Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

267results about How to "Wide spread" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

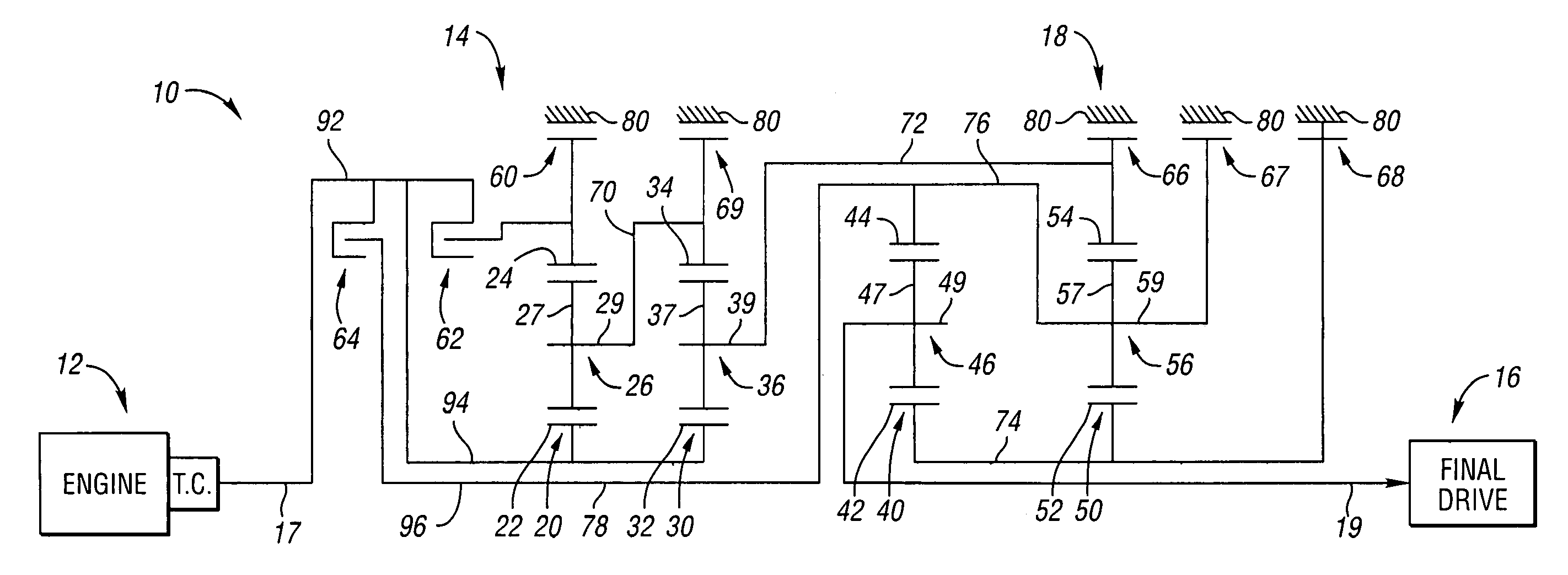

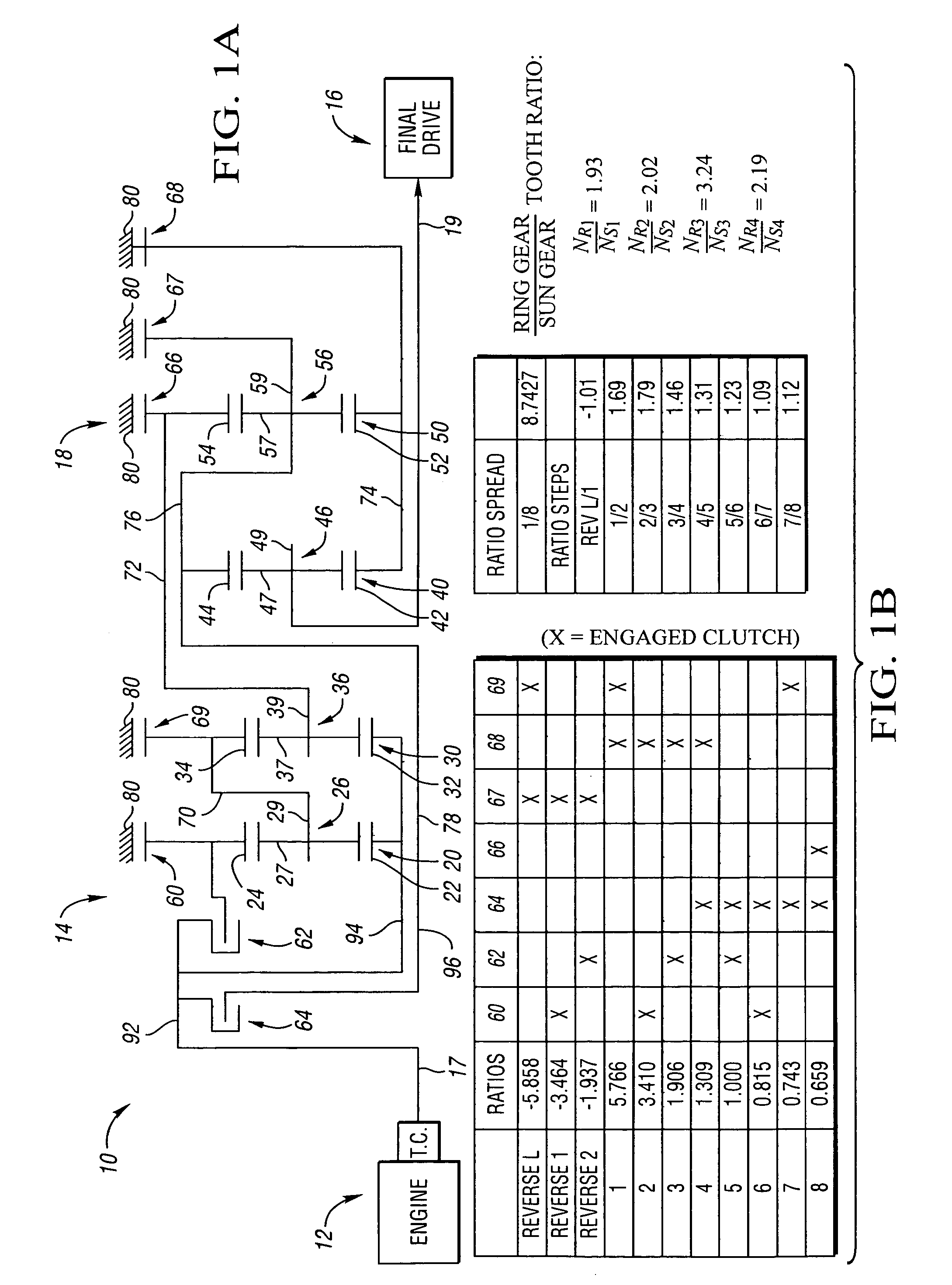

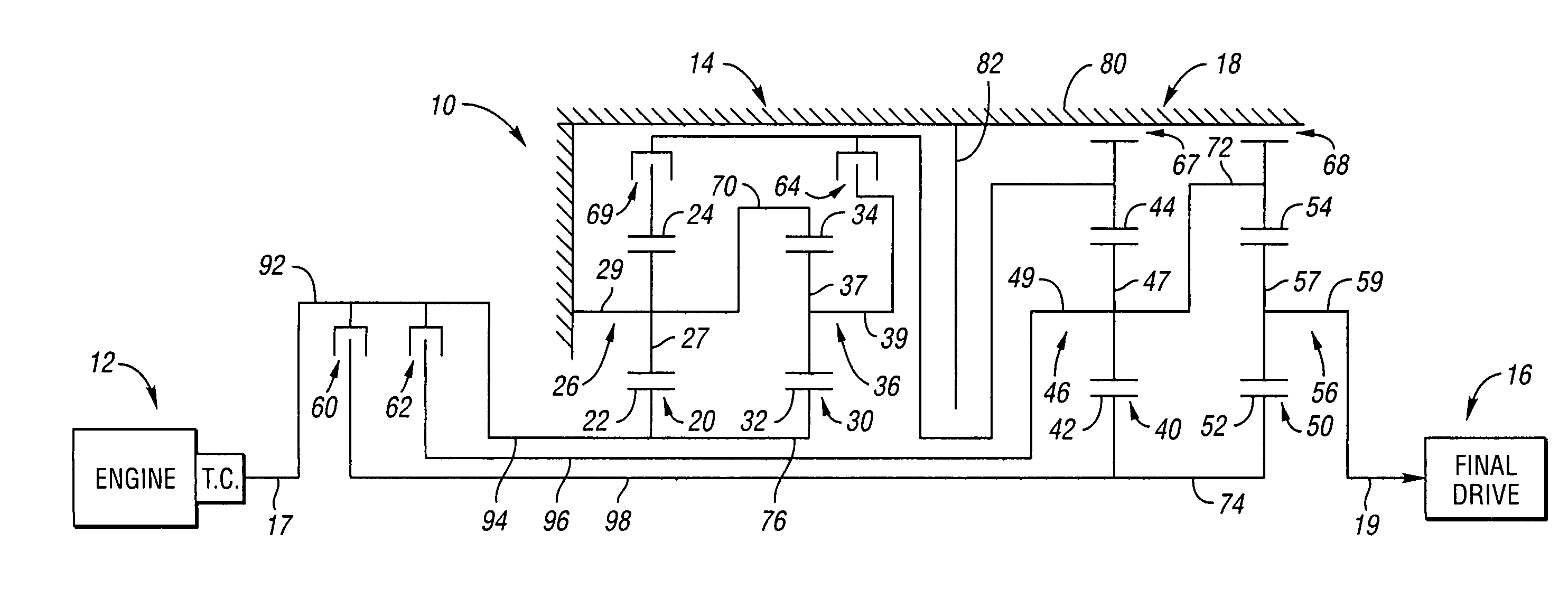

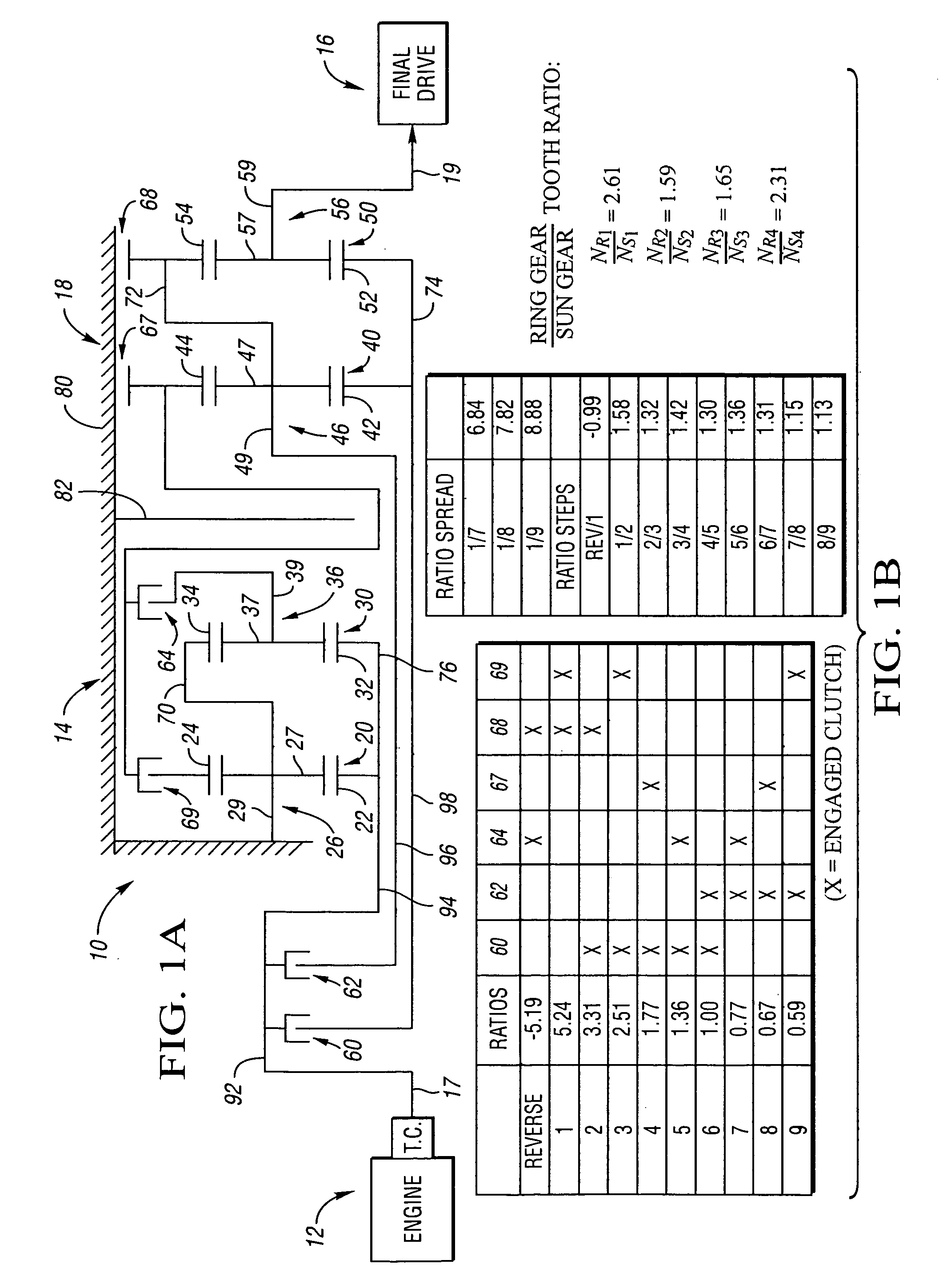

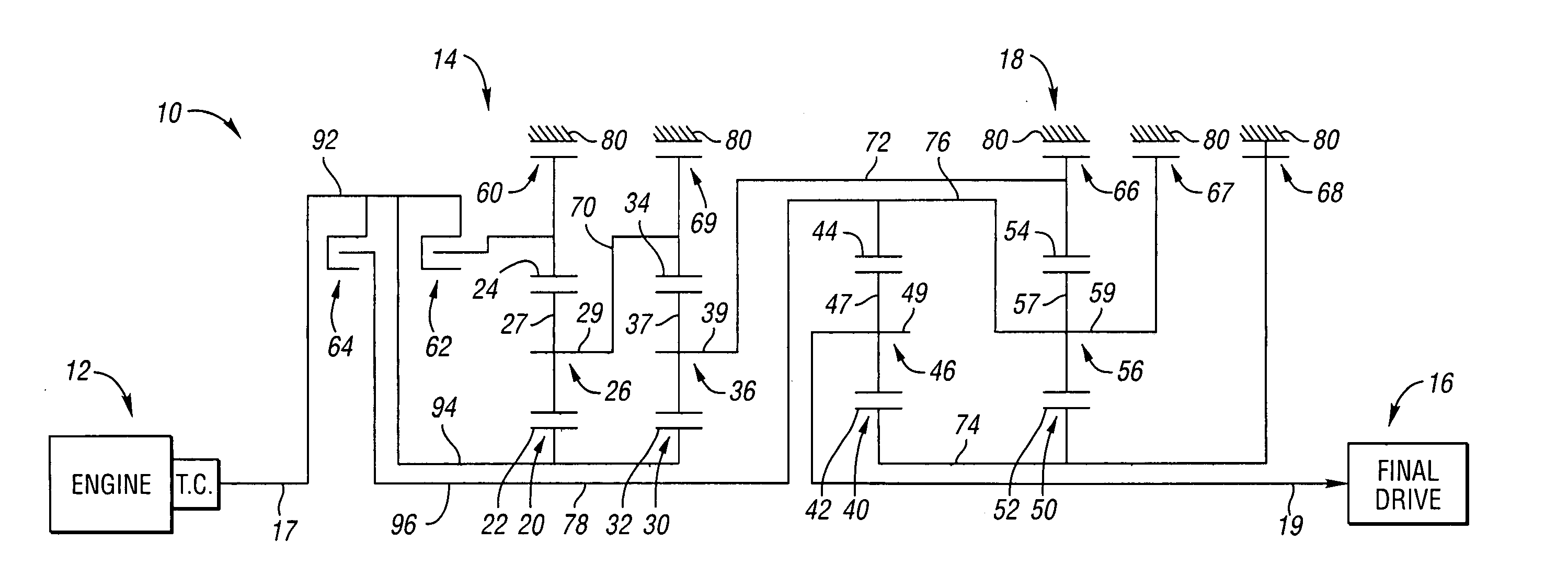

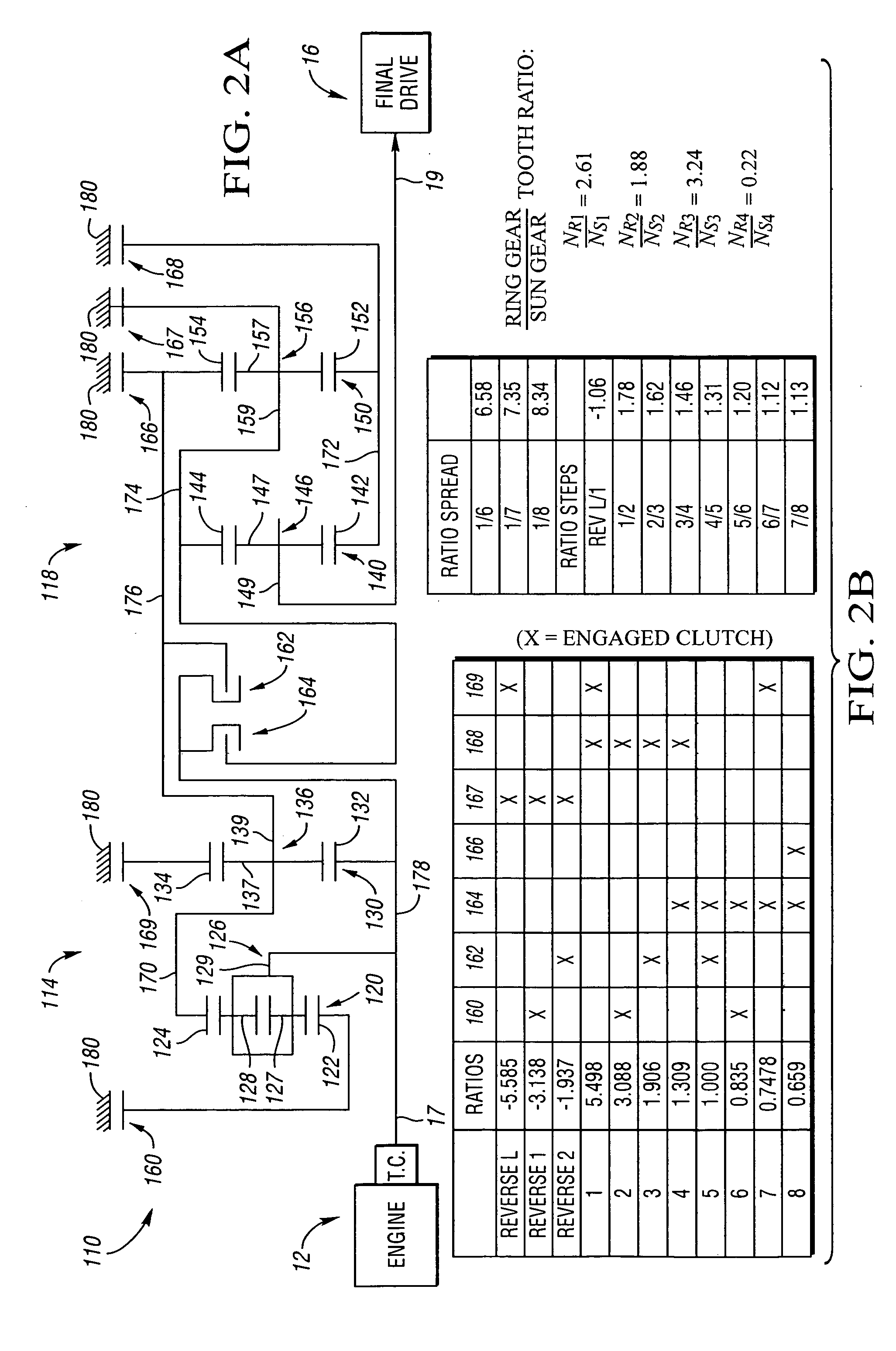

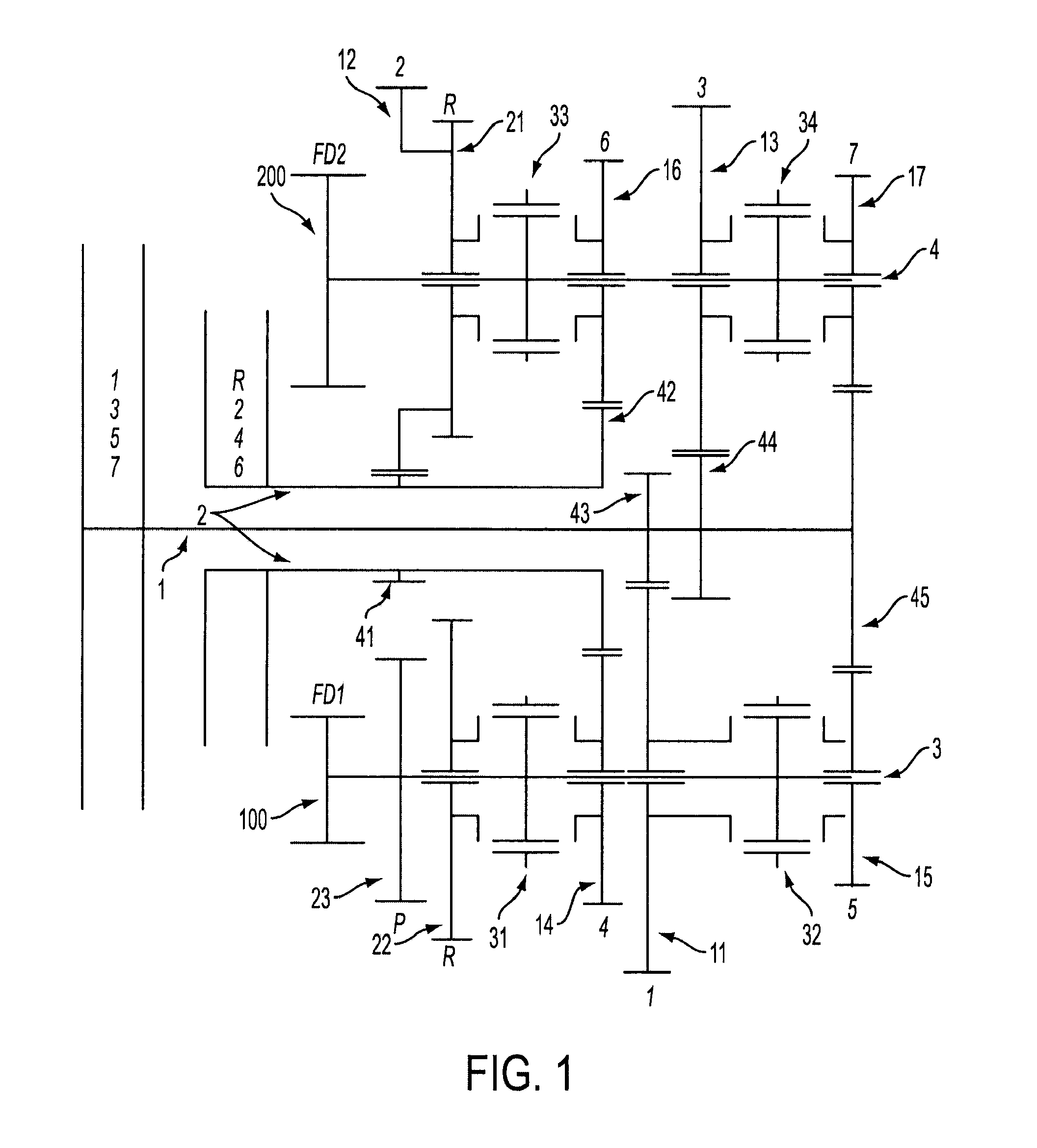

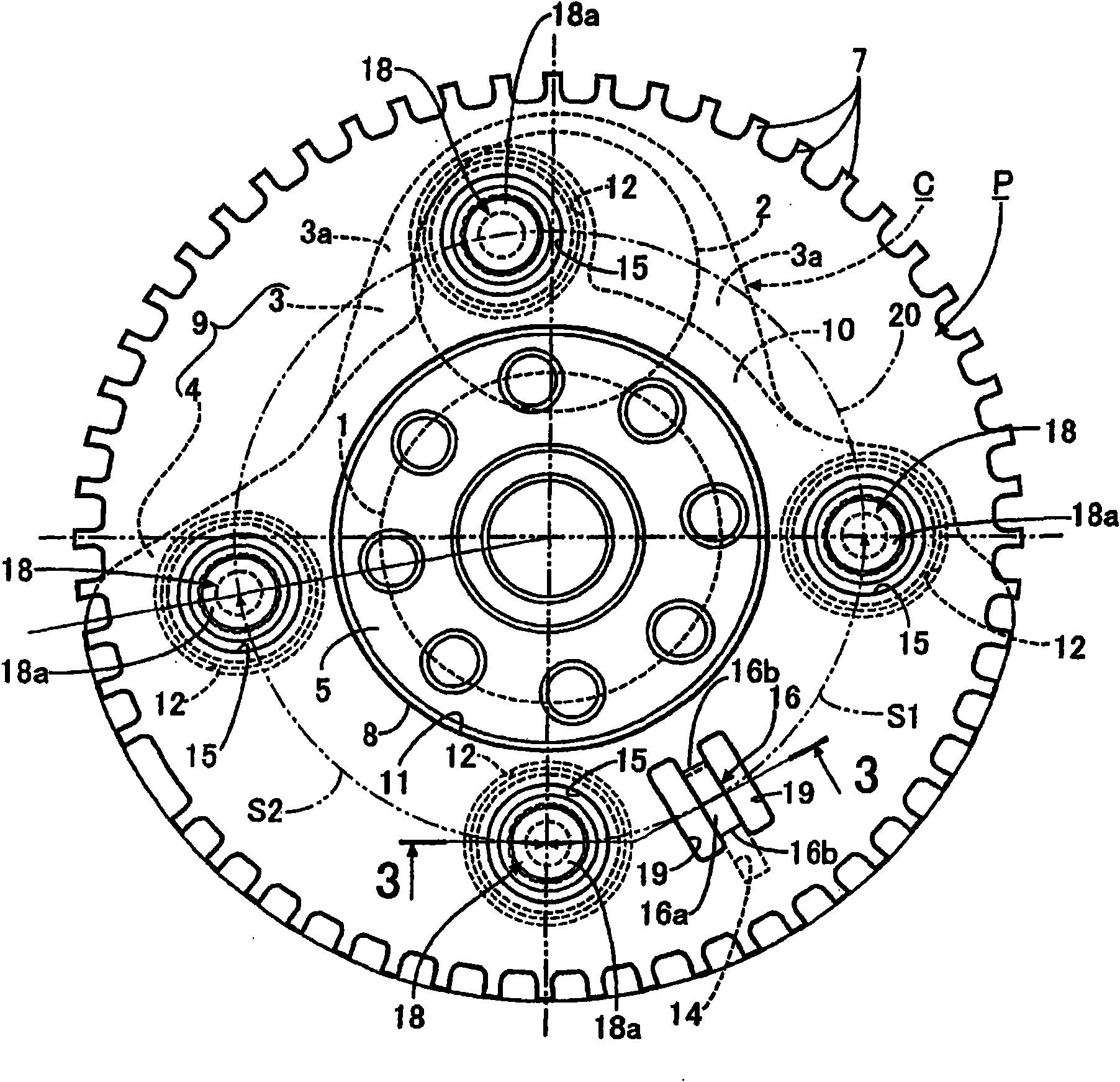

Eight-speed transmissions with four planetary gear sets

ActiveUS7163484B2Shorten speedLow sun gearToothed gearingsTransmission elementsGear wheelInterconnection

Owner:GM GLOBAL TECH OPERATIONS LLC

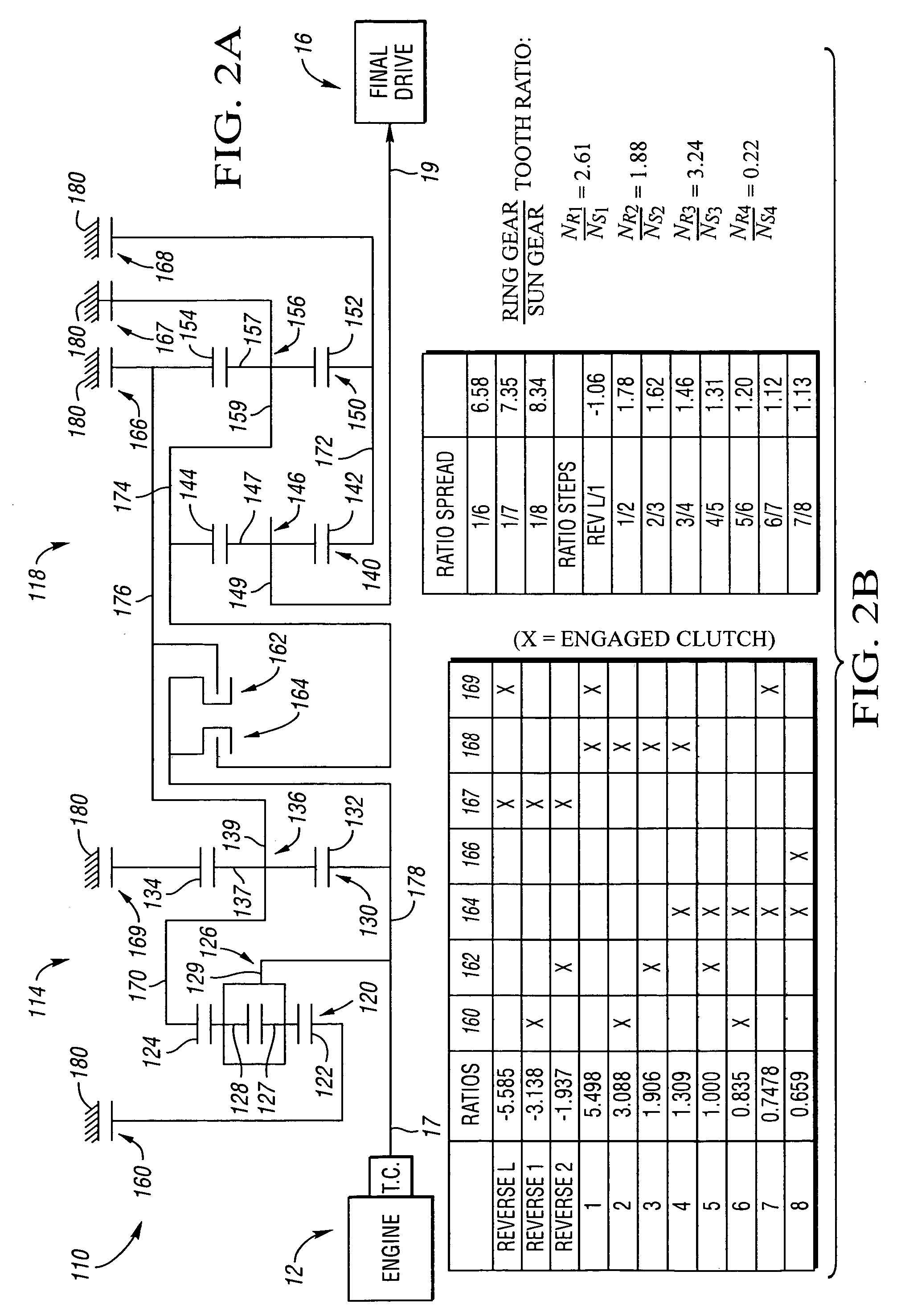

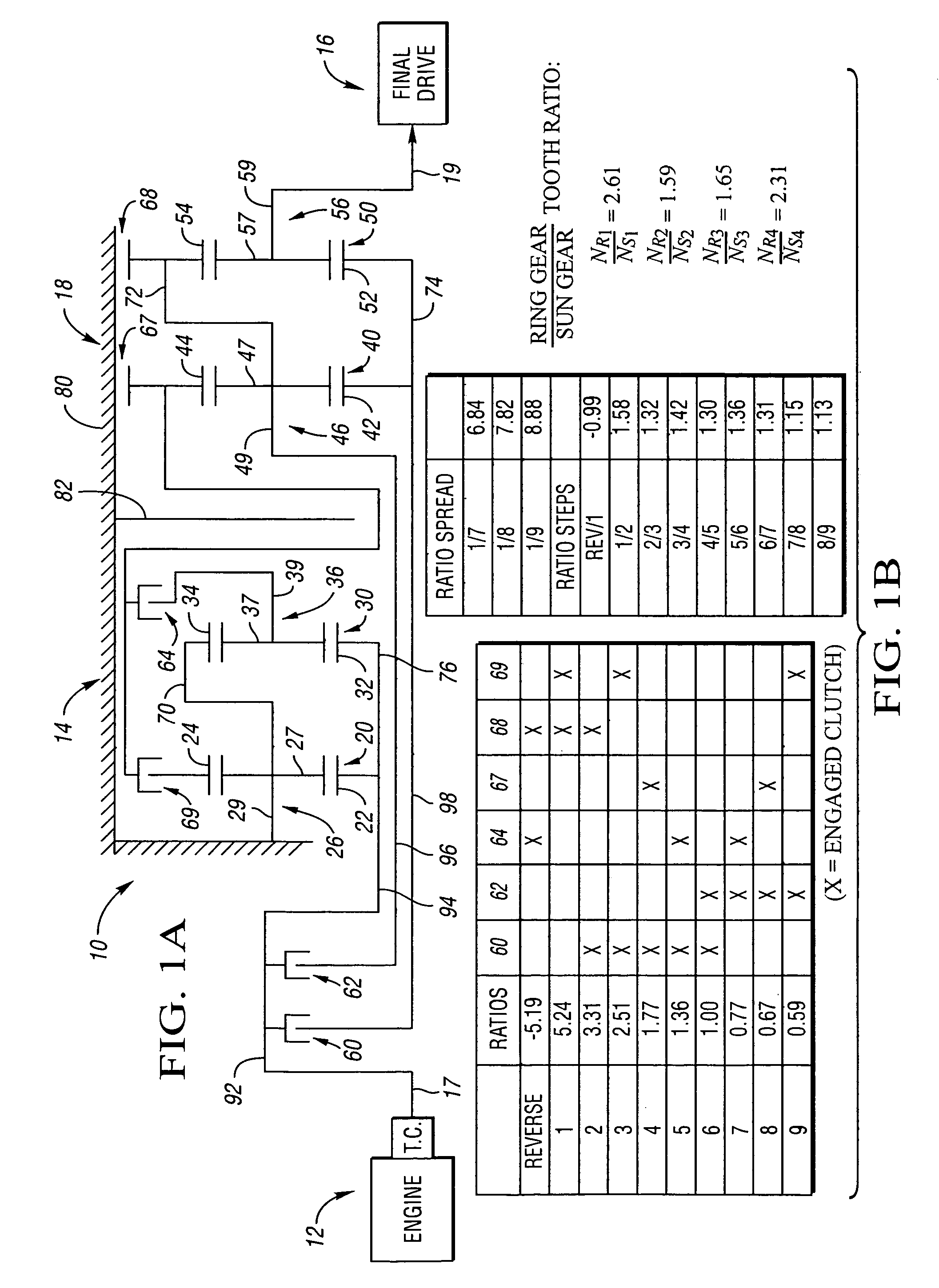

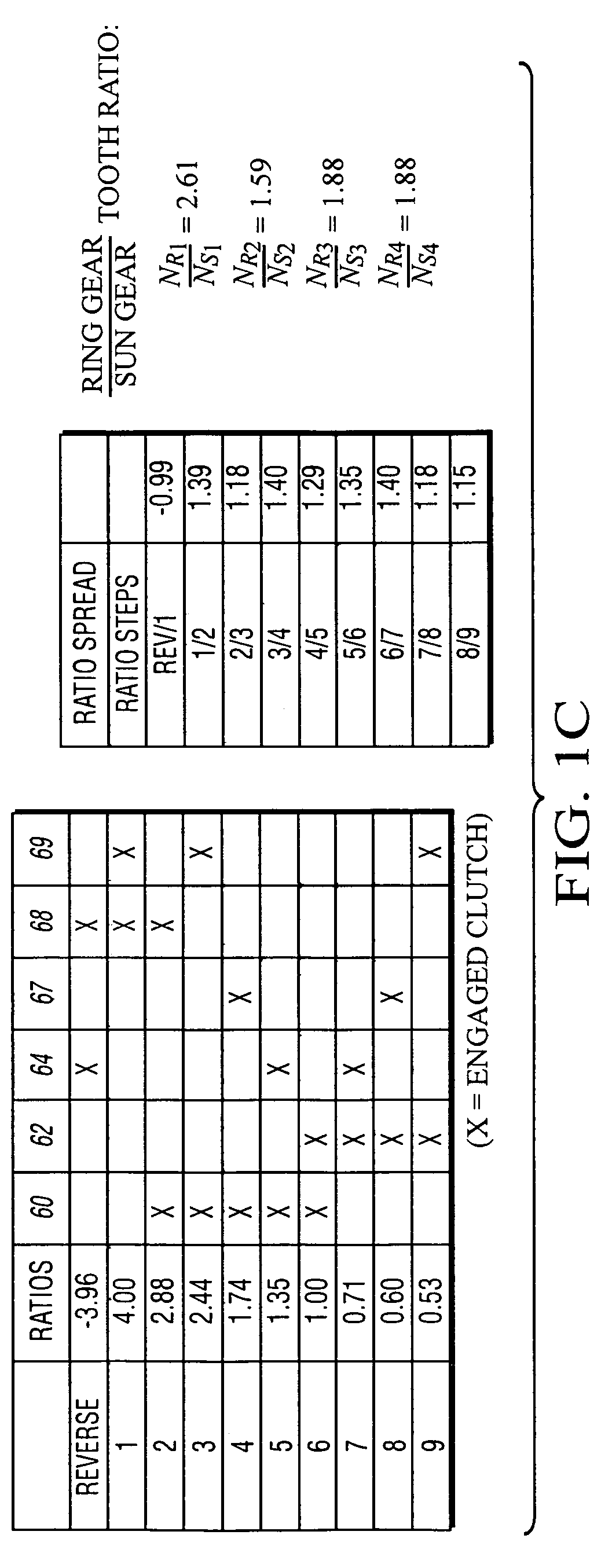

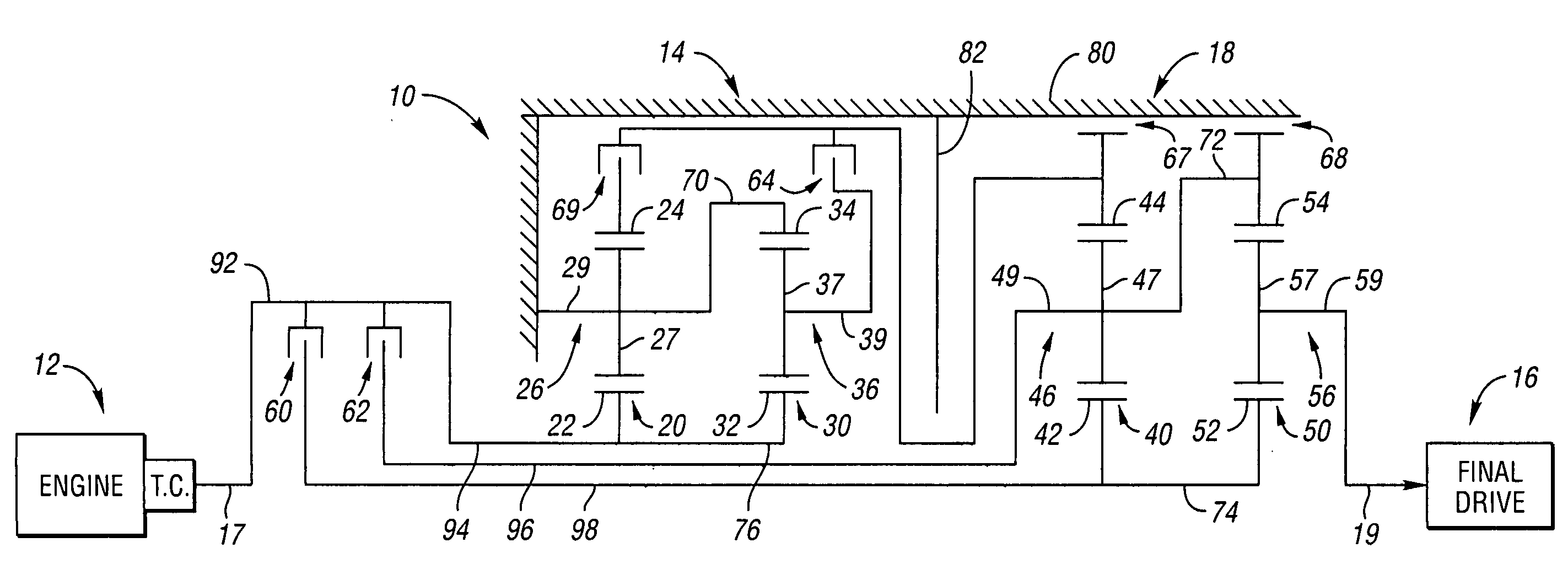

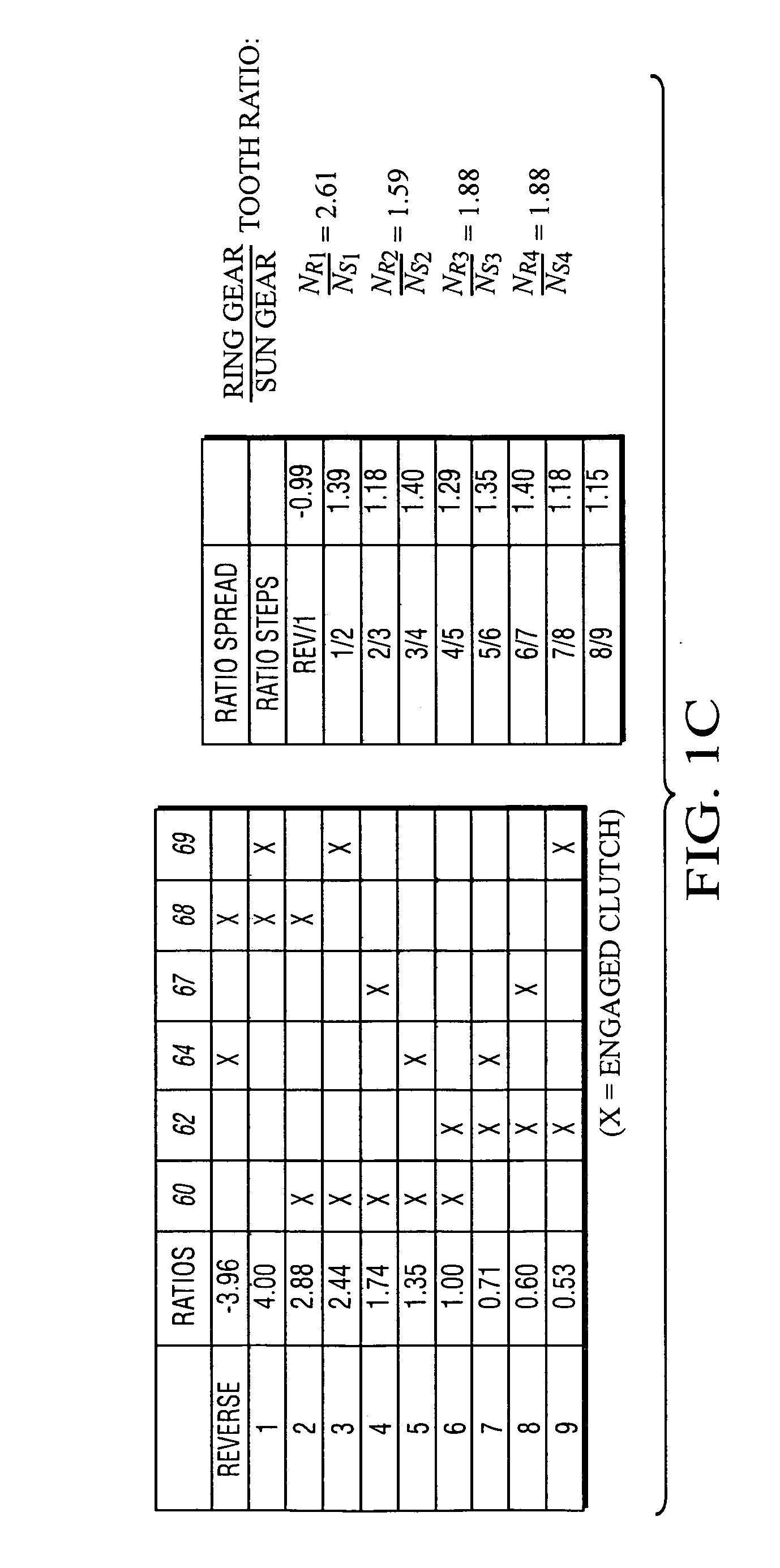

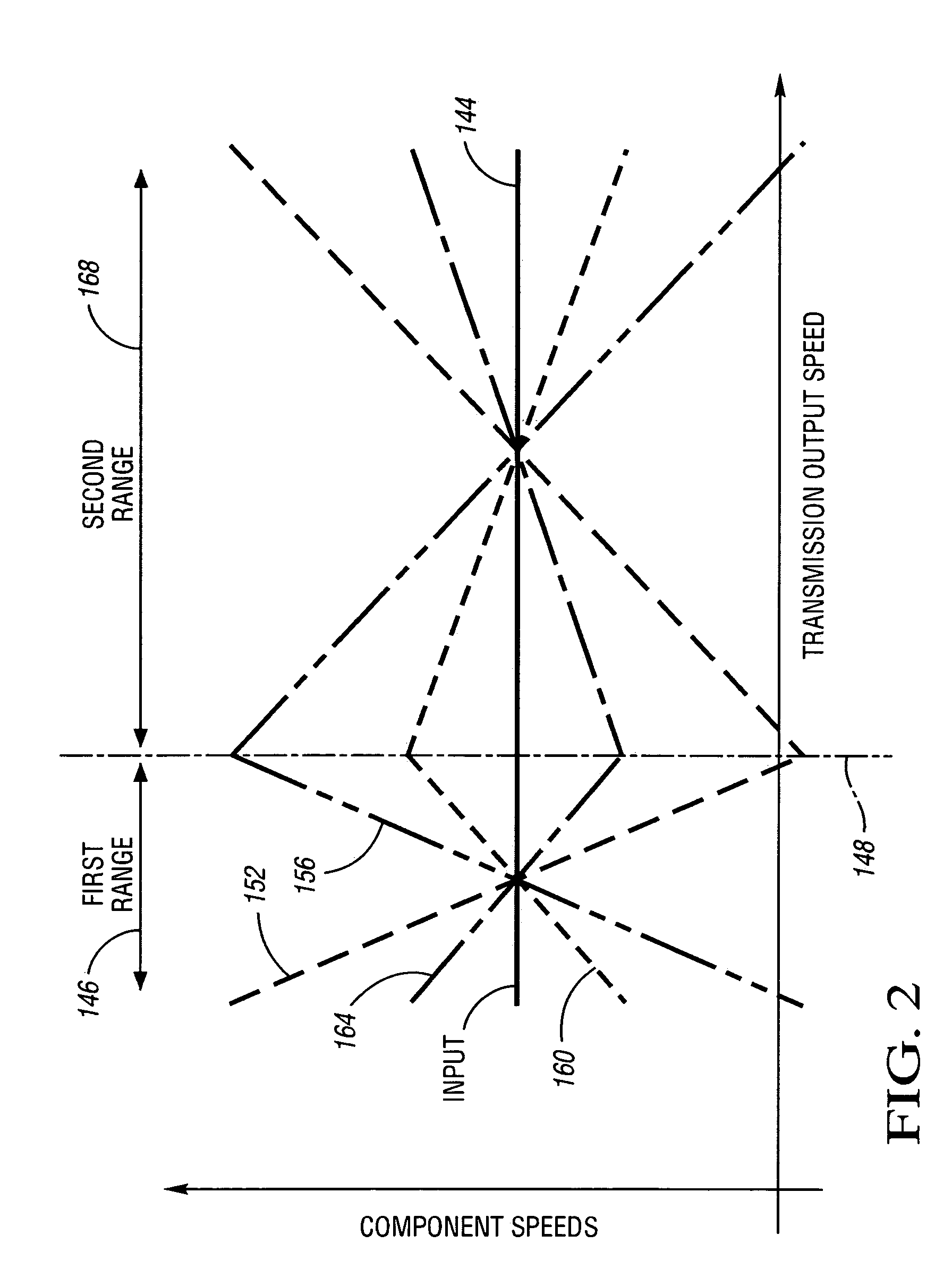

Nine-speed transmissions with four planetary gear sets

ActiveUS7226381B2Improve fuel economyImprove traction performanceToothed gearingsTransmission elementsGear wheelInterconnection

Nine-speed transmissions are provided that include four planetary gear sets having six torque-transmitting mechanisms and various fixed interconnections to provide nine forward speed ratios and a reverse speed ratio. The powertrain includes an engine and torque converter that is continuously connected to at least one of the planetary gear members and an output member that is continuously connected with another of the planetary gear members. The six torque-transmitting mechanisms are operated in combinations of two. Reduced component speeds and improved ratios are achieved.

Owner:GM GLOBAL TECH OPERATIONS LLC

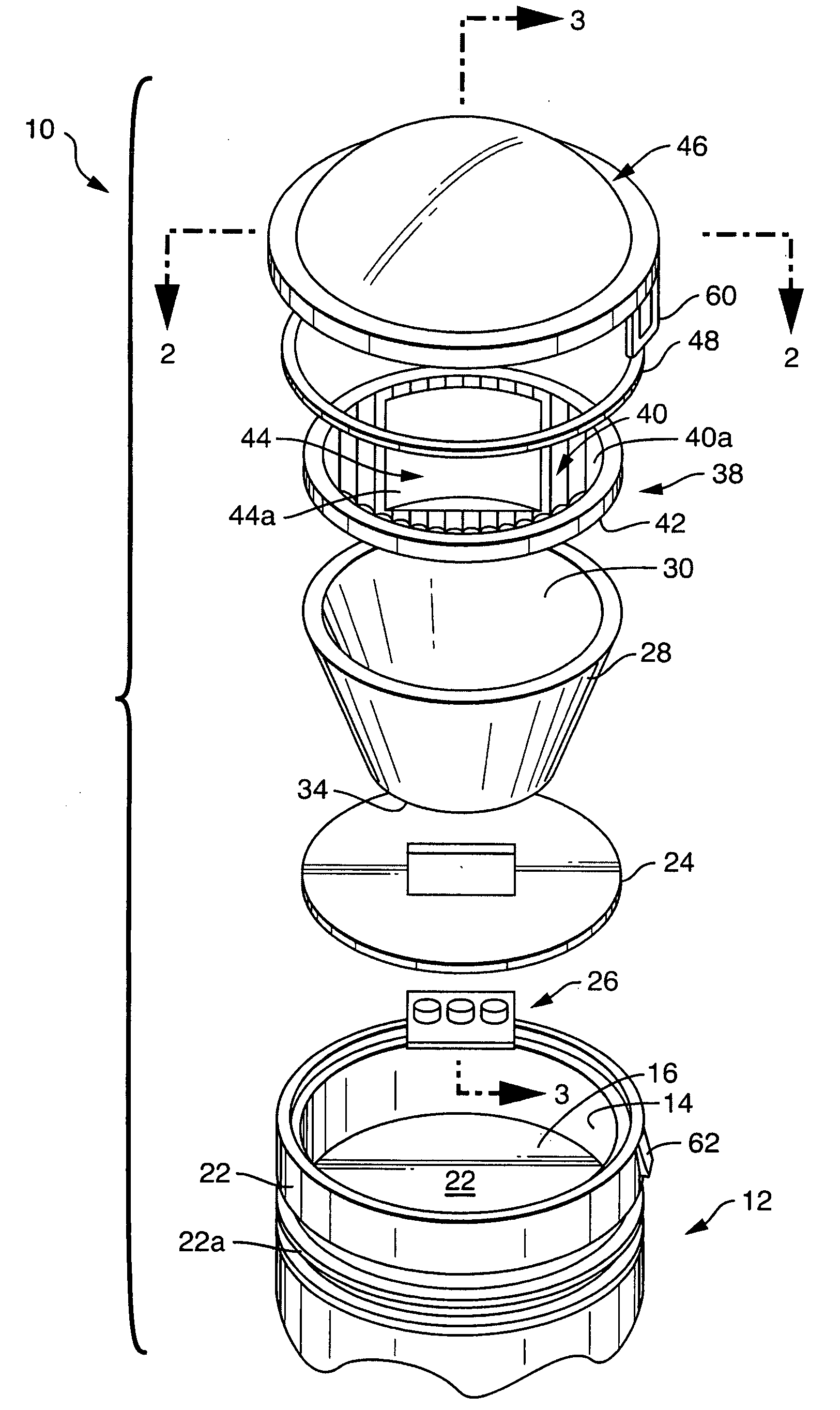

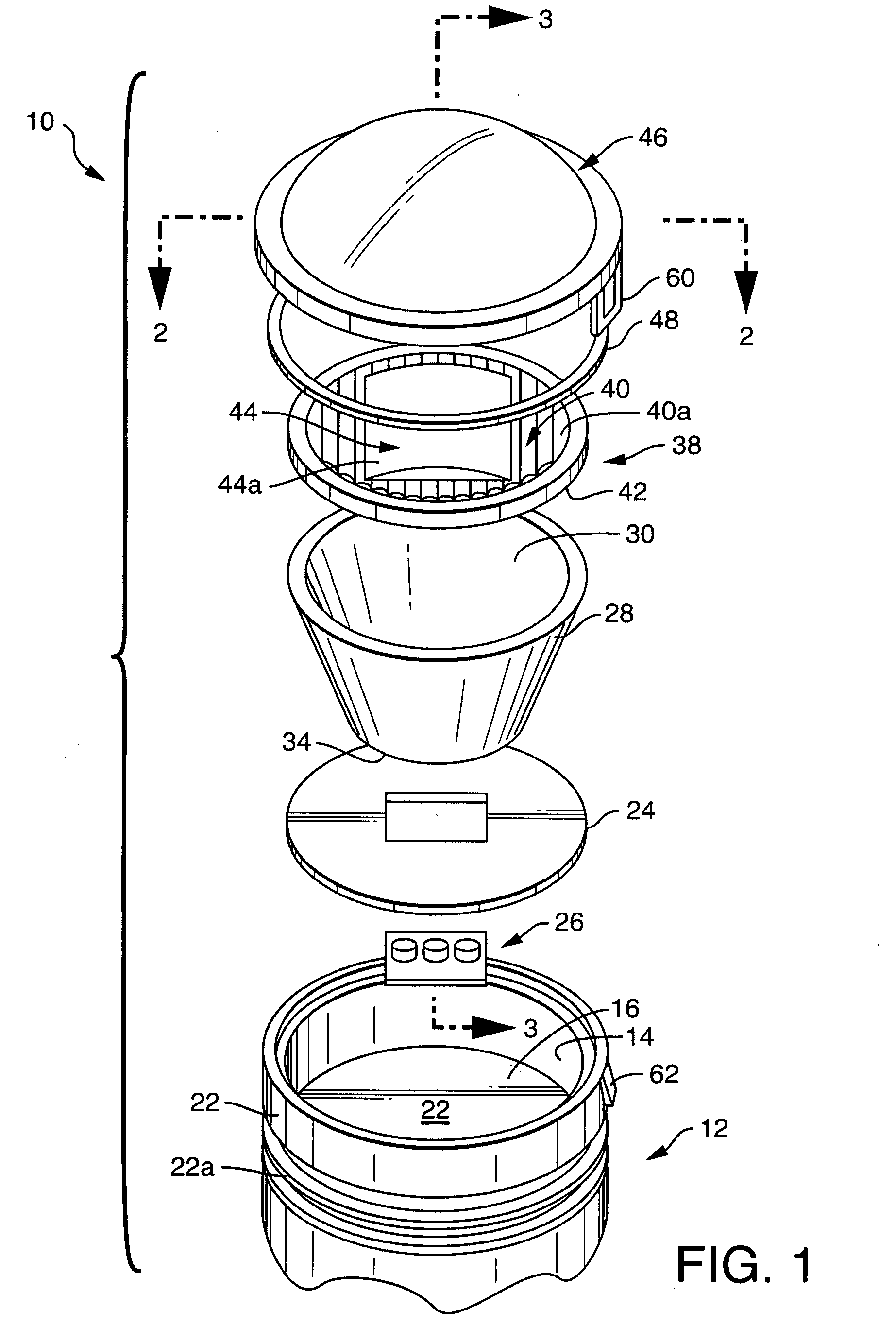

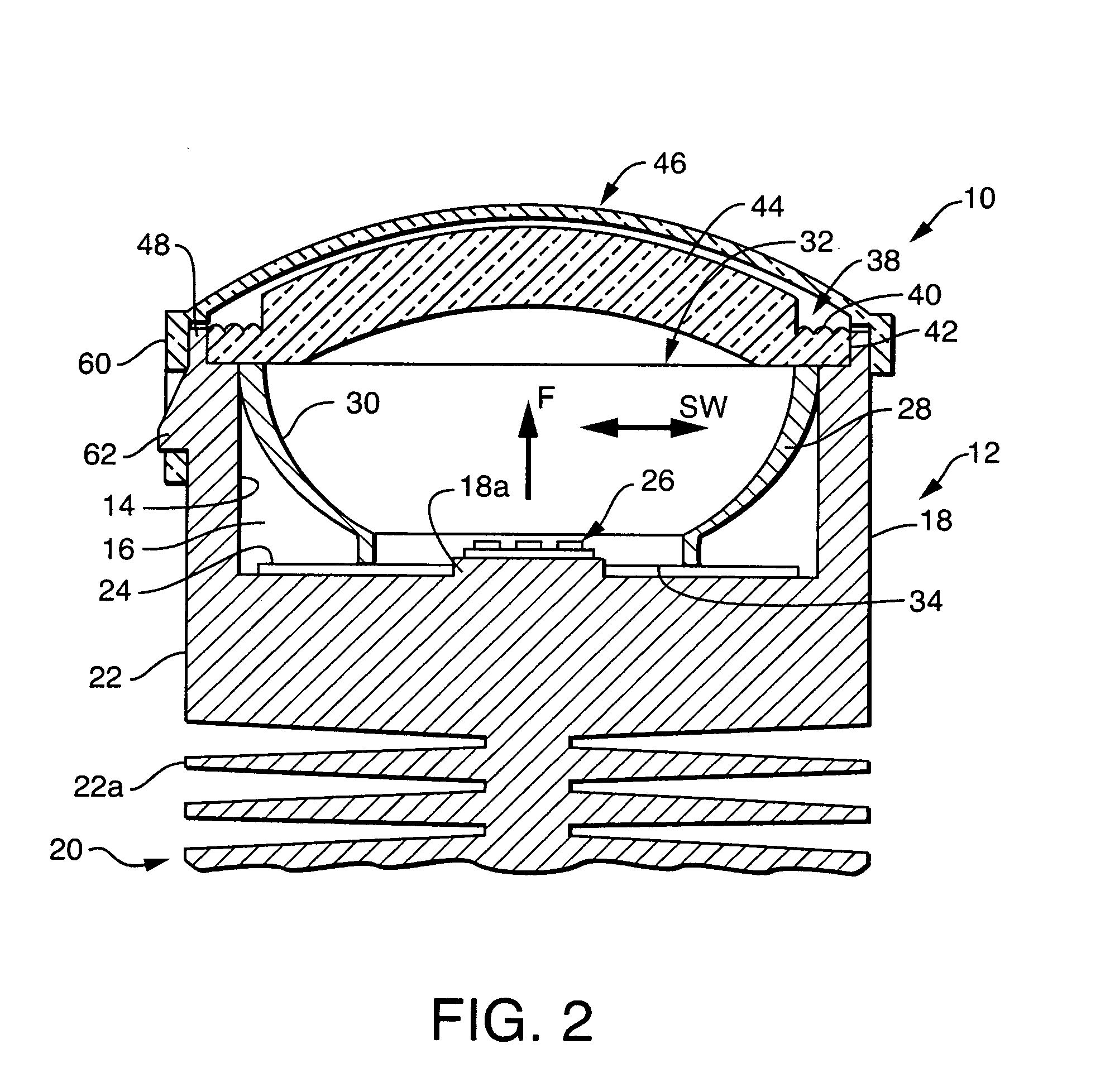

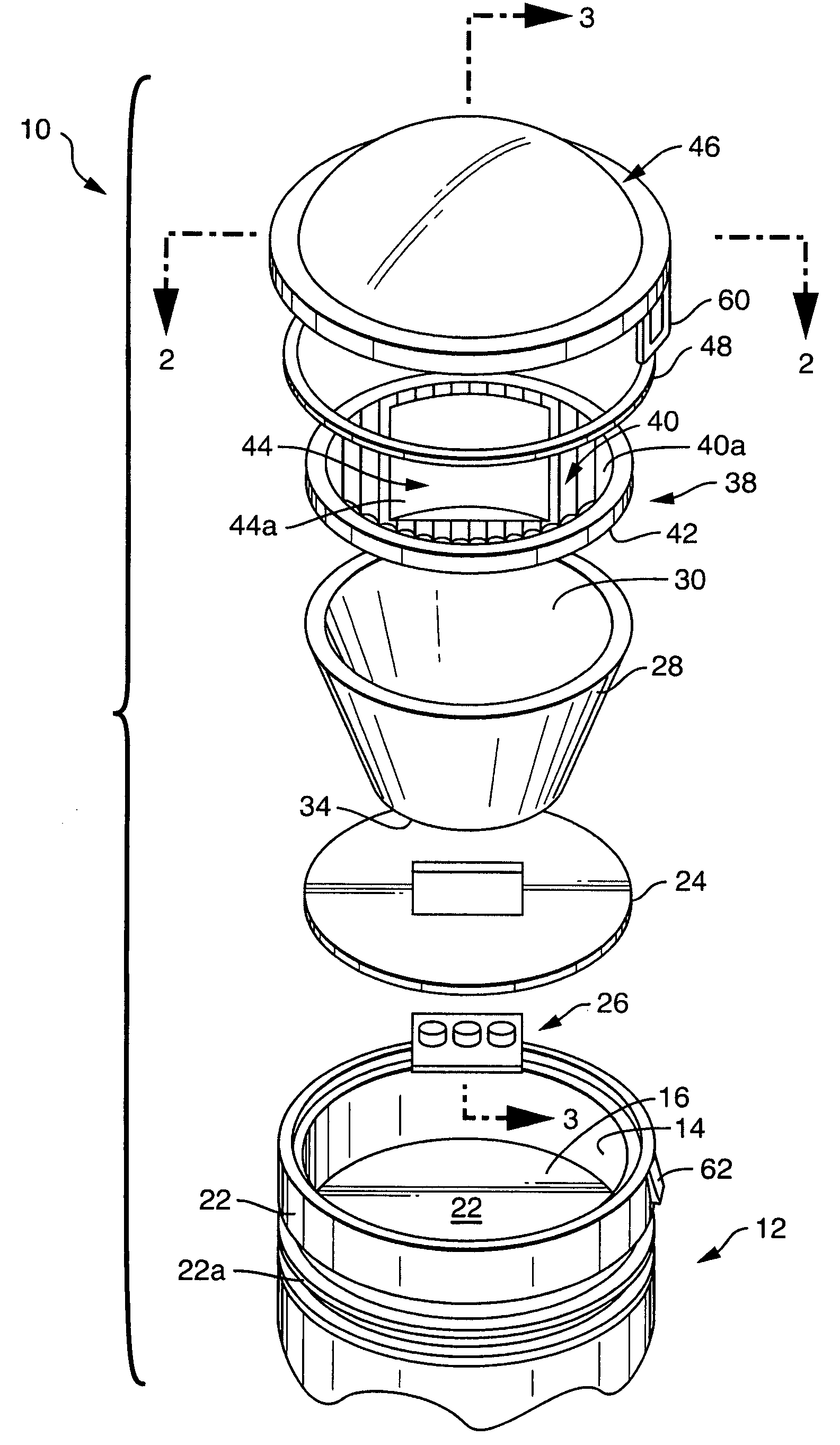

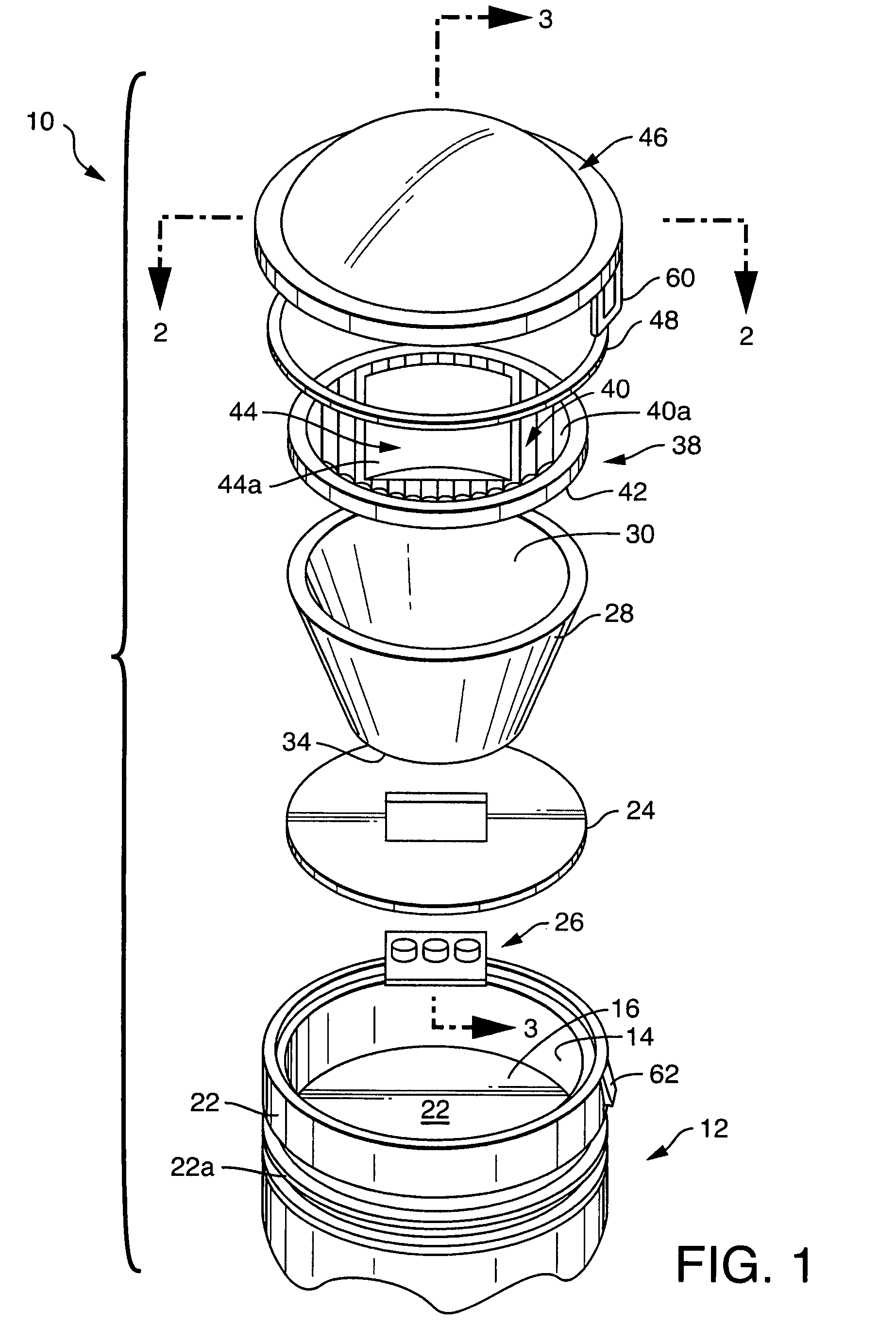

LED lamp module

InactiveUS20090003009A1Improve life expectancyImprove operationVehicle headlampsPoint-like light sourceEngineeringLED lamp

An LED lamp (10) has a housing (12) with an interior wall (14) defining a cavity (16). An LED light source (26) is positioned in the cavity (16) and project light in a forward direction. A reflector (28) having a reflective surface (30), a forward opening (32) and a rear opening (34) surrounds the light source (26) and a complex lens (38) closes the forward opening. The lens (38) comprises a first optical refractive element (40) arranged around a peripheral edge (42) and a second optical refractive element (44) centrally located on the lens (38); the first optical refractive element (40) including a plurality of flute lenses (40a) and the second optical refractive element (44) comprising a concavo-convex lens (44a).

Owner:OSRAM SYLVANIA INC

Nine-speed transmissions with four planetary gear sets

ActiveUS20060205556A1Improve fuel economyImprove traction performanceToothed gearingsTransmission elementsGear wheelEngineering

Nine-speed transmissions are provided that include four planetary gear sets having six torque-transmitting mechanisms and various fixed interconnections to provide nine forward speed ratios and a reverse speed ratio. The powertrain includes an engine and torque converter that is continuously connected to at least one of the planetary gear members and an output member that is continuously connected with another of the planetary gear members. The six torque-transmitting mechanisms are operated in combinations of two. Reduced component speeds and improved ratios are achieved.

Owner:GM GLOBAL TECH OPERATIONS LLC

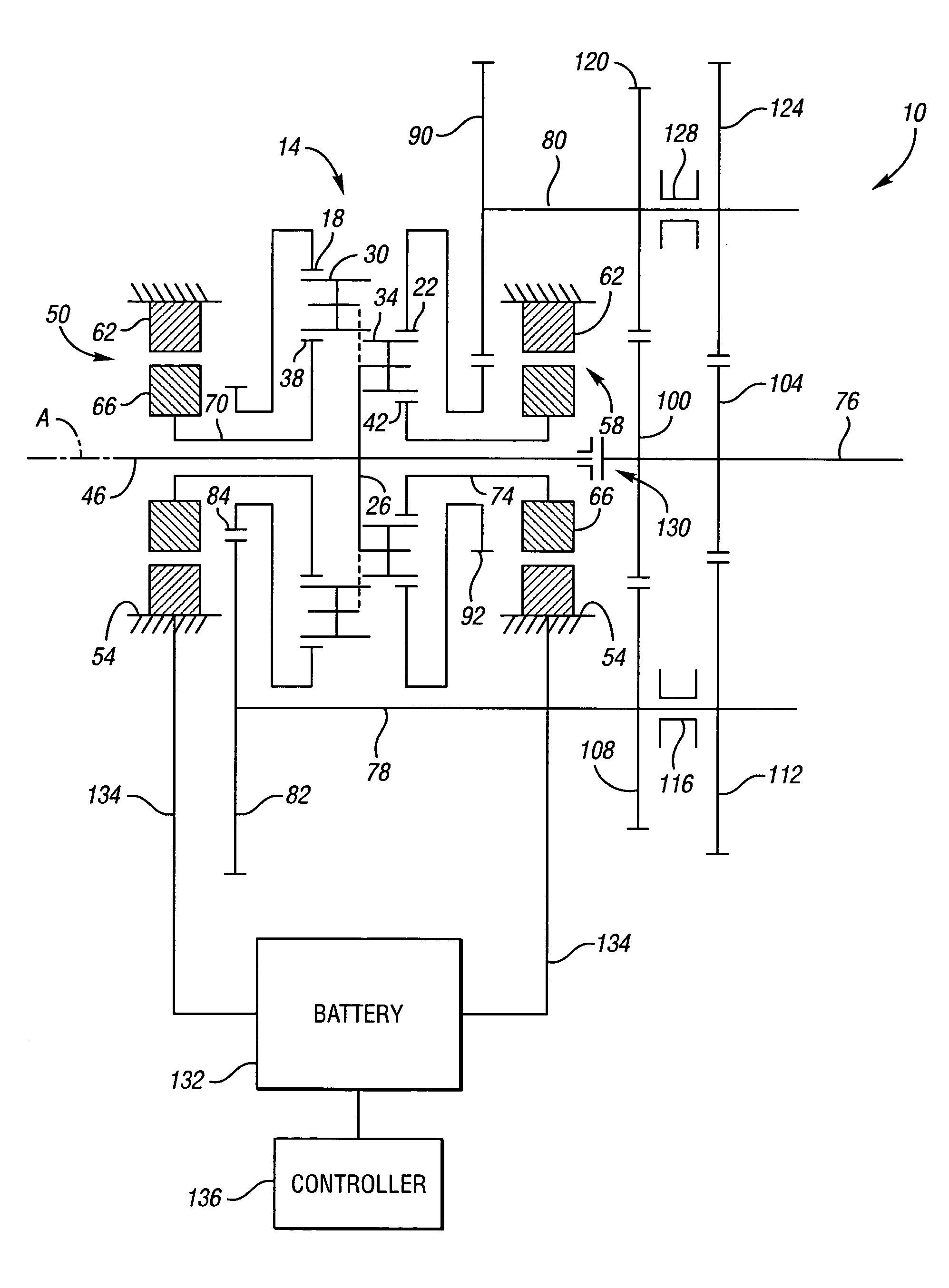

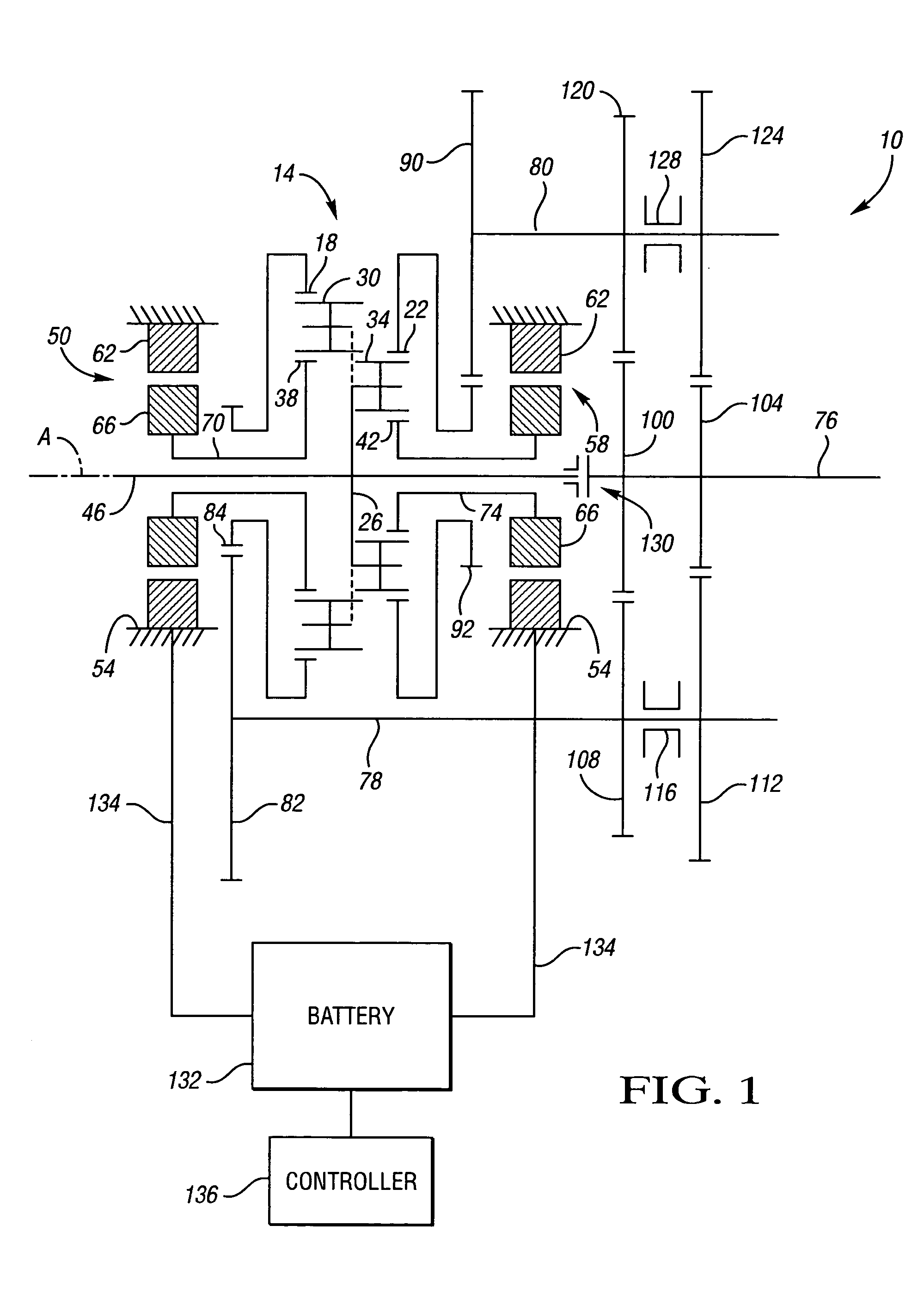

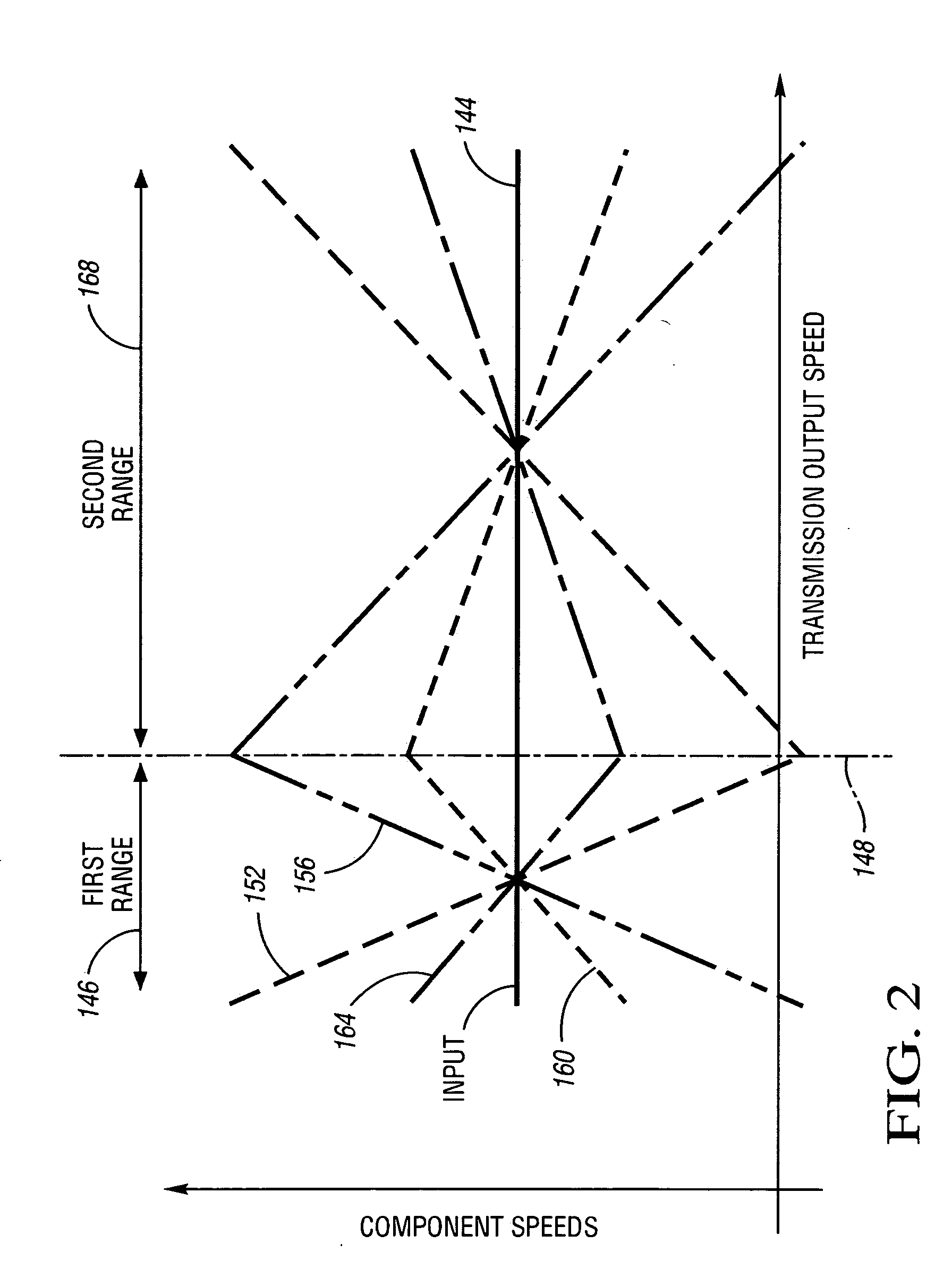

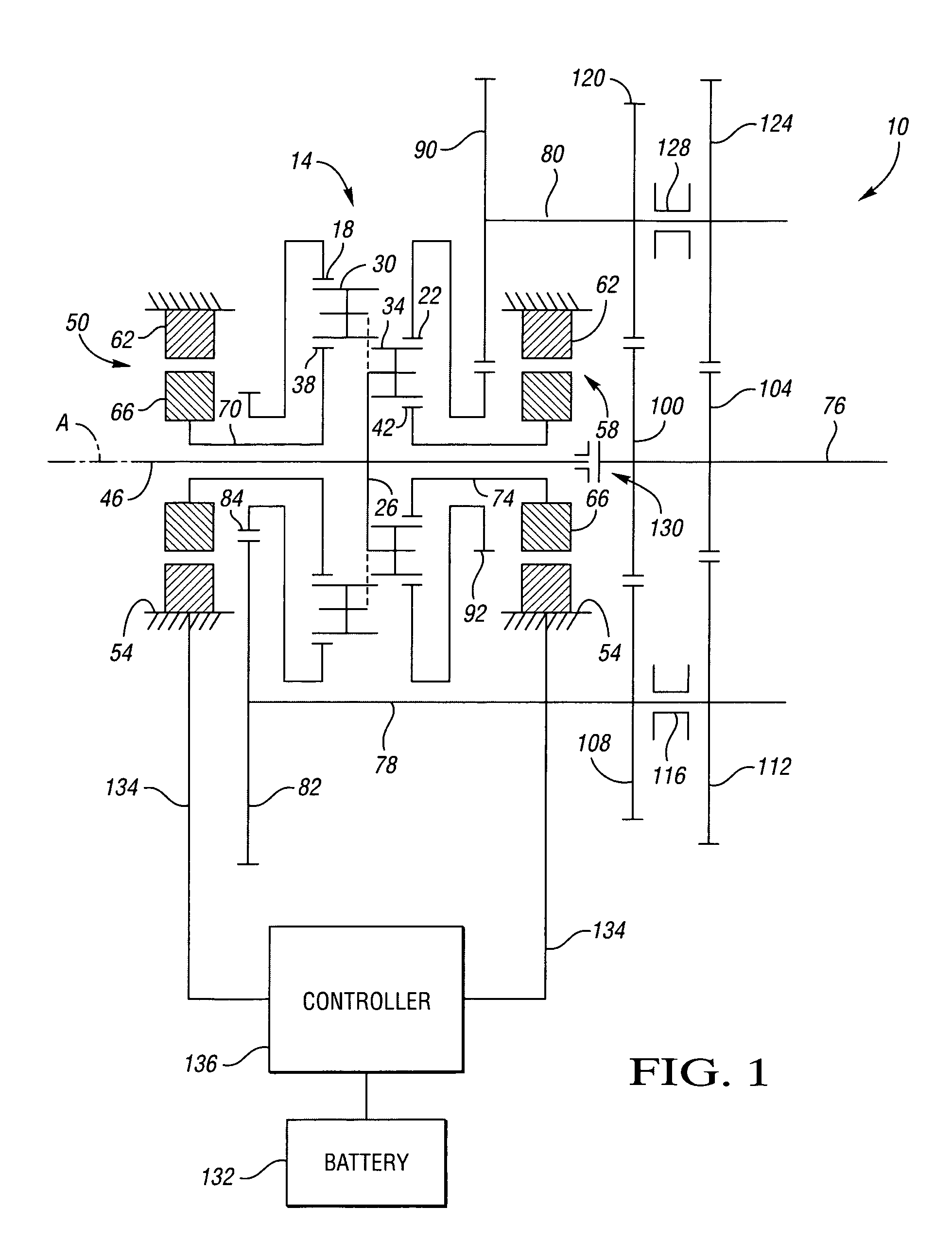

Compound differential dual power path transmission

InactiveUS20050227803A1Wider ratio spreadTransmission relatively inexpensive and efficientHybrid vehiclesElectric propulsion mountingGear wheelTorque transmission

A vehicle transmission includes a differential gearset having five coaxial gear elements and two output members. Two of the gear elements are controllable via torque-transmitting devices such as friction brakes or electric motors to establish a plurality of speed ratios between the input shaft and the two output members. The two output members are selectively operatively connectable to an output shaft via a gear arrangement that allows for a plurality of speed ratios between the output members and the output shaft. If the torque-transmitting devices are electric motors or hydraulic pumps, then a continuously variable speed ratio between the input shaft and the output shaft is achievable. The plurality of speed ratios between the two output members and the output shaft enable a plurality of compound split operating modes, facilitating smaller and less powerful motors or pumps compared to the prior art.

Owner:GM GLOBAL TECH OPERATIONS LLC

Eight-speed transmissions with four planetary gear sets

ActiveUS20060166779A1Reduced internal speedLow sun gearToothed gearingsTransmission elementsPowertrainEngineering

Eight-speed transmissions are provided that include four planetary gear sets having seven torque-transmitting mechanisms and various fixed interconnections to provide eight forward speed ratios and at least one reverse speed ratio. The powertrain includes an engine and torque converter that is continuously connected to at least one of the planetary gear members and an output member that is continuously connected with another of the planetary gear members. The seven torque-transmitting mechanisms are operated in combinations of two. Reduced component speeds and improved ratios are achieved.

Owner:GM GLOBAL TECH OPERATIONS LLC

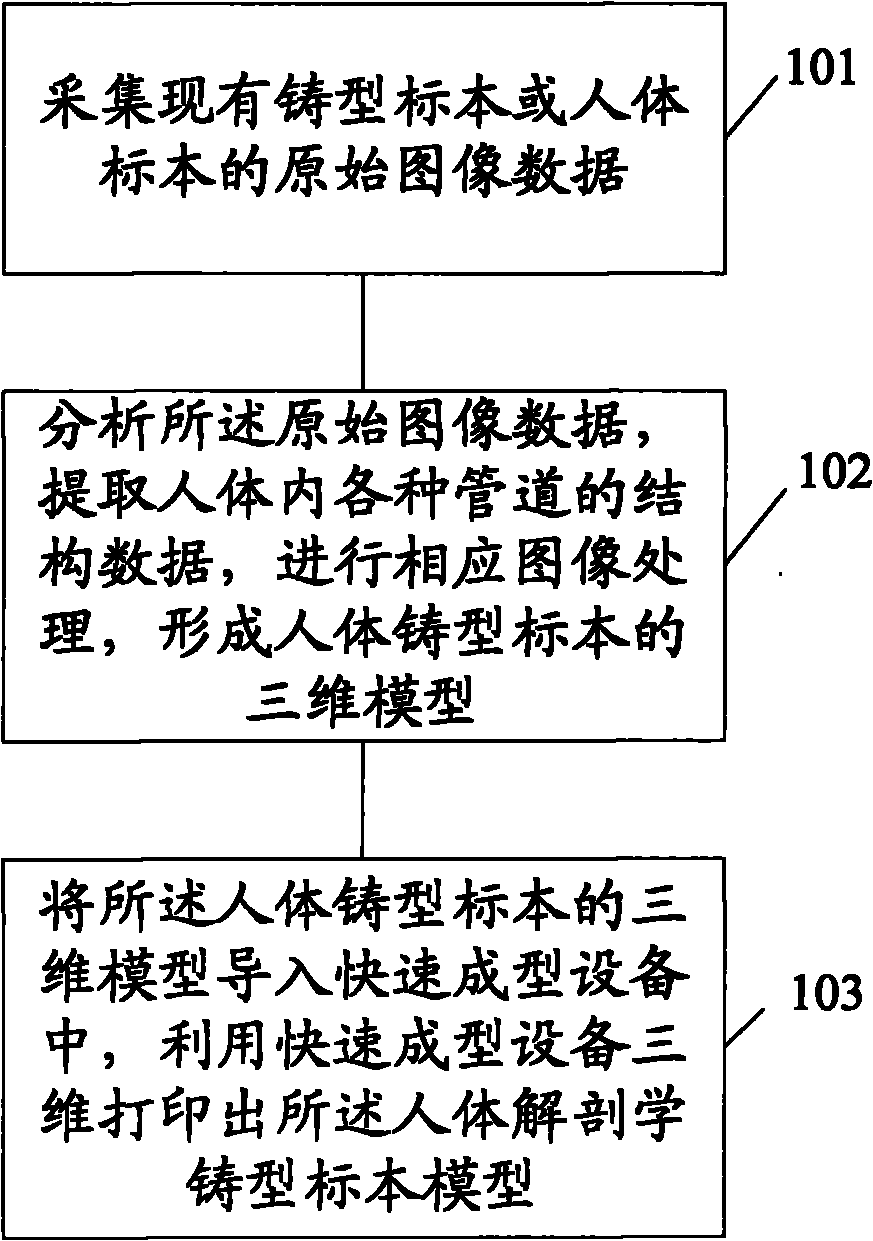

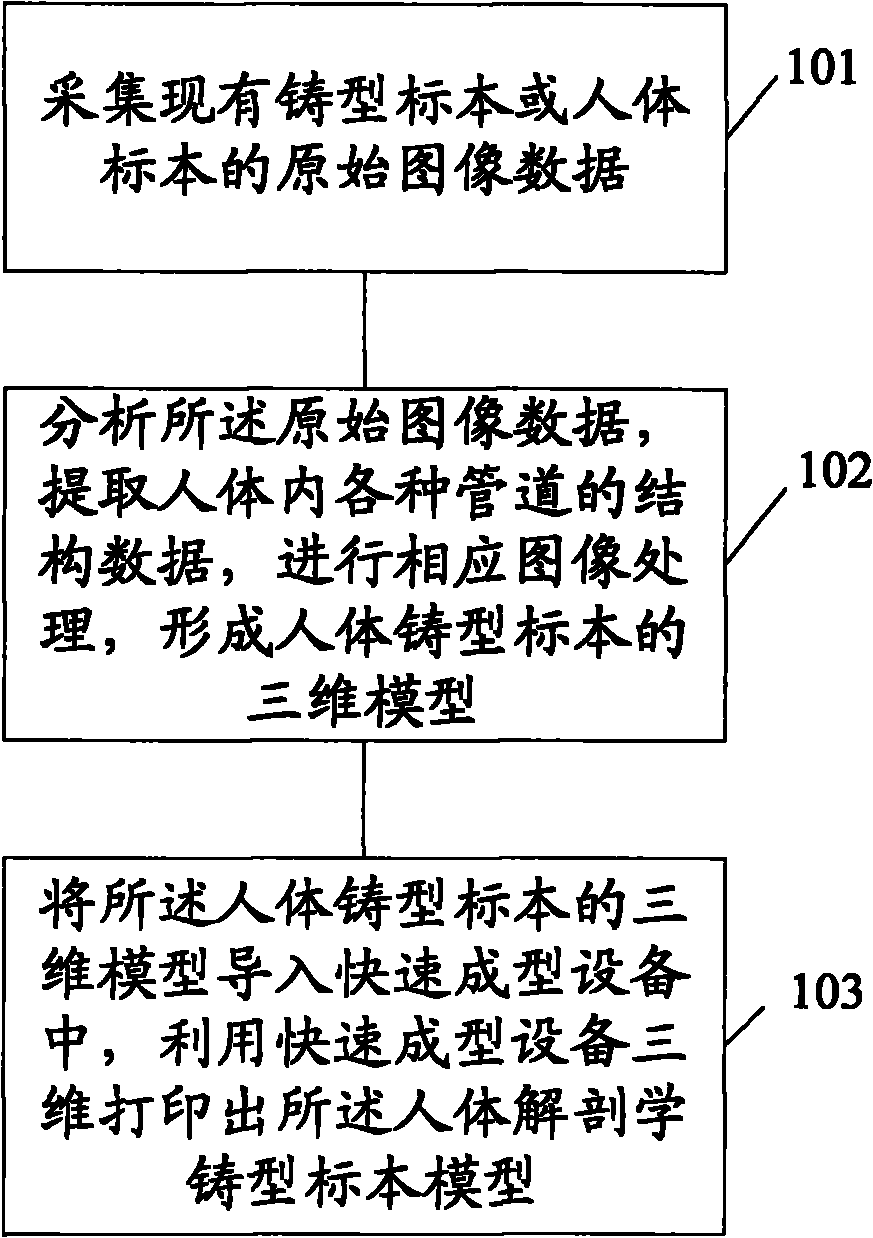

Method for manufacturing anthropotomy cast specimen model

InactiveCN101964155ALow costWide spreadEducational modelsSpecial data processing applicationsThree dimensional model3D printing

The invention discloses a method for manufacturing an anthropotomy cast specimen model, which comprises the following steps of: a, acquiring initial image data of the existing cast specimen or the existing human body specimen; b, analyzing the initial image data, extracting structural data of various ducts in the human body from the initial image data, and performing corresponding image processing to form a three-dimensional model of the human body cast specimen; and c, importing the three-dimensional model of the human body cast specimen into quick forming equipment, and three-dimensionally printing the anthropotomy cast specimen model by using the quick forming equipment. A real human body specimen is not needed to manufacture the cast specimen model in the manufacturing method so as to solve the problem of ethics and the difficult problem of seeking manufacturing materials. The method can accurately and quickly manufacture cast specimen models of different human body parts, and greatly expands the wide spread of the human body cast specimen and the application of teaching experiments.

Owner:SOUTHERN MEDICAL UNIVERSITY

LED lamp module

InactiveUS7686486B2Improve operationImprove life expectancyVehicle headlampsLighting support devicesEngineeringLED lamp

An LED lamp (10) has a housing (12) with an interior wall (14) defining a cavity (16). An LED light source (26) is positioned in the cavity (16) and project light in a forward direction. A reflector (28) having a reflective surface (30), a forward opening (32) and a rear opening (34) surrounds the light source (26) and a complex lens (38) closes the forward opening. The lens (38) comprises a first optical refractive element (40) arranged around a peripheral edge (42) and a second optical refractive element (44) centrally located on the lens (38); the first optical refractive element (40) including a plurality of flute lenses (40a) and the second optical refractive element (44) comprising a concavo-convex lens (44a).

Owner:OSRAM SYLVANIA INC

Compound differential dual power path transmission

InactiveUS7128680B2Wide spreadTransmission relatively inexpensive and efficientHybrid vehiclesElectric propulsion mountingHydraulic pumpControl theory

A vehicle transmission includes a differential gearset having five coaxial gear elements and two output members. Two of the gear elements are controllable via torque-transmitting devices such as friction brakes or electric motors to establish a plurality of speed ratios between the input shaft and the two output members. The two output members are selectively operatively connectable to an output shaft via a gear arrangement that allows for a plurality of speed ratios between the output members and the output shaft. If the torque-transmitting devices are electric motors or hydraulic pumps, then a continuously variable speed ratio between the input shaft and the output shaft is achievable. The plurality of speed ratios between the two output members and the output shaft enable a plurality of compound split operating modes, facilitating smaller and less powerful motors or pumps compared to the prior art.

Owner:GM GLOBAL TECH OPERATIONS LLC

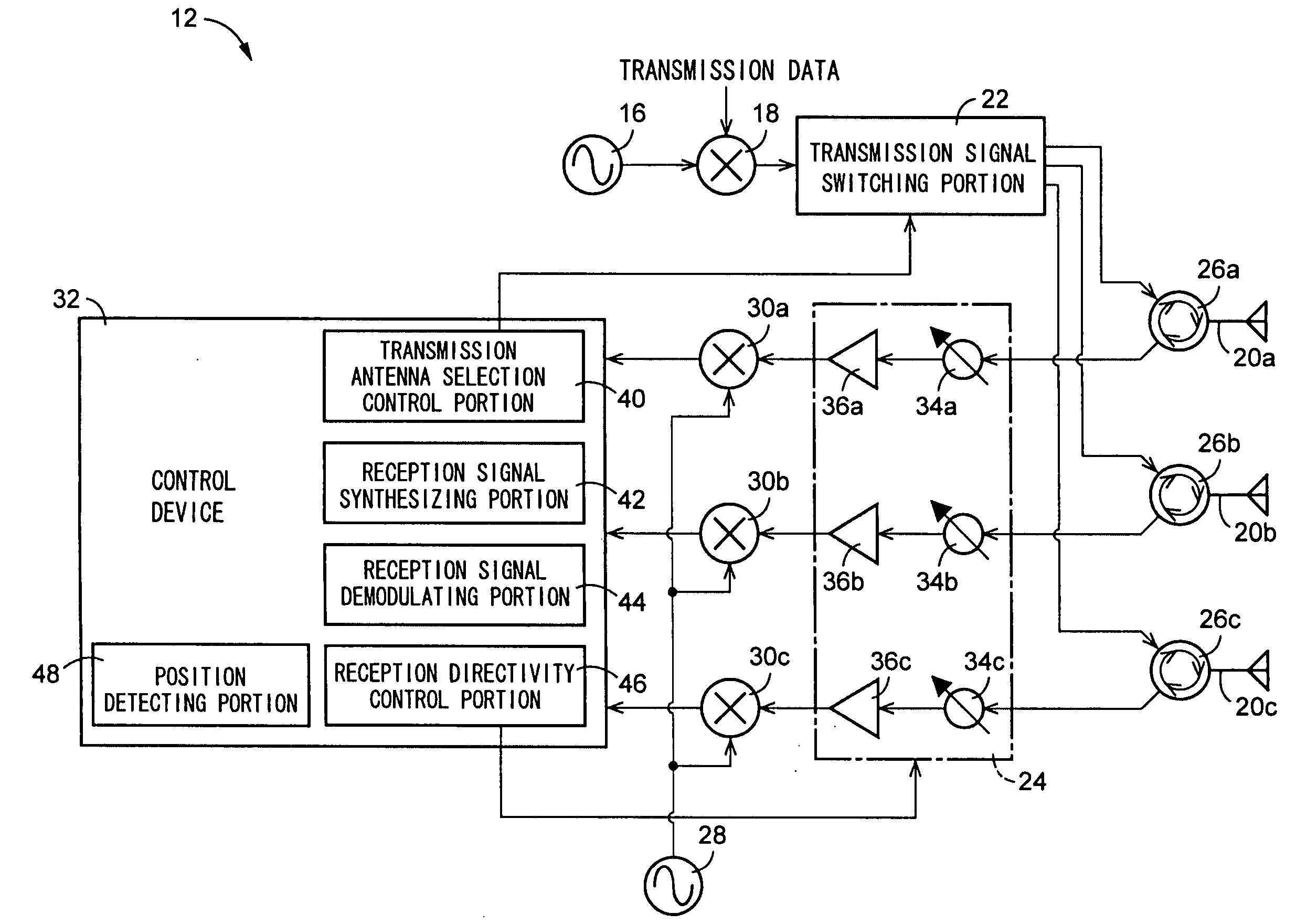

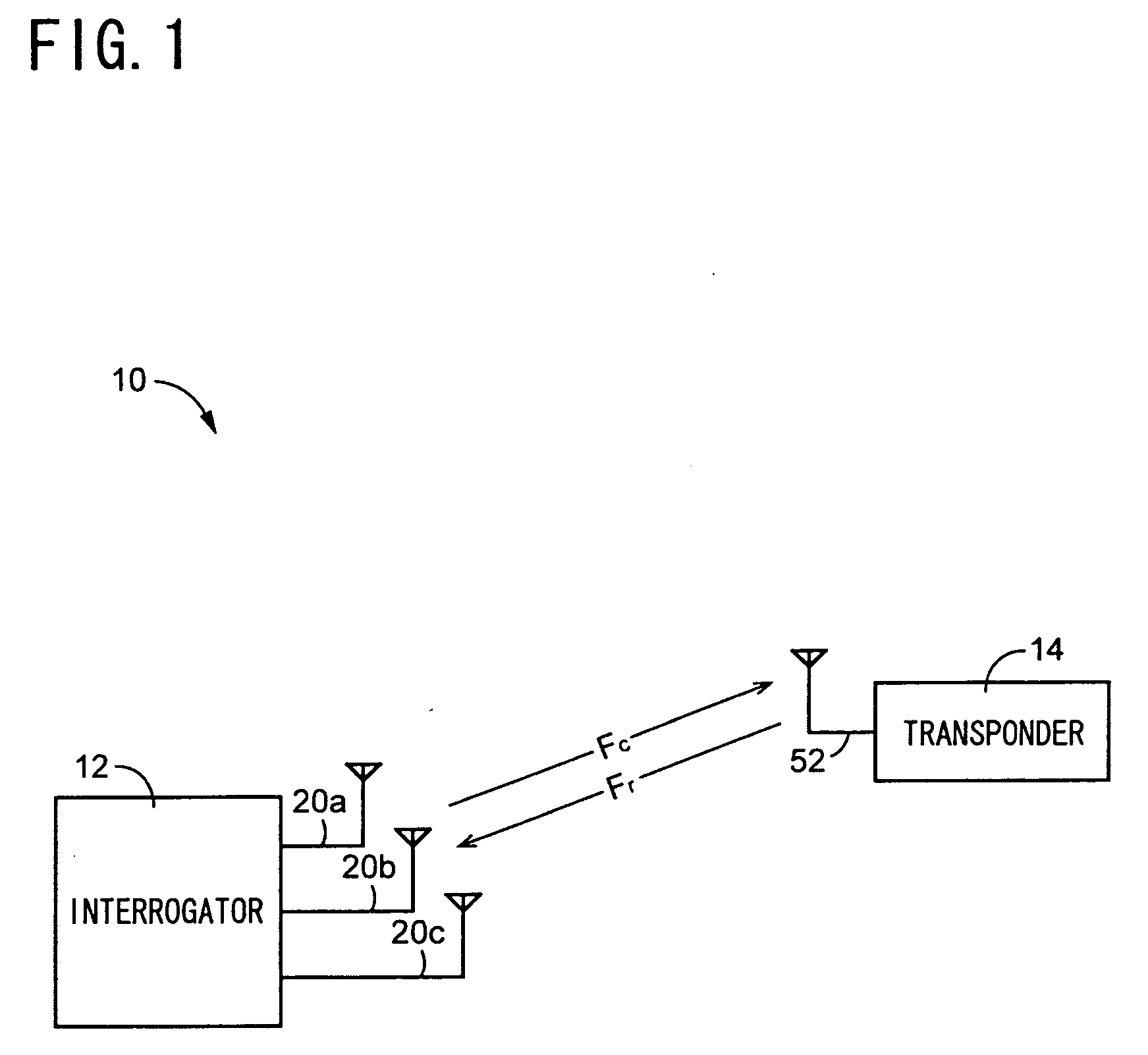

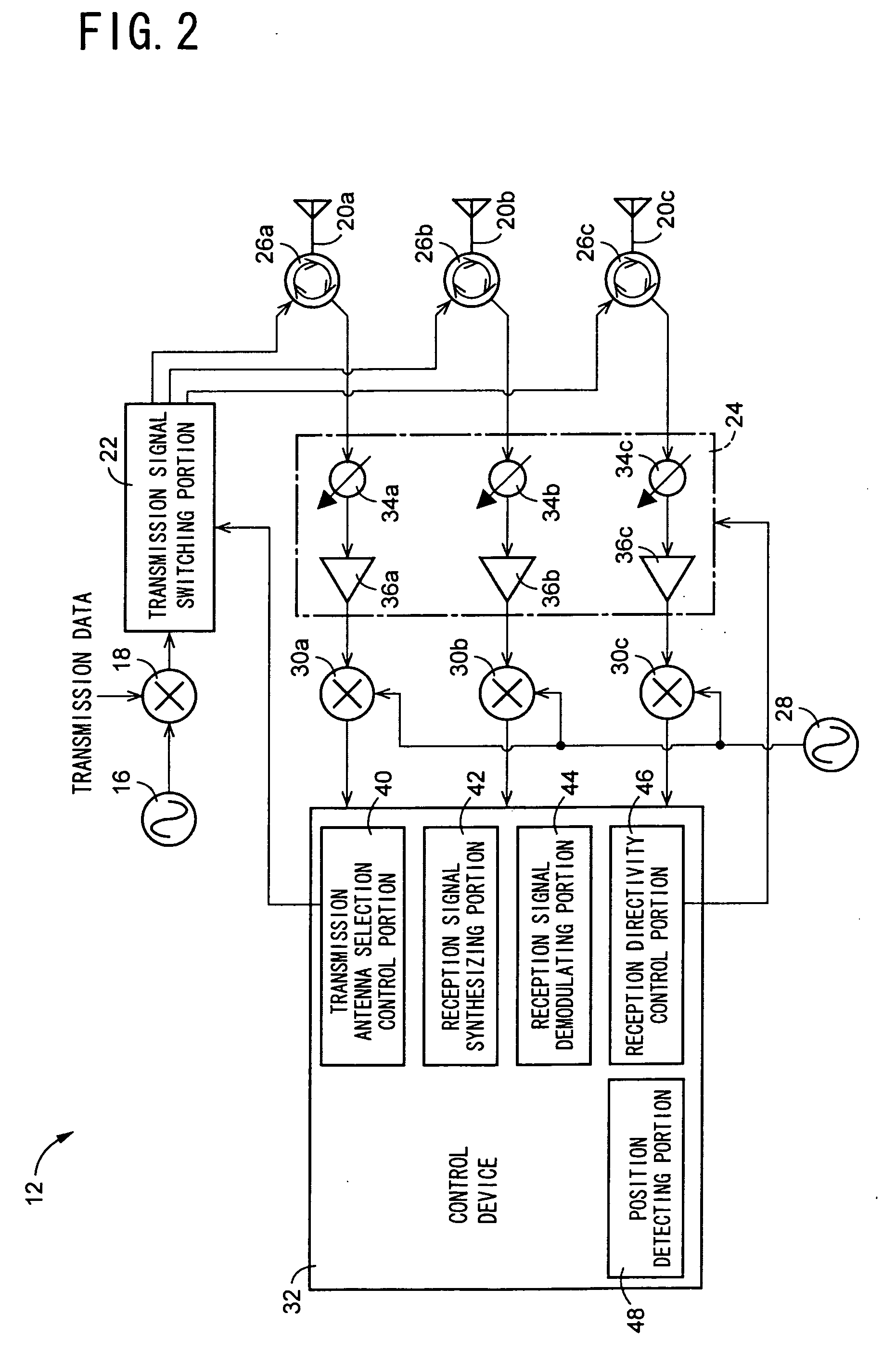

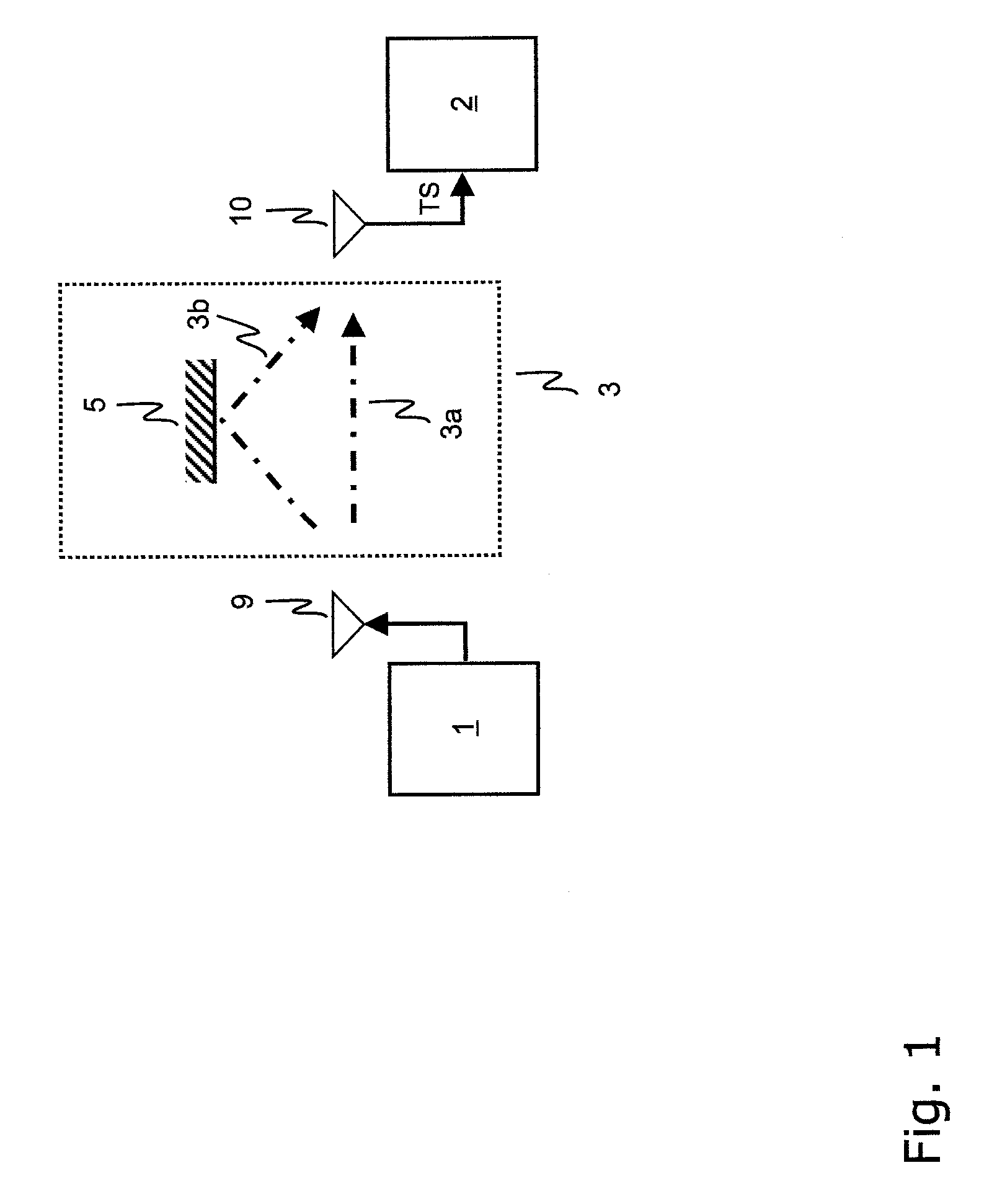

Radio tag communication apparatus

InactiveUS20070037529A1Wide spreadEasy constructionSpatial transmit diversityAntenna arraysEngineeringAntenna element

A radio tag communication apparatus having a broad communicable range and a simple arrangement, is provided. Since there are provided a transmission antenna selection control portion for selecting a single transmission-reception antenna element to transmit a transmission signal, from a plurality of transmission-reception antenna elements, and a reception signal synthesizing portion for synthesizing respective reception signals received by the plurality of transmission-reception antenna elements, with each other, a communicable range of the radio tag communication apparatus can be broadened by transmitting the transmission signal from a diversity antenna having a simple arrangement, and a reception sensitivity of the radio tag communication apparatus can be enhanced by synthesizing the reception signals received by the plurality of transmission-reception antenna elements, with each other.

Owner:BROTHER KOGYO KK

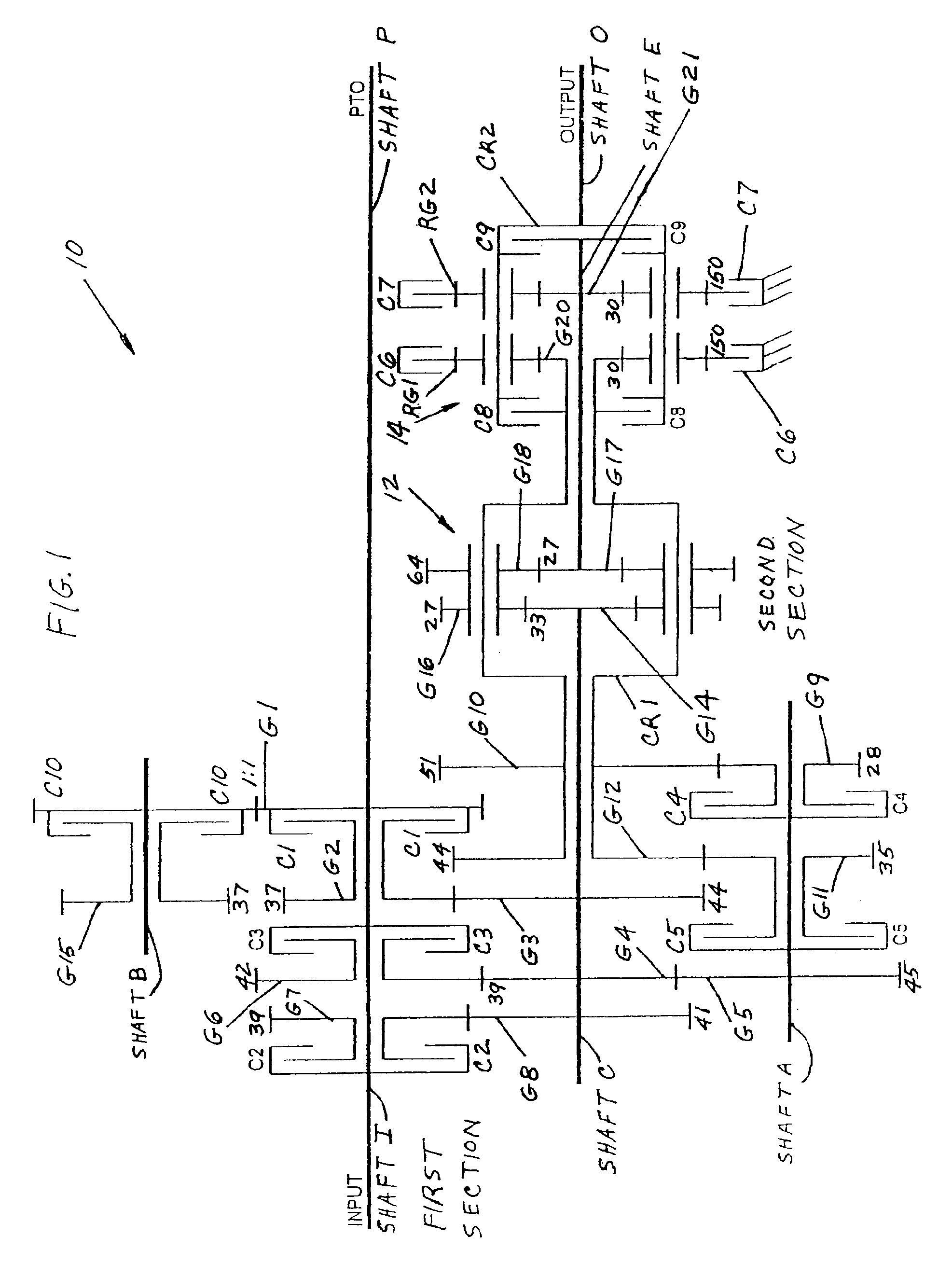

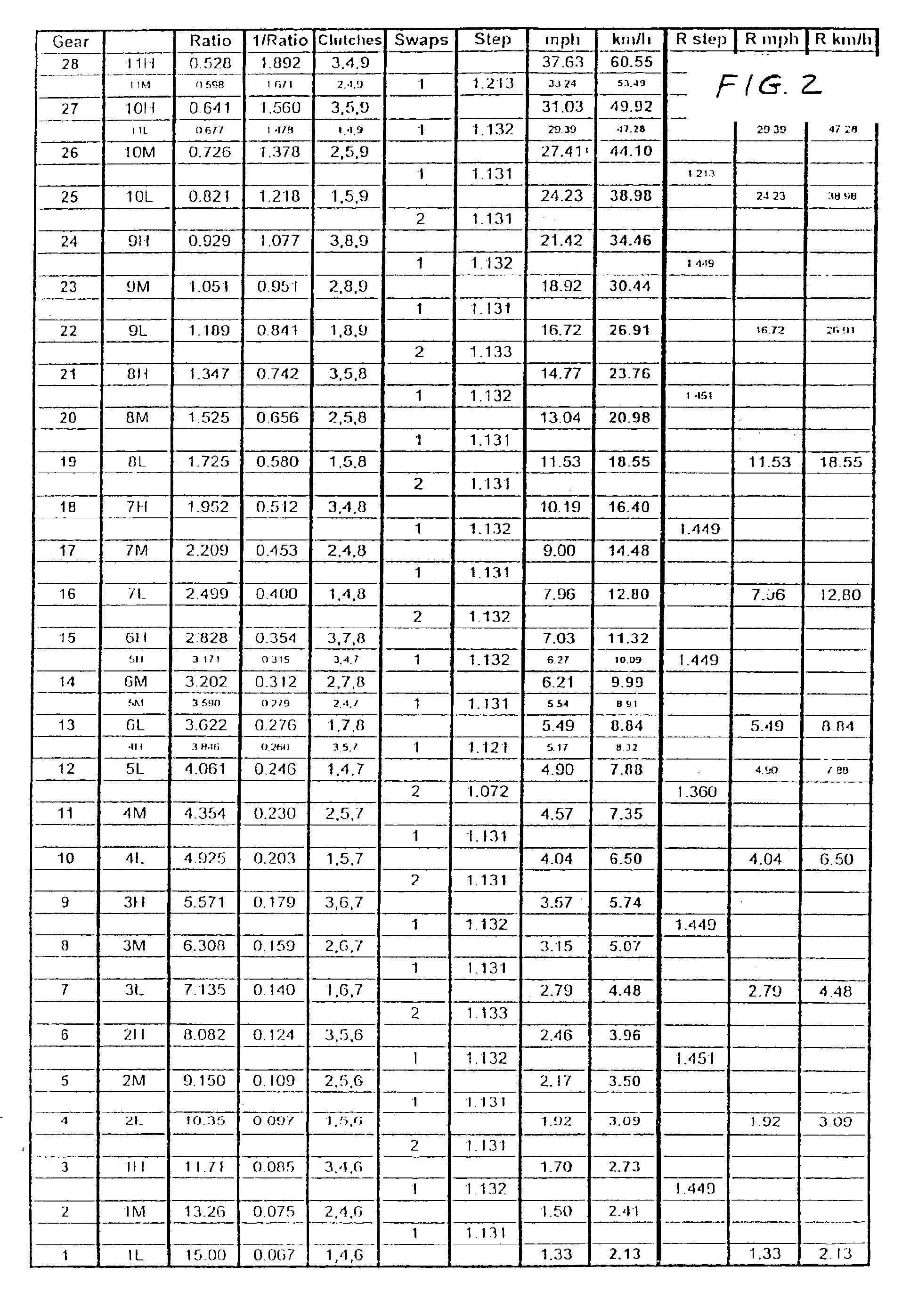

Smoothly shifting multispeed transmission

ActiveUS6845682B1Elimination of difficult shiftSmall ratio stepToothed gearingsTransmission elementsGear wheelEngineering

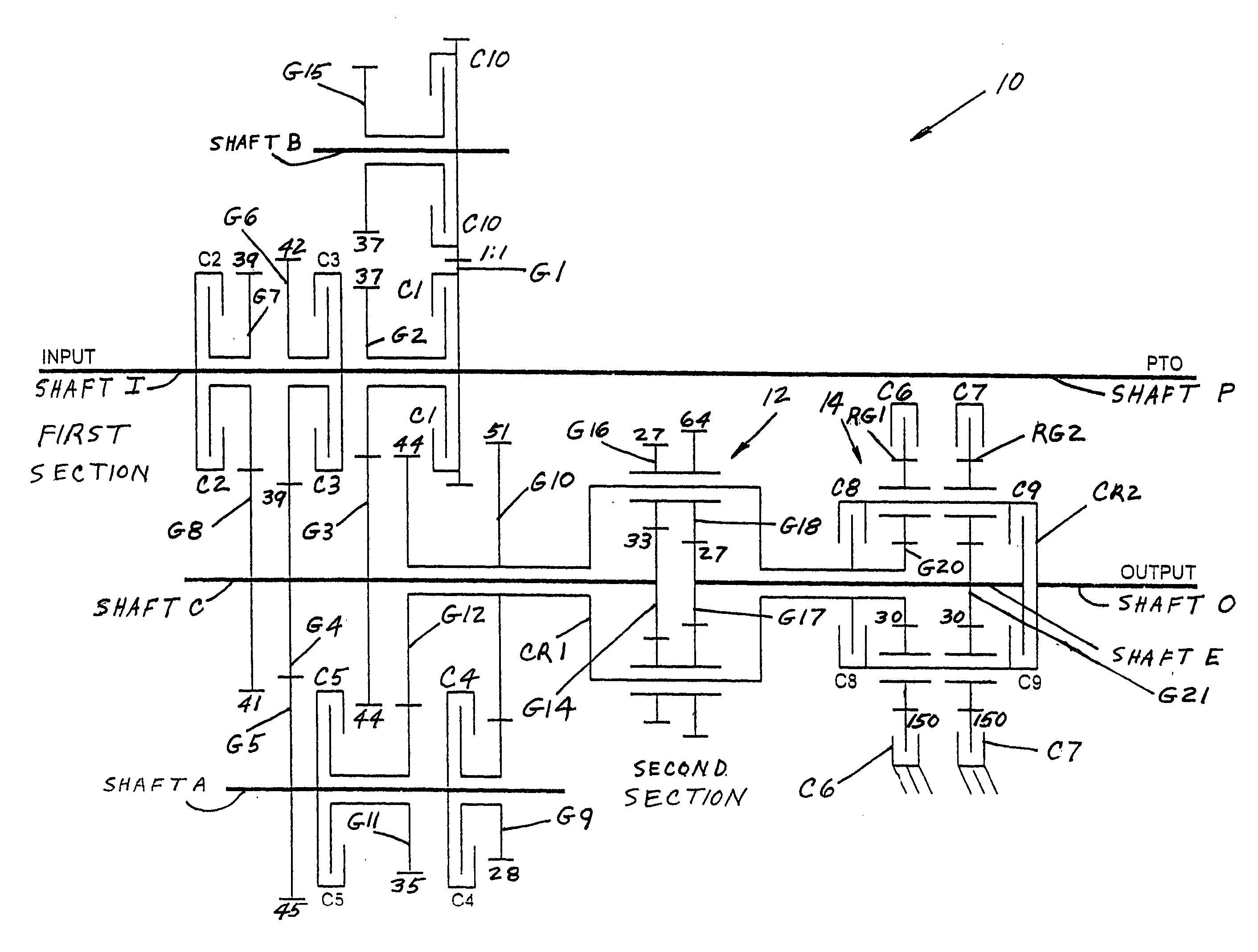

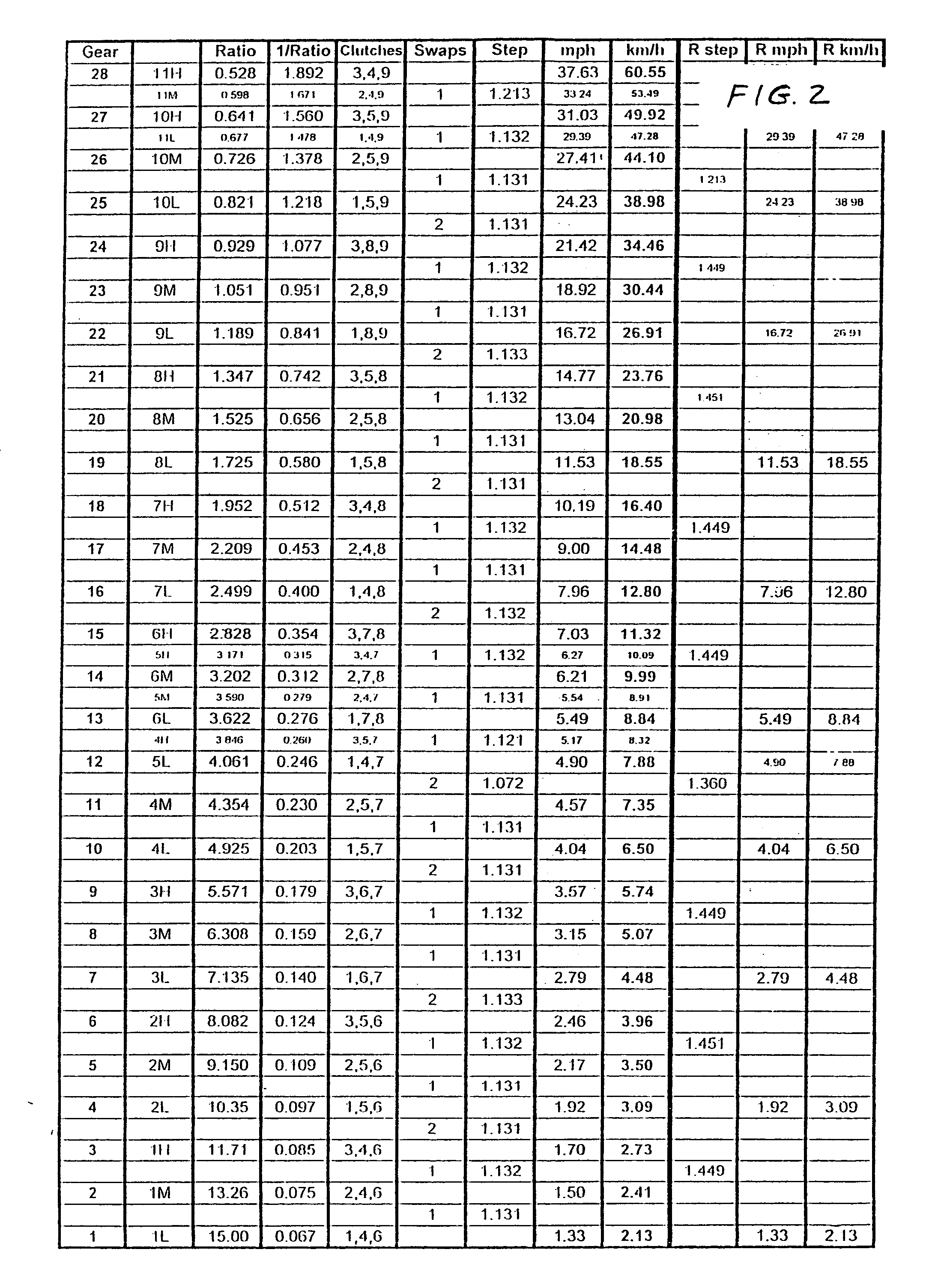

The apparatus is a 28 speed, two section, transmission that requires only a single clutch swap for most changeovers between adjacent ratios. It uses a first section with three close ratio forward speeds and one reverse along with a second section that is an 11 speed, wide ratio, transmission. The two transmission sections are arranged in series resulting at least 28 usable forward speeds. The second section includes an intermediate planetary gear set without a ring gear and an output planetary gear set that is a conventional simple planetary gear set with a two sun gears, two planes of planetary gears on a single carrier, and two ring gears.

Owner:BLUE LEAF I P +1

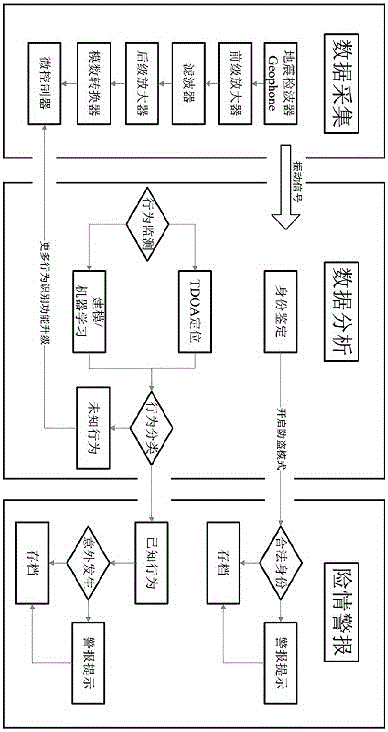

Intelligent household monitoring method and system based on vibration detection

InactiveCN106251572AAvoid privacyEasy to useComputer controlBurglar alarmData acquisitionVibration detection

The invention relates to the technical field of intelligent homes, and discloses an intelligent household monitoring method based on vibration detection. The monitoring method comprises following steps of that a data acquisition module acquires structure vibration information generated by behavior activities of people; and by analyzing and processing signals, the behavior activities of people in a home are intelligently monitored and an alarm is made for the abnormity. The beneficial effects are that a privacy problem of the monitoring in a camera chamber is solved; a user's live will not be affected; and easy use by the user is achieved.

Owner:SHENZHEN UNIV +1

Robust non-coherent receiver for PAM-PPM signals

InactiveUS20060285578A1Broad range of delay spreadReduce complexityTransmissionUltra-widebandLocalization system

A robust method and system for communicating via ultra-wideband (UWB) radio transmission signals over multi-path channels with a very broad range of delay spread. The system includes an optimized non-coherent receiver structure of low complexity and potentially very low power consumption, while offering robust error rate performance for a wide variety of UWB multi-path channel. Use of the proposed transmission signals, referred to as combined PAM-PPM (pulse amplitude modulation-pulse position modulation) signals, together with the disclosed non-coherent receiver method and apparatus are applicable in any UWB communication, identification, sensor or localization system and network, where battery power consumption must be minimized without undue system performance degradation. In particular, timing recovery and synchronization methods and embodiments for bipolar 2PPM (two-slot PPM) signals are disclosed, enabling the construction of particularly robust receivers for systems and networks operating over the ultra-wideband (UWB) radio channel, for example, in the band between 3.1 GHz and 10.6 GHz.

Owner:IBM CORP

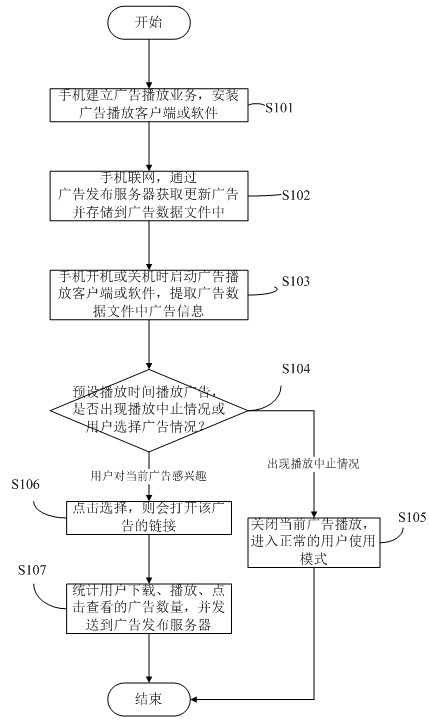

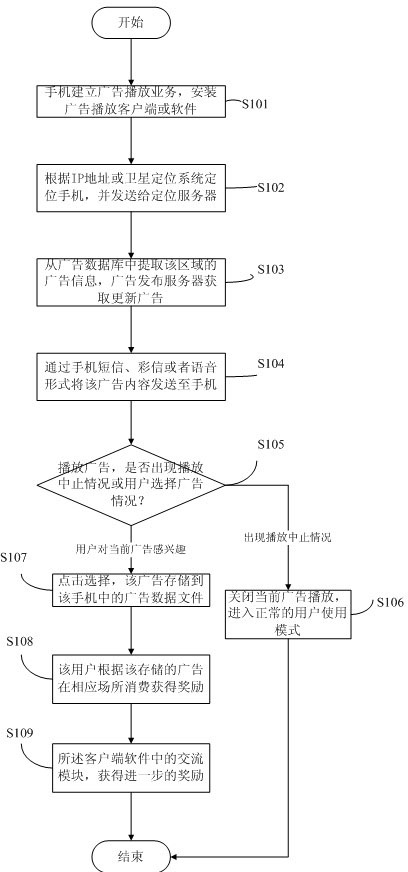

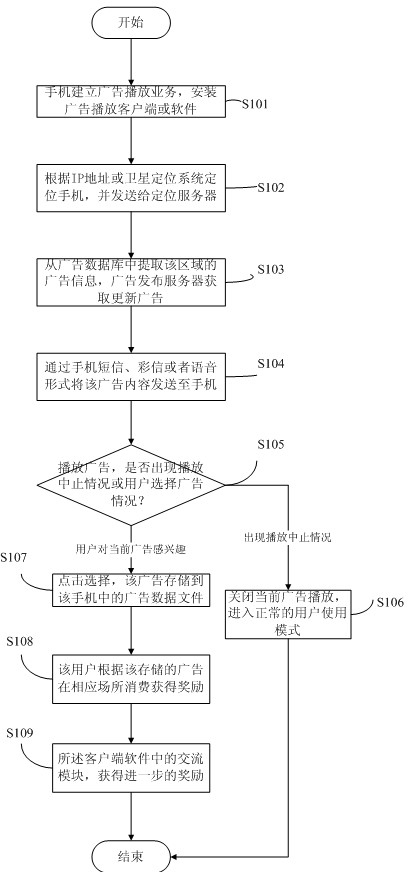

Mobile advertisement playing method

The invention discloses a mobile advertisement playing method, which relates to the technical field of mobile communication. The method comprises the following steps of: pre-establishing an advertisement playing service on a mobile phone of a user, and installing an advertisement playing client-side; when the mobile phone is online, acquiring an updated advertisement through an advertisement publishing server, and storing into an advertisement data file in the mobile phone; when the mobile phone is turned on / off, launching the advertisement playing client-side, and extracting corresponding advertisement information; playing the advertisement in a preserved space on a display screen of the mobile phone according to preset playing time, and stopping current advertisement playing and entering a normal user using mode if playing is paused; if the user selects an interested advertisement, opening the link of the advertisement, so that the user can acquire more information on the advertisement; and counting the downloading, playing and clicking quantities of the advertisement within a certain period of time for the current user by using a counting module in client software, and transmitting statistic data to the advertisement publishing server.

Owner:辜进荣

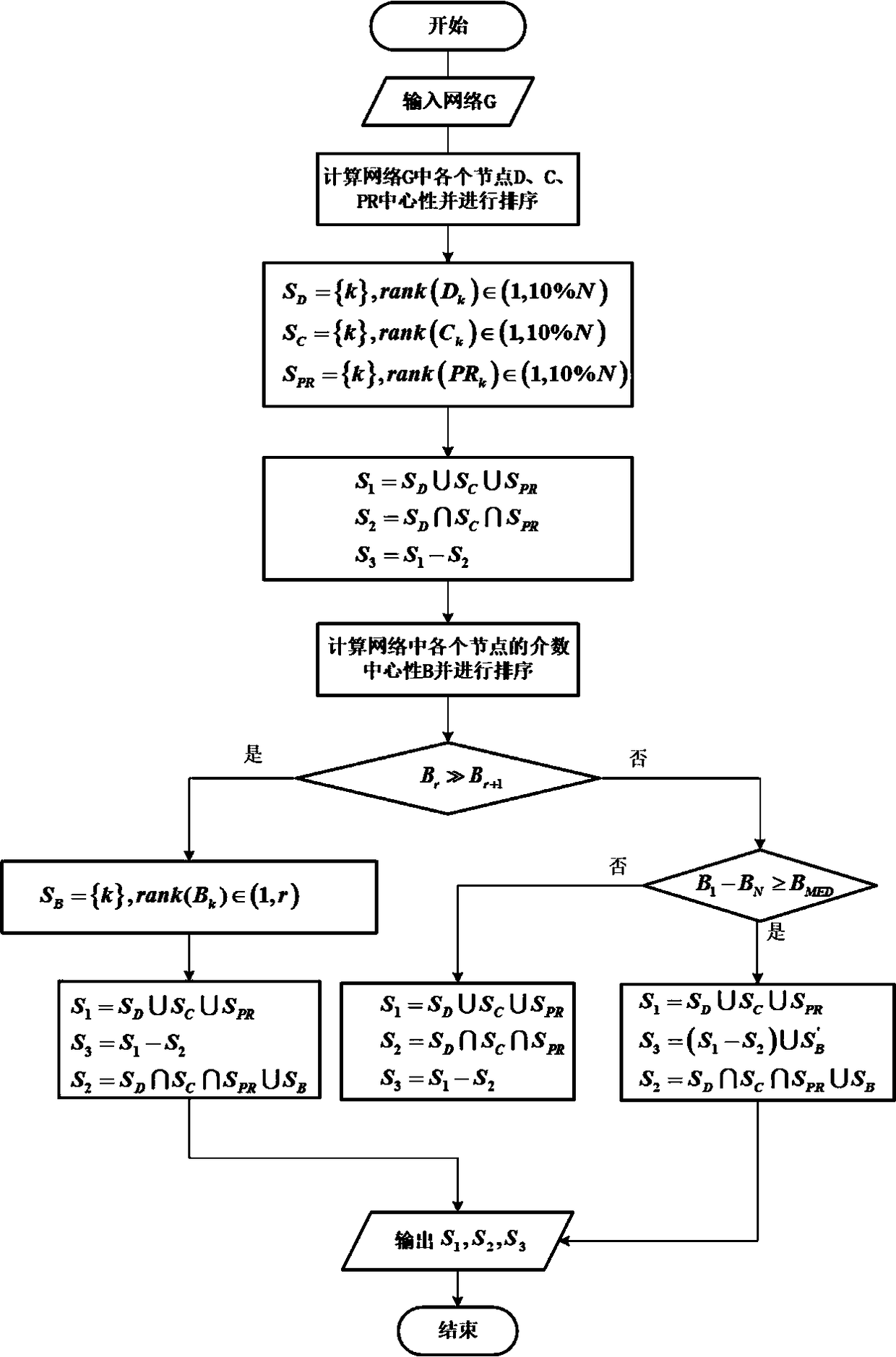

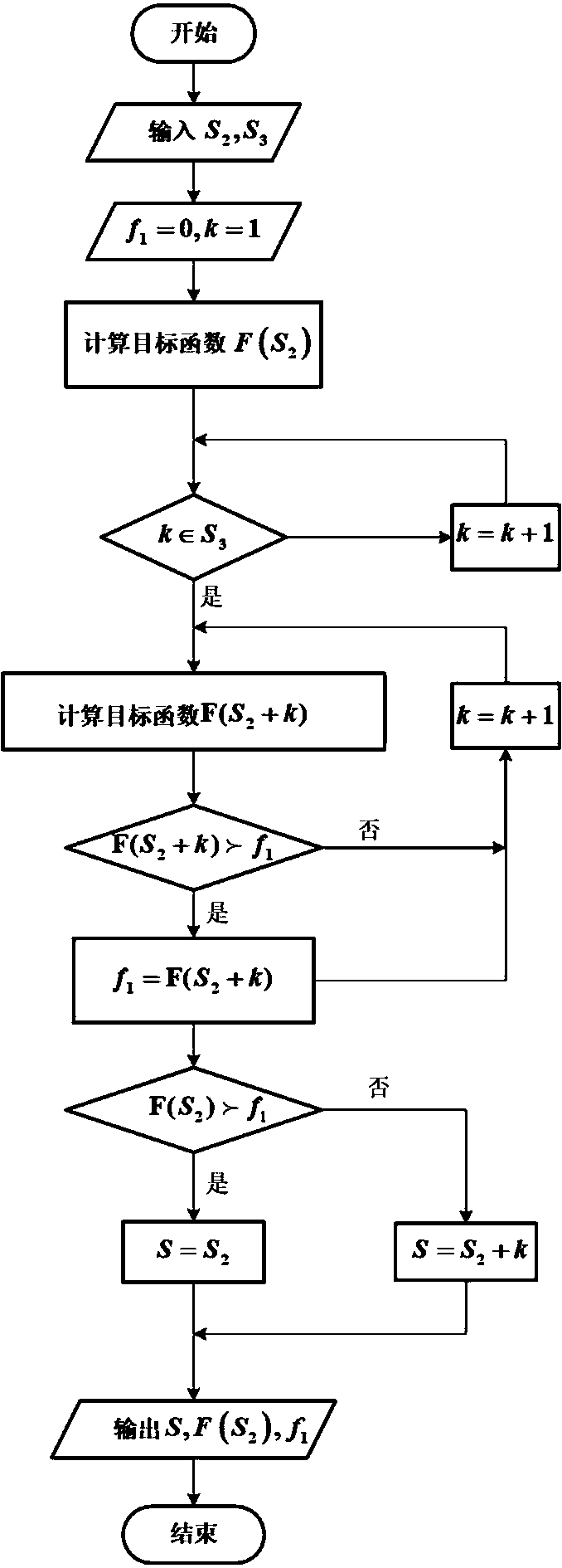

Complex network key node cluster mining method based on combination optimization

ActiveCN109379220AEfficient preprocessingReduce computational complexityData switching networksNode clusteringNODAL

The invention relates to a complex network key node cluster mining method, and specifically discloses a complex network key node cluster mining method based on combination optimization, which is usedfor solving problems of simplified technical indexes, high cost needed for node mining, limited propagation range, insufficient amount of propagation information and no consideration of a strengthening function of reachable neighbors to node centrality in the existing method. The method provided by the invention has the following steps: 1, building an input network model; 2, selecting indexes forpreprocessing network nodes; 3, calculating an initial key node cluster S<2> and a to-be-optimized node cluster S<3>; 4, selecting an objective function of key node cluster combination optimization; 5, performing combination optimization; 6, outputting a key node cluster S. The method provided by the invention has the advantages of preprocessing network node groups, selecting limited nodes for performing combination optimization, being low-complexity in calculation, considering various indexes, preprocessing the network nodes and performing combination optimization for the obtained nodes, andmining the key node cluster which needs low cost for mining, has wide propagation range and large amount of propagation information, and considers the strengthening function of the reachable neighborsto node attributes.

Owner:TAIYUAN UNIV OF TECH

Precisely-positioning cellphone advertisement playing method

InactiveCN102546950AWide spreadImprove interactivitySubstation equipmentSelective content distributionIp addressData file

A precisely-positioning cellphone advertisement playing method relates to the technical field of mobile communication. The method includes that a user cellphone builds advertisement playing business in advance; user area is identified according to an internet protocol (IP) address of the user mobile phone or through a global positioning system and sent to a positioning server; an advertisement publishing server sends advertisement content to the user cellphone through cellphone short messages, multimedia messages or voice modes; advertisements are played in a reserved space of a cellphone display screen, if playing of the advertisements is discontinued in a playing process, the playing of a current advertisement is closed to enter a normal user operating mode; if users want to select interested advertisements, and click selection to store the advertisements in an advertisement data file in a local memory reserved in the cellphone; and the users can be rewarded while consuming at corresponding places according to the stored advertisements. The cellphone advertisements achieved through the method have strong regionalism, and pertinence can be improved.

Owner:辜进荣

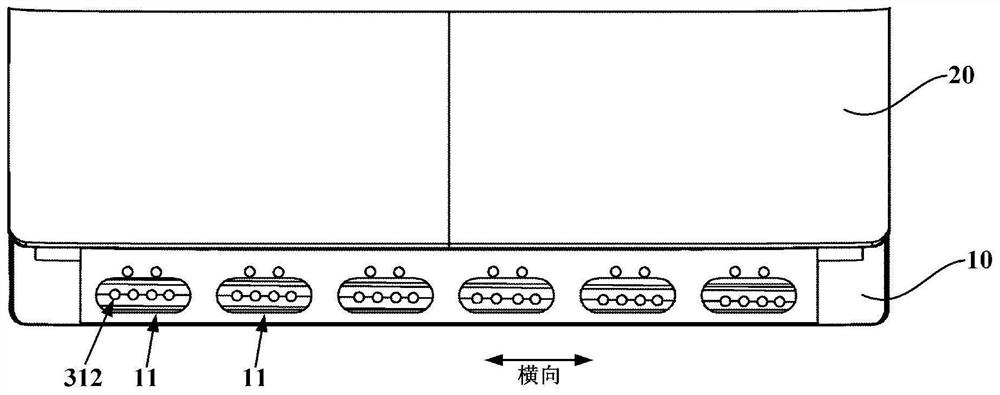

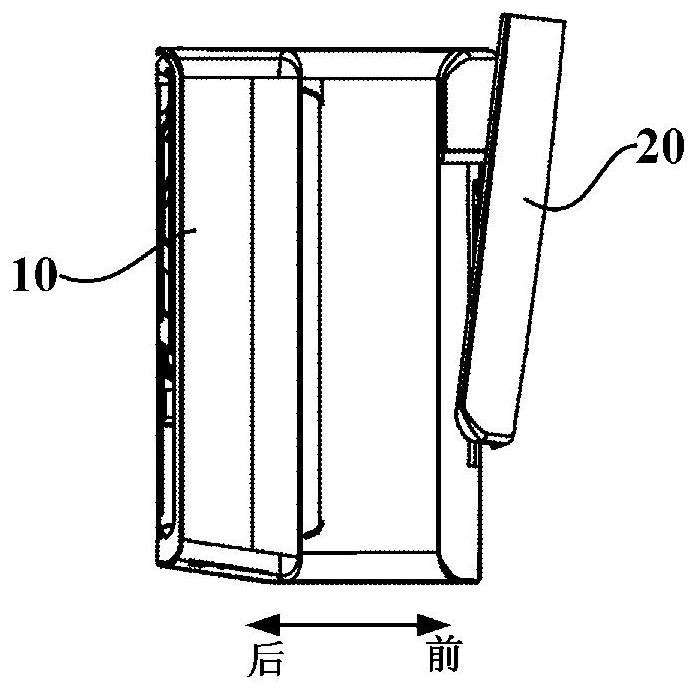

Wall-mounted air conditioner indoor unit

ActiveCN112082207ASmall flow cross sectionFast winding speedLighting and heating apparatusHeating and ventilation casings/coversEnvironmental engineeringBlow out

The invention provides a wall-mounted air conditioner indoor unit which comprises a casing and a flow guide piece; a first air supply outlet and an air duct connected with the first air supply outletare defined in the casing, and the inner wall, close to the first air supply outlet, of the air duct is gradually reduced such that the flow cross section of the air duct is gradually reduced in the airflow direction; the flow guide piece is arranged in the air duct, and an air outlet gap is defined between the flow guide piece and the inner wall of the air duct so that the air supply airflow blown to the first air supply outlet is guided to the inner wall of the air duct, and the air supply airflow gradually flows out of the first air supply outlet towards the airflow center in a gathered mode under the guiding effect of the gradually-reduced part of the inner wall of the air duct; the flow guide piece is of a hollow structure, and spray holes are formed in the side, facing the first airsupply outlet, of the flow guide piece, and the flow guide piece is configured to produce water mist; and in the flowing process of the supply airflow, a negative pressure environment is formed at thespray holes, so that water mist is mixed into the supply airflow and blown out of the first air supply outlet together. The wall-mounted air conditioner indoor unit has better effects of long-distance air supply and strong air supply.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

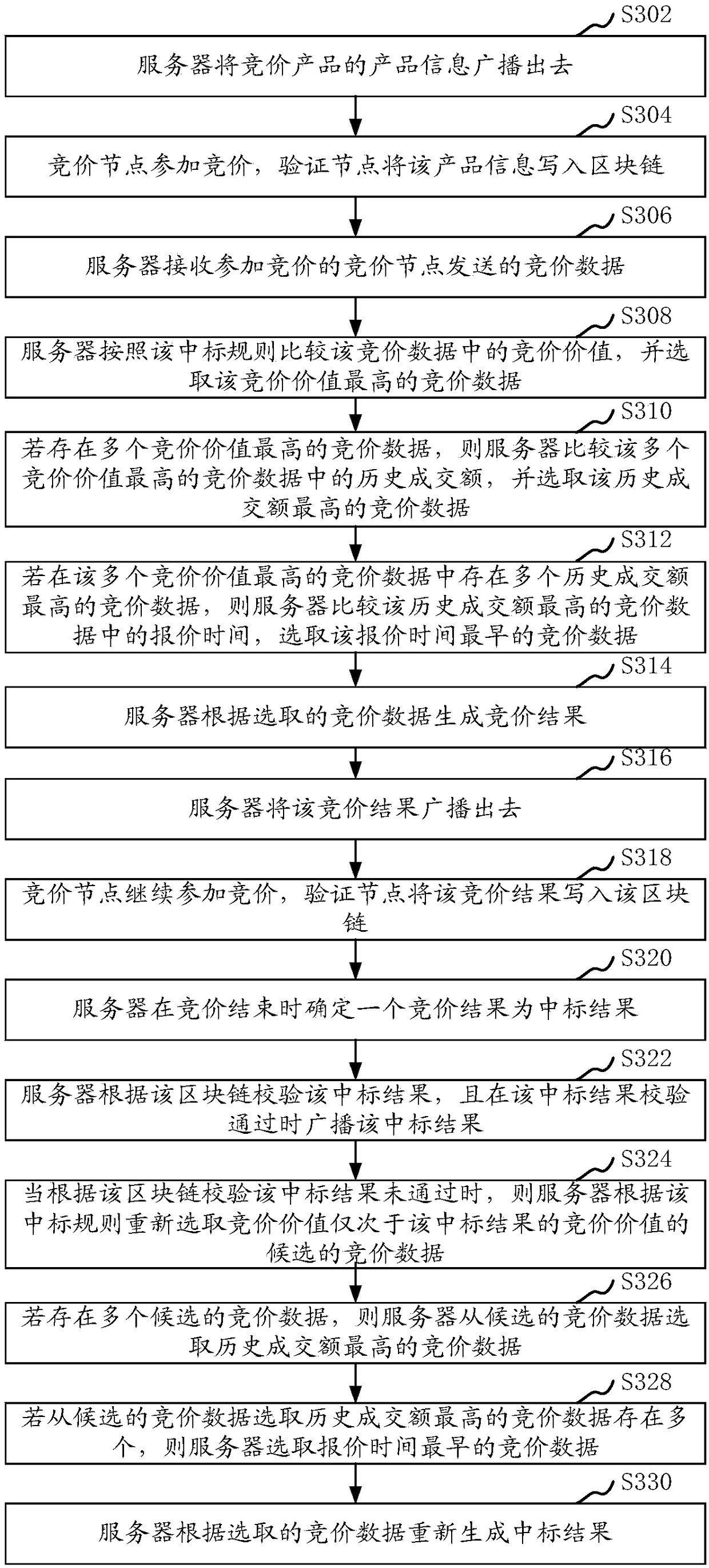

Real-time bidding method and device based on blockchain, equipment and storage medium

InactiveCN108305156AWide spreadGuarantee authenticityPayment protocolsCommerceTime line methodData mining

The invention relates to a real-time bidding method based on a blockchain, a system, computer equipment and a storage medium. The method comprises the steps that the product information of a bid product is broadcast to notify bidding nodes to participate in the bidding and notify a verification node to write the product information into the blockchain; bidding data sent by the bidding nodes participating in the bidding are received; according to a bid winning rule, the received bidding data are bid to acquire bidding results; the bidding results are broadcast to notify the bidding nodes to continue to participate in the bidding and notify the verification node to write the bidding results into the blockchain; a bidding result is determined as a bid winning result at the end of the bidding;the bid winning result is verified according to the blockchain; and the bid winning result is broadcast when the bid winning result is successfully verified. The method can ensure that the bidding data are open, transparent and safe.

Owner:重庆金融资产交易所有限责任公司

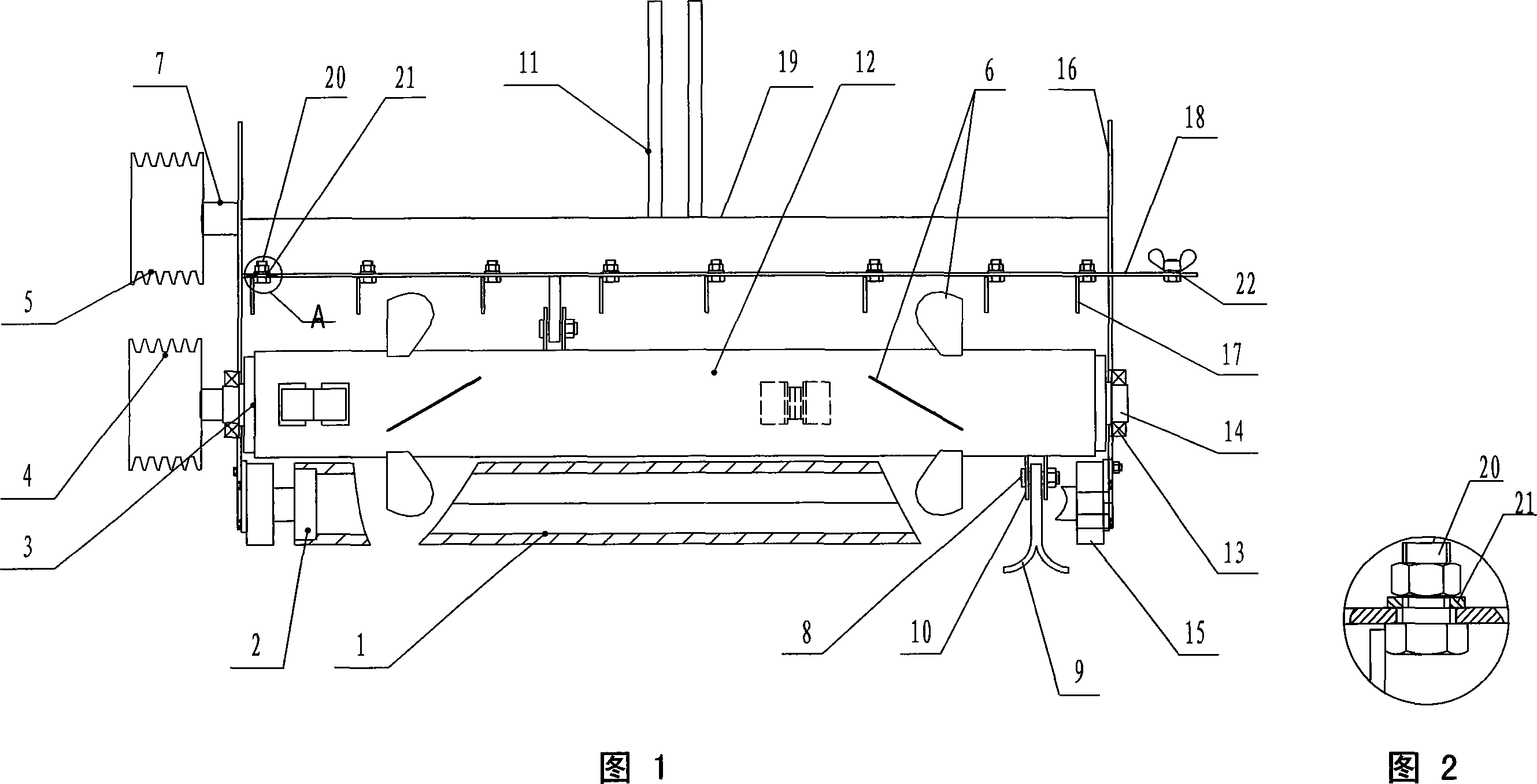

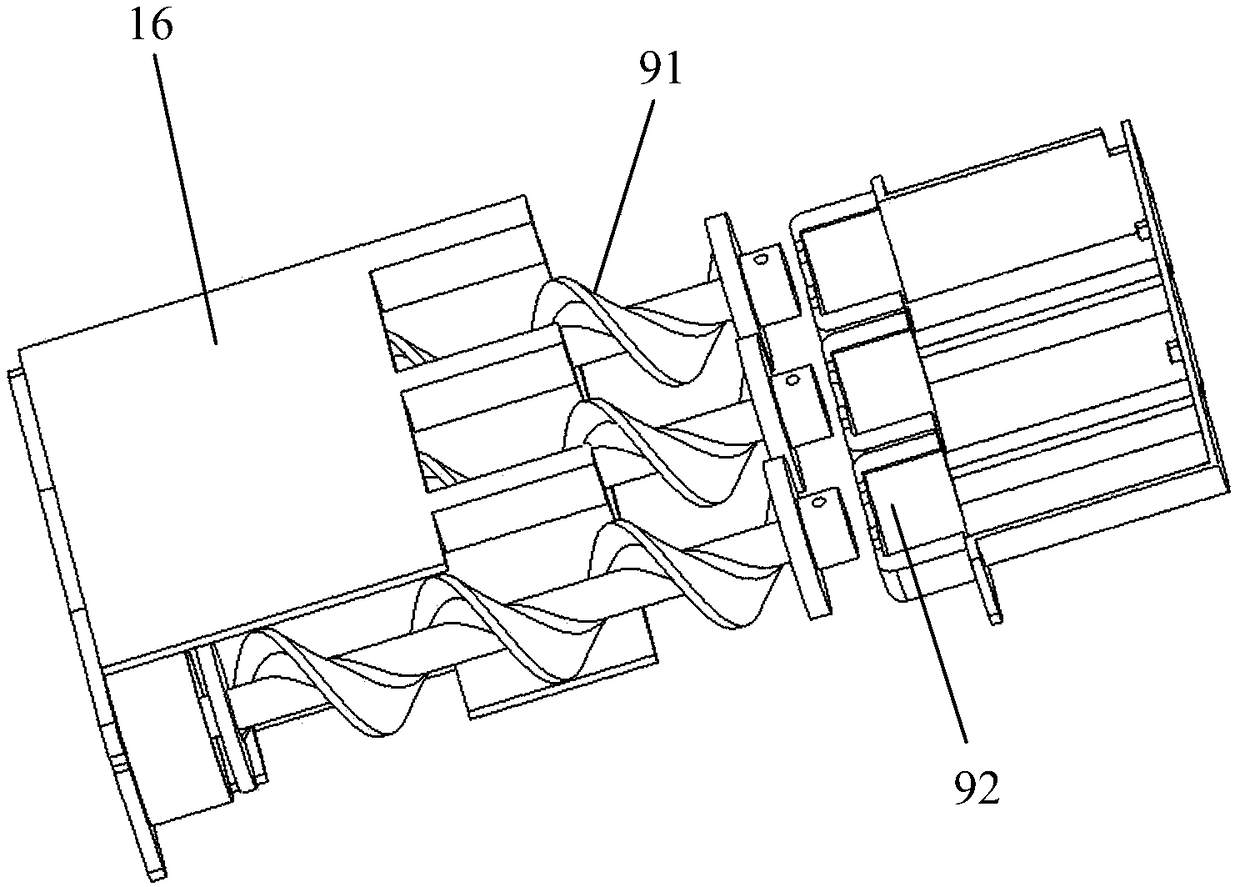

Corn strew grinding return-to-field machinery

InactiveCN101080978AEvenly spread the strawWide spreadCrop conditionersMowersEngineeringMechanical engineering

The corn stalk crushing and throwing machine includes one frame, one spiral throwing cutter with one shaft mounted through rolling bearing onto the frame, one horizontal pressing wheel mounted through sliding bearing onto the frame, one hood and guide plates in the back part of the hood. It features the increased groups of blades mounted homogeneously onto the cutter shaft and the guide plates mounted through an angle regulating mechanism. During operation, the high speed rotating blades produce axial force to through the crushed stalk homogeneously in certain angle range.

Owner:SHANDONG UNIV OF TECH

7-speed layshaft geartrain with dual-use meshes and three axes

InactiveUS20110146445A1Improved gear arrangementWide spreadToothed gearingsTransmission elementsGear systemEngineering

A dual mesh gear system is provided for a motor vehicle transmission having three axes. The transmission includes two input shafts, first and second clutch assemblies, first and second countershafts, and an output shaft. The transmission uses a first dual mesh for gears four and six and a second dual mesh for gears five and seven. Reverse within the transmission is driven by a reverse driver gear fixedly attached to second gear on the second countershaft. The reverse driver gear is continuously meshed with a reverse driven gear on the first countershaft. The reverse gear combination achieves a reverse gear ratio greater than or equal to the gear ratio of first gear.

Owner:FCA US

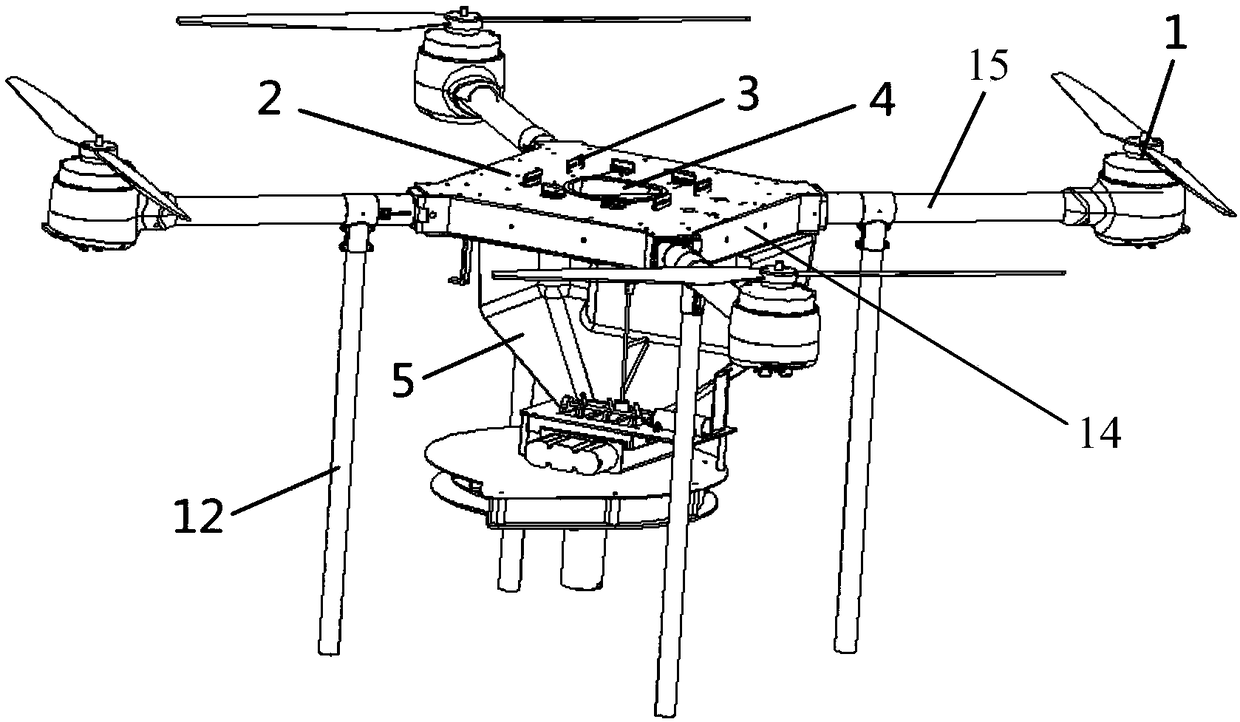

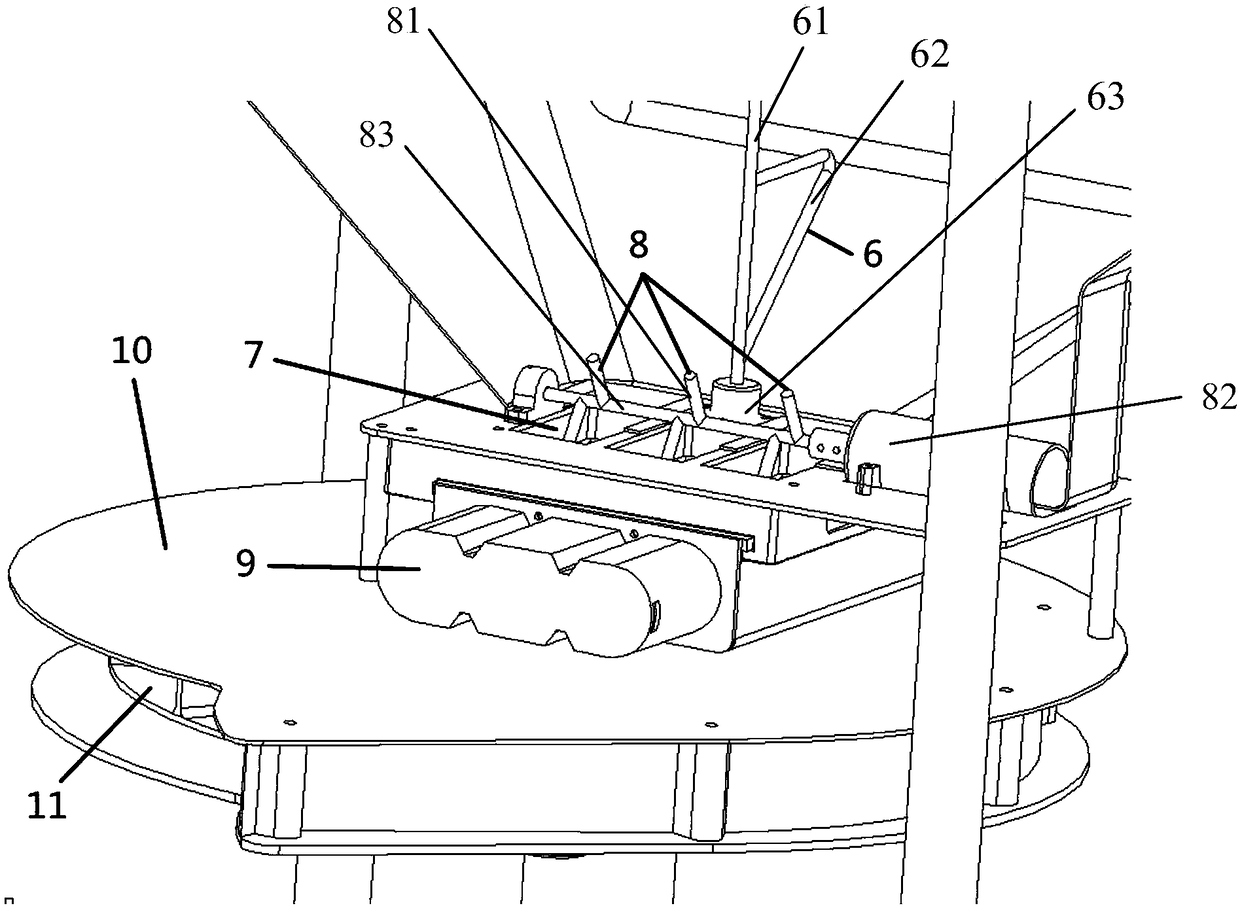

Unmanned aerial vehicle for automatically scattering materials, mobile control end and scattering method

InactiveCN108216632ASpread evenlyThe spreading device is equipped with multiple rotatableAircraft componentsRemote controlled aircraftUncrewed vehicleSimulation

The invention provides an unmanned aerial vehicle for automatically scattering materials, a mobile control end and a scattering method. The unmanned aerial vehicle comprises an unmanned aerial vehiclebody and a scattering device. A plurality of rotatable devices are arranged on the scattering device, so materials can be evenly scattered out; a scattering opening is transversely arranged and rotates at a high speed, so the scattering range of the materials is wider, and work efficiency is effectively improved. The mobile control end with APP control system software is adopted, through an APP system, the full-automatic work of the unmanned aerial vehicle can be controlled without being manually and remotely controlled in the whole process, people can control multiple unmanned aerial vehicles at the same time, and economic benefits are greatly improved; the scattering method is simple and has great intelligence.

Owner:GUANGDONG FECDA TECH CO LTD

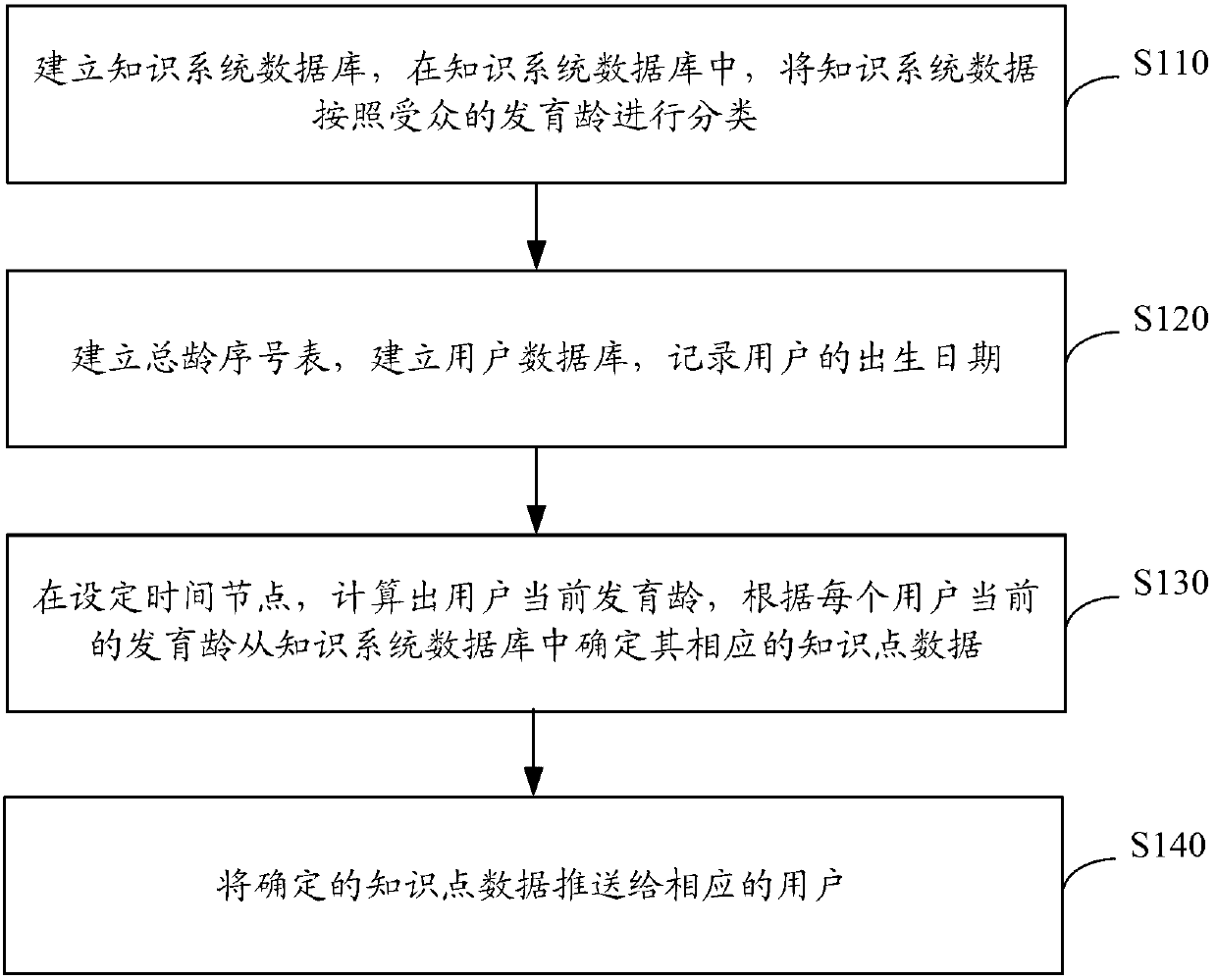

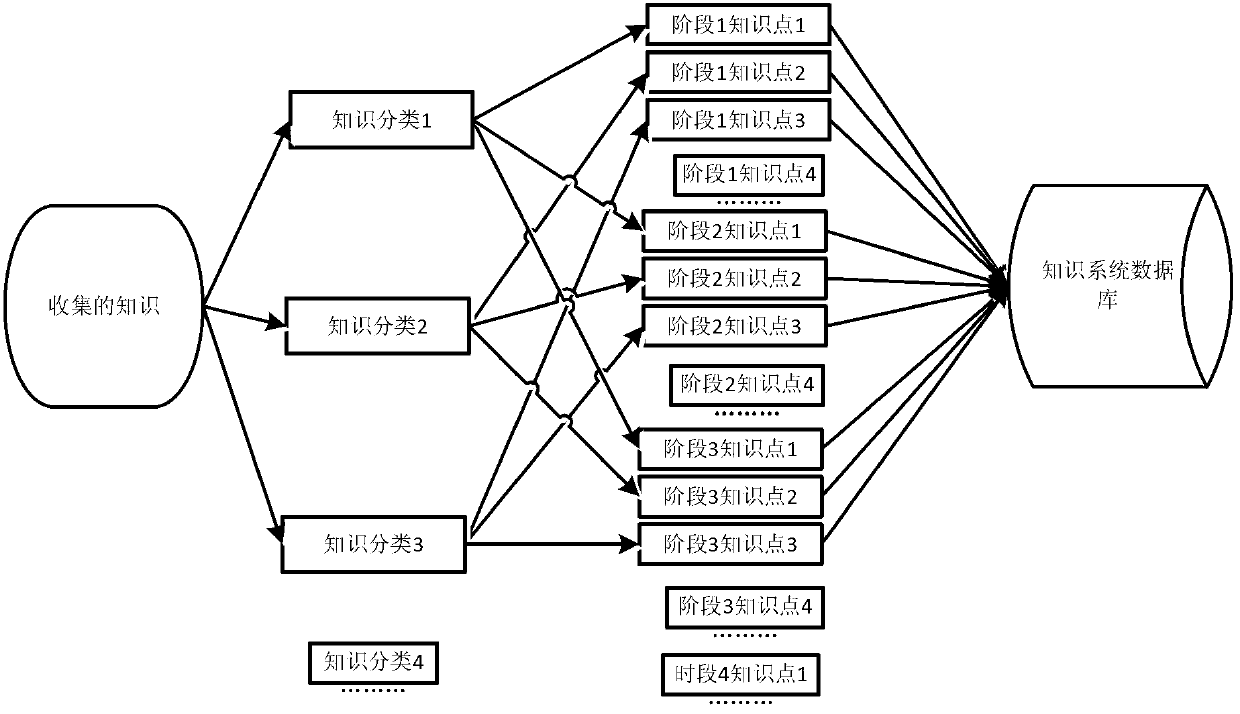

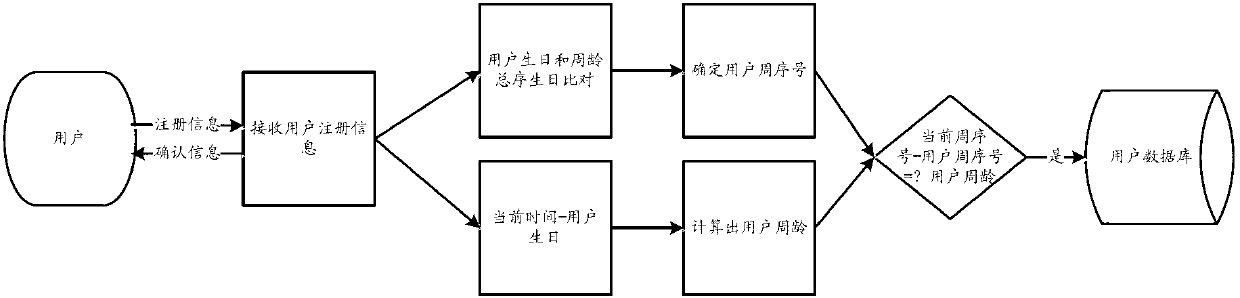

Data pushing method for educational information system

InactiveCN103279908AWide spreadCarrier is simpleData processing applicationsSpecial data processing applicationsSerial codeData science

The invention discloses a data pushing method for an educational information system. The method comprises the following steps: establishing a knowledge system database, and classifying knowledge system data according to development ages of audiences; establishing a user database, recording birthdates of users, and confirming age serial numbers of the users; calculating current development ages of the users at set time nodes; confirming corresponding knowledge point data from the knowledge system database according to the current development ages of the users; pushing the confirmed knowledge point data to corresponding users.

Owner:北京爱心家园育英技术服务中心

Nozzle hole mechanism

A nozzle hole mechanism (10) is provided with a nozzle hole (28) which ejects a raw liquid into the atmosphere, a swirl chamber (30) which supplies the raw liquid to the nozzle hole (28), and a path (27) which supplies the raw liquid to the swirl chamber (30), and the swirl chamber (30) and the nozzle hole (28) are located on the same axis. The swirl chamber (30) is configured so that a solid cylindrical front section (30b), which communicates with the nozzle hole, and an annular rear section (30a) are coaxially arranged. The nozzle hole mechanism is configured in such a manner that the raw liquid is supplied to the rear section (30a) and discharged from the nozzle hole (28) via the front section (30b) or, alternatively, in such a manner that the diameter of the nozzle hole (28) is 0.2 mm or less and the length of the nozzle hole (28) is in the range of 0.05-0.3 mm. The configuration enables the nozzle mechanism to spray fine particles over a wide area using a small spray amount.

Owner:DAIZO

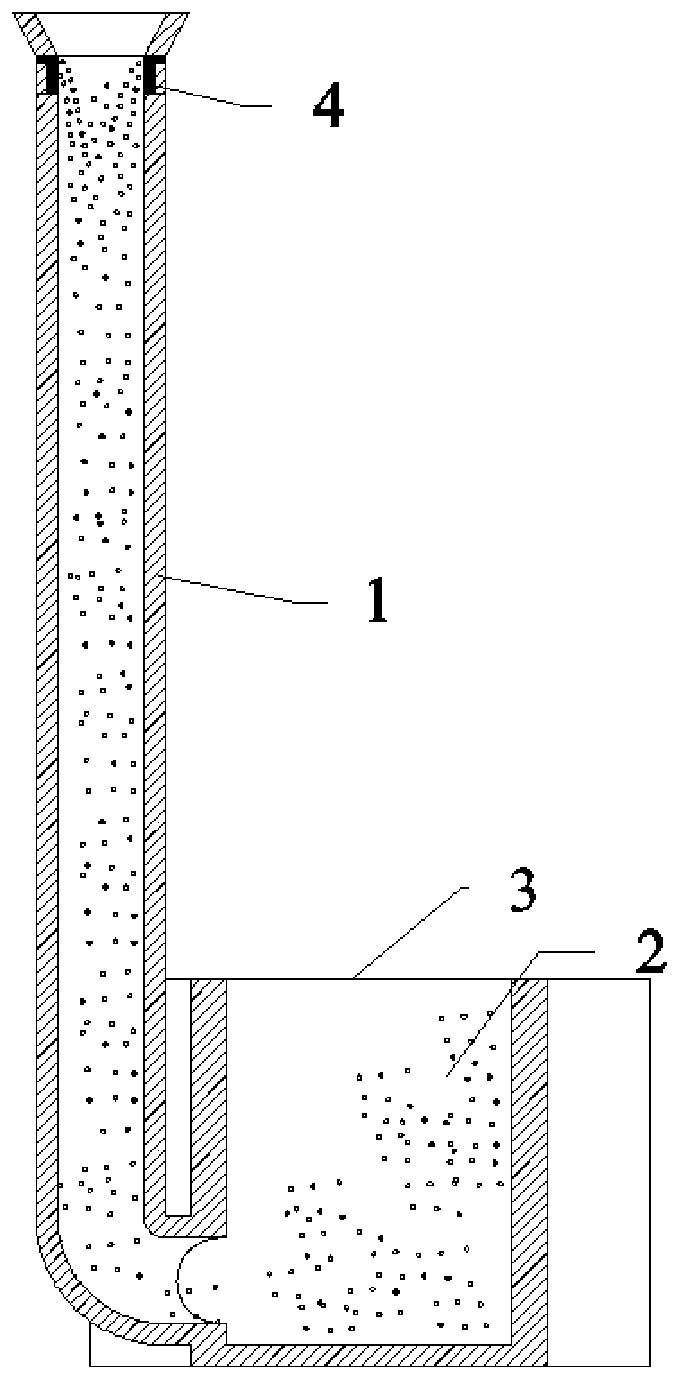

Long nozzle argon blowing refining device and method capable of effectively removing tundish inclusions

InactiveCN110394433AEasy to collide with adsorptionStrong stirringMelt-holding vesselsEngineeringHeat losses

The invention discloses a long nozzle argon blowing refining device capable of effectively removing tundish inclusions. The device is composed of a long nozzle, a swirling chamber and a swirling chamber outlet. An annular groove is reserved in the position, close to the top, of the inner wall of the long nozzle. An annular dispersion gas inlet chamber is arranged in the annular groove and connected with an argon conveying system through gas inlet holes formed in the wall of the long nozzle. The lower portion of the long nozzle is connected with the swirling chamber in the tangential direction.According to an argon blowing refining method adopting the device, the inclusions are removed by means of the adhering effect of dispersed phase argon bubbles, and the problems that a traditional argon blowing device is large in bubble size, the time of standing in molten steel is too short, the casting powder surface is prone to being broken, and consequentially, secondary oxidation and heat loss of the molten steel are caused are solved; and in addition, long nozzle argon blowing prevents scaffolding blockage of the long nozzle to a certain extent, meanwhile, gravitational potential energyof the molten steel in the swirling chamber is converted into rotational kinetic energy, the inclusions are promoted to collide, grow up and float upwards before being removed, and accordingly, the cleanliness of the molten steel is improved.

Owner:NORTHEASTERN UNIV

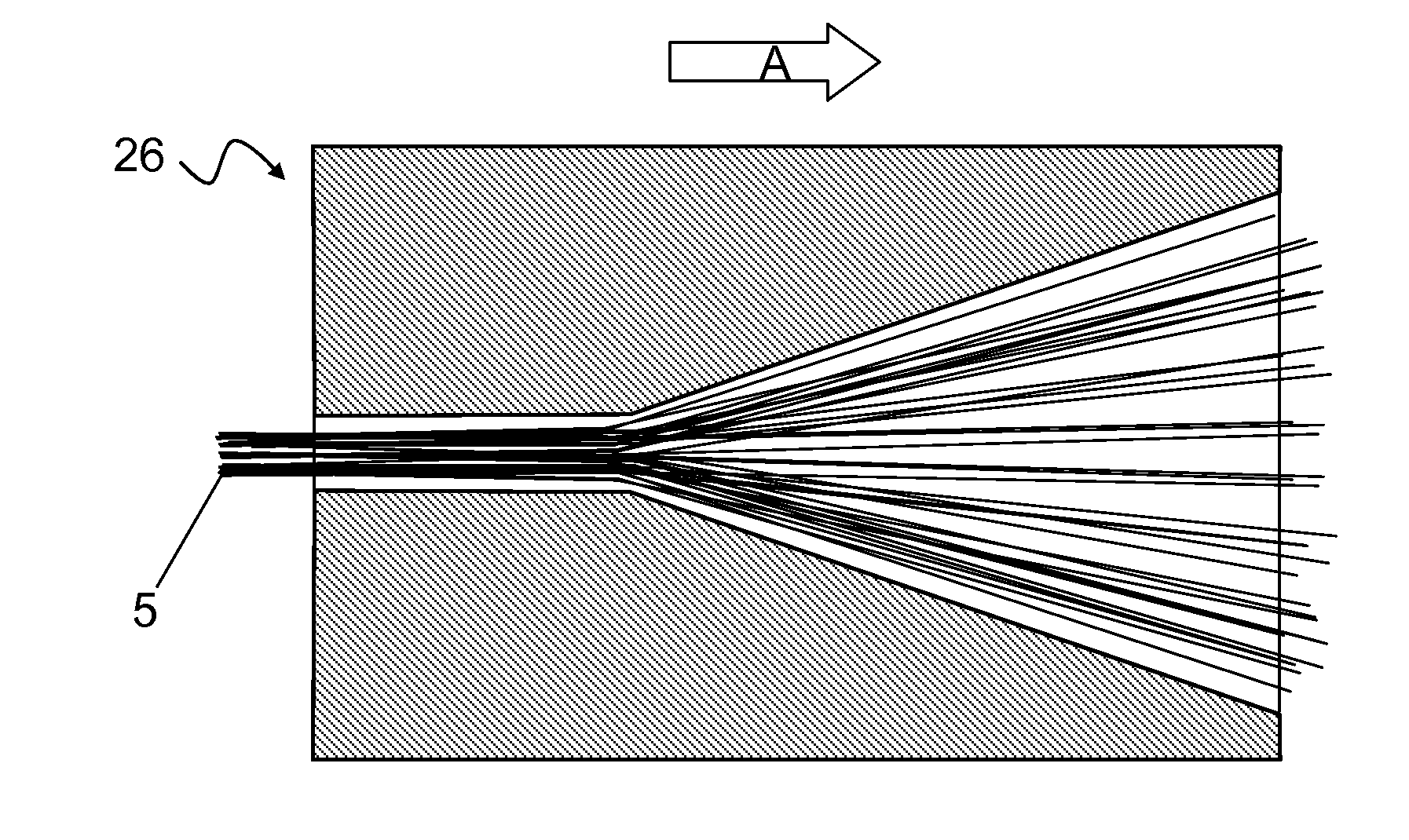

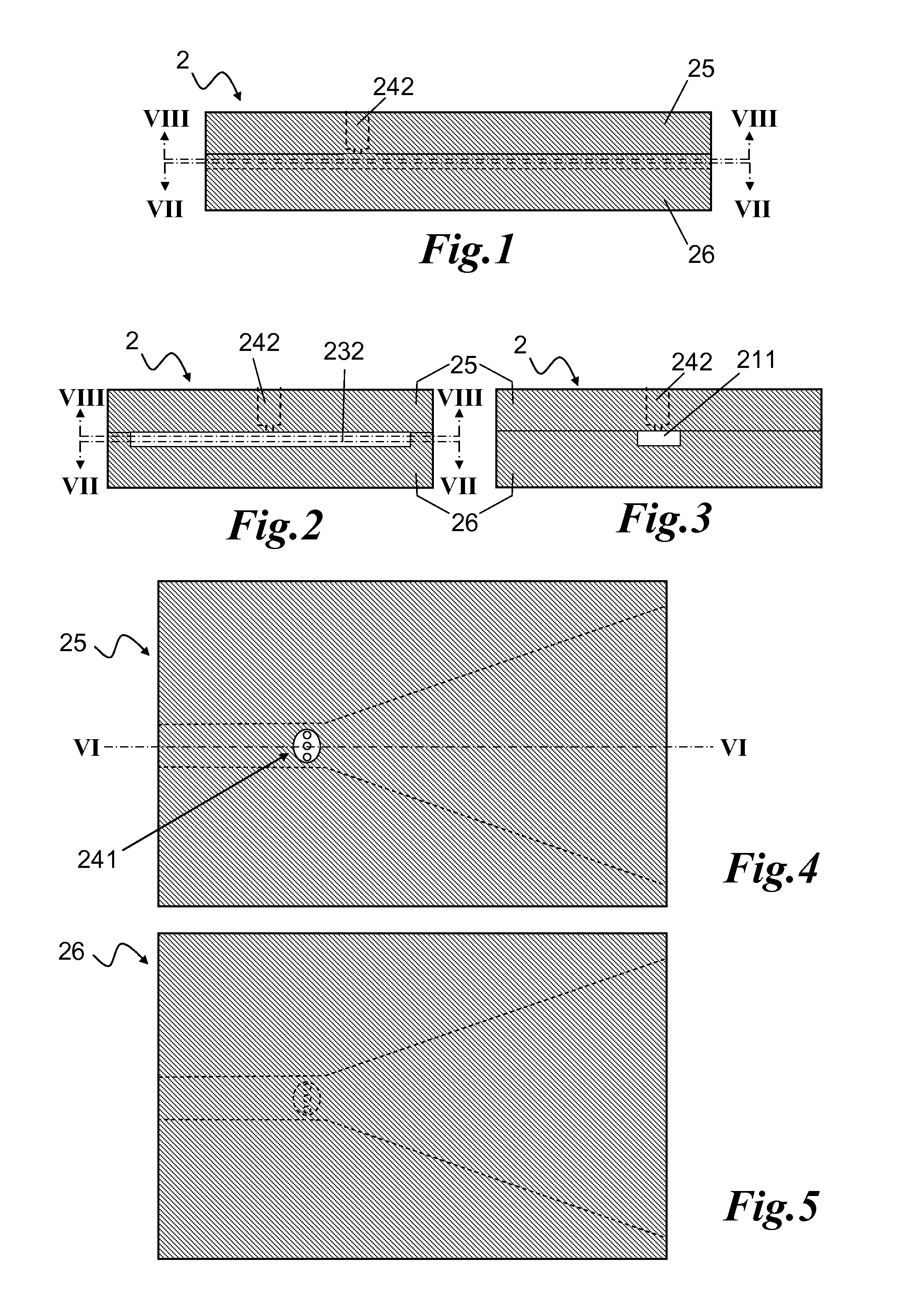

Method and Equipment for Reinforcing a Substance or an Object with Continuous Filaments

InactiveUS20130193623A1Spread widelyAvoid positioningTailstocks/centresConfectioneryFiberEngineering

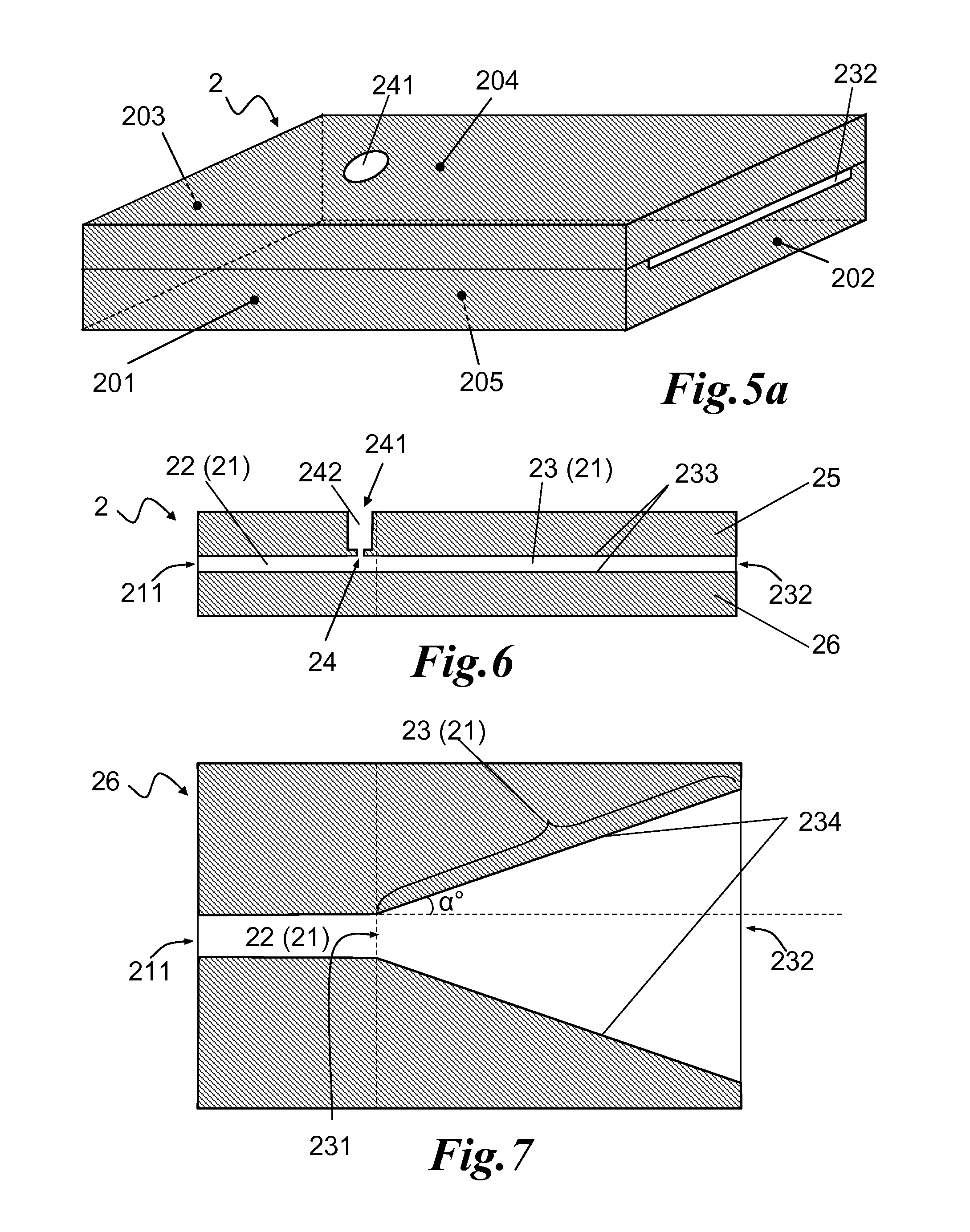

The present invention provides a method of reinforcing a substance or an object with continuous filaments comprising the steps of (a) supplying a fiber strand from a source of fiber strands, (b) passing said fiber strand horizontally through a passageway (21), (c) subjecting said fiber strand to a fluid such as air flow, within a channel (22) of rectilinear shape having an oblong cross-section, at an angle (γ) substantially perpendicular with respect to the moving direction of the filaments so as to separate said fiber strand into a plurality of smaller strands or individual filaments, and then (d) pulling said separated strands and / or individual filaments horizontally through a divergent zone (23), wherein the area of its exit end (232) is larger than the one of its entrance end (231) and has an oblong cross-section, so as to spread said strands and / or filaments along its diverging wall in a plane. Thus, the present invention proposes an improved frictionless solution to spread the fiber strand at higher speeds with a newly designed and simple apparatus as well as an improved process for reinforcing a substance or an object with continuous filament.

Owner:3B FIBERGLASS

Smoothly shifting multispeed transmission

InactiveUS20050032603A1Difficult to eliminateSmall stepToothed gearingsTransmission elementsGear wheelEngineering

The apparatus is a 28 speed, two section, transmission that requires only a single clutch swap for most changeovers between adjacent ratios. It uses a first section with three close ratio forward speeds and one reverse along with a second section that is an 11 speed, wide ratio, transmission. The two transmission sections are arranged in series resulting at least 28 usable forward speeds. The second section includes an intermediate planetary gear set without a ring gear and an output planetary gear set that is a conventional simple planetary gear set with a two sun gears, two planes of planetary gears on a single carrier, and two ring gears.

Owner:BLUE LEAF I P INC +1

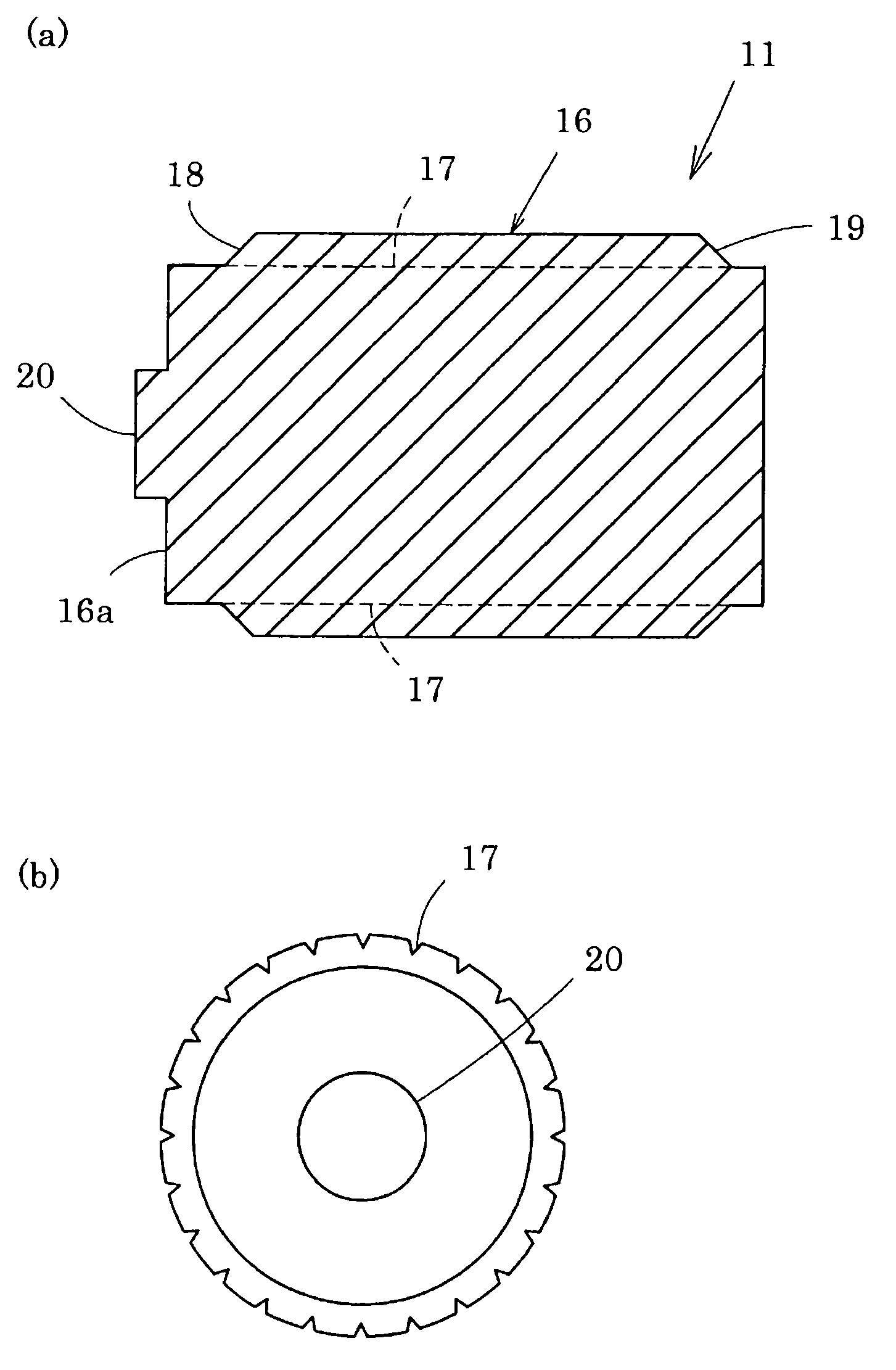

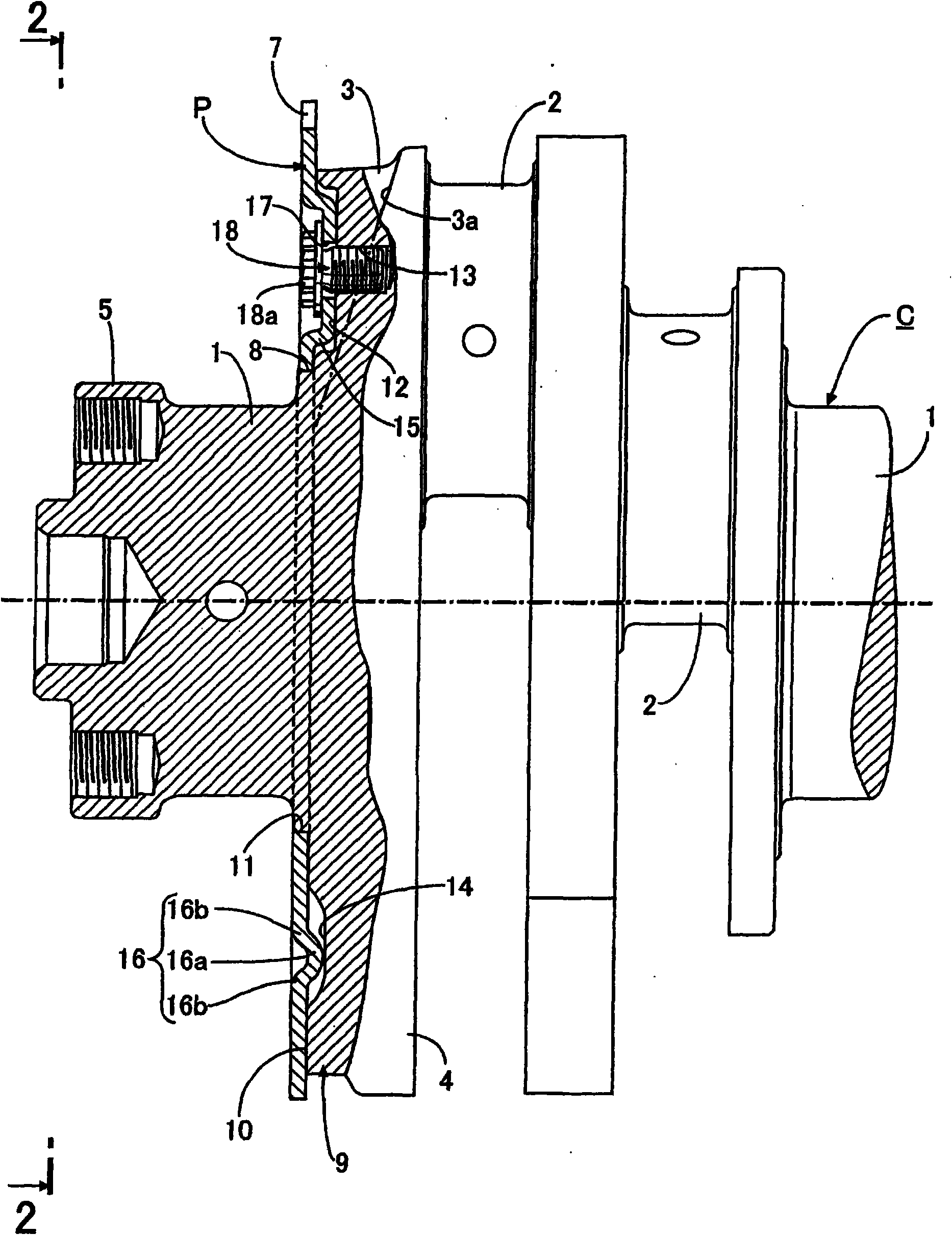

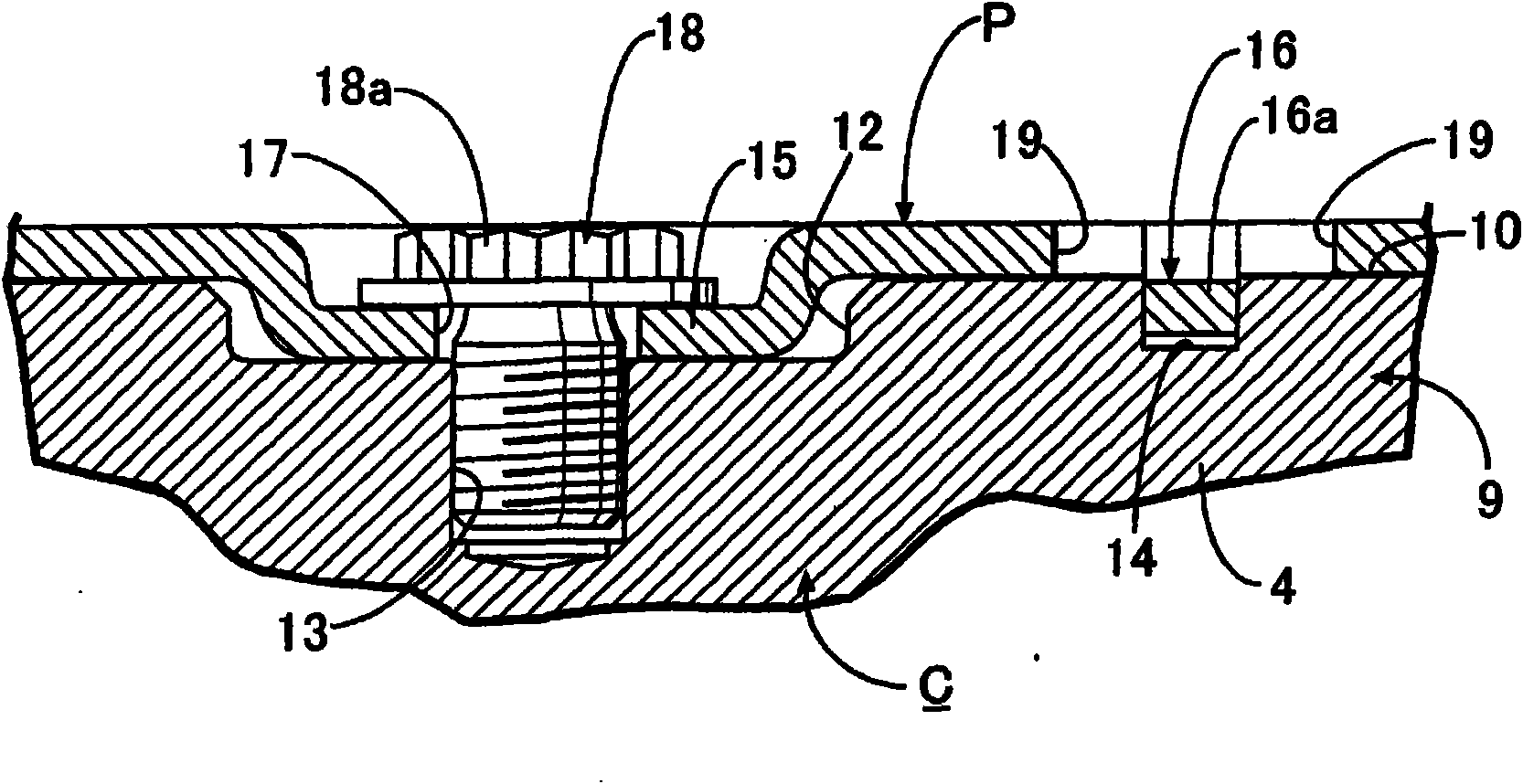

Pulser plate mounting structure

InactiveCN101600871AHigh positioning accuracyImprove productivityCrankshaftsEngine controllersProduction rateBand shape

A pulser plate mounting structure in which a key groove (14) is formed in a mounting surface (10) of a rotation wall section (9) having a crank arm (3) and a counter weight (4), a key section (16) engaging with the key groove (14) is formed on a pulser plate (P) superposed on the mounting surface (10), and the pulser plate (P) is secured to the rotation wall section (9) by a securing member (18). The key section (16) is constructed from an arcuate band-like section (16a) arcuately projecting from the pulser plate (P) toward one end face of the pulser plate and engaging with the key groove (14), and from a pair of connection sections (16b) for integrally connecting both ends of the arcuate band-like section (16a) to the pulser plate (P). The pulser plate mounting structure enables highly accurately positioning of the pulser plate on a crankshaft and provides excellent productivity of the pulser plate.

Owner:HONDA MOTOR CO LTD

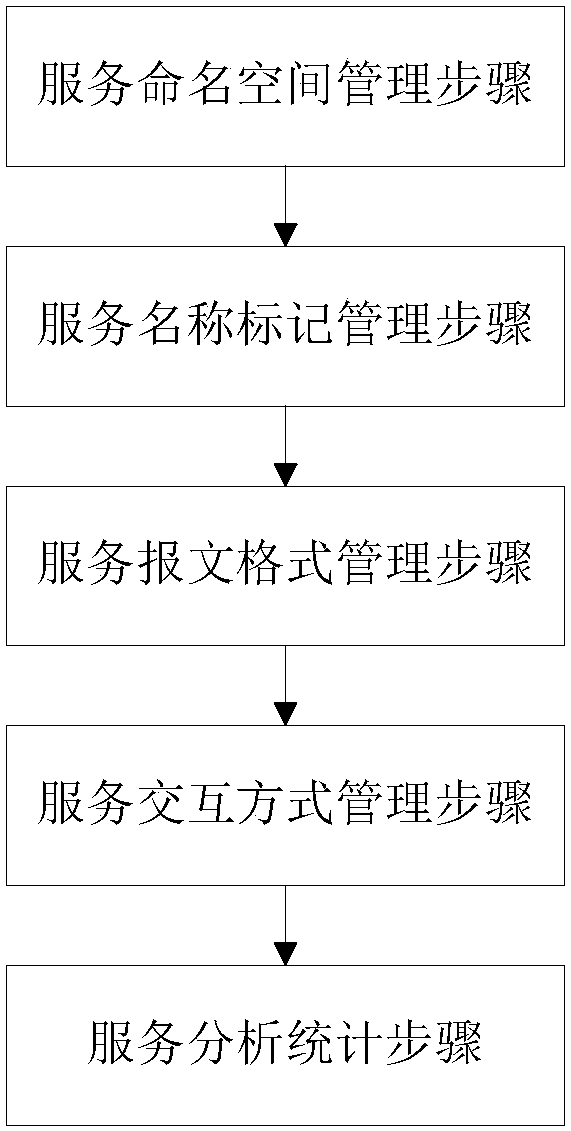

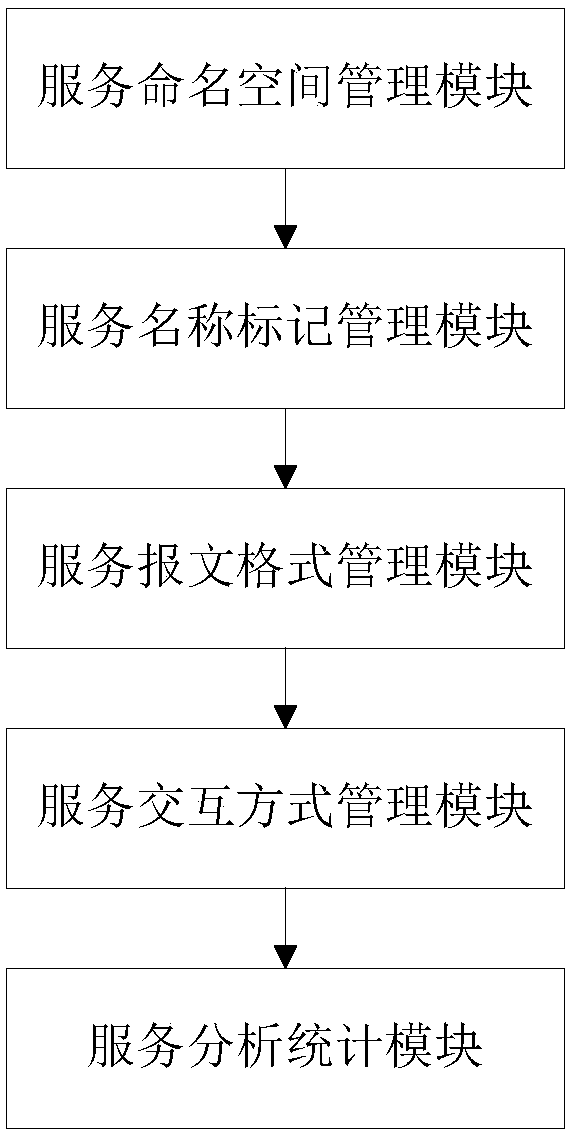

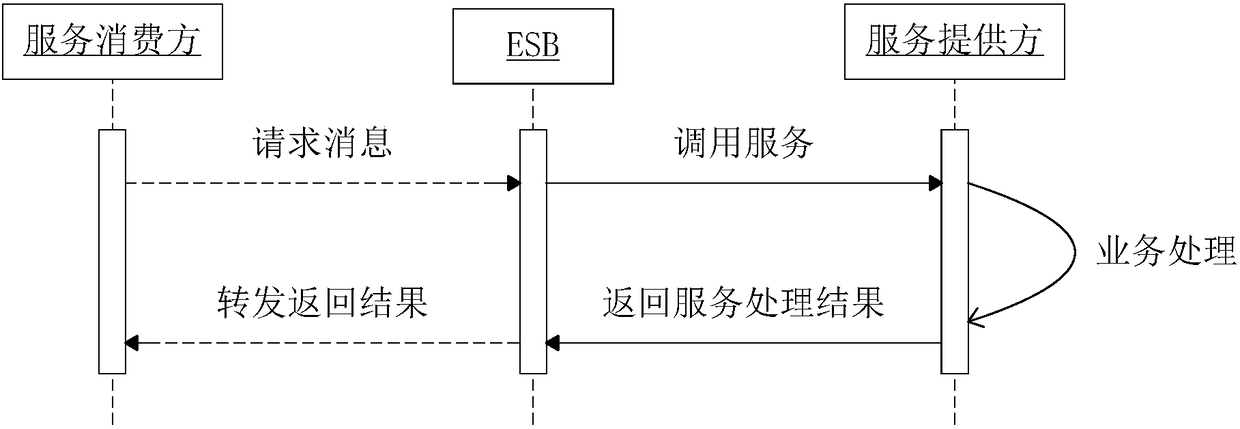

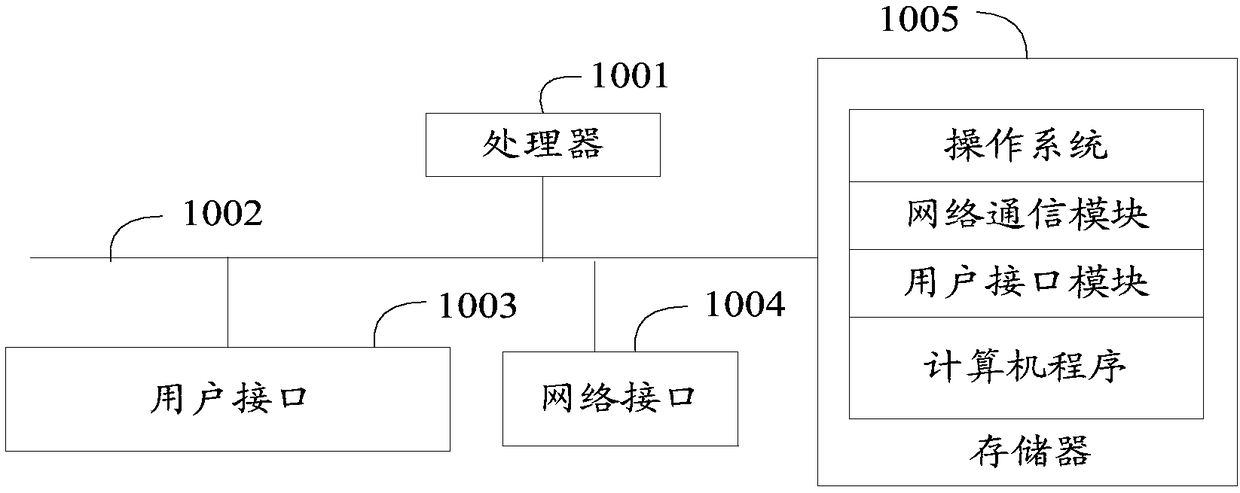

Service management method and system of enterprise bus platform

InactiveCN108234541AStrong real-timeGet results in timeOffice automationResourcesService provisionIT service management

The invention relates to a service management method and system of an enterprise bus platform, and belongs to the service management field of the enterprise bus platform. Various indexes of the service can be conveniently analyzed and counted, various controls on the service are reinforced, and the service abnormal processing efficiency is improved. A service provider sets a namespace of an inputtarget and a namespace of an output target according to the abbreviation of a service corresponding business system, sets service English name, service Chinese name, service ID and service resource identifier, sets input-output parameter of the service, the input-output data, the namespace of the input-output target and an attribute of the element, and sets interaction ways of the service, the interaction ways comprise a both-way interaction mode and a one-way interaction mode; the enterprise bus platform analyzes and counts the service according to the namespace of the service, the name sign,the message format and the interaction way. The control on the service is reinforced, and the service abnormal processing efficiency is improved.

Owner:SHAANXI REGIONAL ELECTRIC POWER GROUP

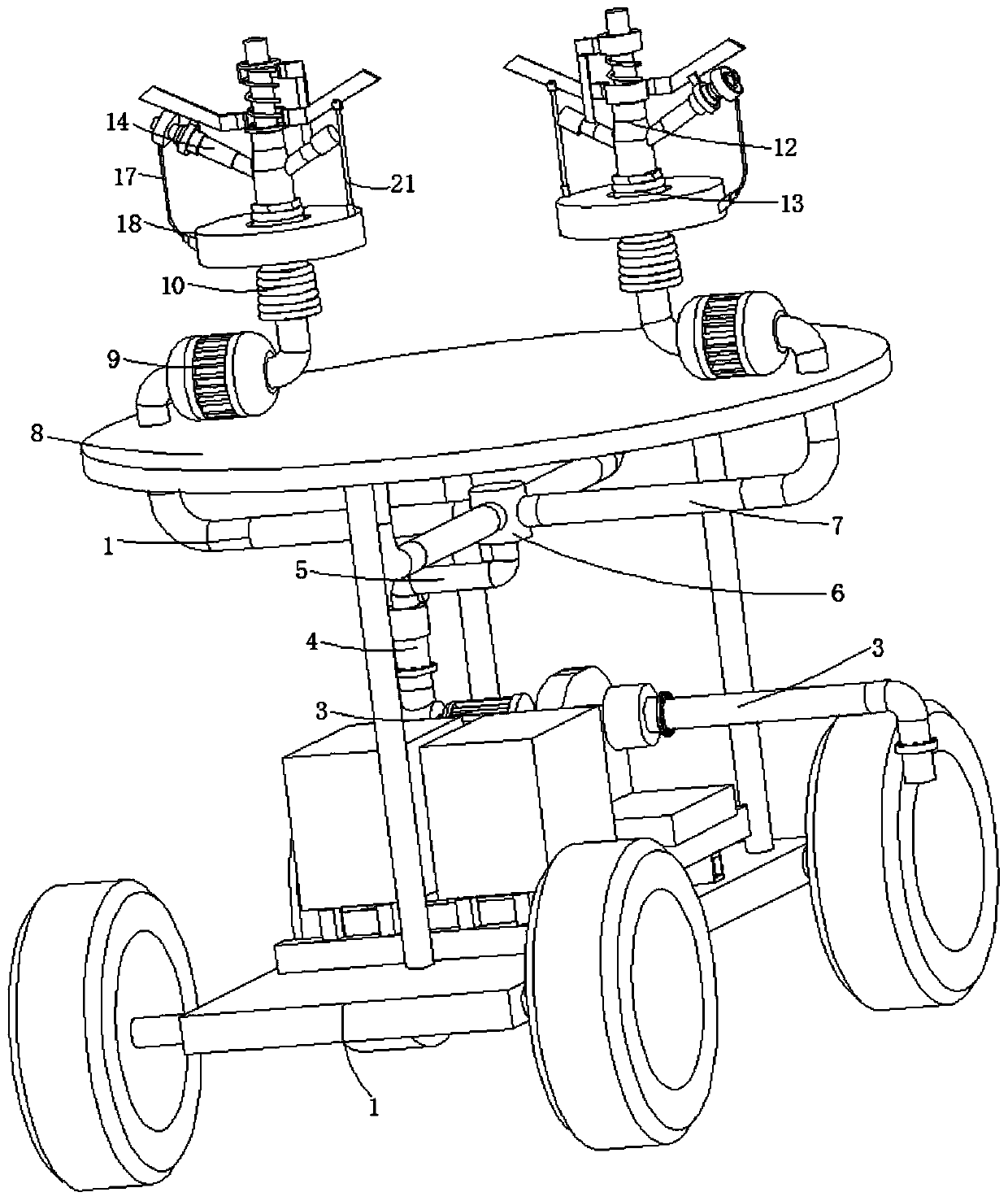

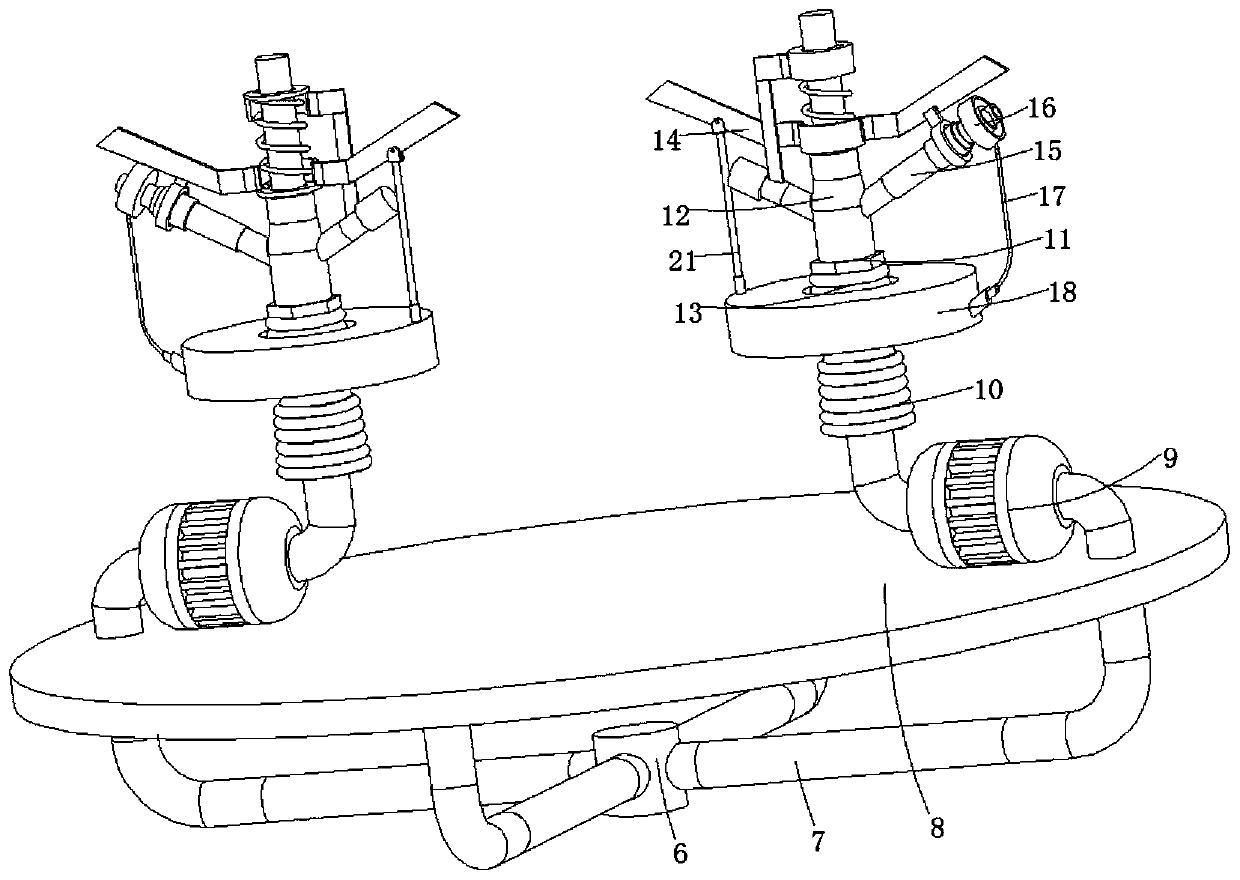

Water conservancy project efficient farmland irrigation device

PendingCN110800592AAchieve left and right swingRealize the push-pull effectClimate change adaptationWatering devicesEnvironmental engineeringWater diversion

The invention discloses a water conservancy project efficient farmland irrigation device and belongs to the technical field of water conservancy project irrigation equipment. The device comprises a moving support, a water pump arranged at the top of the moving support, a water drawing pipe connected with the water incoming end of the water pump and a water outgoing pipe connected with the water outgoing end of the water pump and connected with a connection pipe through a connection water pipe, a water diversion pipe is connected on the connection pipe, a mounting disc is set up at the top of the moving support, the top end of the water diversion pipe penetrates the mounting disc and connected with a pressurizing pump, the output end of the pressurizing pump is connected with a temporary storage pipe, the top end of the temporary storage pipe is connected with a spraying pipe through a connection hose, a spring is connected on the outer wall of the connection hose in a sleeved manner, and two ends of the spring are fixedly connected with the spraying pipe and the temporary storage pipe respectively. Water sprayed by a spraying irrigation nozzle is utilized as power to further push the same to swing, in this way, atomized water sprayed by the spraying irrigation nozzle is emitted in a wide range, so that microspray irrigation effect is improved.

Owner:王长波

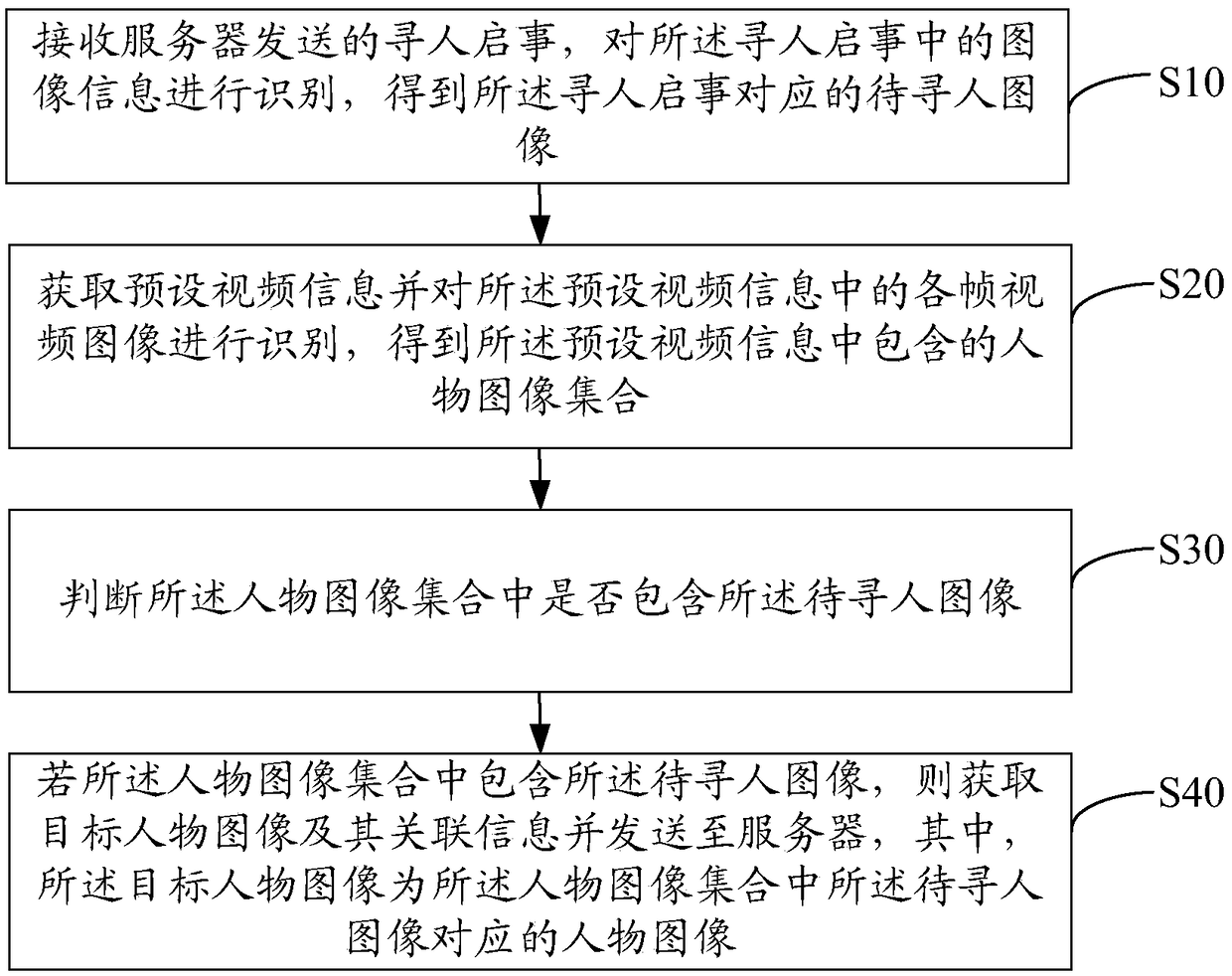

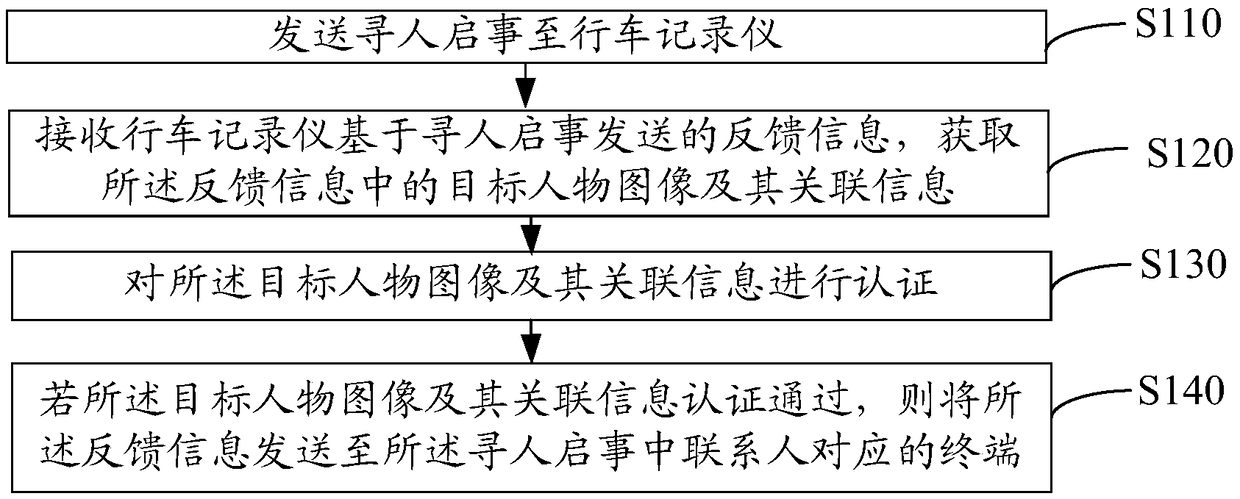

Method, device, system and storage medium for searching a person based on a traffic recorder

InactiveCN109389029AAvoid expirationEasy to findRegistering/indicating working of vehiclesCharacter and pattern recognitionPattern recognitionImaging processing

The invention discloses a searching method based on a traffic recorder, comprising the following steps: the traffic recorder receives a searching notice sent by a server, identifies the image information in the searching notice, and obtains an image of a person to be searched corresponding to the searching notice; Acquiring preset video information and identifying each frame of video images in thepreset video information to obtain a character image set contained in the preset video information; Judging whether the person image set contains the person-to-be-searched image; If the person imagecollection includes the person image to be searched, acquiring and sending the target person image and the related information are acquired and to the server. The invention also discloses a searchingdevice, a system and a computer storage medium based on a traffic recorder. As that traffic recorder carry out image processing by using the face recognition technology, the invention realizes convenient and high-efficient person search.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com