Long nozzle argon blowing refining device and method capable of effectively removing tundish inclusions

A technology of argon blowing refining and tundish, which is applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc. It can solve the problems of unobvious rotation of molten steel, short residence time, and inability to effectively remove non-metallic inclusions, etc., to achieve Promote the effect of collision, agglomeration, growth and floating, uniform composition and temperature of molten steel, and reduction of clogging and nodulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An argon blowing refining method of a long nozzle argon blowing refining device for effectively removing tundish inclusions as described above, comprising the following steps:

[0042] Step 1: Taking the single-flow tundish as an example, select the specific size of the long nozzle argon blowing refining device to be used to effectively remove the inclusions in the tundish;

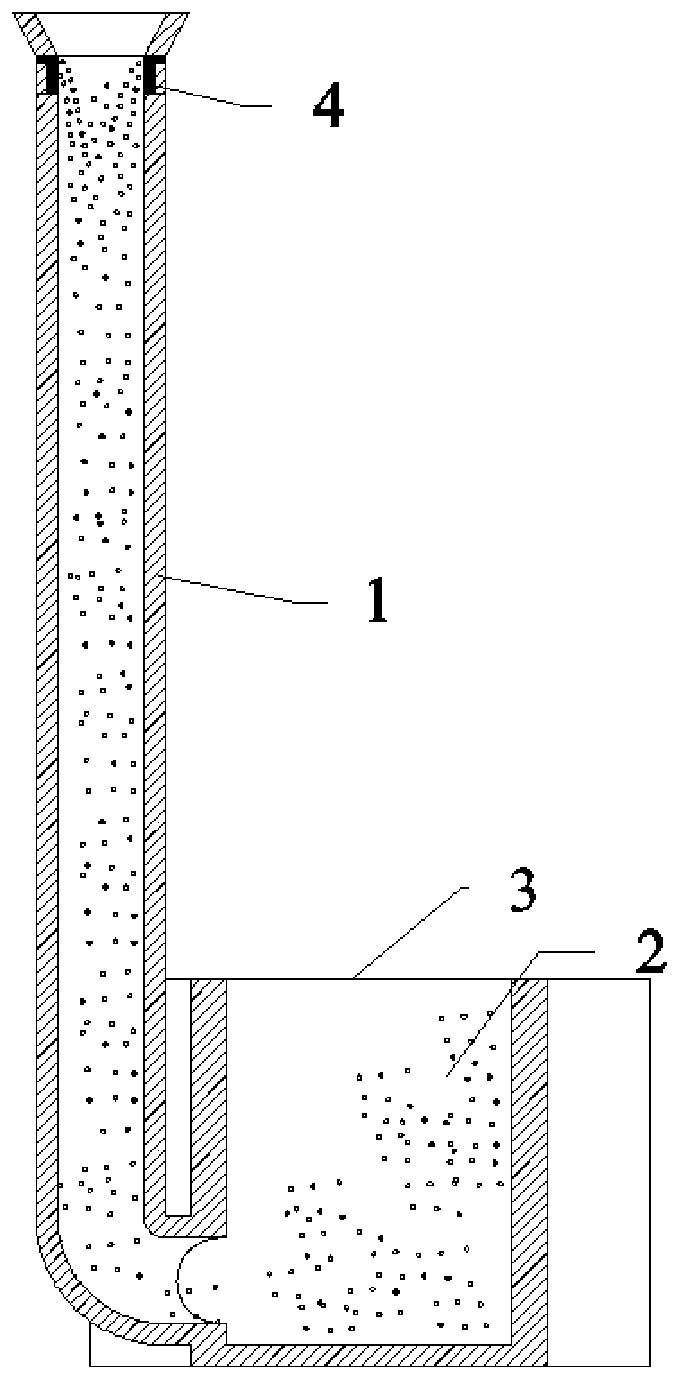

[0043] Step 2: If Figure 4 As shown in (a), the long nozzle argon blowing refining device selected in step 1 is placed in the pouring area of the tundish. The argon gas is transported in the annular diffuse type air inlet chamber 4, and enters the long nozzle to form argon gas bubbles in the dispersed phase. The diameter of the phase argon bubble is 1mm;

[0044] Step 3: During the pouring process, the molten steel flows from the long nozzle 1 into the swirl chamber 2 due to gravity, and the argon bubbles in the dispersed phase are further broken and refined into dispersed phase by the high tu...

Embodiment 2

[0049] An argon blowing refining method of a long nozzle argon blowing refining device for effectively removing tundish inclusions as described above, comprising the following steps:

[0050] Step 1: Taking the single-flow tundish as an example, select the specific size of the long nozzle argon blowing refining device to be used to effectively remove the inclusions in the tundish;

[0051] Step 2: If Figure 4 As shown in (a), the long nozzle argon blowing refining device selected in step 1 is placed in the pouring area of the tundish. The argon gas is transported in the annular diffuse type air inlet chamber 4 and enters the long nozzle to form argon gas bubbles in the dispersed phase. The diameter of the argon bubble is 0.5mm;

[0052] Step 3: During the pouring process, the molten steel flows from the long nozzle 1 into the swirl chamber 2 due to gravity, and the argon bubbles in the dispersed phase are further broken and refined into dispersed phase by the high turbule...

Embodiment 3

[0057] An argon blowing refining method of a long nozzle argon blowing refining device for effectively removing tundish inclusions as described above, comprising the following steps:

[0058] Step 1: Taking the single-flow tundish as an example, select the specific size of the long nozzle argon blowing refining device to be used to effectively remove the inclusions in the tundish;

[0059] Step 2: If Figure 4 As shown in (a), the long nozzle argon blowing refining device selected in step 1 is placed in the pouring area of the tundish. The argon gas is transported in the annular diffuse type air inlet chamber 4, and enters the long nozzle to form argon gas bubbles in the dispersed phase. The diameter of the phase argon bubble is 0.1mm;

[0060] Step 3: During the pouring process, the molten steel flows from the long nozzle 1 into the swirl chamber 2 due to gravity, and the argon bubbles in the dispersed phase are further broken and refined into dispersed phase by the high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com