High-performance microscopic microfiber building heat insulation and heat preservation slurry and using method thereof

A thermal insulation, high-performance technology, applied in the direction of thermal insulation, construction, building components, etc., can solve the problems of unsatisfactory tear resistance and compressive strength, unsatisfactory thermal insulation of products, etc., to achieve adhesion Firmness, improved thermal insulation, easy scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

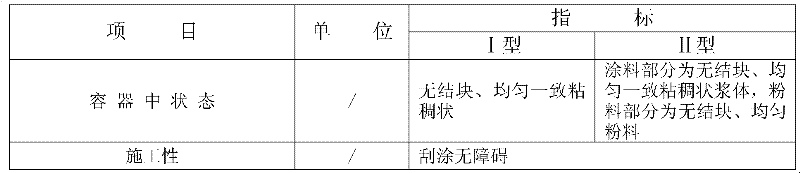

Image

Examples

Embodiment 1

[0111] Example 1: Type I single-component high-performance micro-hollow microfiber building thermal insulation slurry is mainly made of the following raw materials in parts by weight: 10 parts of acrylic synthetic resin, 20 parts of fluorosilicon synthetic resin, water-retaining thickener solution 10 parts, 15 parts of sepiolite fiber, 3 parts of vermiculite fiber, 15 parts of mullite fiber, 5 parts of powdered silica, 20 parts of pearl sand, 5 parts of rock wool fiber, 10 parts of hollow ceramic microbeads, 0.2 parts of foaming agent, 0.2 parts of anti-mold and fungicide, and 1 part of water; mix the above raw materials according to the proportion to form a thermal insulation slurry of mud paste construction material.

Embodiment 2

[0112] Example 2: Type I single-component high-performance micro-hollow microfiber building thermal insulation slurry is mainly made of the following raw materials in parts by weight: 30 parts of acrylic synthetic resin, 5 parts of fluorosilicon synthetic resin, water-retaining thickener solution 30 parts, 5 parts of sepiolite fiber, 10 parts of vermiculite fiber, 5 parts of mullite fiber, 5 parts of powdered silica, 10 parts of perlite fiber, 5 parts of modified pearl sand, 10 parts of rock wool fiber, 5 parts of hollow ceramic microspheres, 0.3 parts of defoamer, 0.1 part of anti-mold and bactericide, and 5 parts of water; the above-mentioned raw materials are mixed according to the proportion to form a thermal insulation slurry of a paste-like construction material.

Embodiment 3

[0113] Example 3: Type I single-component high-performance micro-hollow microfiber building thermal insulation slurry is mainly made of the following raw materials in parts by weight: 20 parts of acrylic synthetic resin, 14 parts of fluorosilicon synthetic resin, water-retaining thickener solution 20 parts, sepiolite fiber 10 parts, vermiculite fiber 6 parts, mullite fiber 10 parts, powdered silica 3 parts, perlite fiber 7 parts, modified pearl sand 10 parts, rock wool fiber 7 parts, 7 parts of hollow ceramic microspheres, 0.25 parts of defoaming agent, 0.15 parts of anti-mold and bactericide, and 3 parts of water; the above-mentioned raw materials are mixed according to the proportion to form a thermal insulation slurry of a paste-like construction material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com