Mixing agitator for materials

A technology for mixing and mixing materials, applied in mixers, mixing methods, mixers with rotating agitating devices, etc., can solve problems such as high operating costs, unsatisfactory, dust pollution, etc., and achieve improved mixing uniformity and long service life , Stir strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

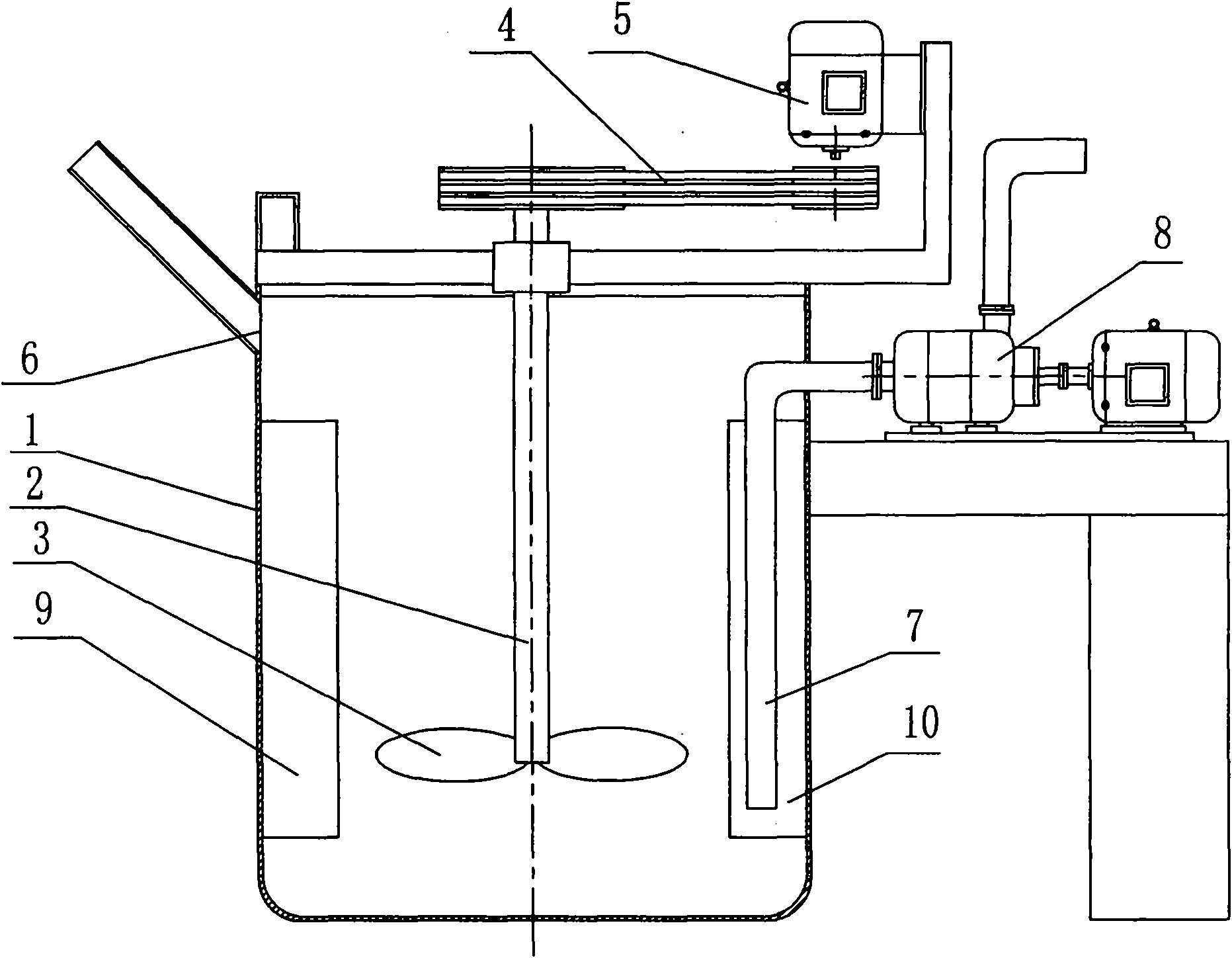

[0009] Such as figure 1 As shown, the present invention is provided with a barrel body 1, a stirring shaft concentrically arranged vertically with the barrel body 1, the lower end of the stirring shaft 2 in the barrel body 1 is connected to the blade 3, and the stirring shaft 1 outside the barrel body 1 passes through a transmission reduction mechanism 4 is connected with the motor 5 that is arranged on the outside of barrel body 1.

[0010] A feed inlet 6 is arranged at the upper end of the barrel body 1, and a suction pipe 7 is arranged inside the barrel body 6. The upper end of the material suction pipe 7 is connected with the inlet end of the water pump 8 arranged outside the barrel body 1, and is symmetrically fixed on the inner wall of the barrel body 1. Connect two vertical deflectors 9,10, the lower end of each deflector 9,10 is located below the horizontal plane of the blade 3, and the inlet end of the suction pipe 7 is arranged between the lower end of the deflector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com