Ammonia-free low-VOC interior wall emulsion and preparation method thereof

An emulsion and interior wall technology, applied in the coating and other directions, can solve the problems of increasing carbon emissions, unfavorable environment, high energy consumption, etc., and achieve the effects of increasing carbon emissions and energy consumption, reducing VOC, and forming a tight film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

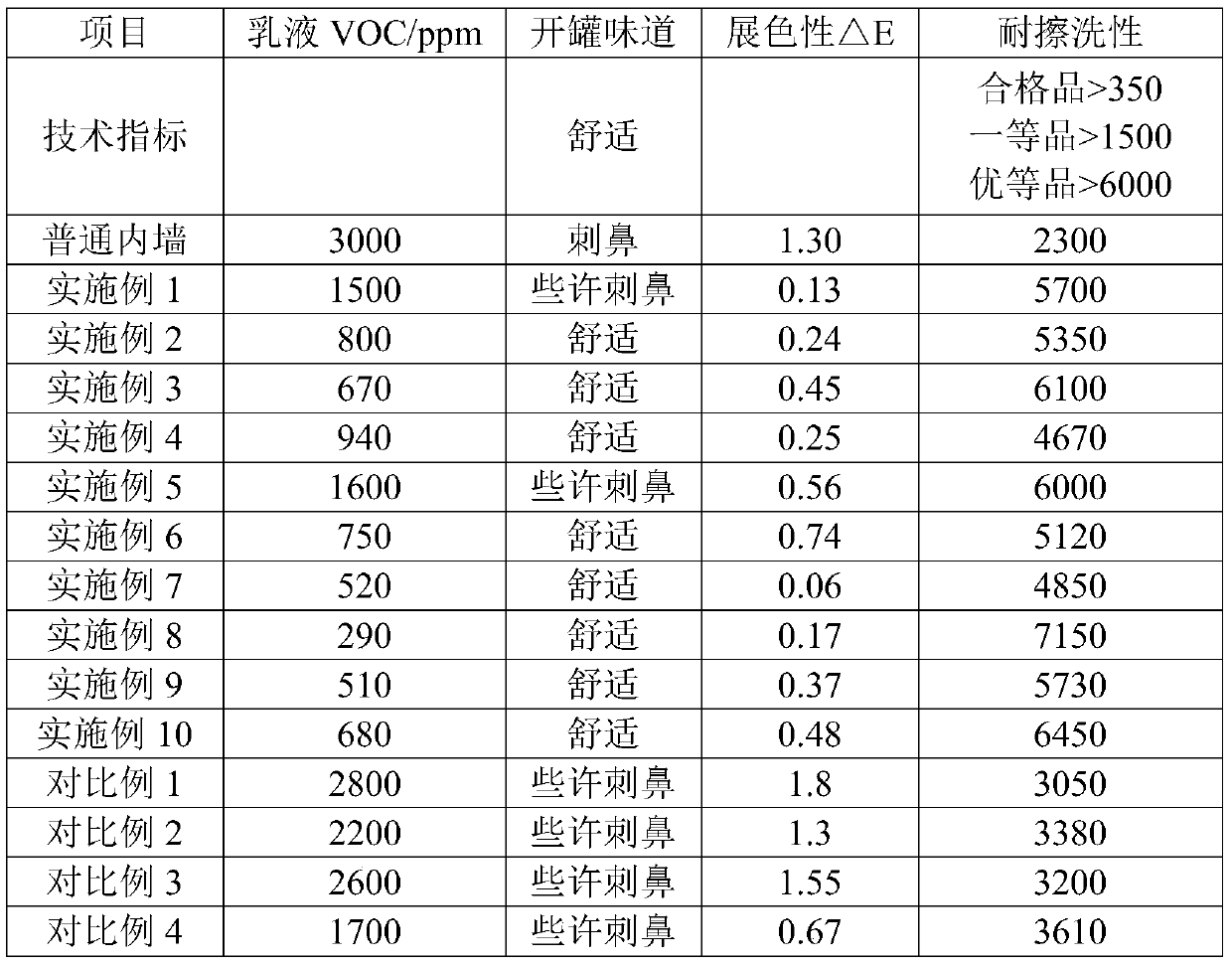

Examples

Embodiment 1

[0035] Ammonia-free low-VOC interior wall emulsion, each component and content: styrene 220g, butyl acrylate 210g, methacrylic acid 10g, acrylic acid 10g, HEMA-P 70M 10g, EGDMA 4g, SR10 5g, RS-610 5g, Sodium sulfate 10g, water 481g, potassium persulfate 8g, tert-butyl hydroperoxide 12g, sodium ascorbate 15g.

[0036] The above-mentioned ammonia-free and low-VOC interior wall emulsion is prepared by the following method:

[0037] (1) Preparation of the first monomer emulsion: Take 48.3g water, 1.5g SR10 and 1.5g RS-610 in a beaker and stir, then add 154g styrene, 42g butyl acrylate, 5g acrylic acid, 2g methacrylic acid , 0.5g HEMA-P 70M and 0.2g EGDMA are emulsified to prepare the first monomer emulsion for use;

[0038] (2) Preparation of the second monomer emulsion: Take 96.9g water, 2g SR10 and 2g RS-610 in a beaker and stir, then add 66g styrene, 168g butyl acrylate, 5g acrylic acid, 8g methacrylic acid, 9.5 g HEMA-P 70M and 3.8g EGDMA are emulsified to prepare the second monome...

Embodiment 2

[0049] Ammonia-free and low-VOC interior wall emulsion, each component and content: styrene 150g, butyl acrylate 280g, methacrylic acid 5g, acrylic acid 5g, HEMA-P 70M 20g, EGDMA 3g, sodium lauryl sulfate 10g, RS- 710 7g, potassium persulfate 8g, t-butyl hydroperoxide 12g, sodium ascorbate 15g, water 485g.

[0050] The above-mentioned ammonia-free and low-VOC interior wall emulsion is prepared by the following method:

[0051] (1) Preparation of the first monomer emulsion: Take 98.9g of water, 5g of sodium lauryl sulfate and 1.8g of RS-710 in a beaker and stir, then add 120g of styrene, 84g of butyl acrylate, 2.5g of acrylic acid, 2.5g methacrylic acid, 2g HEMA-P 70M and 0.3g EGDMA are emulsified to prepare the first monomer emulsion for use;

[0052] (2) Preparation of the second monomer emulsion: Take 101.5g of water, 5g of sodium lauryl sulfate and 1.8g of RS-710 in a beaker and stir, then add 30g of styrene, 196g of butyl acrylate, 2.5g of acrylic acid, 2.5g methacrylic acid, 1...

Embodiment 3

[0063] Ammonia-free low-VOC interior wall emulsion, each component and content: styrene 300g, butyl acrylate 130g, methacrylic acid 7g, acrylic acid 5g, sodium lauryl sulfate 10g, RS-6107g, potassium persulfate 8g, tertiary 17 g of butyl hydroperoxide, 13 g of sodium ascorbate, 20 g of HEMA-P 70M, 5 g of diethylene glycol dimethacrylate, and 478 g of water.

[0064] The above-mentioned ammonia-free and low-VOC interior wall emulsion is prepared by the following method:

[0065] (1) Preparation of the first monomer emulsion: Take 52.5g of water, 4.1g of sodium lauryl sulfate and 1g of RS-610 in a beaker and stir, then add 210g of styrene, 26g of butyl acrylate, and 2.5g of acrylic acid , 1.4g methacrylic acid, 2g HEMA-P70M and 0.5g diethylene glycol dimethacrylate for emulsification to prepare the first monomer emulsion for use;

[0066] (2) Preparation of the second monomer emulsion: Take 100.3g of water, 4.1g of sodium lauryl sulfate and 1g of RS-610 in a beaker and stir, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com