Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Fewer side effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

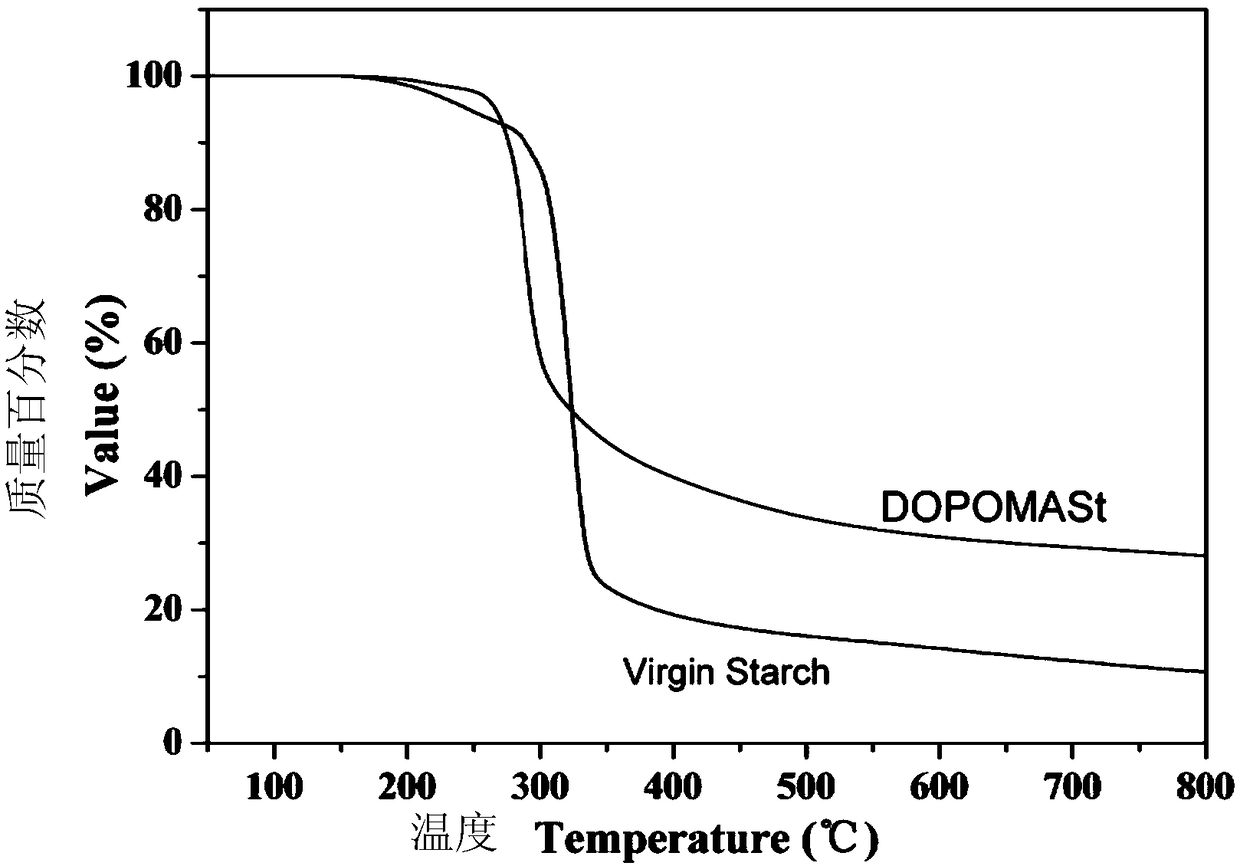

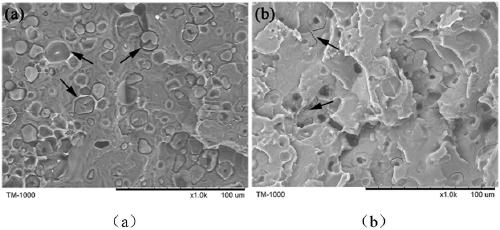

Polylactic acid/starch expansion flame-resistant composite material, and preparation method thereof

ActiveCN106496975AImprove charcoal abilityImprove high temperature thermal stabilityMaleic anhydrideChemistry

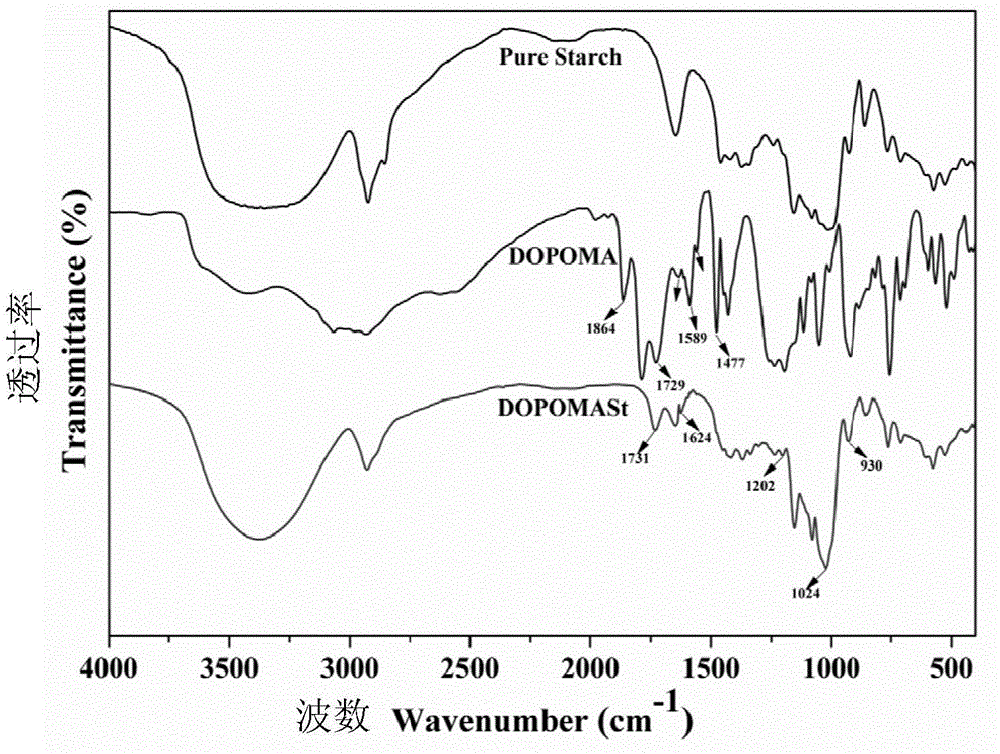

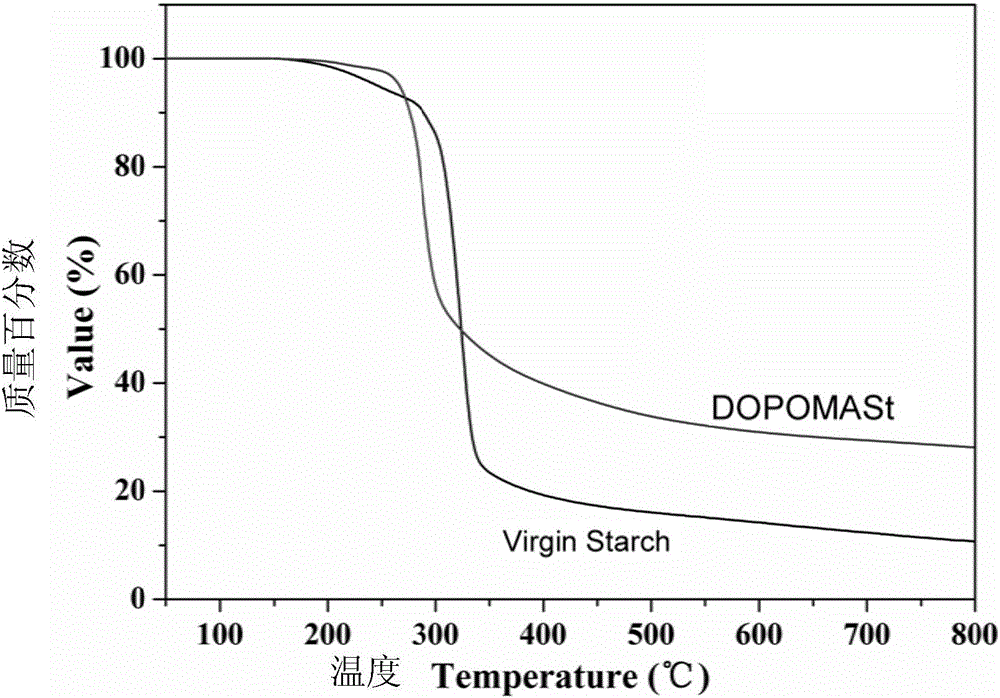

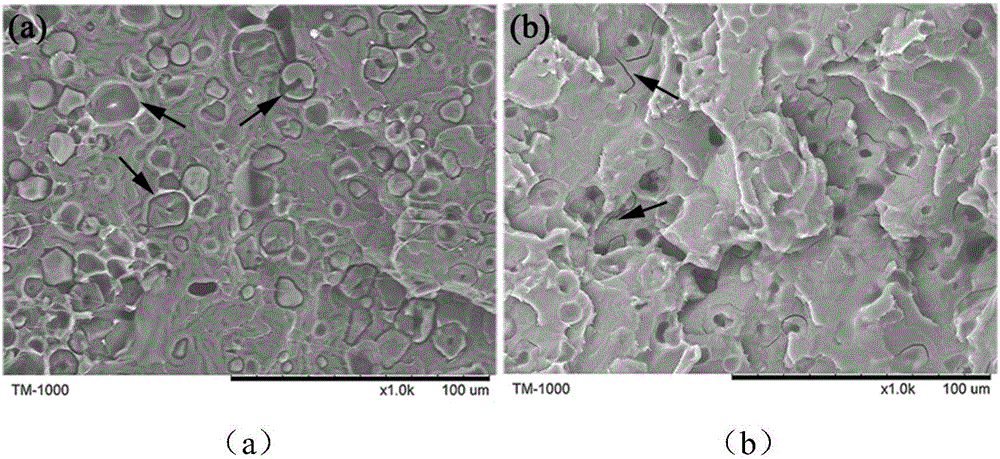

The invention discloses a polylactic acid / starch expansion flame-resistant composite material with excellent flame resistance, and a preparation method thereof. The polylactic acid / starch expansion flame-resistant composite material is composed of, by weight, 60 to 89% of polylactic acid, 5 to 30% of an acid source, 5 to 30% of a modified starch, and 1 to 15% of a gas source. In a preferred embodiment, the modified starch is phosphorized maleic anhydride grafting modified starch (bio-based phosphorus containing starch). According to the preparation method, polylactic acid possesses excellent compatibility with the modified starch; synergistic effect of the acid source, the carbon source (the modified starch), and the gas source is capable of improving charring forming capability of the polylactic acid matrix, and improving high temperature stability and flame resistance of polylactic acid greatly. According to the preparation method, adoption of an existing double-screw extruder is enough for production; preparation is simple and convenient; and the preparation method is convenient for industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

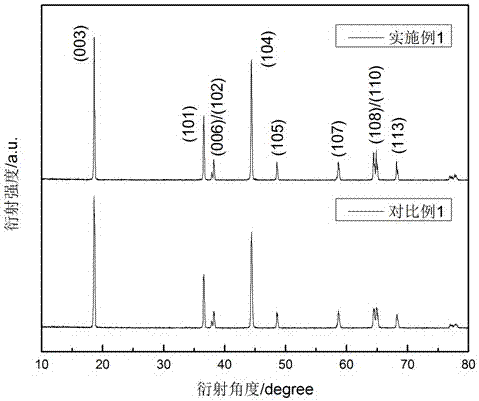

Method of lithium vanadium phosphate-coated ternary material of lithium ion battery

InactiveCN107204428AIncrease energy densityHas a core-shell structureElectrode thermal treatmentLithium vanadium phosphate batteryPhysical chemistry

The invention relates to a method of a lithium vanadium phosphate-coated ternary material of a lithium ion battery. The active electrode material of lithium vanadium phosphate is used as a coating material, and can form a uniform coating layer at the surface of the ternary material. A preparation method comprises the following steps of (1) preparing the ternary material; (2) mixing the ternary material and the lithium vanadium phosphate; (3) calcining a mixed sample under the reduction atmosphere. The method has the advantages that the transmission rate of lithium ions of the surface-coated lithium vanadium phosphate material is quick, and the large rate property of the material is improved; the lithium vanadium phosphate material has good stability, the erosion of electrolyte to the ternary material of an inner core is effectively inhibited, the coated ternary material integrates the advantages of the ternary material and the lithium vanadium phosphate, and the good rate property and cyclic property are realized.

Owner:CENT SOUTH UNIV

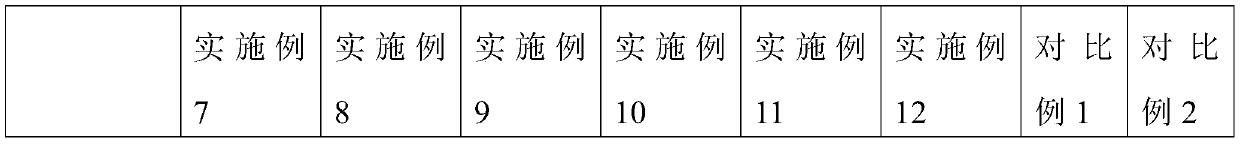

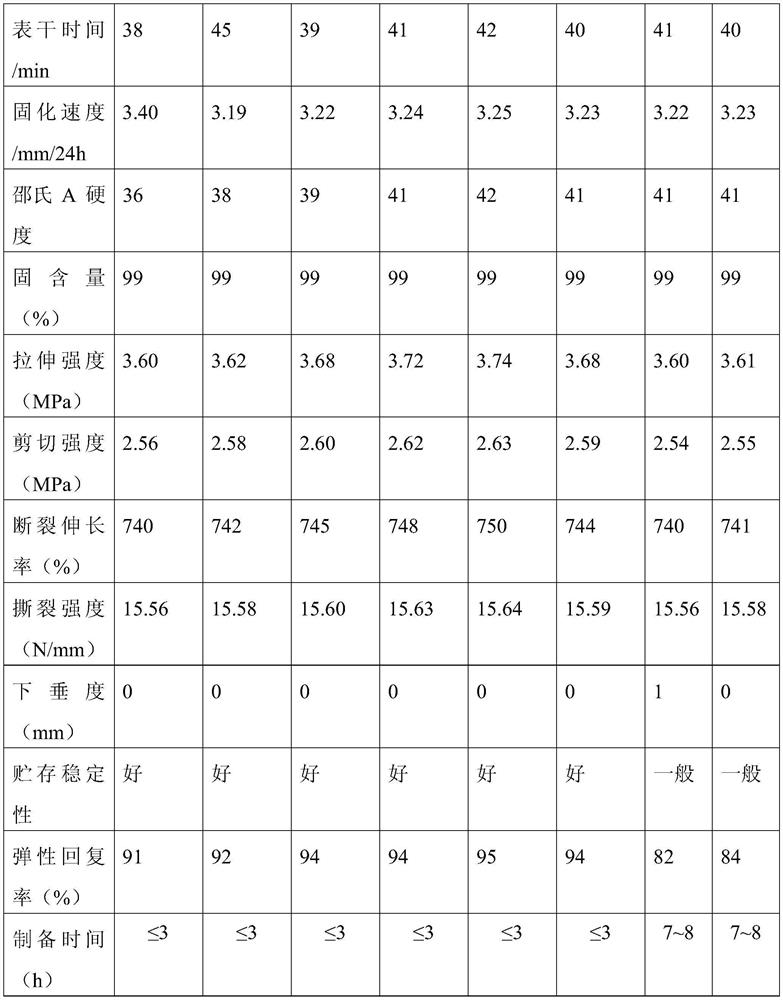

Single-component polyurethane sealant and low-temperature and rapid preparation method thereof

ActiveCN111073584AHigh tensile strengthIncreased shear strengthPolyureas/polyurethane adhesivesPolymer scienceReaction temperature

A single-component polyurethane sealant and a low-temperature rapid preparation method thereof have the advantages that the single-component polyurethane sealant is high in tensile strength, shearingstrength and tearing strength, moderate in viscosity and good in storage stability; according to the preparation method of the single-component polyurethane sealant, the time is short, the preparationof the product can be completed within 2-3 hours, and the production efficiency is high; the reaction temperature in the preparation process does not exceed 100 DEG C; the preparation method of the single-component polyurethane sealant has the advantages of short high-temperature reaction time retention time, few reaction side reactions and low energy consumption, the preparation process is simple and easy to operate, the preparation can be completed by using the existing equipment, the preparation of the prepolymer is not limited in a reaction kettle any more, and the equipment cost and thelabor cost are greatly reduced; according to the preparation process of the single-component polyurethane sealant, prepolymer molecules always coexist with filler and functional additive molecules inthe production and formation processes, organic materials and inorganic materials can be better matched and interwoven, and the shearing strength, the tensile strength and the elongation at break of the product are improved.

Owner:SHANDONG NORTH MODERN CHEM IND

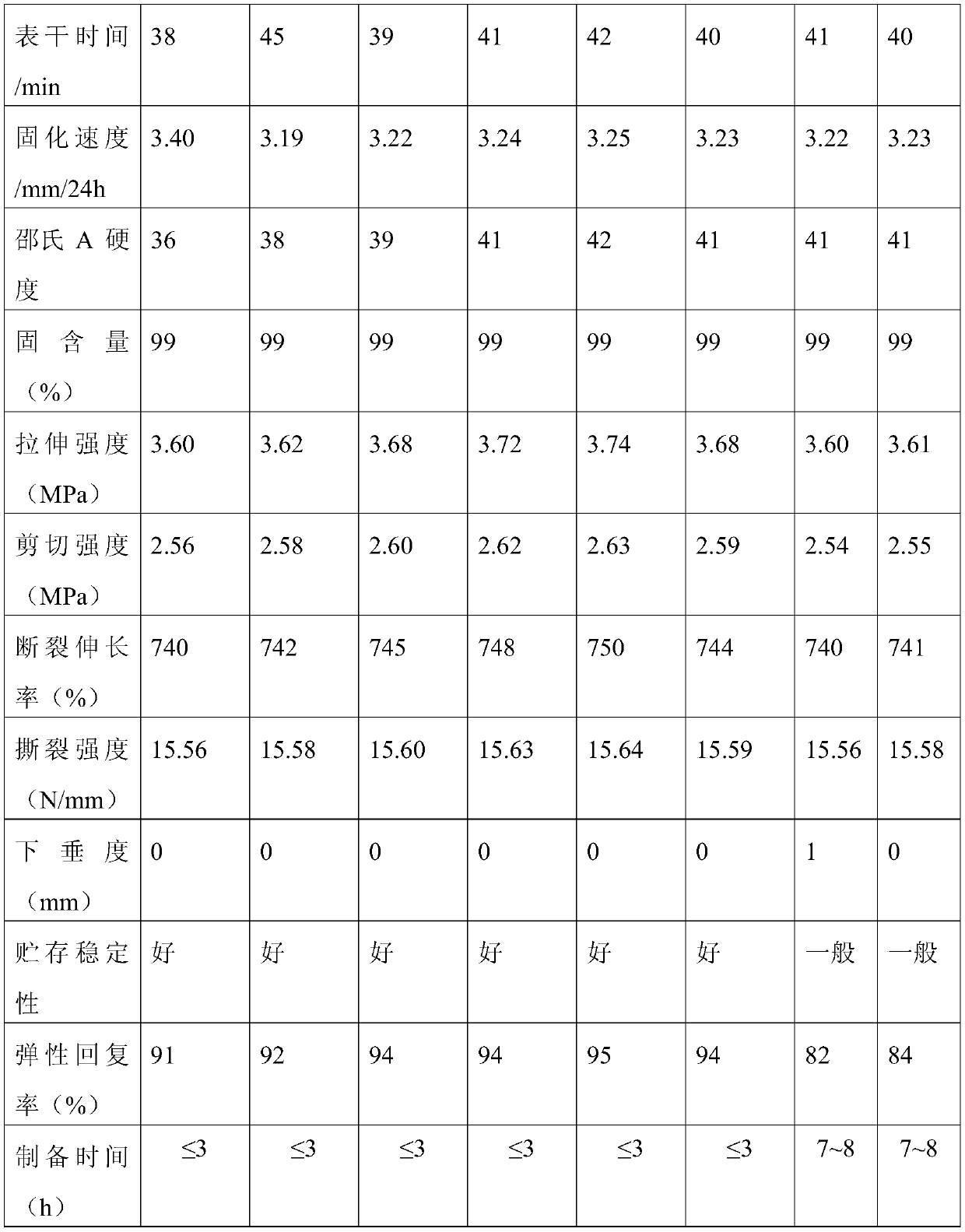

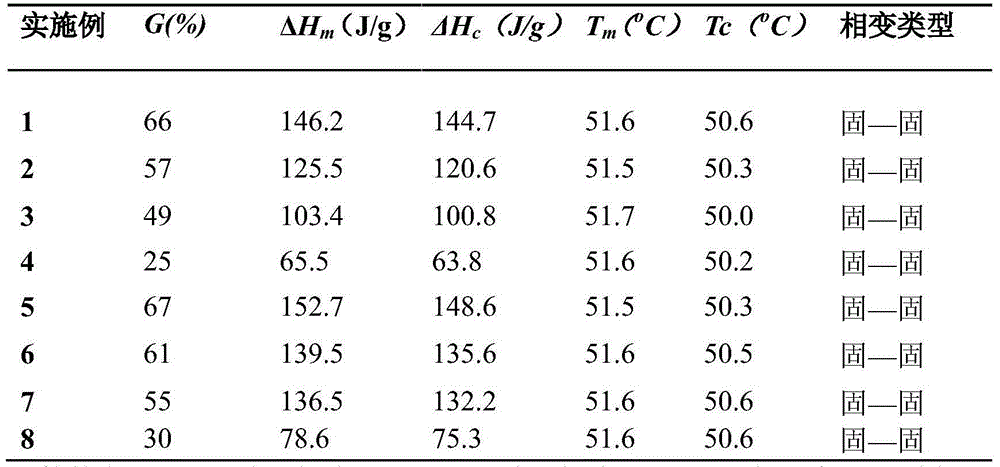

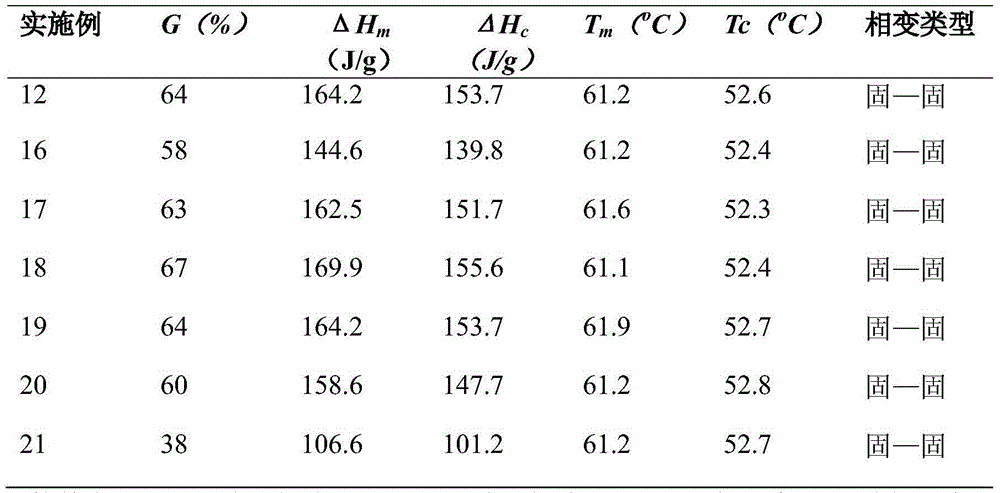

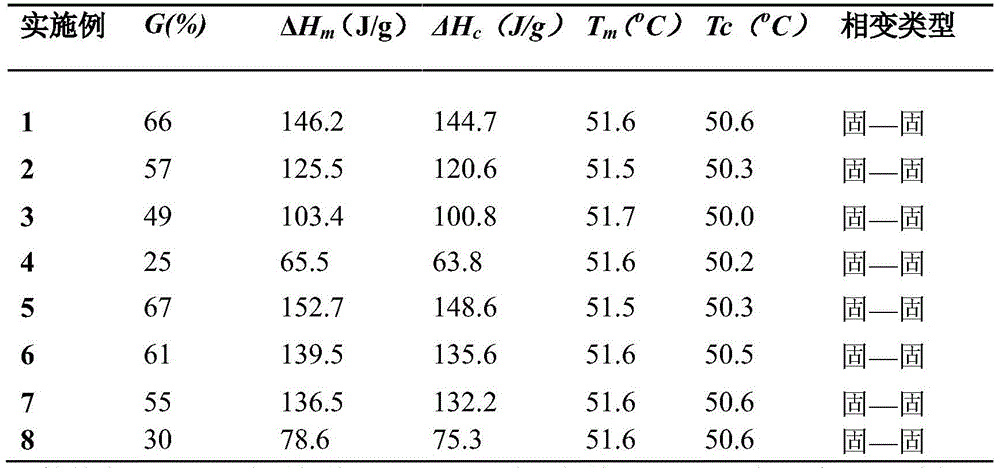

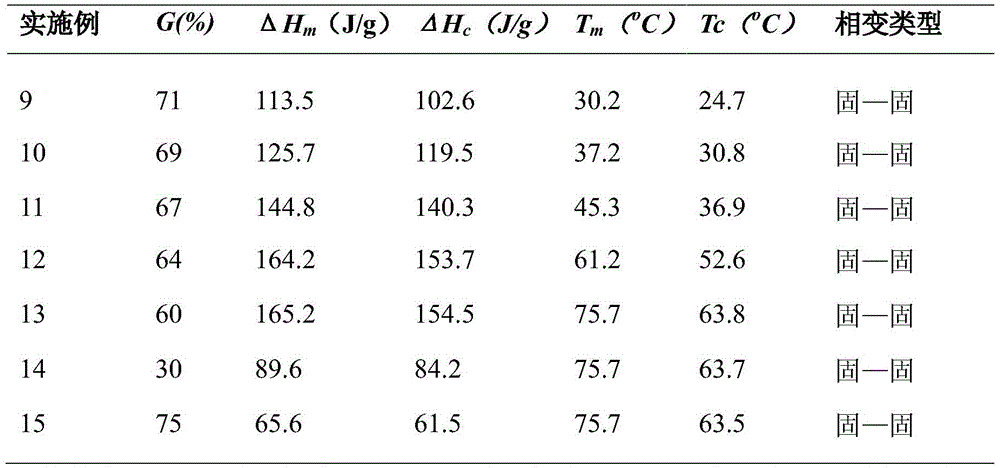

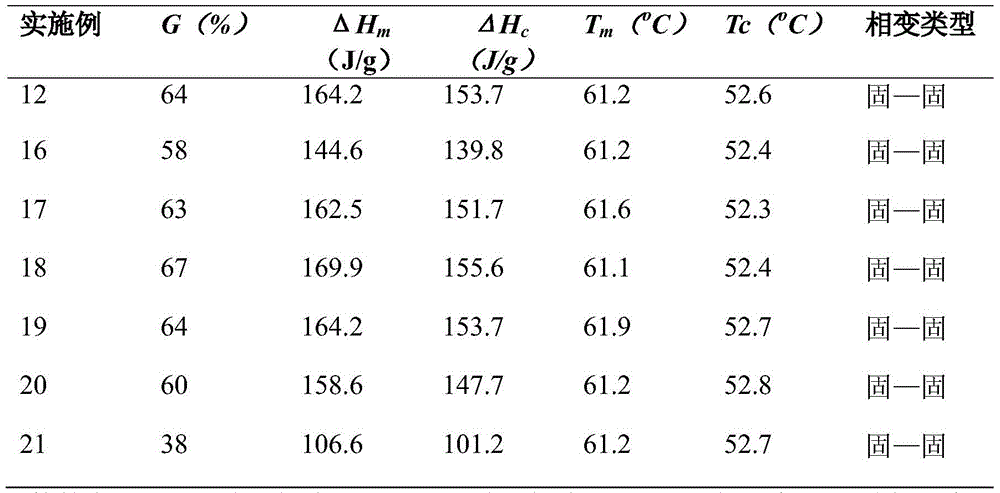

Preparation method of comb-shaped polymer phase change energy storage material

ActiveCN104356306AHigh crystallinityImprove thermal stabilityHeat-exchange elementsMaleic anhydrideSolvent

The invention discloses a preparation method of a comb-shaped polymer phase change energy storage material. The preparation method comprises the following steps: 1) adding polyethylene grafted maleic anhydride and alcohol with a hydroxyl active group on a terminal group, ether with a hydroxyl active group on a terminal group or mercaptan with a sulfydryl active group on a terminal group which are in a molar ratio of 1 to (0.5-5) into a reaction container, in the presence of nitrogen gas, adding an organic solvent subjected to water removal and a catalyst, and reacting for 6-12 hours at 60-120 DEG C to obtain reaction primary products; 2) cooling the reaction primary products, and washing and drying after removing the solvent to obtain the comb-shaped polymer phase change energy storage material. The preparation method disclosed by the invention is fewer in side reactions, high in yield, high in reaction speed, and convenient and simple in preparation. The prepared comb-shaped polymer phase change energy storage material has good crystallization property, thermal stability, setting performance and machinable property.

Owner:TIANJIN POLYTECHNIC UNIV

Medicine for treating spleen and stomach deficiency-cold type reflux esophagitis and preparation method

InactiveCN105148151AControl clinical symptomsLDigestive systemPlant ingredientsReflux esophagitisSide effect

The invention provides medicine for treating reflux esophagitis. The medicine is prepared from piper cubeba, poria cocos, mangnolia officinalis, thunberg fritillary bulb, cortex phellodendri, galangal, myristica fragrans, milkvetch roots, cuttlebone, selaginella tamariscina, dendrobium, cornus officinalis, radix angelicae, cattail pollen, bupleurum, spreading hedyotis herb, American ginseng, polygonum hydropiper, orchis morio and nodding clinacanthus. The medicine has the advantages that clinical symptoms of reflux esophagitis can be fast controlled, mucous membrane histopathologic changes can be fast restored, the state of the illness can be fast controlled, the long-term therapeutic effect is good, and few side effects exist, and is worthy of clinical application and popularization.

Owner:王栩

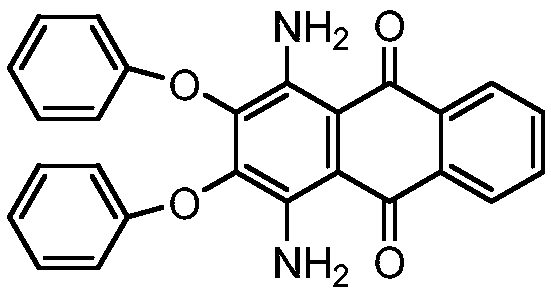

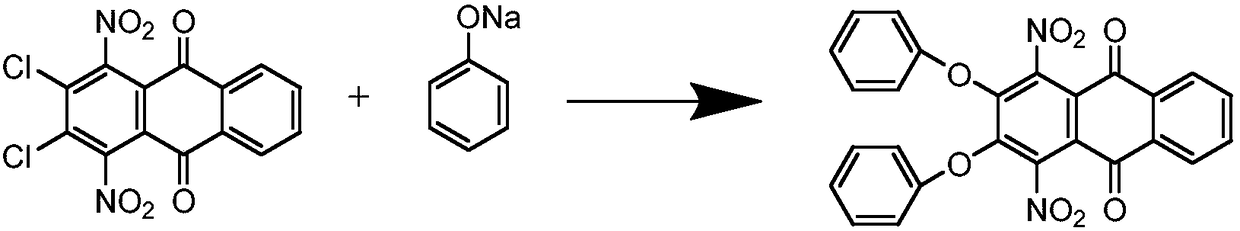

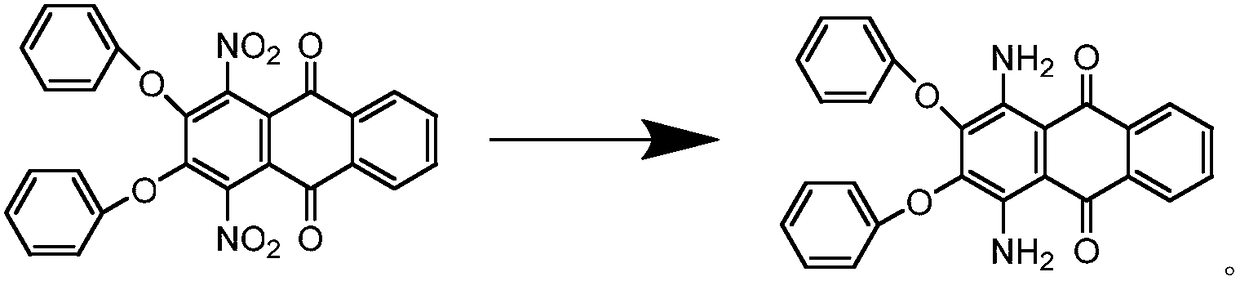

Synthesis process of solvent violet 59

The invention discloses a synthesis process of solvent violet 59. The synthesis process of the solvent violet 59 comprises the following steps: taking 1,4-binitro-2,3-dichloroanthraquinone and sodiumphenoxide as raw materials, performing condensation reaction under the existence of an organic solvent orthodichlorobenzene to generate 1,4-binitro-2,3-diphenoxyanthraquinone, and reducing the 1,4-binitro-2,3-diphenoxyanthraquinone to generate 1,4-diamido-2,3-diphenoxyanthraquinone. The activity of the 1,4-binitro-2,3-dichloroanthraquinone is higher than the activity of the 1,4-diamido-2,3-dichloroanthraquinone, and the reaction is easier to conduct, so the reaction time is greatly shortened; furthermore, the reaction has little side reactions, the yield is high and undissolved substances aregreatly reduced; moreover, the synthesis route avoids generation of a large amount of salt-containing waste water, and the process is relatively clean and environment-friendly.

Owner:JIANGSU DAOBO CHEM

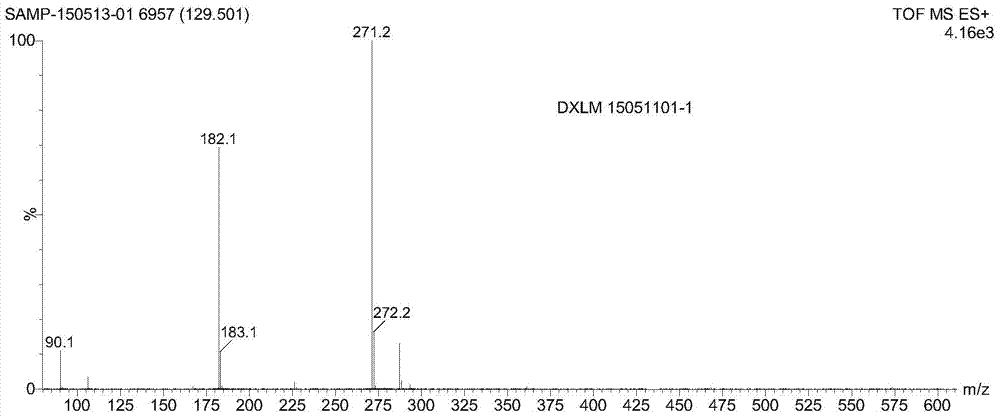

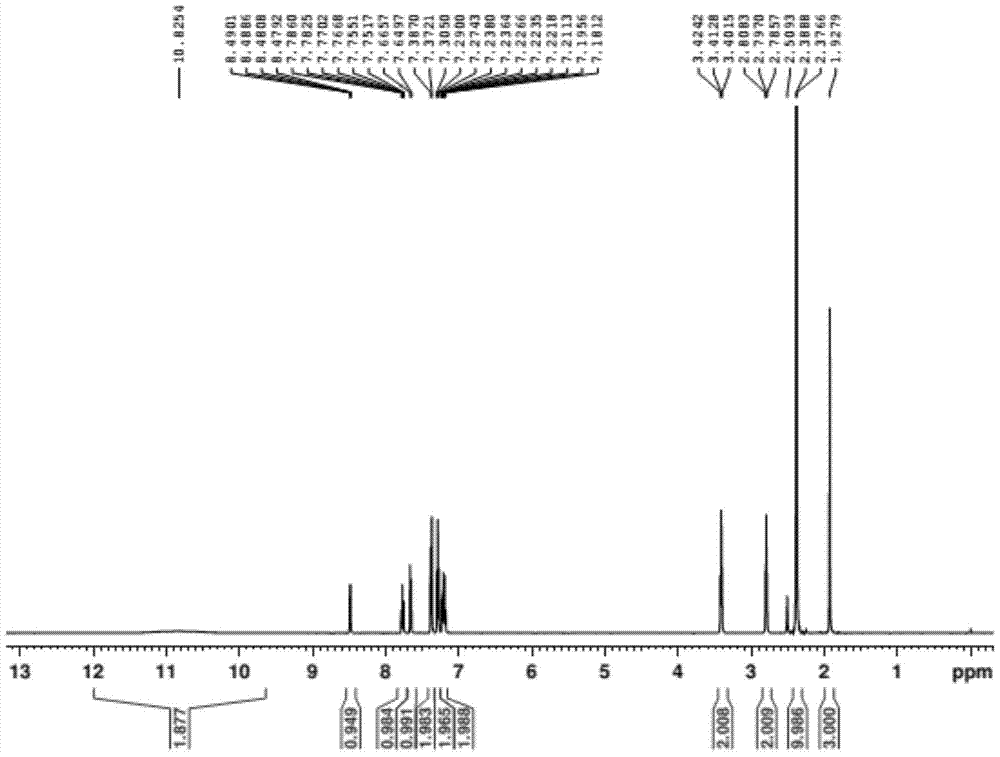

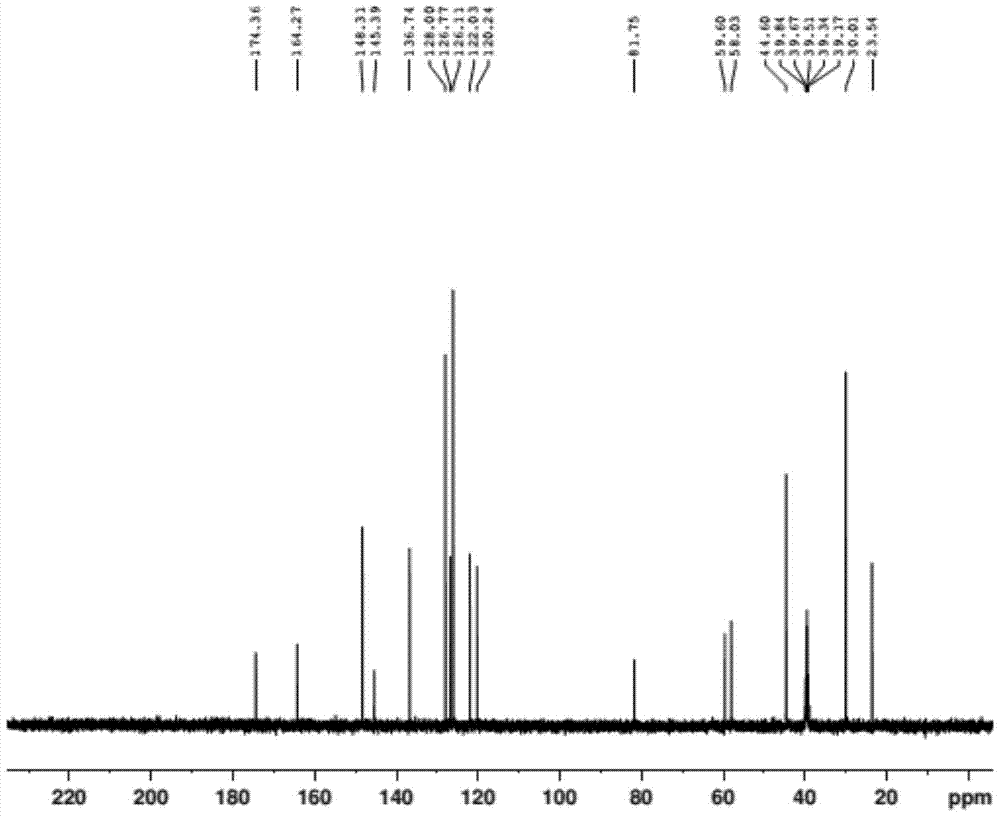

A kind of preparation method of doxylamine succinate

The invention discloses a preparation method of doxylamine succinate. The preparation method comprises following steps: step 1, 2-pyridyl phenyl methyl carbinol is dissolved in an organic solvent, and is reacted with 2-dimethylaminoethyl chloride hydrochloride at high temperature, after reaction, target product N,N-dimethyl-2-[1-phenyl-1-(2-pyridine)oxethyl]ethylamine is obtained via quenching extracting separation; and step 2, N,N-dimethyl-2-[1-phenyl-1-(2-pyridine) oxethyl]ethylamine obtained in the step 1 and succinic acid are subjected to salt forming in an organic solvent; and finished product N,N-dimethyl-2-(1-phenyl-1-(2-pyridine)ethoxy)ethanamine succinate (doxylamine succinate) is obtained via cooling crystallization. The preparation method is simple, safe, and reliable, is high in doxylamine succinate yield, and is suitable for industrialized enlarged production; and post-treatment is simple and convenient.

Owner:NANJING GRITPHARMA CO LTD

Compound stabilizer for epoxidation reaction of unsaturated compound and application method thereof

ActiveCN102850298AImprove stabilityReduce usageOrganic chemistryEthylenediaminePotassium sodium tartrate

The invention discloses a compound stabilizer for the epoxidation reaction of an unsaturated compound and an application method of the compound stabilizer. The compound stabilizer comprises carbamide, ethylene diamine tetraacetic acid, potassium sodium tartrate and sodium silicate. Peroxide and a peroxoic acid stabilizer including the ethylene diamine tetraacetic acid, the potassium sodium tartrate, concentrated sulfuric acid and 732 resin are uniformly mixed; the addition of the peroxoic acid stabilizer is 0.1 to 5 wt% of that of the peroxide; organic acid is dropwise added to the peroxide and the peroxoic acid stabilizer at 25 to 35 DEG C, so that peroxoic acid mixed solution is obtained after reaction; an epoxidation stabilizer including the carbamide, the ethylene diamine tetraacetic acid, and the potassium sodium tartrate and the sodium silicate is added into the unsaturated compound, and then the peroxoic acid mixed solution is added into the epoxidation stabilizer at 65 to 95 DEG C, so that an epoxidation compound is obtained after epoxidation reaction. The compound stabilizer has the advantages that the coordination of various stabilizers improves the stability of hydrogen peroxide and peroxoic acid in reaction solution, the frequency of the occurrence of secondary reaction is reduced, the reaction time is shortened, and the production cost is reduced.

Owner:甄曰菊

Preparation method of trimethylolpropane diallyl ether

ActiveCN102040486BControlled hydrolysisReduce dosageEther preparation by ester reactionsPtru catalystPotassium hydroxide

The invention discloses a preparation method of trimethylolpropane diallyl ether. A reaction process comprises the steps of: firstly, carrying out azeotropic dehydration on trimethylolpropane and alkali metal hydroxide in the presence of butyl ether to obtain trimethylolpropane alkali metal salt, then subjecting chloropropene and the trimethylolpropane alkali metal salt to etherification reaction, removing peroxide from a reaction fluid after the etherification reaction, and carrying out vacuum distillation to obtain the trimethylolpropane diallyl ether. In the invention, solid sodium hydroxide or potassium hydroxide is used as a reaction raw material to reduce side reactions; nitrogen protection and a phase transfer catalyst are not used so that the cost is saved; the butyl ether is used as a reaction medium and an azeotropic dehydrating agent so that the content of the trimethylolpropane diallyl ether is greatly improved and the content of triether and monoether is reduced; the product is stable and reliable in quality, the production operation is simple and convenient and is easy to apply, three wastes are less, and the preparation process is suitable for industrialized production.

Owner:CHEM TECH ACAD OF SHANDONG PROVINCE

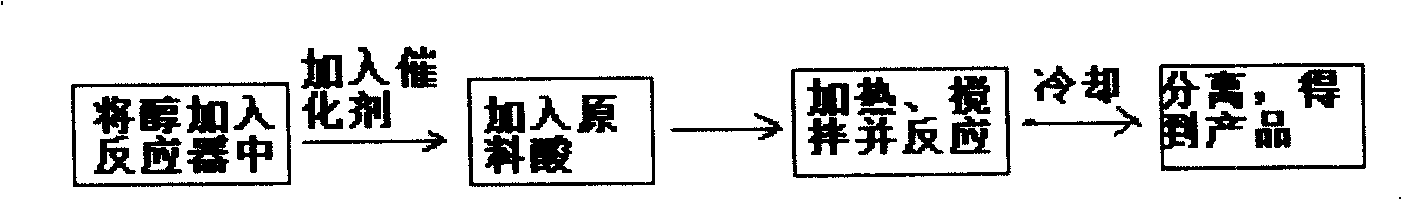

Esterification catalyst and method for synthesizing ester using the catalyst

InactiveCN101279290AReduce aggregationReduce colorOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholEsterification reaction

The present invention discloses an acidic esterification catalyst which can reduce corrosion and a method for utilizing the catalyst to synthesize ester. The catalyst is formed by mixing acid amide and oil of vitriol according to a certain proportion. The method of utilizing the catalyst to synthesize ester includes: firstly adding a fixed amount of ester into a reactor, then adding the catalyst into the ester and dissolving, finally adding the acid according to a proper proportion and separating after heating and stirring reaction, thus obtaining the required ester. The catalyst provided by the present invention is easy to obtain with high catalyzing efficiency, which greatly reduces the occurrence of the secondary reactions and the color of the product and simultaneously decreases the corrosion to reacting equipment caused by a reaction system.

Owner:NANJING UNIV

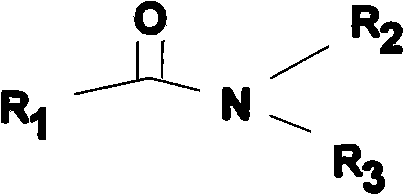

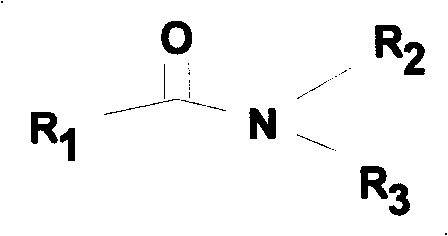

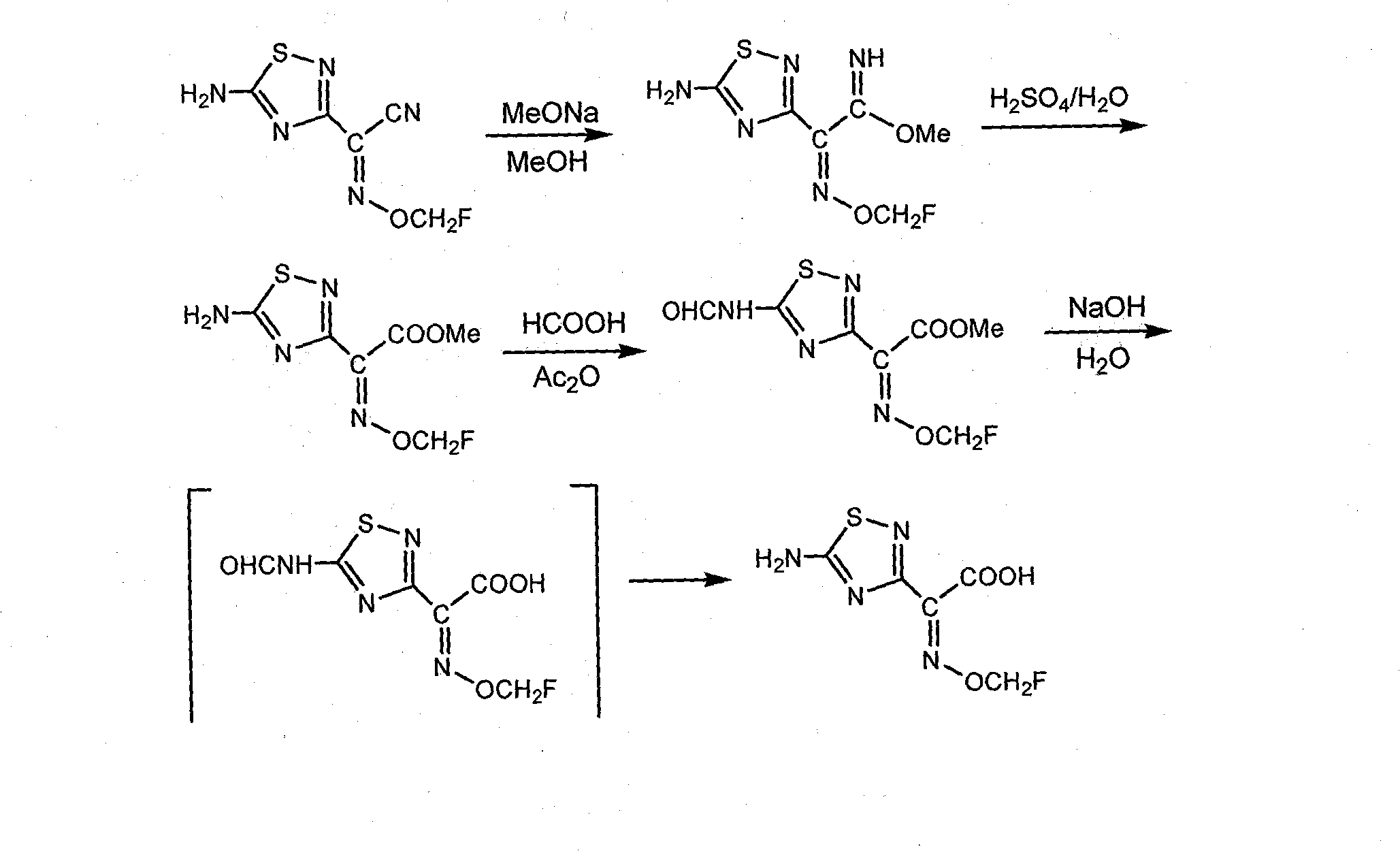

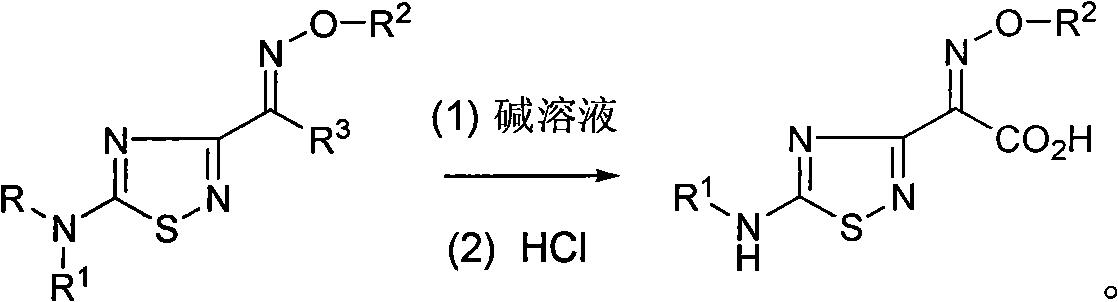

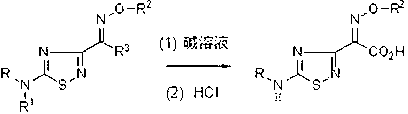

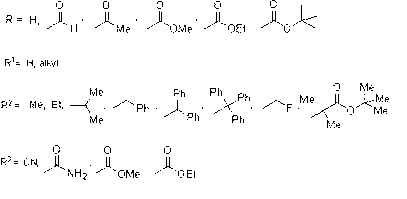

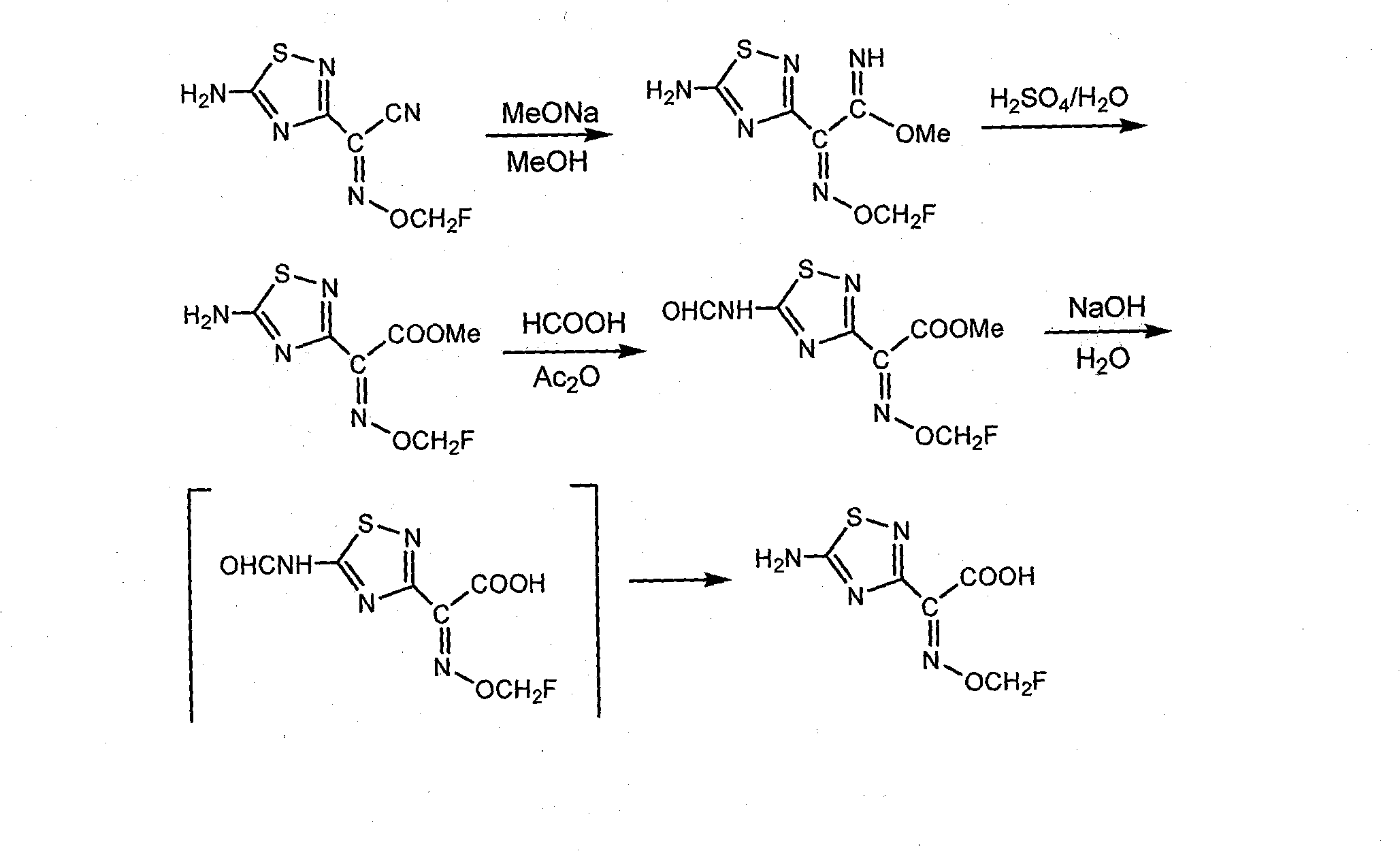

Preparation method of 1,2,4-thiadiazole oximido acetic acid compound

The invention provides a preparation method of a 1,2,4-thiadiazole oximido acetic acid compound, relating to the technical field of preparation technology of 7-site side chain 1,2,4-thiadiazole oximido acetic acid compound of fourth-generation cephalosporin and fifth-generation cephalosporin. The product is obtained by alkali hydrolysis reaction of the derivative of the 1,2,4-thiadiazole oximido acetic acid compound, and the temperature of the hydrolysis reaction system is controlled to be below 150 DEG C. The method of the invention has peculiar principle, and solves the problems of various technical steps, complex operation and the like in the prior art; in addition, product purification technology and operation technology are simple, the operation steps for manufacturing the thiadiazole oximido acetic acid compound are greatly shortened and reaction yield and product purity are higher. A byproduct which can be detected in a reaction mixture can be lower than 5%, reaction yield can be improved to 75-85%, and purity can be more than 97%. The method of the invention is especially suitable for producing the thiadiazole oximido acetic acid compound products with high purity.

Owner:HEBEI BOLUNTE PHARMA

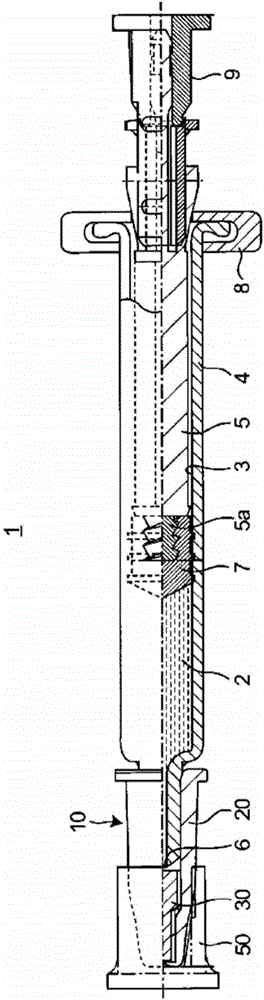

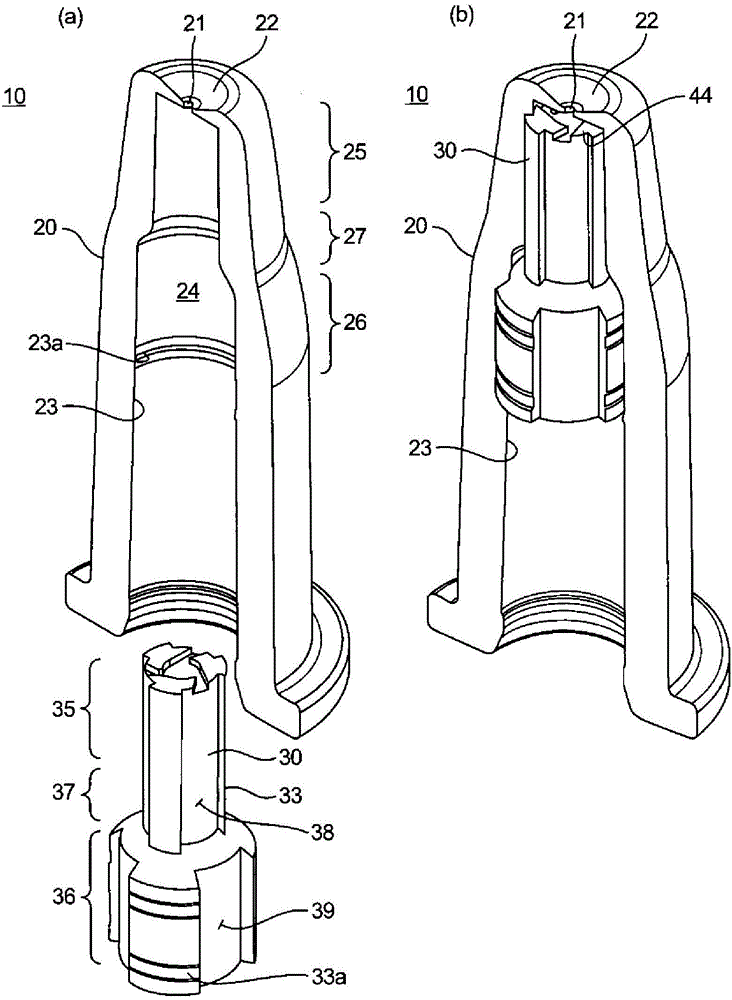

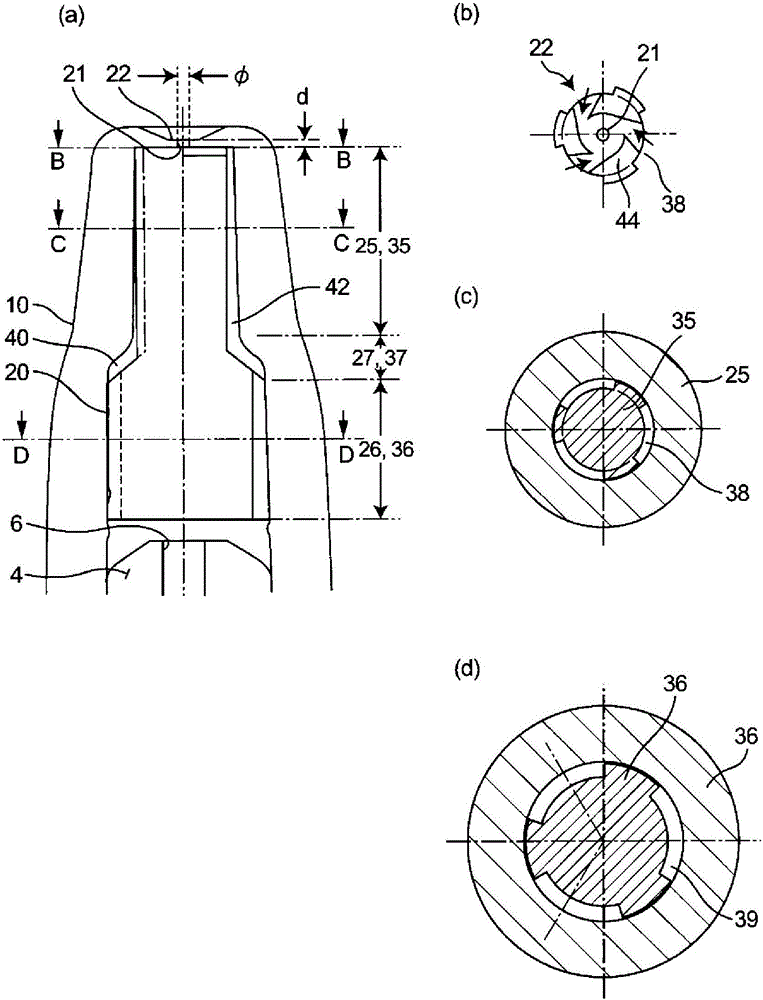

Influenza vaccine nasal vaccination system

ActiveCN106573045AFewer side effectsWide spreadSsRNA viruses negative-senseViral antigen ingredientsNasal cavityAntigen

The present invention pertains to an influenza vaccine nasal vaccination system in which an influenza vaccine composition characterized by including a gel base that contains a carboxyvinyl polymer and an influenza virus deactivated full particle antigen, and including no adjuvants, is packed into a medical syringe for administration to the mucus membrane of the nasal cavity.

Owner:TOKO YAKUHIN IND CO LTD

Preparation method of 1,2,4-thiadiazole oximido acetic acid compound

The invention provides a preparation method of a 1,2,4-thiadiazole oximido acetic acid compound, relating to the technical field of preparation technology of 7-site side chain 1,2,4-thiadiazole oximido acetic acid compound of fourth-generation cephalosporin and fifth-generation cephalosporin. The product is obtained by alkali hydrolysis reaction of the derivative of the 1,2,4-thiadiazole oximido acetic acid compound, and the temperature of the hydrolysis reaction system is controlled to be below 150 DEG C. The method of the invention has peculiar principle, and solves the problems of various technical steps, complex operation and the like in the prior art; in addition, product purification technology and operation technology are simple, the operation steps for manufacturing the thiadiazole oximido acetic acid compound are greatly shortened and reaction yield and product purity are higher. A byproduct which can be detected in a reaction mixture can be lower than 5%, reaction yield can be improved to 75-85%, and purity can be more than 97%. The method of the invention is especially suitable for producing the thiadiazole oximido acetic acid compound products with high purity.

Owner:HEBEI BOLUNTE PHARMA

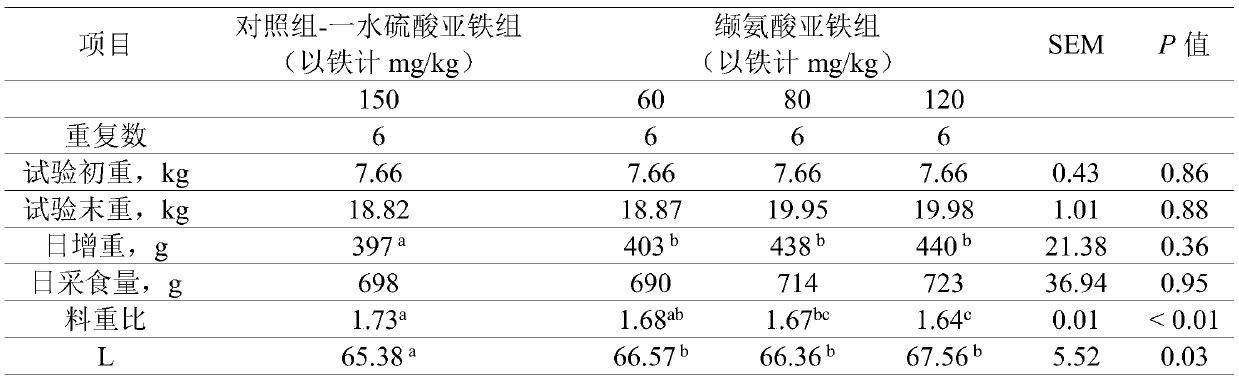

Preparation method and application of ferrous valine

ActiveCN111116394APriority absorptionImprove overall utilizationOrganic compound preparationAccessory food factorsFerrous saltsSaline solutions

The invention discloses a preparation method of ferrous valine. The method comprises the following steps: (1) adding valine into water, adding sodium carbonate / potassium carbonate, and stirring to react until no air bubbles emerge in order to obtain a valine salt solution; and (2) heating the valine salt solution, adding an inorganic ferrite, performing a reaction, carrying out solid-liquid separation after the reaction is finished, and drying to obtain the ferrous valine. The invention also provides an application of the ferrous valine as an animal feed additive in animals. The reaction is divided into two steps, the sodium carbonate / potassium carbonate is added into the valine solution and reacts to generate the valine salt, and then the valine salt reacts with the inorganic ferrite to obtain the product, so reaction side reactions are few, and the product purity is high.

Owner:昕嘉生物技术(长沙)有限公司

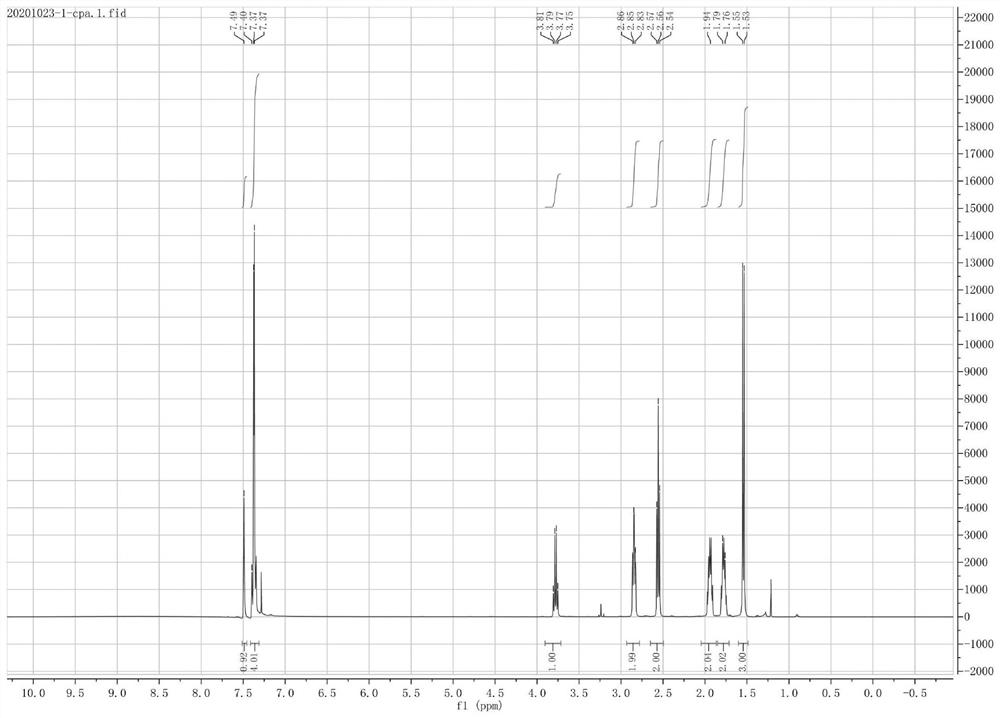

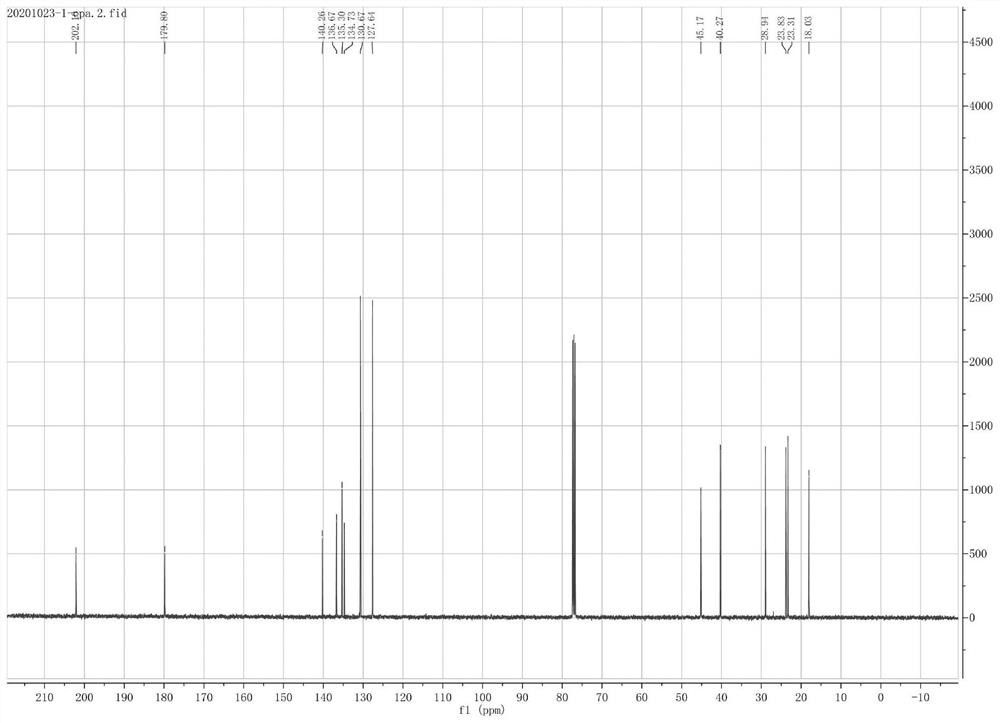

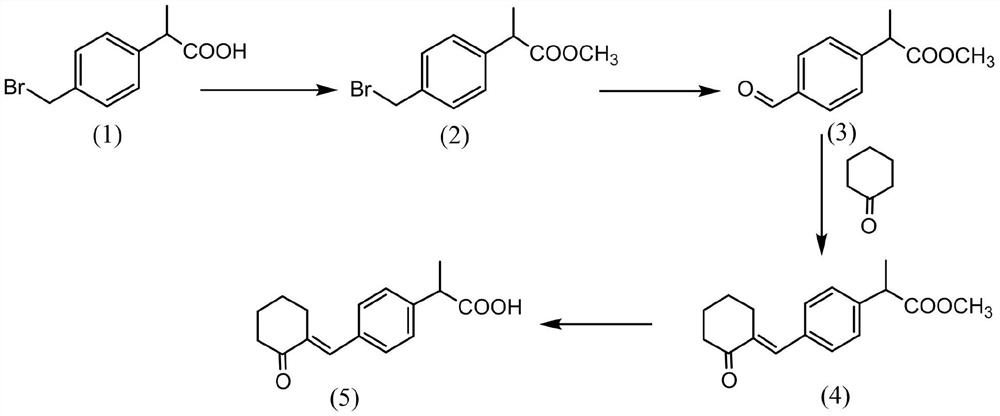

Preparation process of pebiprofen

InactiveCN113149826APost-processing is simpleMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationPropanoic acidNon steroid anti inflammatory drug

The invention belongs to the field of chemistry, and particularly relates to a novel process for preparing a phenylpropionic acid non-steroidal anti-inflammatory drug pebiprofen. According to the invention, 2-(4-bromomethyl phenyl) propionic acid which is easy to obtain is used as a starting raw material, and the product is prepared by four steps of esterification, hydroformylation, condensation and hydrolysis reaction. The method has the characteristics of simplicity in operation, high reaction selectivity, few byproducts and high product quality.

Owner:台州市源众药业有限公司 +1

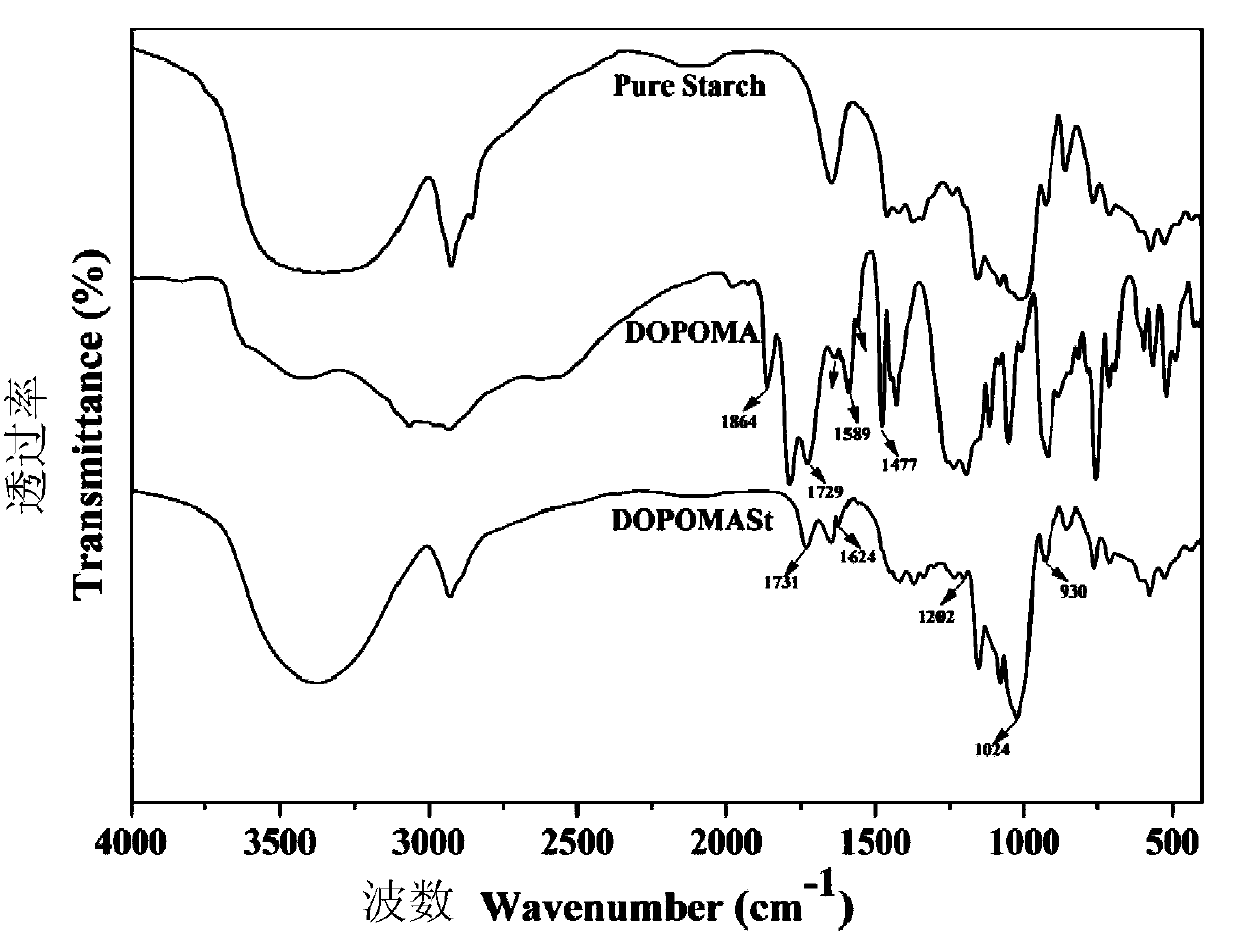

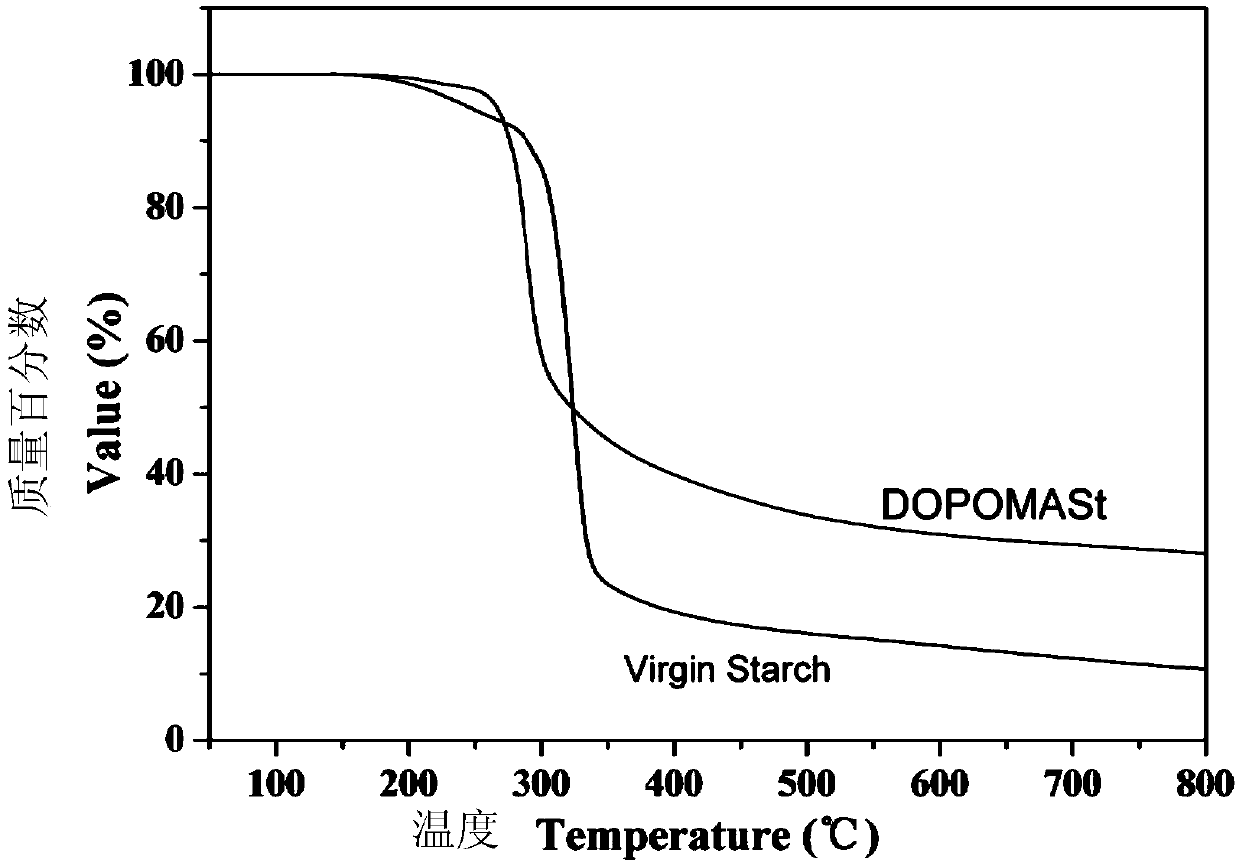

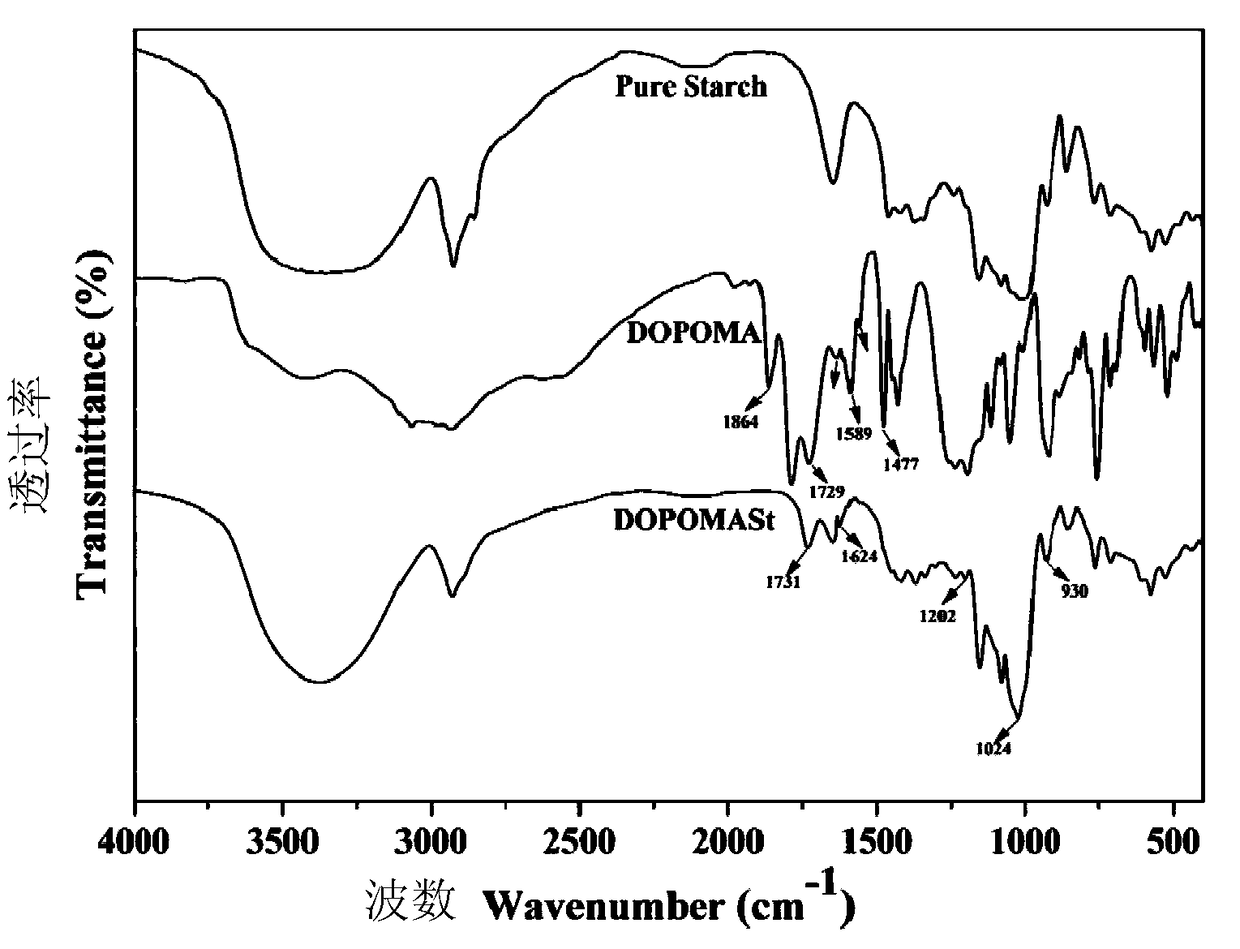

A kind of bio-based phosphorus-containing starch and its preparation method and application

The invention discloses bio-based phosphoric starch and a preparation method and application thereof. The preparation method comprises the steps that 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, maleic anhydride and a first organic solvent are mixed, reflux reaction is performed at the temperature of 40-100 DEG C and under protective gas for 12-36 hours, reduced pressure distillation and drying are performed to obtain a product 1; starch, a catalyst and a second organic solvent are mixed, heating activation is performed at the temperature of 60-120 DEG C and under protective gas for 2-24 hours to obtain an activated starch solution; the product 1 is added to the cooled activated starch solution, reaction continues at the temperature of 30-90 DEG C and under protective gas for 12-64 hours, and washing and drying are performed to obtain the bio-based phosphoric starch. The bio-based phosphoric starch has high grafting rate and high phosphorus content, both the thermal stability of the obtained bio-based phosphoric starch and the compatibility with a matrix resin interface are significantly improved, and the practical application requirements can be met.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing N-ethoxy oxalyl alanine ethyl ester

ActiveCN102311360BReduce pollutionHas acid catalytic activityOrganic compound preparationCarboxylic acid amides preparationDiethyl oxalateSide reaction

The invention discloses a method for preparing N-ethoxy oxalyl alanine ethyl ester. The method comprises the following steps: heating and dissolving alanine, oxalic acid and alcohol, and then adding a catalyst, a water-carrying agent benzene and diethyl oxalate, wherein the catalyst is a mixture of sulfuric acid and urea in a molar ratio of 1: (1-3); heating the obtained mixture to 60-100 DEG C; carrying out reflux rectification reaction for 10-150 hours, wherein in the process of reaction, the water produced in the process of reaction is timely evaporated by using the water-carrying agent benzene; and after the reaction is finished, carrying out after-treatment so as to obtain a target product, namely, the N-ethoxy oxalyl-alanine ethyl ester. Compared with the prior art, the method disclosed by the invention has the following advantages that: the catalyst is the mixture of sulfuric acid and urea, therefore, the catalyst has acidity catalytic activity and contains ammonium salt cations, and the ammonium salt cations can be adsorbed on the surface of metal, thereby reducing the corrosion of the catalyst on equipment; and meanwhile, the catalytic efficiency is high, the reaction yield is high, and the side reaction is less.

Owner:HUBEI HUISHENG PHARMA

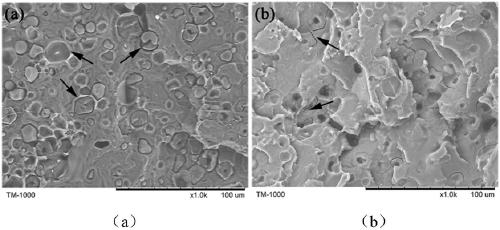

A polylactic acid/starch intumescent flame-retardant composite material and its preparation method

The invention discloses a polylactic acid / starch expansion flame-resistant composite material with excellent flame resistance, and a preparation method thereof. The polylactic acid / starch expansion flame-resistant composite material is composed of, by weight, 60 to 89% of polylactic acid, 5 to 30% of an acid source, 5 to 30% of a modified starch, and 1 to 15% of a gas source. In a preferred embodiment, the modified starch is phosphorized maleic anhydride grafting modified starch (bio-based phosphorus containing starch). According to the preparation method, polylactic acid possesses excellent compatibility with the modified starch; synergistic effect of the acid source, the carbon source (the modified starch), and the gas source is capable of improving charring forming capability of the polylactic acid matrix, and improving high temperature stability and flame resistance of polylactic acid greatly. According to the preparation method, adoption of an existing double-screw extruder is enough for production; preparation is simple and convenient; and the preparation method is convenient for industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

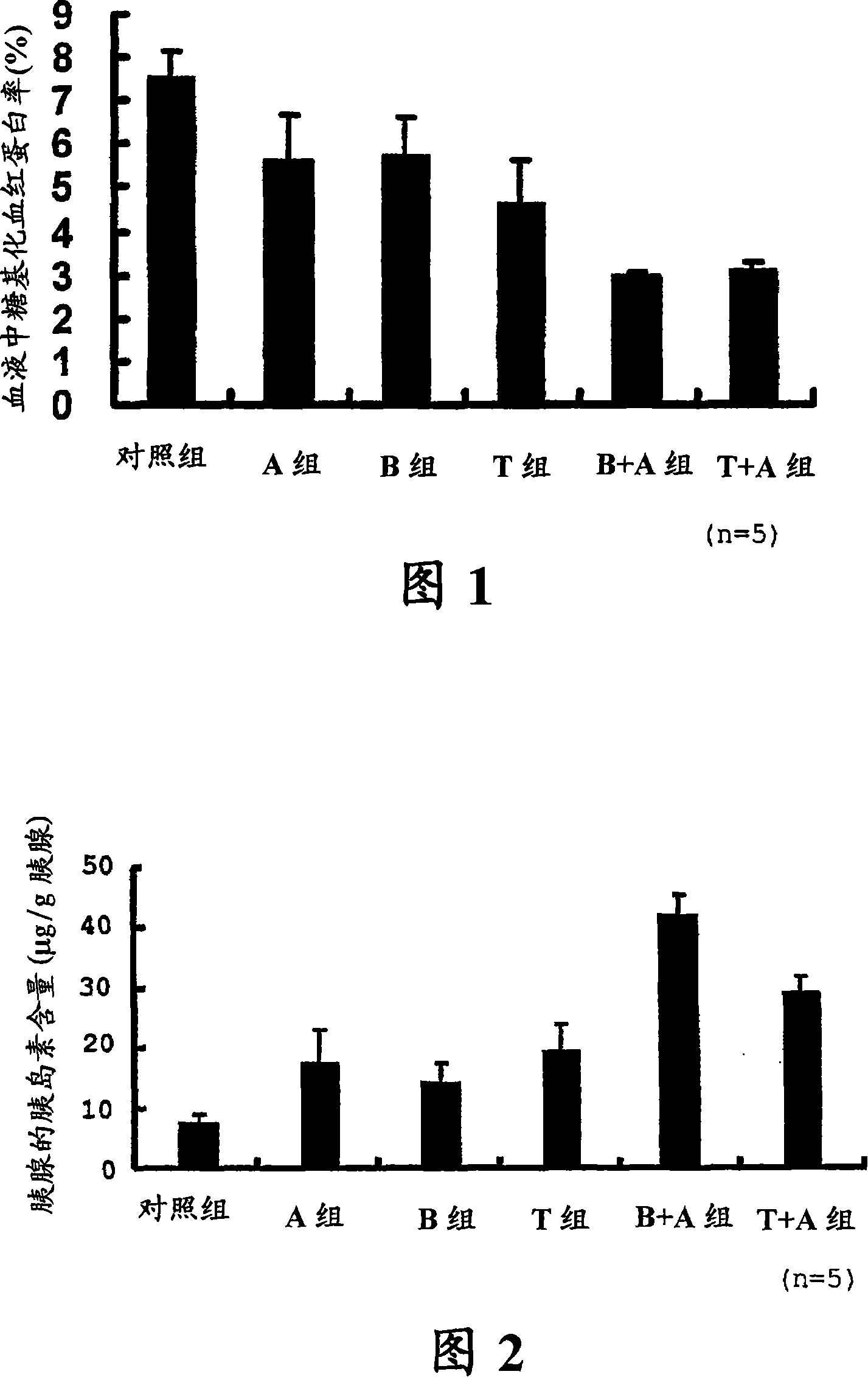

Pharmaceutical composition containing fbpase-inhibiting agent

InactiveCN101115483AGood hypoglycemic effectImprove blood sugarOrganic active ingredientsMetabolism disorderDiabetes mellitusDepressant

A pharmaceutical composition containing an FBPase inhibitor and an insulin sensitizer which is 5-[4-(6-methoxy-1-methyl-1H-benzimidazol-2-ylmethoxy)benzyl]thiazolidine-2,4-dione or a pharmacologically acceptable salt thereof; and a method for preventing or treating diabetes mellitus by administering the composition to a human.

Owner:DAIICHI SANKYO CO LTD

Method for efficiently and environmentally friendly preparing dibutyl itaconate on basis of heterogeneous catalysis

InactiveCN109485563AEasy to separateSimple post-processingOrganic compound preparationCarboxylic acid esters preparationSolid acidReaction temperature

The invention discloses a method for efficiently preparing dibutyl itaconate on the basis of heterogeneous catalysis. Particularly, an efficient solid acid catalyst is adopted, itaconic acid and n-butanol are catalyzed heterogeneously to react without a water-carrying agent to generate the dibutyl itaconate under the conditions that the reaction temperature is 100-140 DEG C and the reaction time is 2-5 hours; and the solid acid catalyst hydrogenated macroporous strong acid type cation exchange resin. Compared with a traditional proton acid catalysis method, the method has the characteristics that 1, the catalytic efficiency is high, the reaction time is short, and the energy consumption is low; 2, heterogeneous catalysis is carried out, a reaction product and a catalyst are easily separated, and aftertreatment is simple; 3, esterification reaction are gentle, and side reactions are less; and 4, after the catalyst is separated, the repeated utilization rate of the catalyst is high.

Owner:BEIJING UNIV OF CHEM TECH

Compound stabilizer for epoxidation reaction of unsaturated compound and application method thereof

ActiveCN102850298BImprove stabilityReduce usageOrganic chemistryEthylenediaminePotassium sodium tartrate

The invention discloses a compound stabilizer for the epoxidation reaction of an unsaturated compound and an application method of the compound stabilizer. The compound stabilizer comprises carbamide, ethylene diamine tetraacetic acid, potassium sodium tartrate and sodium silicate. Peroxide and a peroxoic acid stabilizer including the ethylene diamine tetraacetic acid, the potassium sodium tartrate, concentrated sulfuric acid and 732 resin are uniformly mixed; the addition of the peroxoic acid stabilizer is 0.1 to 5 wt% of that of the peroxide; organic acid is dropwise added to the peroxide and the peroxoic acid stabilizer at 25 to 35 DEG C, so that peroxoic acid mixed solution is obtained after reaction; an epoxidation stabilizer including the carbamide, the ethylene diamine tetraacetic acid, and the potassium sodium tartrate and the sodium silicate is added into the unsaturated compound, and then the peroxoic acid mixed solution is added into the epoxidation stabilizer at 65 to 95 DEG C, so that an epoxidation compound is obtained after epoxidation reaction. The compound stabilizer has the advantages that the coordination of various stabilizers improves the stability of hydrogen peroxide and peroxoic acid in reaction solution, the frequency of the occurrence of secondary reaction is reduced, the reaction time is shortened, and the production cost is reduced.

Owner:甄曰菊

Enema for cleaning gut in rectoscopy

InactiveCN103655534ALess irritatingFewer side effectsHydroxy compound active ingredientsDigestive systemIrritationDocusate Sodium

The invention discloses enema liquid for cleaning gut in rectoscopy. The enema liquid is characterized in that each bottle of enema liquid is prepared from the following raw materials in parts by weight: 0.05-0.15 part of docusate sodium, 1-70 parts of sorbitol, 0.02-0.1 part of sodium benzoate, 0.1-0.3 part of methyl parahydroxybenzoats and a proper amount of water; the enema liquid disclosed by the invention has smaller irritation on human and can be generally tolerated; the enema liquid especially generates few side effects on people with allergic constitutions.

Owner:王海华

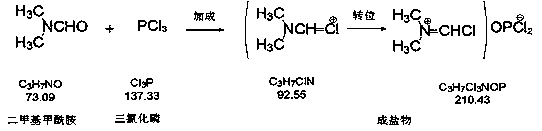

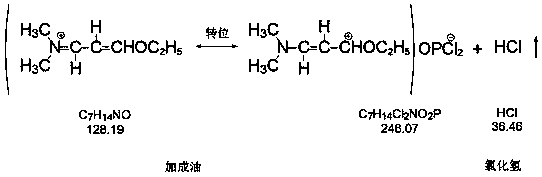

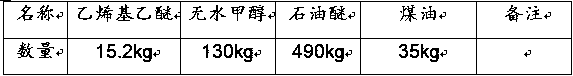

A kind of preparation and purification method of aldehyde oil methanol solution

ActiveCN107602412BHigh purityQuality improvementImino compound preparationWater methanolSulfadiazine

The invention relates to a medicinal intermediate and a purification method of the medicinal intermediate, in particular to a method for purifying an aldehyde-oil methanol solution. The aldehyde-oil methanol solution is prepared from ethyl vinyl ether, dimethylformamide and phosphorus trichloride, and a preparation method of the medicinal intermediate comprises the steps of: performing an additionreaction by adopting kerosene as solvent to prepare aldehyde oil, diluting the obtained aldehyde oil with anhydrous methanol, and carrying out extraction and purification with petroleum ether to obtain the medicinal intermediate, i.e., the aldehyde-oil methanol solution. The medicinal intermediate can be applied to the production of chemical raw material sulfadiazine products, wherein the petroleum ether, the kerosene, the ethyl vinyl ether and the anhydrous methanol can be reused after fractional distillation. The preparation method of the medicinal intermediate has the advantages of mild reaction conditions and high product yield, the aldehyde-oil methanol solution is good in quality and high in purity, and the improvement of the quality of the chemical raw material sulfadiazine products is facilitated; since the petroleum ether, the kerosene, the ethyl vinyl ether and the anhydrous methanol can be recycled and reused, material consumption can be reduced, postprocessing of the production of follow-up products can be reduced, and pollution on the environment can be reduced.

Owner:JILIN BEISHA PHARMA

Method for fully continuously preparing waterborne polyurethane through prepolymerization-emulsification

The invention discloses a process method for fully continuously preparing waterborne polyurethane through prepolymerization-emulsification. According to the method, a sonochemical enhanced double-screw extruder is used as a waterborne polyurethane prepolymerization and neutralization reactor, a static mixer and a tubular emulsifier are used as a prepolymer emulsification device, prepolymerization and emulsification are carried out continuously, the production efficiency is high, the cost is low, the product quality is stable, and the method is particularly suitable for producing high-solid-content waterborne polyurethane. More importantly, a special ultrasonic generator is additionally arranged in a specific area of the double-screw extruder to carry out sonochemical treatment on a prepolymerization intermediate, so that the reaction activity of materials can be remarkably improved, the prepolymerization reaction can be quickly completed at the low temperature of 70-80 DEG C in the later stage, the production process is energy-saving and environment-friendly, side reactions such as branching, crosslinking and degradation caused by high temperature in the later stage are avoided, and the obtained waterborne polyurethane is controllable in structure and stable in quality. The process method does not use any organic solvent, has no selectivity to raw materials, and is suitable for synthesis of any type of waterborne polyurethane.

Owner:SICHUAN UNIV

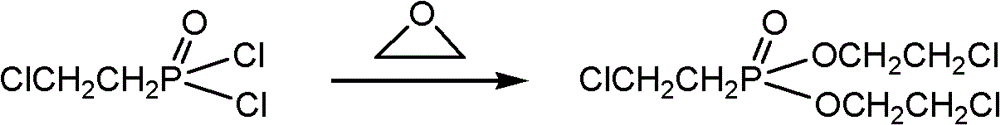

Method for preparing 2-chloroethylphosphonic acid bis(2-chloroethyl)ester

ActiveCN102382137BHigh purityHigh yieldGroup 5/15 element organic compoundsEthylene oxideReaction temperature

The invention discloses a method for preparing 2-chloroethylphosphonic acid bis(2-chloroethyl)ester. The method comprises the following steps of: adding ethylene oxide into 2-chloroethylphosphonic dichloride, reacting at the temperature of between 0 and 100DEG C for 8 to 18 hours, and removing residual ethylene oxide under reduced pressure to obtain a target product. The yield is more than or equal to 97 percent, the purity is more than or equal to 97.5 percent, the quality of the product is stable, and the product has a good application prospect.

Owner:SHANGHAI HUAYI GRP CO

A kind of prepolymerization-emulsification fully continuous method for preparing waterborne polyurethane

The invention discloses a process method for fully continuous preparation of water-based polyurethane by prepolymerization-emulsification. In this method, the sonochemically strengthened twin-screw extruder is used as the water-based polyurethane prepolymerization and neutralization reactor, and the static mixer and tubular emulsifier are used as the prepolymer emulsification device. The prepolymerization and emulsification are fully continuous, and the production efficiency is high. , low cost, stable product quality, especially suitable for the production of high-solid aqueous polyurethane. More importantly, in a specific area of the twin-screw extruder, a special ultrasonic generator is installed to perform sonochemical treatment on the prepolymerization intermediate, which can significantly improve the reactivity of the material, so that the late stage of the prepolymerization reaction can be at 70‑80 It is completed quickly under low temperature conditions, the production process is energy-saving and environmentally friendly, and side reactions such as branching, cross-linking, and degradation caused by high temperatures in the later stage are avoided. The obtained water-based polyurethane has a controllable structure and stable quality. The above process method does not use any organic solvent, has no selectivity to raw materials, and is applicable to the synthesis of any type of water-based polyurethane.

Owner:SICHUAN UNIV

A kind of one-component polyurethane sealant and low temperature, fast preparation method

ActiveCN111073584BHigh tensile strengthIncreased shear strengthPolyureas/polyurethane adhesivesPolymer scienceReaction temperature

A kind of one-component polyurethane sealant and the one-component polyurethane sealant of the low-temperature, fast preparation method have high tensile strength, shear strength and tear strength, moderate viscosity, and good storage stability; the single-component polyurethane sealant of the present invention The preparation method of the component polyurethane sealant takes a short time, and the preparation of the product can be completed in 2 to 3 hours, and the production efficiency is high; the reaction temperature during the preparation process does not exceed 100°C, the high-temperature reaction time is kept for a short time, and there are few side reactions. Low energy consumption, the preparation method of the one-component polyurethane sealant of the present invention, the preparation process is simple and easy to operate, and can be completed by using existing equipment, and the preparation of the prepolymer is no longer limited to the reaction kettle, which greatly reduces the Equipment cost and labor cost; the preparation process of the one-component polyurethane sealant of the present invention, the prepolymer molecule always coexists with the filler and the functional auxiliary molecule during the production and formation process, and the organic material and the inorganic material can better cooperate and interweave , The shear, tensile strength and elongation at break of the product.

Owner:SHANDONG NORTH MODERN CHEM IND

Preparation method of comb polymer phase change energy storage material

ActiveCN104356306BHigh crystallinityImprove thermal stabilityHeat-exchange elementsPolymer scienceSolvent

The invention discloses a preparation method of a comb-shaped polymer phase change energy storage material. The preparation method comprises the following steps: 1) adding polyethylene grafted maleic anhydride and alcohol with a hydroxyl active group on a terminal group, ether with a hydroxyl active group on a terminal group or mercaptan with a sulfydryl active group on a terminal group which are in a molar ratio of 1 to (0.5-5) into a reaction container, in the presence of nitrogen gas, adding an organic solvent subjected to water removal and a catalyst, and reacting for 6-12 hours at 60-120 DEG C to obtain reaction primary products; 2) cooling the reaction primary products, and washing and drying after removing the solvent to obtain the comb-shaped polymer phase change energy storage material. The preparation method disclosed by the invention is fewer in side reactions, high in yield, high in reaction speed, and convenient and simple in preparation. The prepared comb-shaped polymer phase change energy storage material has good crystallization property, thermal stability, setting performance and machinable property.

Owner:TIANJIN POLYTECHNIC UNIV

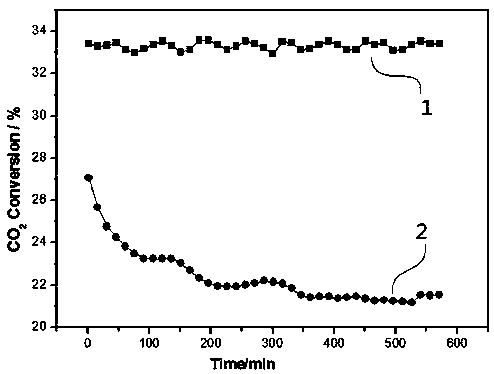

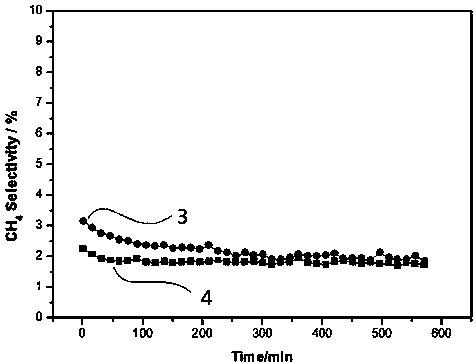

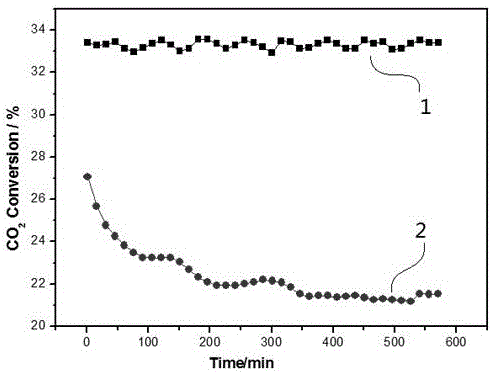

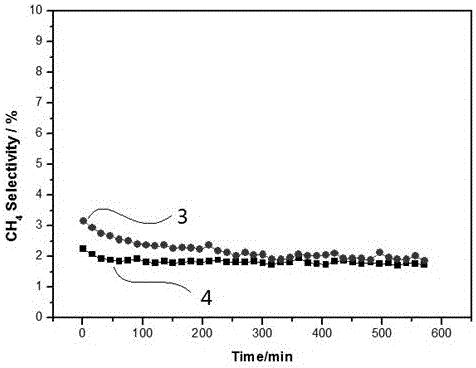

A mesoporous reverse water gas shift catalyst and its preparation method

ActiveCN106732743BImprove conversion rateFewer side effectsHydrogenMolecular sieve catalystsMethanationNanoparticle

The invention provides a mesoporous reversible water gas conversion catalyst and a preparation method thereof. The mesoporous reversible water gas conversion catalyst is prepared firstly by adopting a vacuum roasting manner. The beneficial effects are as follows: the mesoporous reversible water gas conversion catalyst is prepared by adopting a vacuum roasting method, the obtained catalyst is of a highly ordered porous structure, and an active ingredient Ni is highly dispersed into pore channels of an SBA-16 carrier in a nano-particle manner; the content of Ni is low, and the catalyst is free of methanation side effect; the catalyst is high in sintering resistance and high in stability; by using the prepared catalyst, the activity of catalyzing a carbon dioxide reversible water gas conversion reaction (CO-2+H2=CO+H2O) is high, the conversion rate of carbon dioxide is high, and the side reaction product methane is less; and the preparation steps are simple, the raw materials are wide in sources, and the economic value is high.

Owner:ZHEJIANG OCEAN UNIV

Mesoporous reversible water gas conversion catalyst and preparation method thereof

ActiveCN106732743AImprove conversion rateFewer side effectsHydrogenMolecular sieve catalystsMethanationNanoparticle

The invention provides a mesoporous reversible water gas conversion catalyst and a preparation method thereof. The mesoporous reversible water gas conversion catalyst is prepared firstly by adopting a vacuum roasting manner. The beneficial effects are as follows: the mesoporous reversible water gas conversion catalyst is prepared by adopting a vacuum roasting method, the obtained catalyst is of a highly ordered porous structure, and an active ingredient Ni is highly dispersed into pore channels of an SBA-16 carrier in a nano-particle manner; the content of Ni is low, and the catalyst is free of methanation side effect; the catalyst is high in sintering resistance and high in stability; by using the prepared catalyst, the activity of catalyzing a carbon dioxide reversible water gas conversion reaction (CO-2+H2=CO+H2O) is high, the conversion rate of carbon dioxide is high, and the side reaction product methane is less; and the preparation steps are simple, the raw materials are wide in sources, and the economic value is high.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com