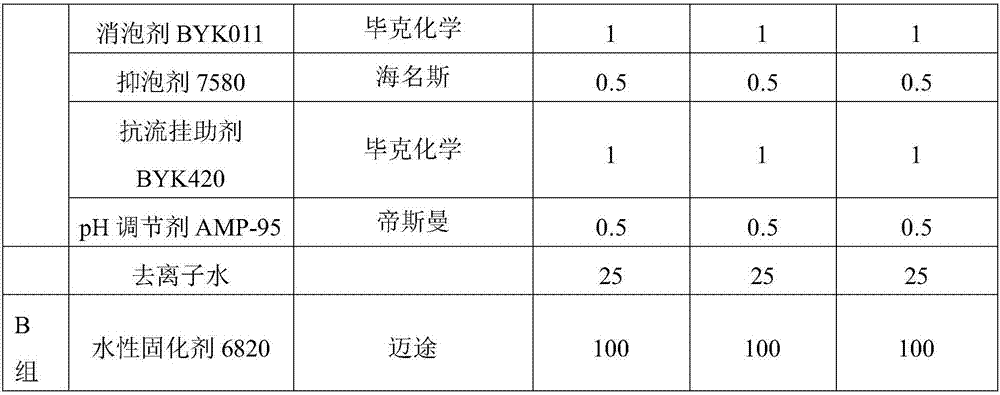

Waterborne half-PU leather bottom material and preparation method thereof

ActiveCN106047224AGood adhesionImprove stabilityMonocarboxylic acid ester polymer adhesivesMacromolecular adhesive additivesEmulsionPolyvinyl alcohol

The invention provides a half-PU leather bottom material and a preparation method thereof. The half-PU leather bottom material comprises the following raw materials in parts by weight: 10-30 parts of waterborne polyurethane, 50-80 parts of vinyl acetate-ethylene copolymer emulsion, 0.5-1.0 part of pH regulator, 1-3 parts of polyvinyl alcohol, 2-5 parts of tackifying emulsion, 3-6 parts of water, 0.1-1 part of antifoaming agent, 0.5-1.2 parts of wetting agent and 0.5-2 parts of thickening agent. In the invention, by compounding the low-modulus anionic waterborne polyurethane and cationic vinyl acetate-ethylene copolymer emulsion, the waterborne half-PU leather bottom material system has perfect stability, adhesive force and water-alkali resistance; and by applying the waterborne half-PU leather bottom material to the bottom layer of half-PU synthetic leather, the peel strength is high and can reach 30N / m or over.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

Environment-friendly high-adhesion building primer and preparation method thereof

InactiveCN111073402AImproved resistance to water penetrationImprove salt and alkali resistanceAntifouling/underwater paintsAlkali metal silicate coatingsSilicic acidCompatibilization

The invention provides environment-friendly high-adhesion building primer and a preparation method thereof. The primer comprises a polymer emulsion, a potassium silicate solution, a pH regulator, a freeze-thaw stabilizer, a dispersing agent, a wetting agent, a defoaming agent, pigment, a thickening agent, a coalescing agent, a base material wetting agent and water. The potassium silicate solutionand the cement in the base material belong to silicate inorganic substances and have very good compatibility, and the molecular-level potassium silicate solution can easily wet and permeate into capillary holes of the base material under low surface tension, so that the alkali efflorescence resistance of the primer is improved, the base material is reinforced, and the bonding strength of the basematerial and the primer is improved. Besides, the primer is excellent in performance, all raw materials adopted are environment-friendly and low-odor, harmful substances such as VOC, formaldehyde, heavy metals, APEO and a biocide are not added artificially, the produced product is non-toxic and odorless, and therenewable potassium silicate solution is used as a film forming substance.

Owner:南京古田化工有限公司 +1

Water-based paint for multifunctional fiber textile and preparation method thereof

PendingCN107841241ALow refractive indexLarge specific surface areaFireproof paintsAntifouling/underwater paintsWater basedFiber

The invention discloses water-based paint for multifunctional fiber textile. The water-based paint is prepared from the following raw material components in parts by mass: 10 to 25 parts of water-based organic silicon resin, 1 to 30 parts of a polytetrafluoroethylene solution, 1 to 5 parts of organic silicone powder, 1 to 15 parts of a pigment, 1 to 5 parts of nano barium sulfate, 0.05 to 0.5 partof nano zinc oxide, 0.1 to 1 part of silica sol, 5 to 10 parts of a flame retardant, 2 to 15 parts of fluorescent powder and the like. Furthermore, the invention further provides a simple and feasible preparation method of the water-based paint for the multifunctional fiber textile. By adopting the formula and the method, disclosed by the invention, the prepared paint has adhesive force, flexibility, weather resistance and flame-retarding performance and has a suitable paint film thickness; meanwhile, the water-based paint also has the characteristics of no fluffiness, no fading and smooth hand feeling, and a plurality of effects of heat prevention, flame retarding, corrosion resistance, fluorescence warning, easiness for cleaning, bacterium inhibition and sterilization, environment protection and the like, so that the water-based paint has very strong market competitiveness.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

High self-cleaning water-based inner wall paint

The invention belongs to the field of building materials, and particularly discloses high self-cleaning water-based inner wall paint. The high self-cleaning water-based inner wall paint consists of titanium white powder, talcpowder, light calcium carbonate, methyl amyl alcohol, acrylic emulsion, triethanolamine, methyl sodium silicate, carboxymethyl cellulose ether, water and preservative in a certain weight part. The paint has simple preparation, good use effect, economy, effectiveness, strong pollution resistance and good water and alkali resistance, can effectively prevent mildew and cracking, and is suitable for wide popularization and application.

Owner:潍坊绿城低碳建筑科技有限公司

Polymer cement waterproofing mortar

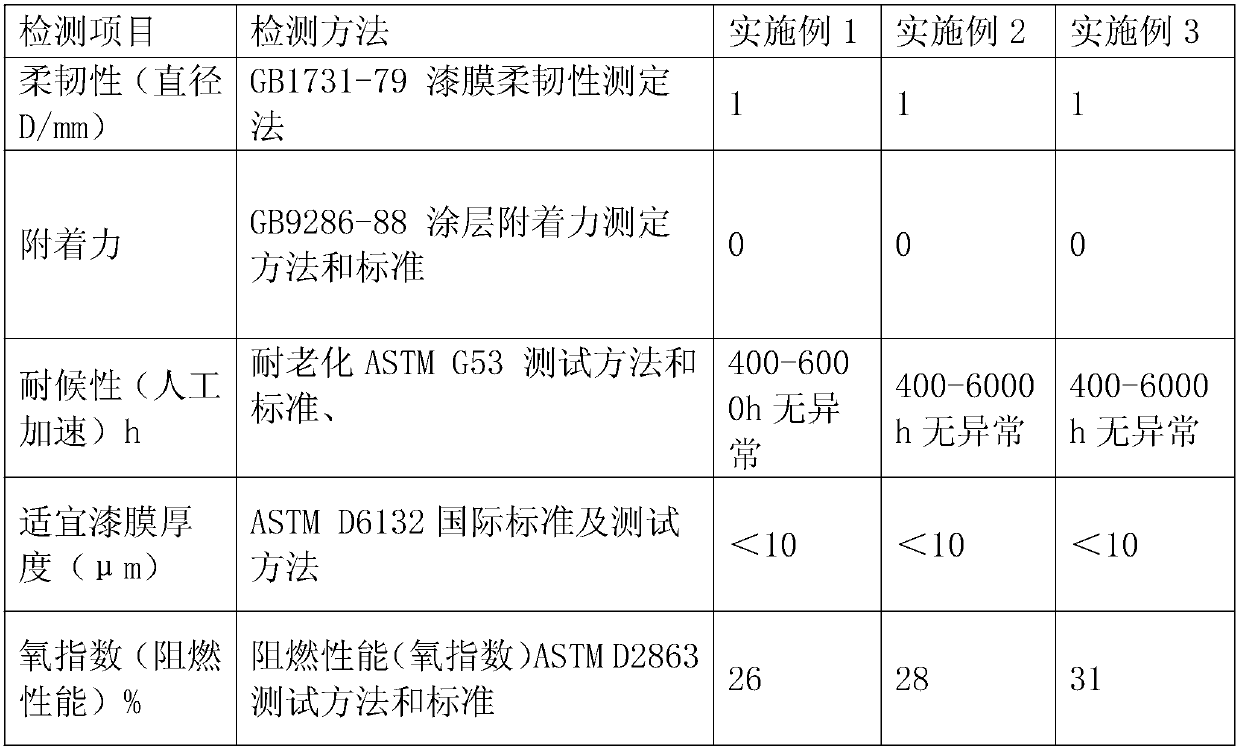

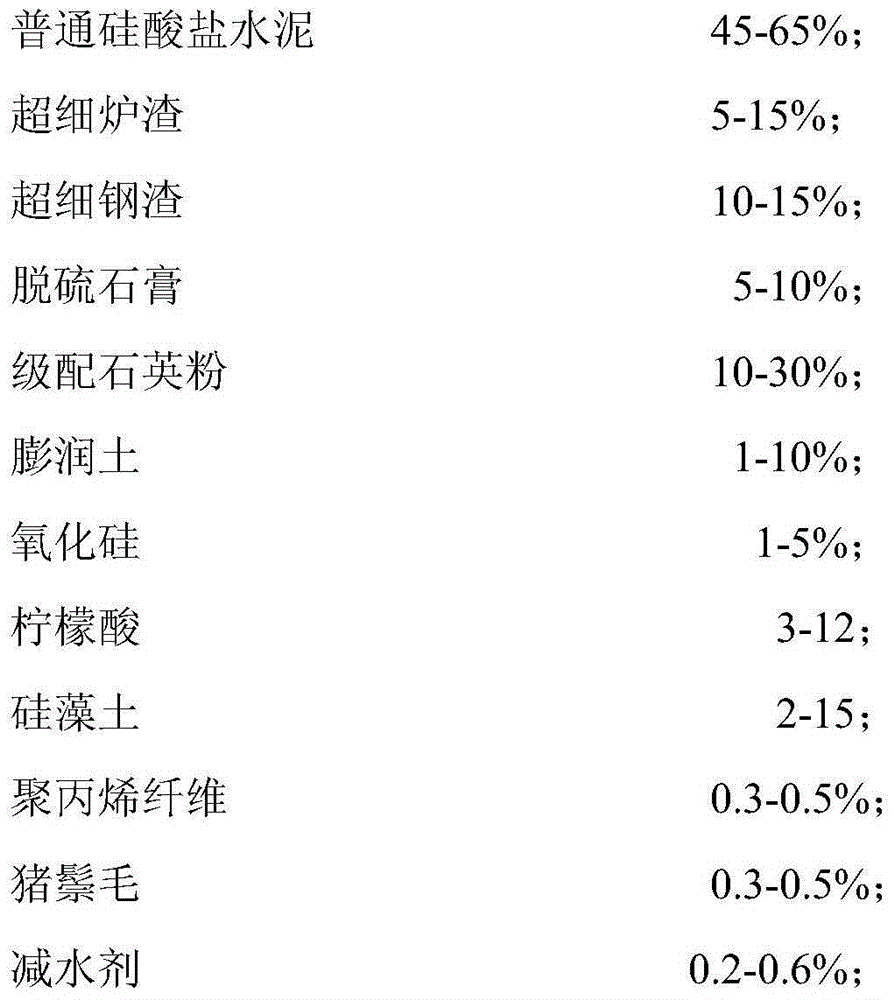

Disclosed is a polymer cement waterproofing mortar comprising a liquid material component and a powder material component, wherein the liquid material component includes styrene-acrylic emulsion, a dispersing agent, an anti-corrosion agent, a defoamer and the balanced being water; and the powder material component includes ordinary Portland cement, ultrafine furnace slag, ultrafine steel slag, desulfurization gypsum, graded quartz powder, bentonite, silicon oxide, citric acid, diatomite and a water reducer. The polymer cement waterproofing mortar has excellent anti-seepage and adhesive performances, is anti-aging and acid- and alkali-resistant, can effectively consume solid wastes, is reduced in environment damage and meanwhile production cost, is wide in market prospect and can be popularized in large scope.

Owner:ANHUI LENCAQI BUILDING MATERIAL

Mercerizing emulsion paint for interior walls and preparation method thereof

InactiveCN103173071AThe coating film is smooth and smoothFine textureAntifouling/underwater paintsPaints with biocidesEmulsionChemistry

The invention discloses a mercerizing emulsion paint for interior walls and a preparation method thereof. The mercerizing emulsion paint for interior walls comprises the following substances by mass ratio: 300-400 parts of styrene-acrylate emulsion, 20-40 parts of an antifreezing agent, 300 parts of water, 1.5-3.5 parts of a wetting agent, 2-4 parts of a dispersing agent, 35-60 parts of ground limestone, 180-240 parts of titanium dioxide, 2-5 parts of an antifoaming agent, 4-6 parts of an acrylic acid thickening agent, 15-30 parts of a coalescing agent and 2-5 parts of a sterilization anticorrosive agent. By utilizing the mercerizing emulsion paint for interior walls, a paint film is level and smooth and has delicate texture, and the mercerizing emulsion paint has silk gloss, high covering power, strong adhesive power, excellent antimicrobial and mould-proof performances, excellent water resistance and alkaline resistance; and the paint film can be scrubbed and has durable gloss. The mercerizing emulsion paint is suitable for indoor interior walls and low in production cost, has low toxicity and is suitable for being popularized and used.

Owner:王程皓

Novel diatom-ooze environment-friendly wall material and preparation method thereof

The invention discloses a novel diatom-ooze environment-friendly wall material. The novel diatom-ooze environment-friendly wall material is prepared from the following raw materials in parts by weight: 35-50 parts of diatomite, 13-22 parts of bentonite, 8-16 parts of kaolin, 4-9 parts of heavy-calcium powder, 8-15 parts of modified zeolite powder, 3-7 parts of sepiolite powder, 2-5 parts of mica powder, 1-2 parts of zinc oxide, 1-2 parts of nano titanium dioxide, 2-5 parts of aluminium hydroxide, 1-4 parts of negative ion powder, 4-6 parts of plant cellulose, 2-3 parts of cellulose ether, 1-2parts of preservative, 3-9 parts of redispersible rubble powder and 45-60 parts of water. The novel diatom-ooze environment-friendly wall material disclosed by the invention is good in water resistance and alkaline resistance, is moisture-proof, mildew-proof and antibacterial, and has the air-purifying and humidity-regulating functions.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

Modified powder capable of raising stability of polymer-cement waterproof coating

A modified powder capable of raising stability of a polymer-cement waterproof coating is characterized by being prepared from the following ingredients (by weight): 5% of nano-silicon carbide, 5% of kaolin powder, 5% of nano-boron carbide, 5% of fly ash, 0.02% of micro-alumina, 0.01% of graphene, 0.2% of modified starch, 0.3% of potassium carbonate, 0.05% of a rare-earth light conversion agent and the rest of nano-silica. As the powder of the polymer-cement waterproof coating is specially prepared and modified, the prepared polymer-cement waterproof coating has good stability, large elongation, high bonding strength and good water resistance, alkali resistance and weather fastness, can be directly constructed on a water-free base surface, and is widely applied in waterproofing of low-activity bases of kitchens, rest rooms, balconies, basements and the like.

Owner:ANHUI YOUYANG WATERPROOF TECH CO LTD

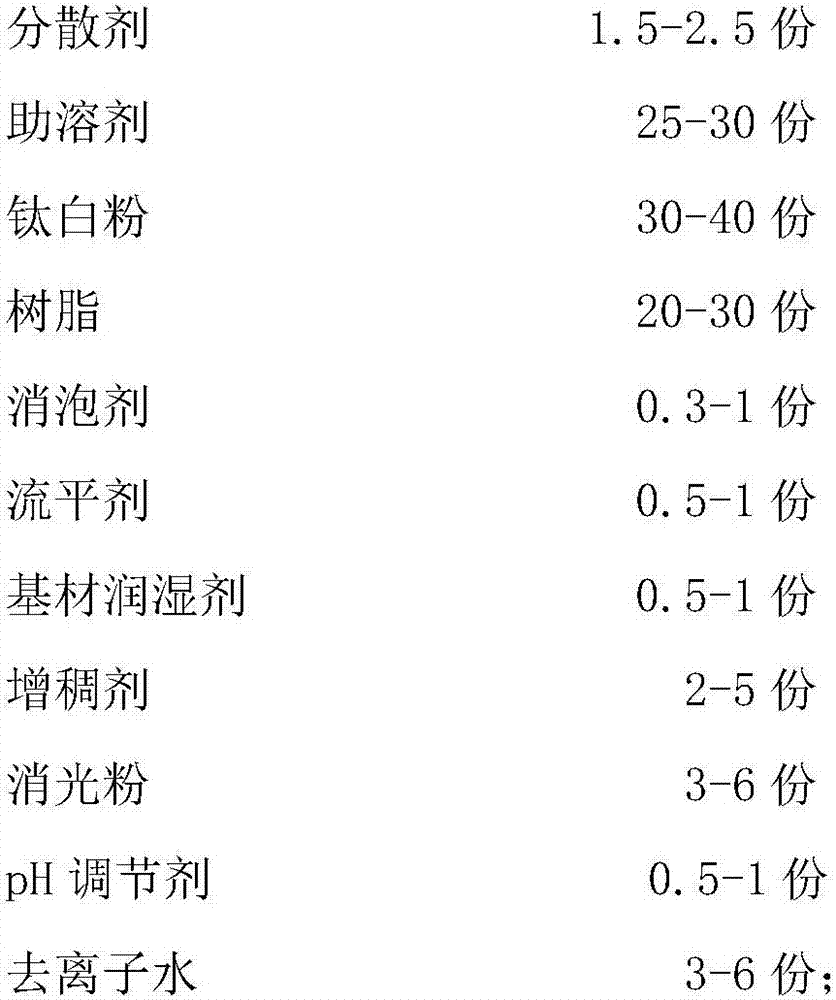

Waterborne two-component automotive interior paint and preparation method thereof

InactiveCN107974184AEasy constructionImprove adhesionPolyurea/polyurethane coatingsExtinctionHazardous substance

The invention discloses waterborne two-component automotive interior paint. The waterborne two-component automotive interior paint is characterized by being prepared from the following components in parts by weight: 1.5 to 2.5 parts of dispersant, 25 to 30 parts of cosolvent, 30 to 40 parts of titanium dioxide, 20 to 30 parts of resin; 0.3 to 1 part of defoamer; 0.5 to 1 part of flatting agent; 0.5 to 1 part of substrate wetting agent; 2 to 5 parts of thickener; 3 to 6 parts of extinction powder; 0.5 to 1 part of pH regulator; and 3 to 6 parts of deionized water. Compared with other waterborneinterior paints on the market, the waterborne two-component automotive interior paint has slight odor after opening, no odorless residue after drying, is easy to construct and free from benzene, heavy metals and high content of VOC and other poisonous and harmful substances, can significantly improve an odor problem of the waterborne interior paint, provides excellent construction performance, and has greater market demands and broader prospects.

Owner:江苏足迹涂料有限公司

Anti-stain clear varnish and preparation method thereof

ActiveCN105238264AGood value for moneyStrong adhesionWax coatingsAntifouling/underwater paintsWaxEmulsion

The invention provides anti-stain clear varnish. The anti-stain clear varnish is mainly prepared from, by weight, 350-400 parts of emulsion, 80-90 parts of auxiliaries, 30-40 parts of water-borne wax and 500-530 parts of water. According to the clear varnish, the functional components of the water-borne wax, the emulsion and the auxiliaries are combined together according to the scientific proportion, therefore, the prepared clear varnish not only has the traditional advantages of being high in cost performance and adhesive force, good in water resistance and alkali resistance, fine and smooth in varnish film, capable of covering tiny cracks, good in scrubbing resistance, easy to clean and good in anti-stain performance, but also has the high resisting effect on various stains and dirt matter, and the varnish film can be continuously scrubbed, so that the varnish film always keeps new.

Owner:辽宁斓溪新材料有限公司

Rapid heat dissipation coating and preparation method thereof

InactiveCN105062236AGood cooling performanceGood water and alkali resistanceCoatingsAntifoam agentPolymer chemistry

The invention discloses a rapid heat dissipation coating and a preparation method thereof. The rapid heat dissipation coating comprises the following components in parts by weight: 15.0-40 parts of water, 15.0-20.0 parts of a compound material, 20.0-40.0 parts of fillings, 12-35 parts of an emulsion, 1.0-5.0 parts of a film-forming auxiliary, 1.0-3.0 parts of an anti-freeze agent, 0.2-0.5 parts of a thickening agent, 0.1-1.0 part of a dispersing agent, 0.1-0.5 part of a wetting agent, 0.1-0.5 part of bactericide, 0.1-0.5 part of a mildewproof agent, 0.1-0.5 part of an antifoaming agent, 0.1-0.5 part of cellulose and 0.1-0.3 part of a pH adjusting agent. The rapid heat dissipation coating disclosed by the invention has excellent heat dispersion performance, and favorable water resistance and alkali resistance, can enable the difference between the indoor temperature and the outdoor temperature to be decreased, and reduces heat conduction, so that the absorbed indoor heat is reduced, and the effects of insulation and energy conservation are achieved.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

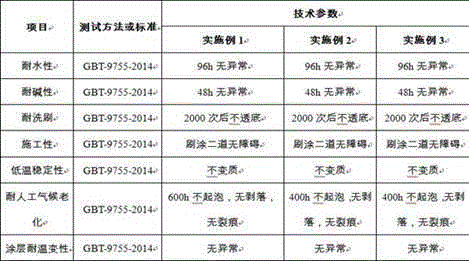

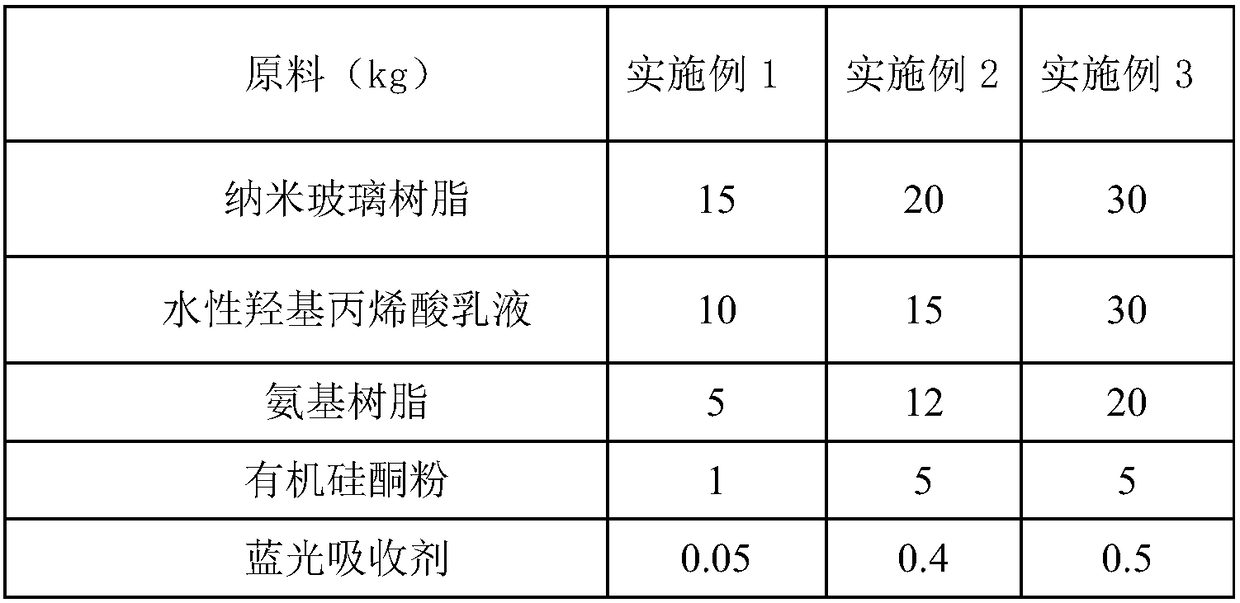

Dazzling anti-blue-ray water-based paint for tempered glass screen protector and preparing method thereof

InactiveCN108285676AReduce the chance of breakageExtended use timeRadiation-absorbing paintsMulticolor effect coatingsWater basedDefoamer

The invention discloses a dazzling anti-blue-ray water-based paint for a tempered glass screen protector and a preparing method thereof, and relates to the field of water-based paints. The dazzling anti-blue-ray water-based paint is prepared from, by weight, 15-30 parts of nanometer glass resin, 10-30 parts of aqueous hydroxy-acrylic emulsion, 5-20 parts of amino resin, 1-5 parts of organic silicone powder, 1-5 parts of nano barium sulfate, 0.1-3 parts of dazzling pigment, 0.05-0.5 part of blue-ray absorber, 0.1-1 part of ludox, 0.1-0.2 part of pH regulator, 0.1-0.2 part of defoamer, 2-5 partsof coalescing agent, 0.3-0.5 part of dispersant, 0.3-0.5 part of base material wetting agent, 5-10 parts of deionized water and 0.5-1 part of thickener. Through the improvement of the wetting and leveling performance of a system, the dazzling anti-blue-ray water-based paint meets the using requirements of application to a glass material; by adding the blue-ray absorbing substance, blue-ray emitting from a screen is effectively reduced, and accordingly the damage to human eyes is reduced; meanwhile, a coating has good hardness and dazzling colors.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

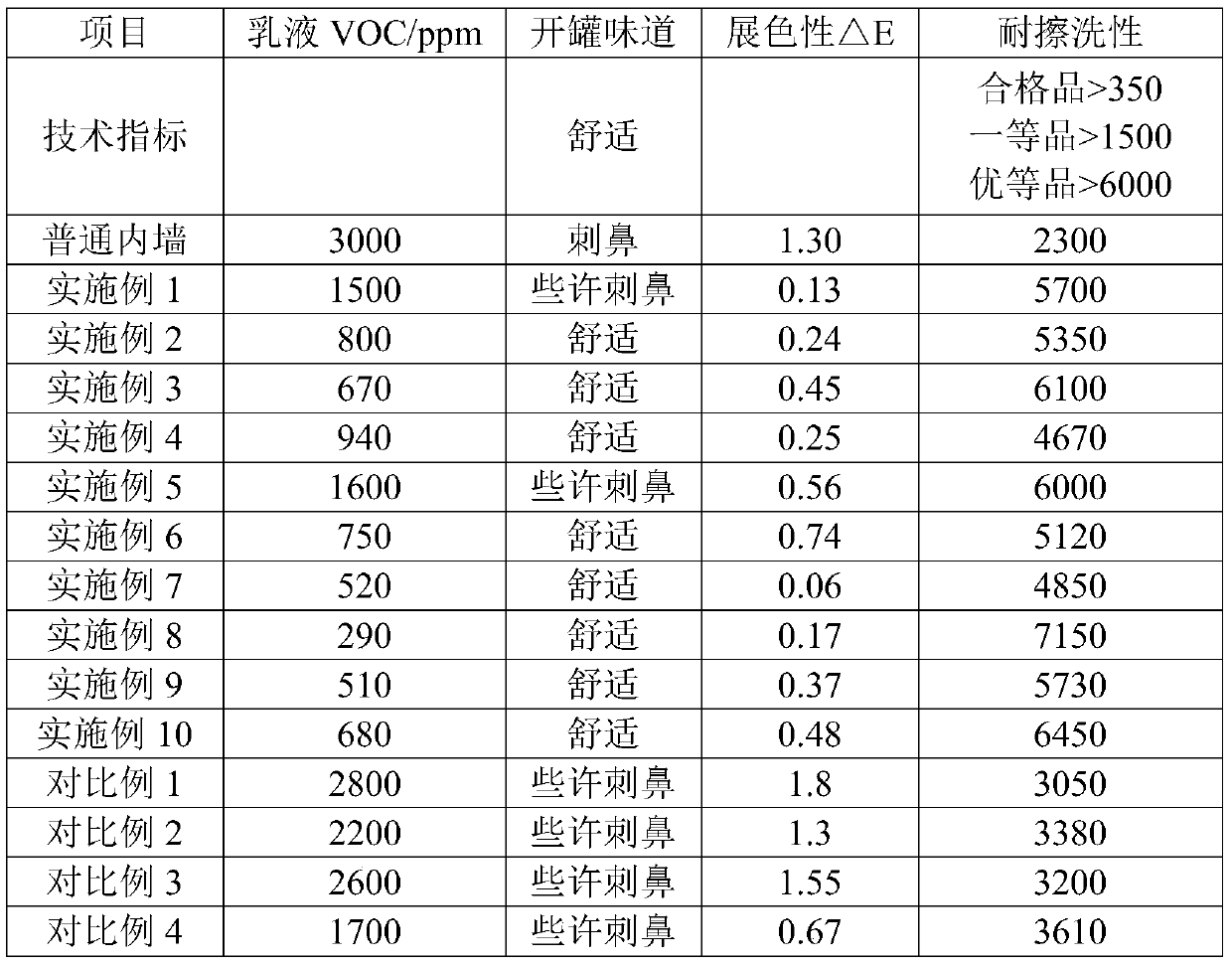

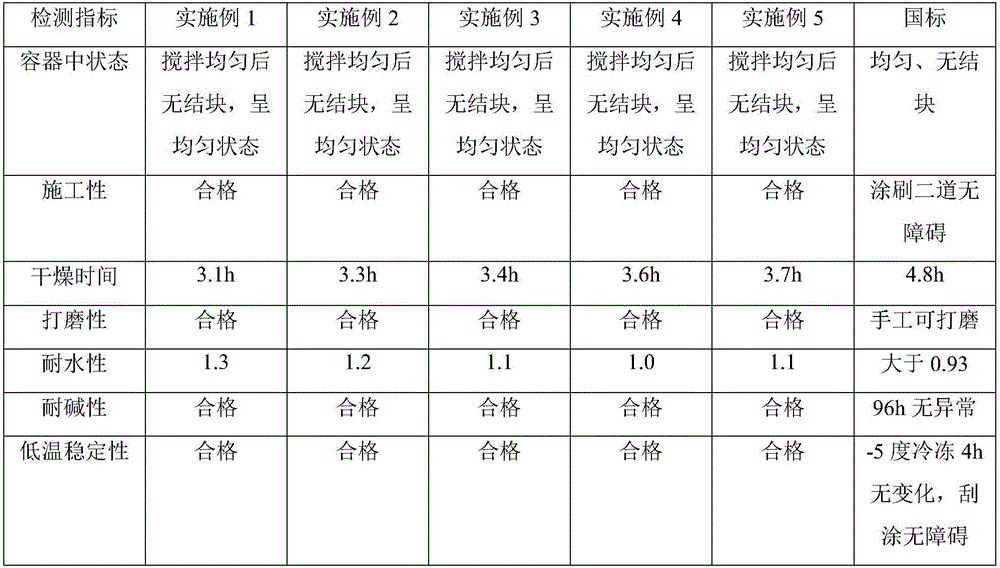

Ammonia-free low-VOC interior wall emulsion and preparation method thereof

ActiveCN110483677AImprove general performanceGood scrub resistanceCoatingsPolymer scienceFunctional monomer

The invention relates to an ammonia-free low-VOC interior wall emulsion and a preparation method thereof. The invention belongs to the technical field of building coatings. The emulsion is prepared from the following components in percentage by mass: 30-55% of water, 0.5%-3% of an emulsifier, 0.1%-3% of persulfate, 0.1%-3% of tert-butyl hydroperoxide, 0.1%-3% of a reducing agent, 10%-60% of styrene, 5%-30% of butyl acrylate, 0.5%-3% of acrylic acid, 0.5%-3% of methacrylic acid, 0.1%-6% of a functional monomer I and 0.1%-6% of a functional monomer II, wherein the functional monomer I is 2-methacryloyloxyethyl phosphate, and the functional monomer II is one or a mixture of more than two of ethylene glycol dimethacrylate, diethylene glycol dimethacrylate, 1, 3-butanediol dimethacrylate, 1, 4-butanediol dimethacrylate and allyl methacrylate. The interior wall emulsion has the advantages of no ammonia, low VOC, effective improvement of the smell, low energy consumption, consideration of theglass transition temperature and the lowest film forming temperature, and improvement of the scrubbing resistance and other performances of the emulsion.

Owner:GUANGDONG HENGGUANG CHEM CO LTD

PVC transfer printing composite tablecloth and manufacturing method thereof

InactiveCN110204842AImprove performanceExtended service lifeLamination ancillary operationsSynthetic resin layered productsSurface patternEngineering

The invention discloses a PVC transfer printing composite tablecloth and a manufacturing method thereof. The PVC transfer printing composite tablecloth is provided with a structure of four layers which are a base cloth layer, an intermediate PVC film layer, a surface PVC film layer and an ink layer. The addition of functional additives to all the layers effectively improves the performance of thelayers of the composite tablecloth and improves the service life of the composite tablecloth. Moreover, the composite tablecloth is firm in surface pattern and good in water and alkali resistance.

Owner:FOSHAN WELL PLASTICS

Interior wall mildew-proof coating and preparation method thereof

ActiveCN106221331AHigh tensile strengthHigh elongation at breakAntifouling/underwater paintsPaints with biocidesFungicideEmulsion

The invention discloses an interior wall mildew-proof coating and a preparation method thereof. The interior wall mildew-proof coating is prepared from, by weight, 20-30 parts of butyl acrylate, 15-25 parts of dibutyl phthalate, 20-30 parts of elastic emulsion, 10-20 parts of nonylphenol polyoxyethylene ether, 20-30 parts of titanium dioxide,10-20 parts of thickening agent, 10-30 parts of foaming agent, 20-30 parts of fungicide, 10-20 parts of water-soluble silicone oil and 20-30 parts of deionized water. After the interior wall mildew-proof coating is applied, a formed coating film has the advantages of high tensile strength and breaking elongation rate, the coating film is flat and smooth and fine and smooth in texture, has silk glossiness, high masking power, strong adhesion, excellent antibacterial and mildew-proof properties and excellent water and alkali resistant properties, the coating can be brushed and has strong brushing resistance and lasting glossiness.The interior wall mildew-proof coating is suitable for indoor interior walls, has waterproof, mildew-proof and anti-seepage effect, has high abrasion resistance and pollution resistance, is low in manufacturing cost, low in toxicity and suitable for popularization and usage.

Owner:张家口市凯博风房地产开发有限公司

Polymer cement waterproof paint having good adhesion performance

InactiveCN105368225AHigh elongationHigh bonding strengthAnti-corrosive paintsPolymer scienceRare earth

The invention relates to polymer cement waterproof paint having good adhesion performance. The polymer cement waterproof paint having good adhesion performance comprises the following raw materials by mass percentage: 60% of a pure acrylic emulsion, 5% of modified polymer powder, 0.5% of a rare earth light conversion agent, 0.5% of an antifoaming agent, 4% of polyether polyol, 6% of a polyurethane thickening agent, 0.2% of an antiseptic, 1% of hydroxyethyl cellulose, 0.8% of sodium dodecanesulphonate, 3% of a phenylpropane emulsion, 0.4% of a dispersant, and the balance of deionized water. The prepared high built crack-resistant polymer cement waterproof paint has the advantages of large elongation percentage, high bonding strength, good water resistance, good alkali resistance and good weatherability, can be directly applied on bases without obvious water, and can be widely applied for watertightness of the bases with small activity such as kitchen, toilet, balcony and basement.

Owner:ANHUI YOUYANG WATERPROOF TECH CO LTD

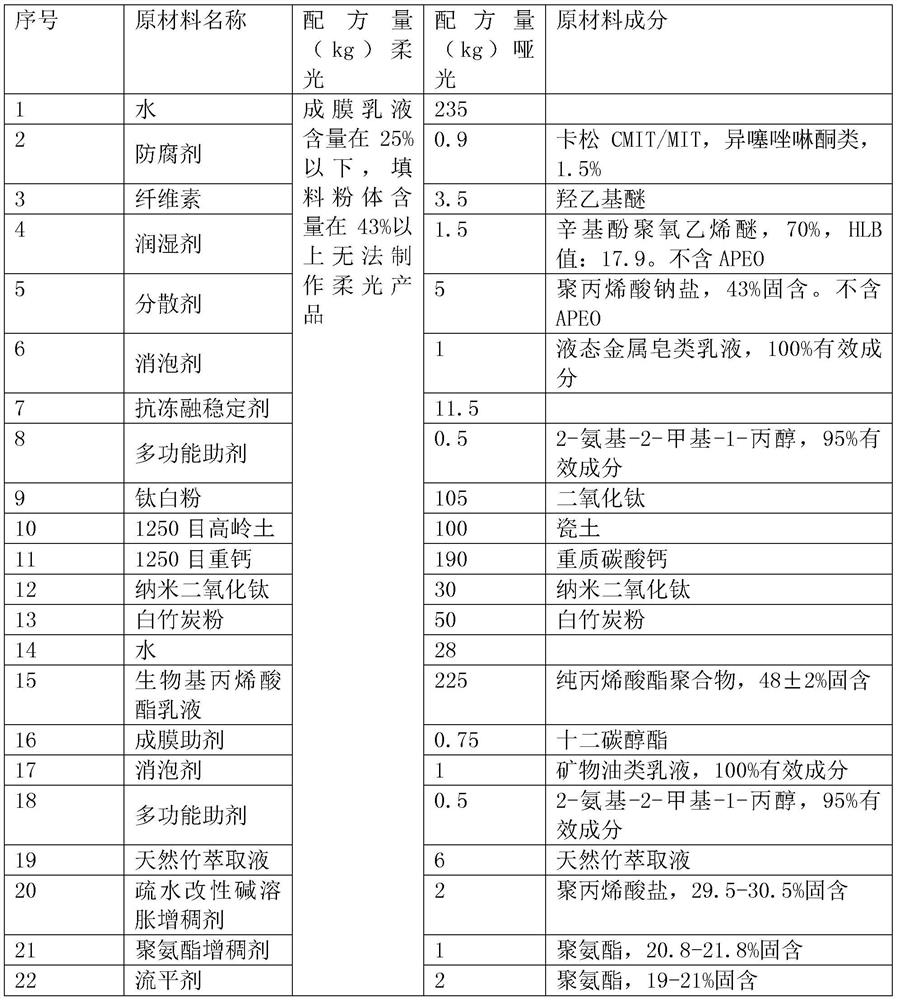

Plant extract interior wall latex paint and preparation method thereof

InactiveCN113321980AWith exterminationAnti-mold and sterilizingAntifouling/underwater paintsPaints with biocidesPolymer scienceEmulsion

The invention provides a plant extract interior wall latex paint and a preparation method thereof. The plant extract interior wall latex paint is prepared from, by weight, 25 to 30 parts of water, 2.5 to 5 parts of nano titanium dioxide, 2.5 to 5 parts of white bamboo charcoal powder, 25 to 40 parts of a powder filler, 0.5 to 1 part of natural bamboo extract, 20 to 25 parts of film-forming emulsion and 5 to 10 parts of other auxiliaries, wherein the film-forming emulsion is a plant extract acrylate emulsion. The preparation method comprises the following steps: mixing the water and part of the auxiliary agent, dispersing and stirring, adding the powder filler, the nano titanium dioxide and the white bamboo charcoal powder, dispersing and stirring, adding the phytoextraction acrylate emulsion, and dispersing and stirring to obtain a third raw material; and then adding the other auxiliaries and the bamboo extract, and dispersing and stirring to obtain the product. In addition to excellent traditional performance, the plant extract interior wall latex paint also has multiple functions of extracting renewable resources from plants, removing formaldehyde, expelling and killing mosquitoes, preventing mildew, sterilizing and the like.

Owner:江西亚卡科技有限公司

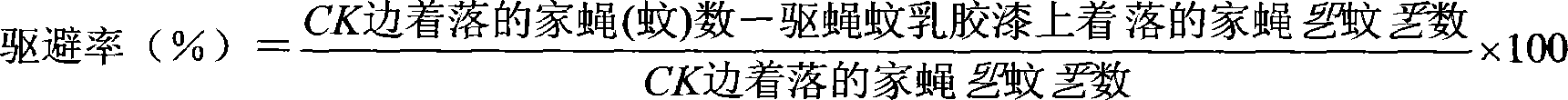

Helminthic emulsion paint and preparation method thereof

InactiveCN101186772BLow VOCExtend the mosquito repellent timeAntifouling/underwater paintsPaints with biocidesAlcoholEmulsion

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com