A kind of preparation and purification method of aldehyde oil methanol solution

A methanol solution and purification method technology, applied in the preparation of imino compounds, organic chemistry, etc., can solve the problems of increasing the production cost of sulfadiazine products, not involving purification methods, affecting the safety of medication, etc., to improve labor productivity and reduce impurities , the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

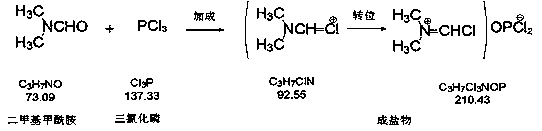

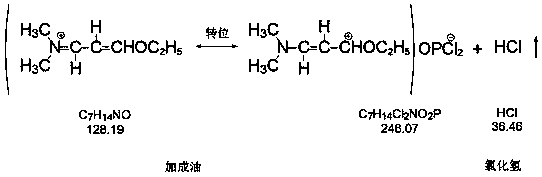

Method used

Image

Examples

Embodiment 1

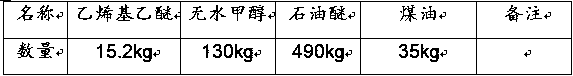

[0028] Ingredients: 340kg of vinyl ether, 306kg of dimethylformamide, 323kg of phosphorus trichloride, 1360kg of kerosene, 850kg of anhydrous methanol, 510kg of petroleum ether;

[0029] In a 3000L glass-lined addition reactor, add 1360kg of kerosene, turn on the chilled water to cool down to 29℃, add 91.8kg of dimethylformamide into the addition reactor, the temperature of the material rises to 40℃; after the addition, continue to cool to At 38°C, the remaining 214.2kg of dimethylformamide and 96.9kg of phosphorus trichloride were added dropwise at the same time. The process took 45 minutes for the material temperature to be 30-37°C, and the temperature was reduced to 35°C; then the remaining 226.1kg was added dropwise at the same time Phosphorus trichloride and 340kg vinyl ethyl ether, dripping takes 58 minutes, the material temperature during the dripping process is 32-35℃, after the dripping is completed, continue to stir for 10 minutes, the material liquid temperature is 34℃,...

Embodiment 2

[0037] Ingredients: 340kg of vinyl ether, 340kg of dimethylformamide, 357kg of phosphorus trichloride, 1530kg of kerosene, 1020kg of anhydrous methanol, 544kg of petroleum ether;

[0038] In a 3000L glass-lined addition reactor, add 1530kg of kerosene, turn on the chilled water to cool to 30℃, then add 119kg of dimethylformamide to the addition reactor, the material temperature will rise to 42℃; continue after adding Cool down to 38°C, start to add the remaining 221 dimethylformamide and 125kg phosphorus trichloride simultaneously. The dropping takes 50 minutes. The temperature of the materials during the dropping process is 30-38°C and the temperature is reduced to 35°C; then at the same time Add the remaining 232 phosphorus trichloride and 340 vinyl ethyl ether dropwise. The dropping time takes 65 minutes. The material temperature during the dropping process is 32-34°C. After the dropping is completed, continue to stir for 12 minutes. The material liquid temperature is 34°C. Af...

Embodiment 3

[0046] Ingredients: 340kg of vinyl ether, 289kg of dimethylformamide, 306kg of phosphorus trichloride, 1190kg of kerosene, 680kg of anhydrous methanol, 408kg of petroleum ether;

[0047] In a 3000L glass-lined addition reactor, add 1190kg of kerosene, turn on the chilled water to cool down to 28°C, then add 115.6kg of dimethylformamide into the addition kettle, the material temperature rises to 43°C; continue to cool down after the addition is complete When the temperature reaches 38°C, start to add the remaining 173.4kg of dimethylformamide and 122.4kg of phosphorus trichloride simultaneously. The addition takes 40 minutes. The temperature of the materials during the dropping process is 30-38°C and the temperature is reduced to 35°C; Add the remaining 183.6kg phosphorus trichloride and 340kg vinyl ethyl ether. The dripping takes 55 minutes. The material temperature during the dripping process is 32-34℃. After the dripping is completed, continue to stir for 10 minutes. The materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com