Polymer cement waterproofing mortar

A waterproof mortar and polymer technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problem of poor acid and alkali resistance, corrosion resistance, insufficient scientific formula design, and inability to ensure construction safety and other problems, to achieve good water and alkali resistance, excellent impermeability and bonding performance, and improve the effect of building water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

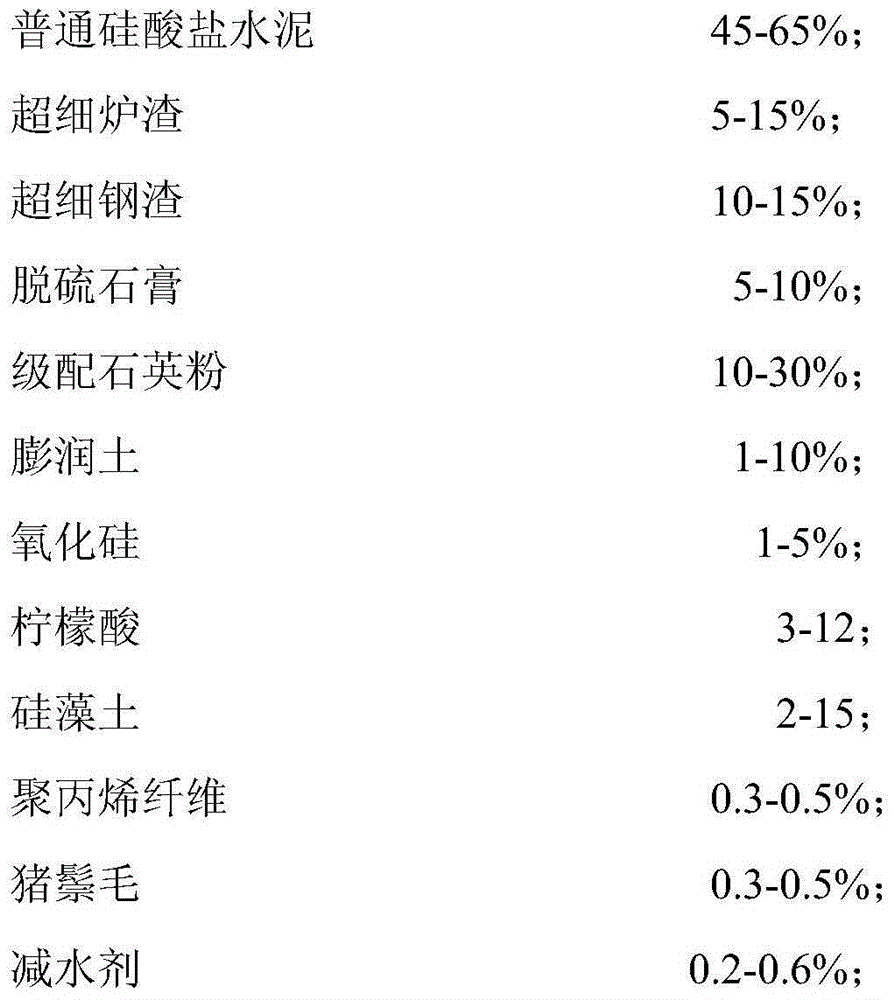

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, the mixing ratio of the liquid material component and the powder material component is 1:3 by weight. According to the national standard, the formula is tested and listed in the table below. In the table below, the sum of the liquid components is 100kg, and the sum of the powder components is 300kg.

[0043]

[0044]

Embodiment 2

[0046] In this embodiment, the mixing ratio of the liquid material component and the powder material component is 1:3.5 by weight. According to the national standard, the formula is tested and listed in the table below. In the table below, the sum of the liquid components is 100kg, and the sum of the powder components is 350kg.

[0047]

[0048]

Embodiment 3

[0050] In this embodiment, the mixing ratio of the liquid material component and the powder material component is 1:4 by weight. According to the national standard, the formula is tested and listed in the table below. In the table below, the sum of the liquid components is 100kg, and the sum of the powder components is 400kg.

[0051]

[0052]

[0053] It can be seen from Examples 1 to 3 that the preparation of the polymer cement waterproof mortar according to the present invention can meet the national standard JC / T984-2011.

[0054] Simultaneously, the present invention has also carried out comparative test with traditional waterproof paint, and the result is as follows:

[0055] Test items

[0056] As can be seen from the above table, it can be seen from the comparison that the polymer cement waterproof mortar of the present invention has obvious advantages in compressive strength, flexural strength, bonding strength and corner cracking performance compare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com