Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Excellent process parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

MXene@CS@PDMS three-dimensional porous composite material and preparation method and application thereof

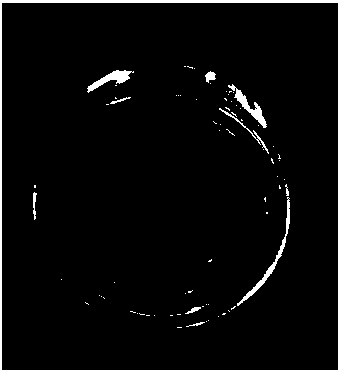

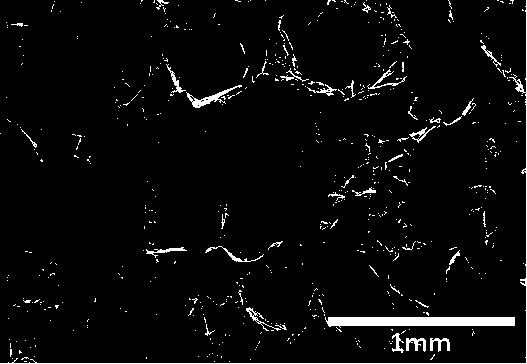

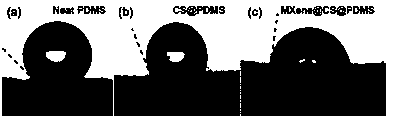

ActiveCN110375894AVariety of shapesSimple methodMaterial nanotechnologyFluid pressure measurement using ohmic-resistance variationGranularityConductive materials

The invention relates to an MXene@CS@PDMS three-dimensional porous composite material and a preparation method and application thereof. A high-sensitivity and high-reliability piezoresistive sensor isprepared by using the material. Since the cube sugar micro-pore granularity is proper and the structure is loose, the prepared PDMS has a three-dimensional sponge-like porous structure by using the cube sugar as a template and has the high flexibility and deformability. With introduction of the MXen@CS@PDMS system, an MXene nanosheet is attached to the PDMS surface tightly after successful loading of the MXene, so that a reliable three-dimensional conductive material is formed. Moreover, reaction parameters in the process of preparing the sensor are optimized to obtain the MXene@CS@PDMS composite three-dimensional structure with good stress and strain is obtained.

Owner:BEIJING UNIV OF CHEM TECH

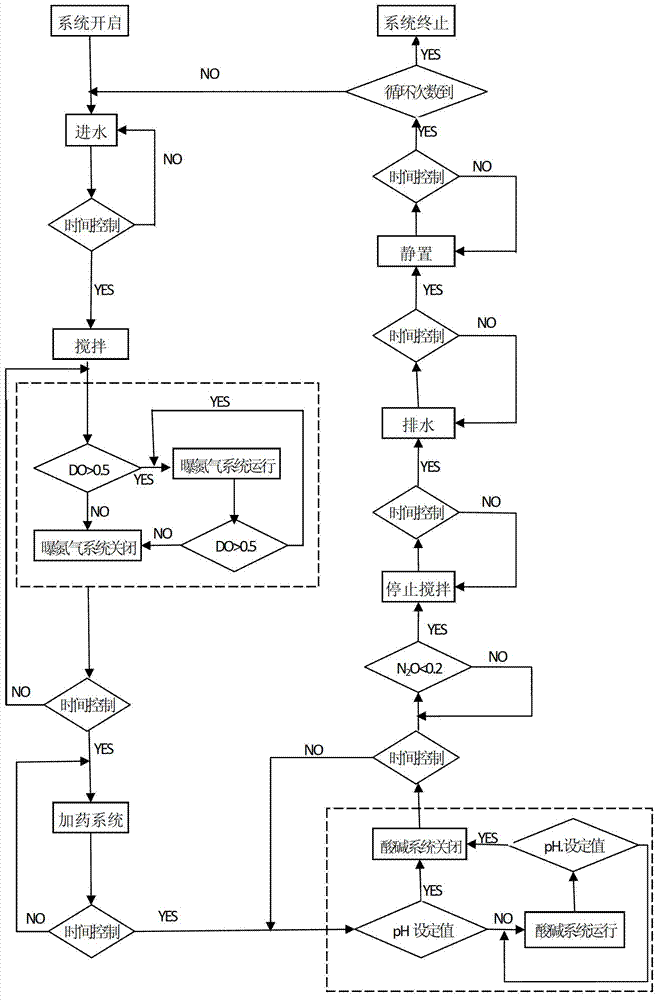

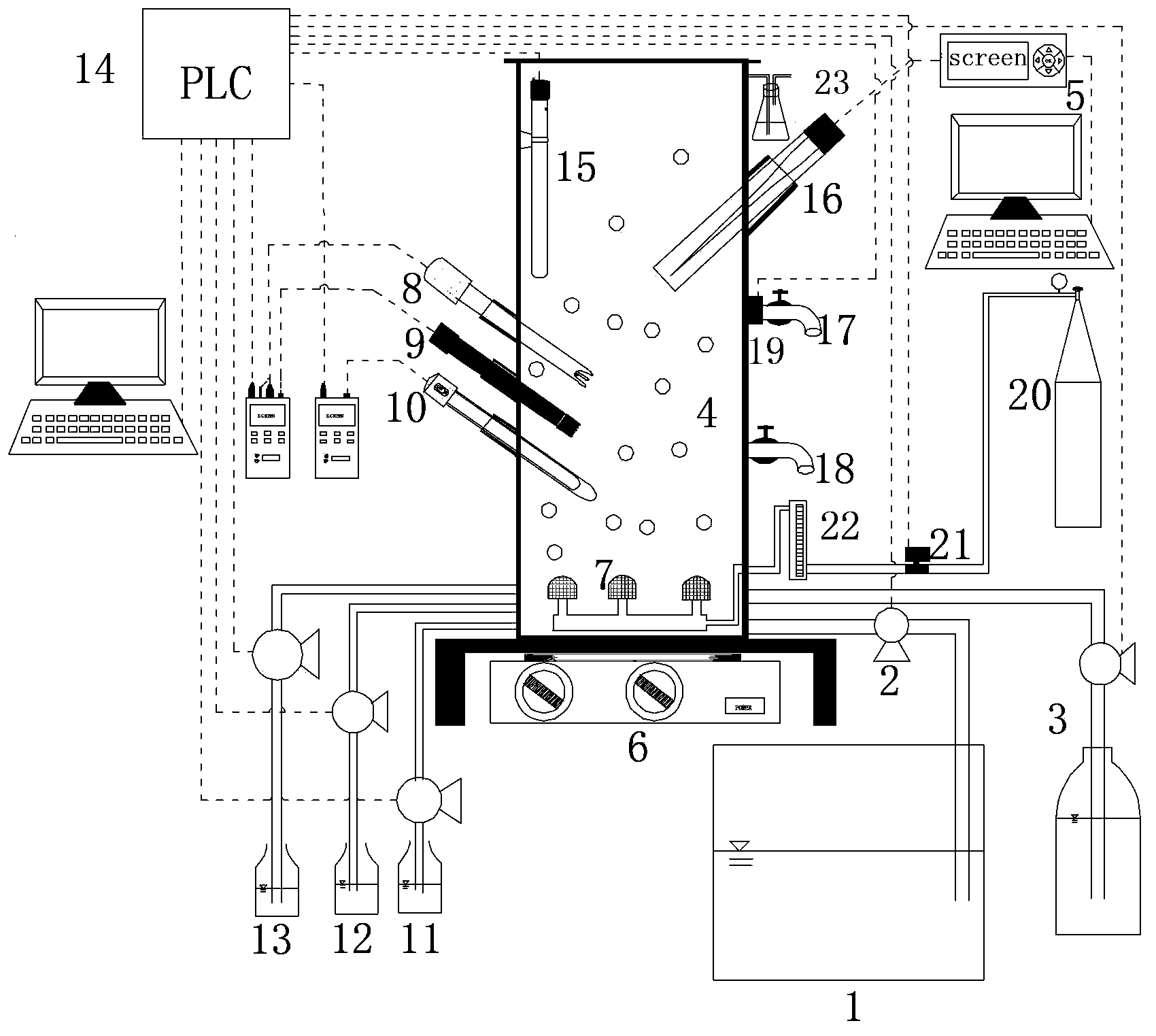

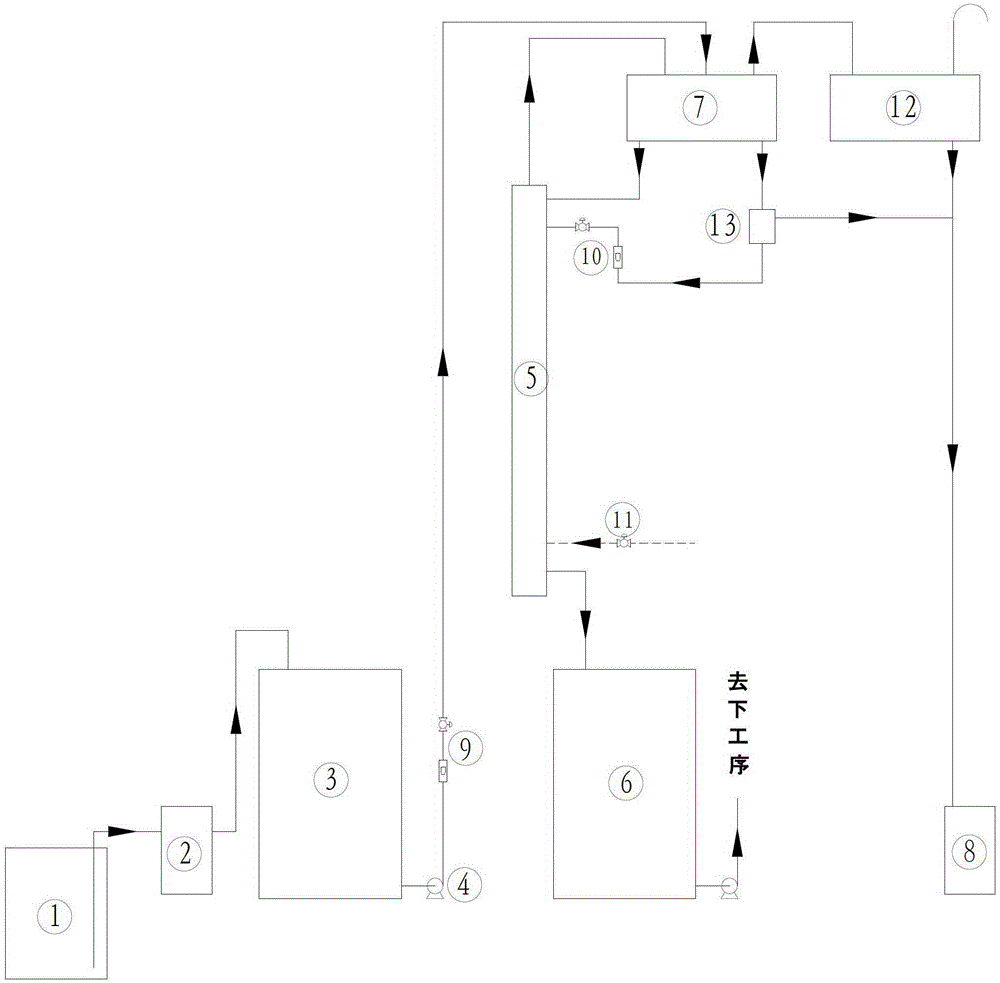

Reduction control device and method for N2O produced in denitrification dephosphorization process

ActiveCN102849850AAutomatic control of online recording dataExcellent process parametersTreatment with aerobic and anaerobic processesTotal factory controlPeristaltic pumpActivated sludge

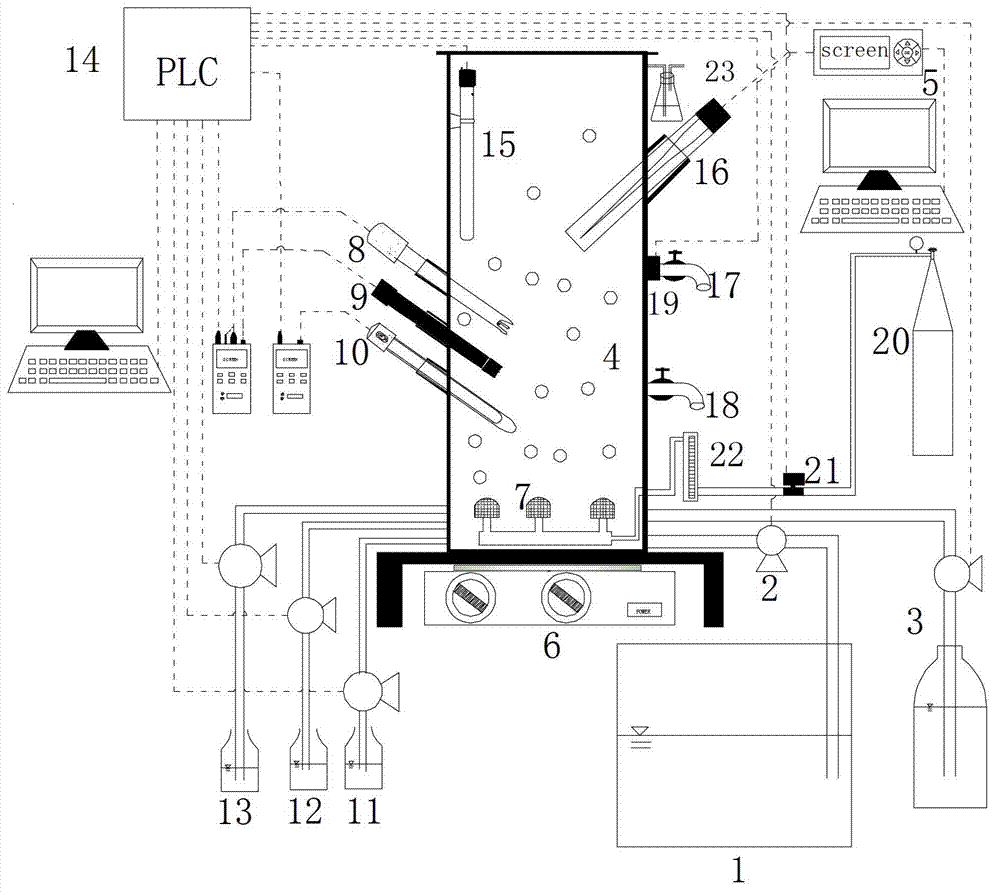

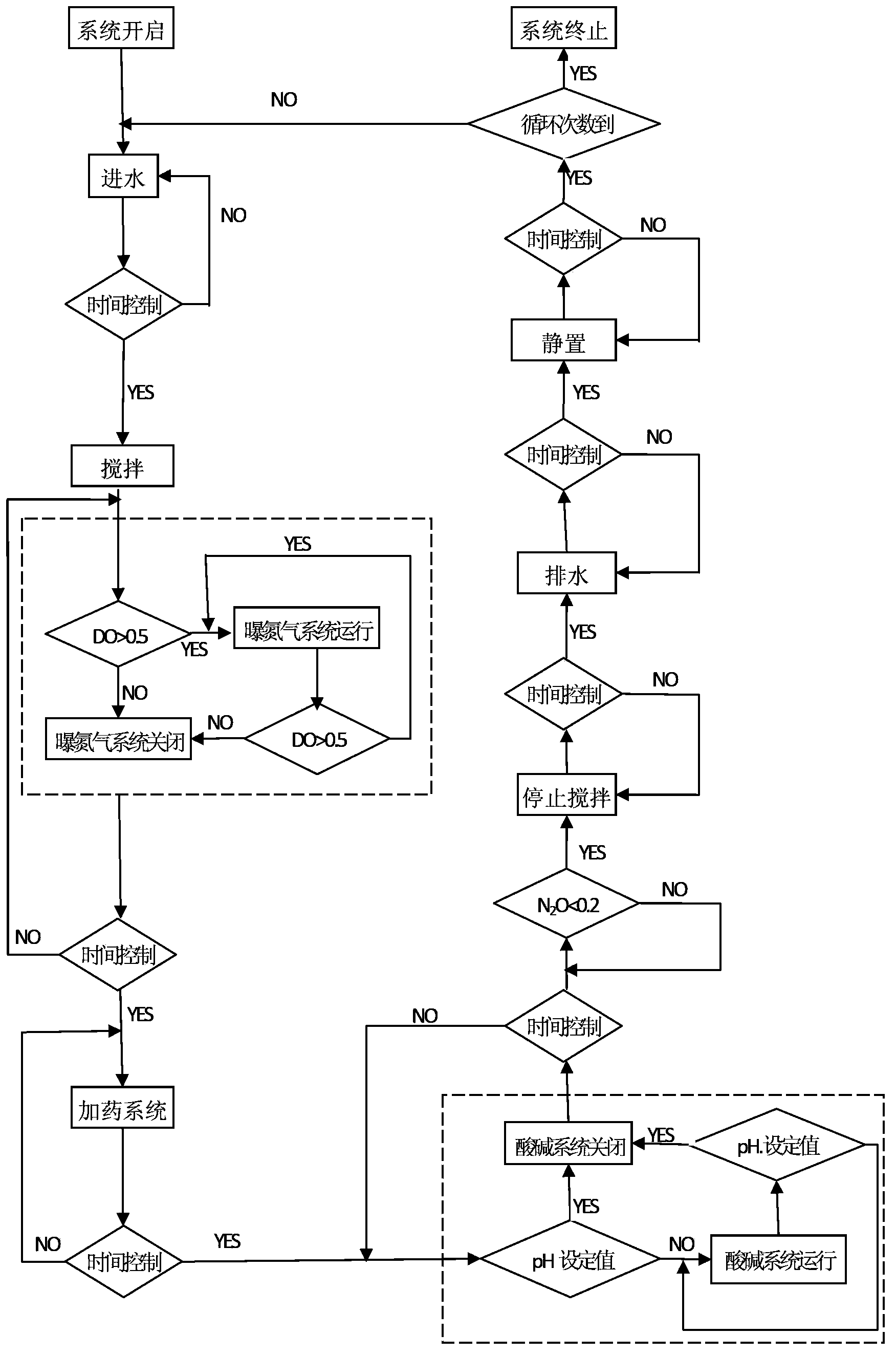

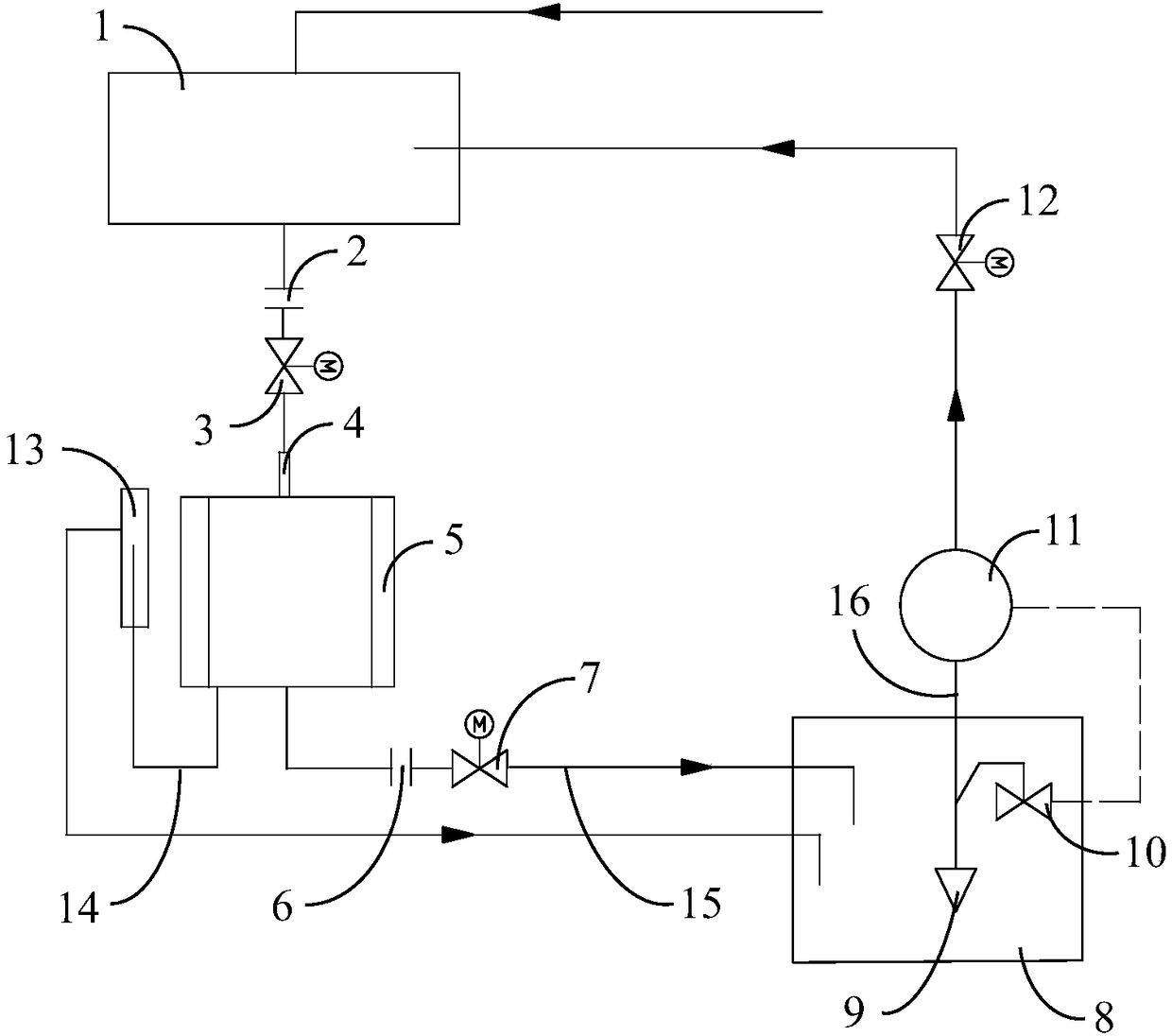

The invention provides a reduction control device and method for N2O produced in the denitrification dephosphorization process and belongs to the technical fields of automatic control of an activated sludge process treatment system and wastewater biological denitrification dephosphorization by means of a sequencing batch reactor (SBR) process. Aiming at solving the technical problem that sodium nitrite adopted to serve as an electron acceptor produces N2O in the denitrification dephosphorization process in the existing SBR process, the device uses an SBR as a main body and comprises a water distribution tank, a peristaltic pump, a magnetic stirring apparatus, an acid adding system, an alkali adding system, an on-line control system connected with a computer and a N2O on-line detecting system. The on-line control system is connected with a water inlet peristaltic pump, a mud discharging system, the acid adding system, the alkali adding system, a temperature control device, the stirring apparatus, a drain valve, a relay on a magnetic valve of a nitrogen aerating system, an oxidation reduction potential (ORP) sensor, a pH sensor and a dissolved oxygen sensor. The N2O on-line detecting system is connected with a N2O microelectrode. The whole process is automatically finished through a programmable logic controller (PLC) of the computer, and the N2O on-line detecting system performs quantitative analysis to the nitrogen conversion condition to confirm dominant mechanism and influencing factors for the N2O production in the denitrification dephosphorization process.

Owner:SDIC XINKAI WATER ENVIRONMENT INVESTMENT CO LTD

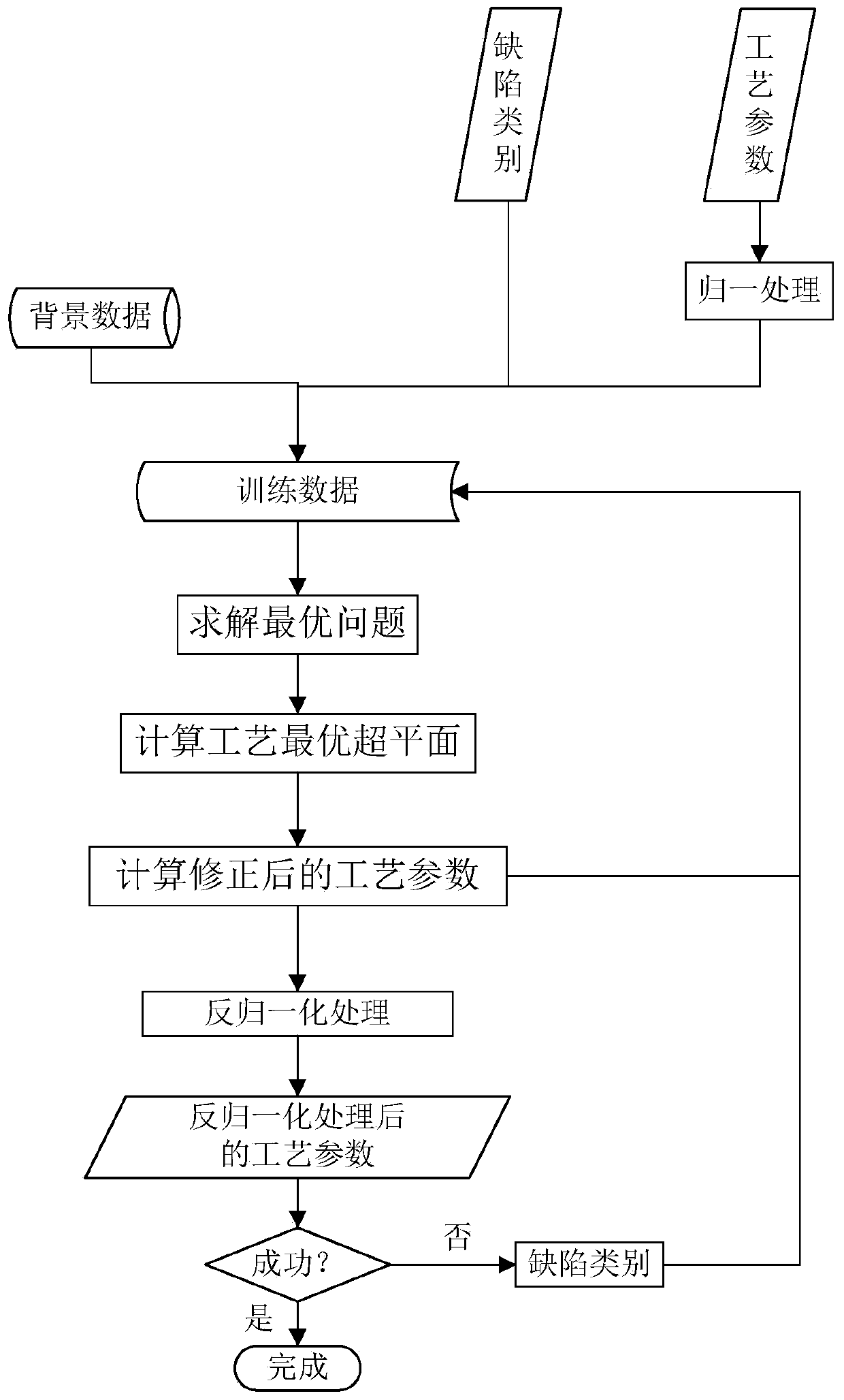

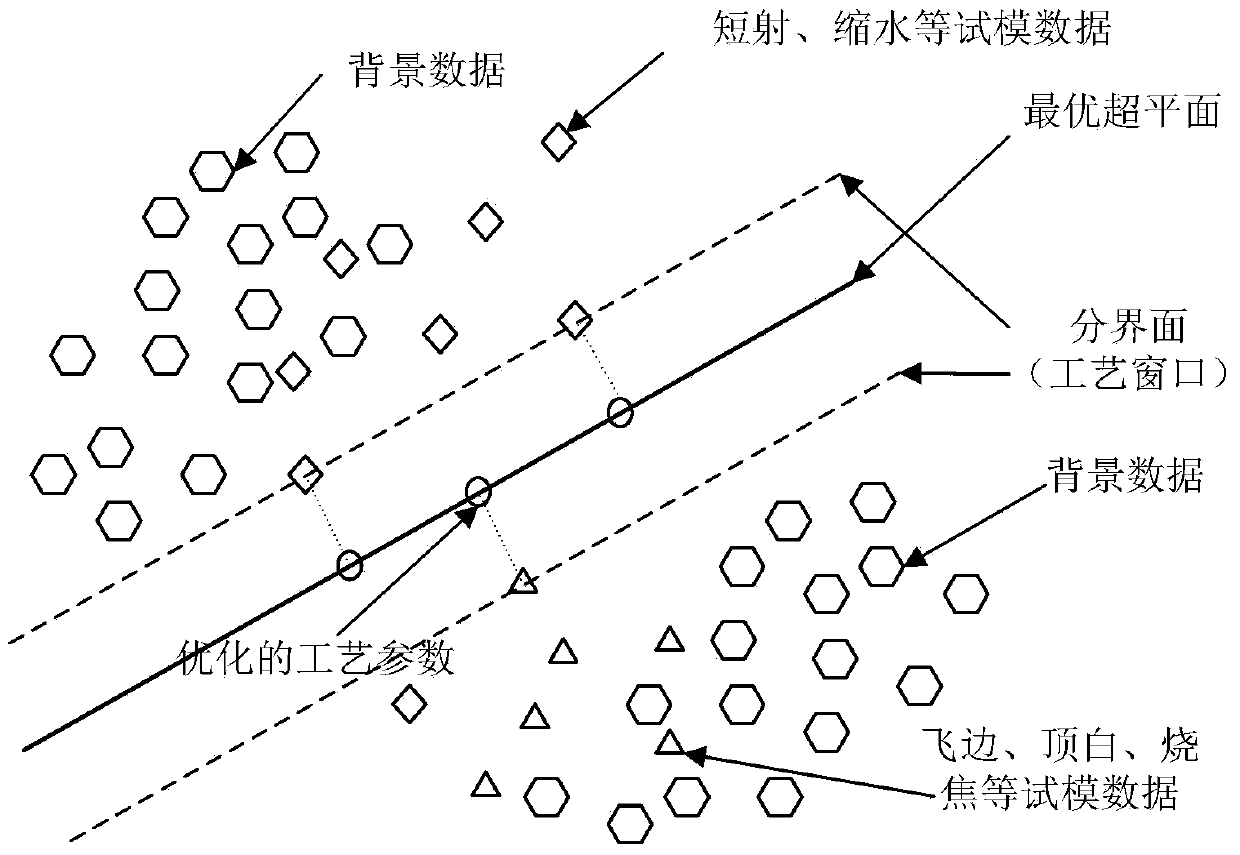

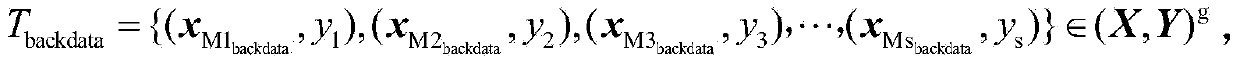

Injection molding defect online correcting method and injection molding machine

ActiveCN103737878ALower requirementOmit regular expressionProcess engineeringInjection molding machine

The invention discloses an injection molding defect online correcting method and an injection molding machine. The method comprises the following steps: (1) determining optimization parameters and number; (2) setting background data according to injection molding technological parameters required to be optimized and defect types; (3) testing a mold and feeding back the quality; (4) carrying out normalization processing on the test mold technological parameters; (5) solving the optimal problem; (6) calculating the optimal hyperplane of the technology; (7) calculating the corrected technological parameters; (8) carrying out inverse normalization on the technological parameters, acquiring the actual test mold technological parameters, and testing the mold. The invention also provides the injection molding machine based on the online correction injection molding defect method. According to the invention, the sample data are subjected to pretreatment, and rules are introduced into the test mold data in the form of background data; the problem of organization and expression difficulty of rules of an expert system and reasoning based on rules, as well as the problems of high requirements for samples and collection difficulty for artificial neural network and living example reasoning can be overcome.

Owner:HUAZHONG UNIV OF SCI & TECH

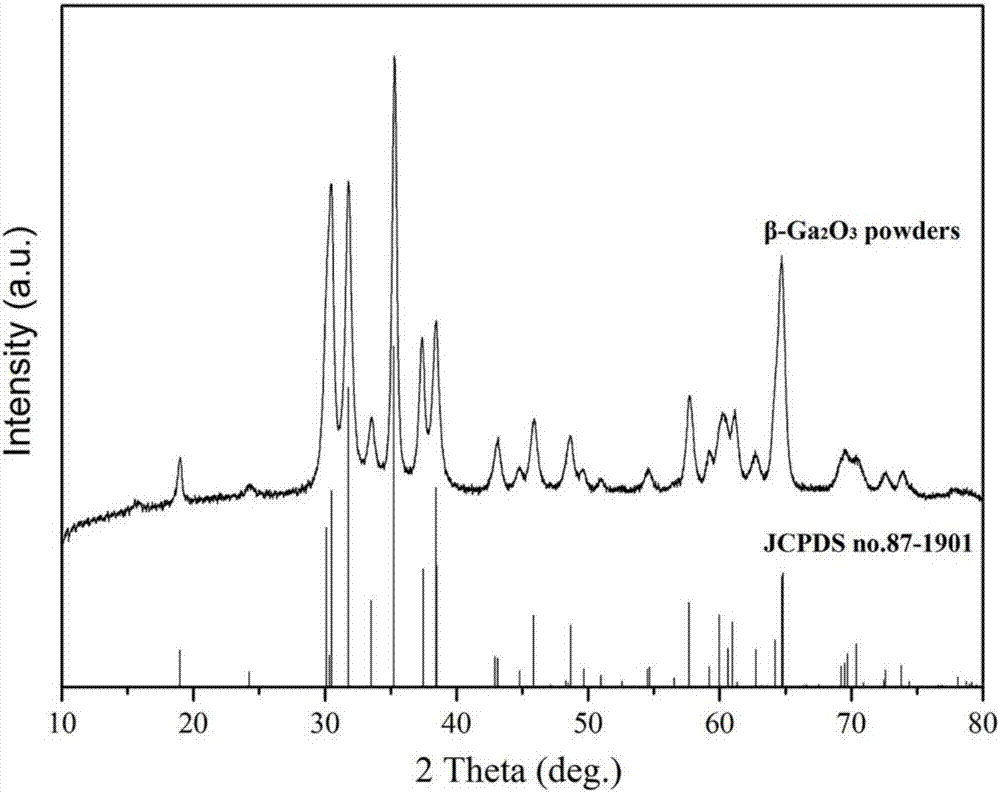

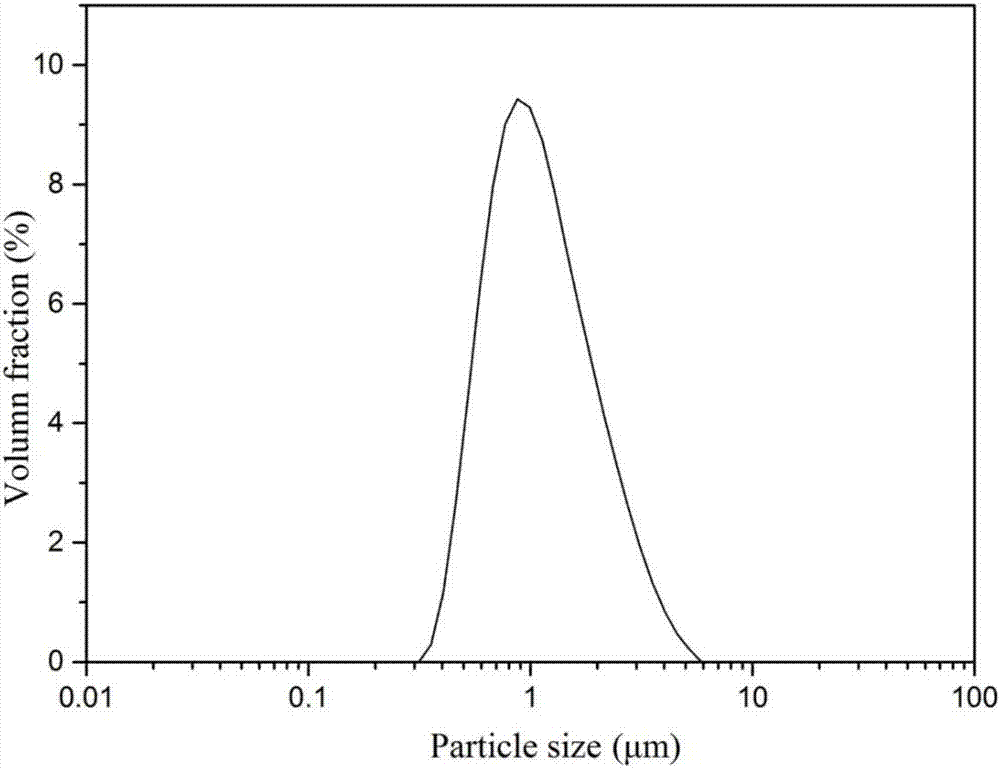

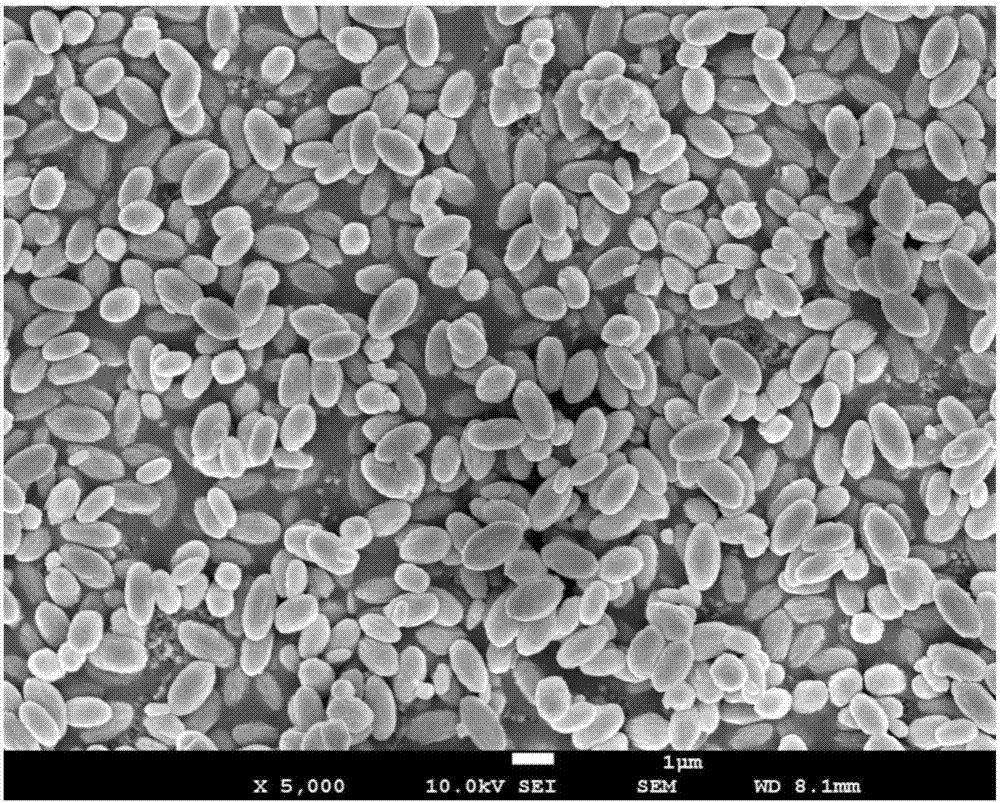

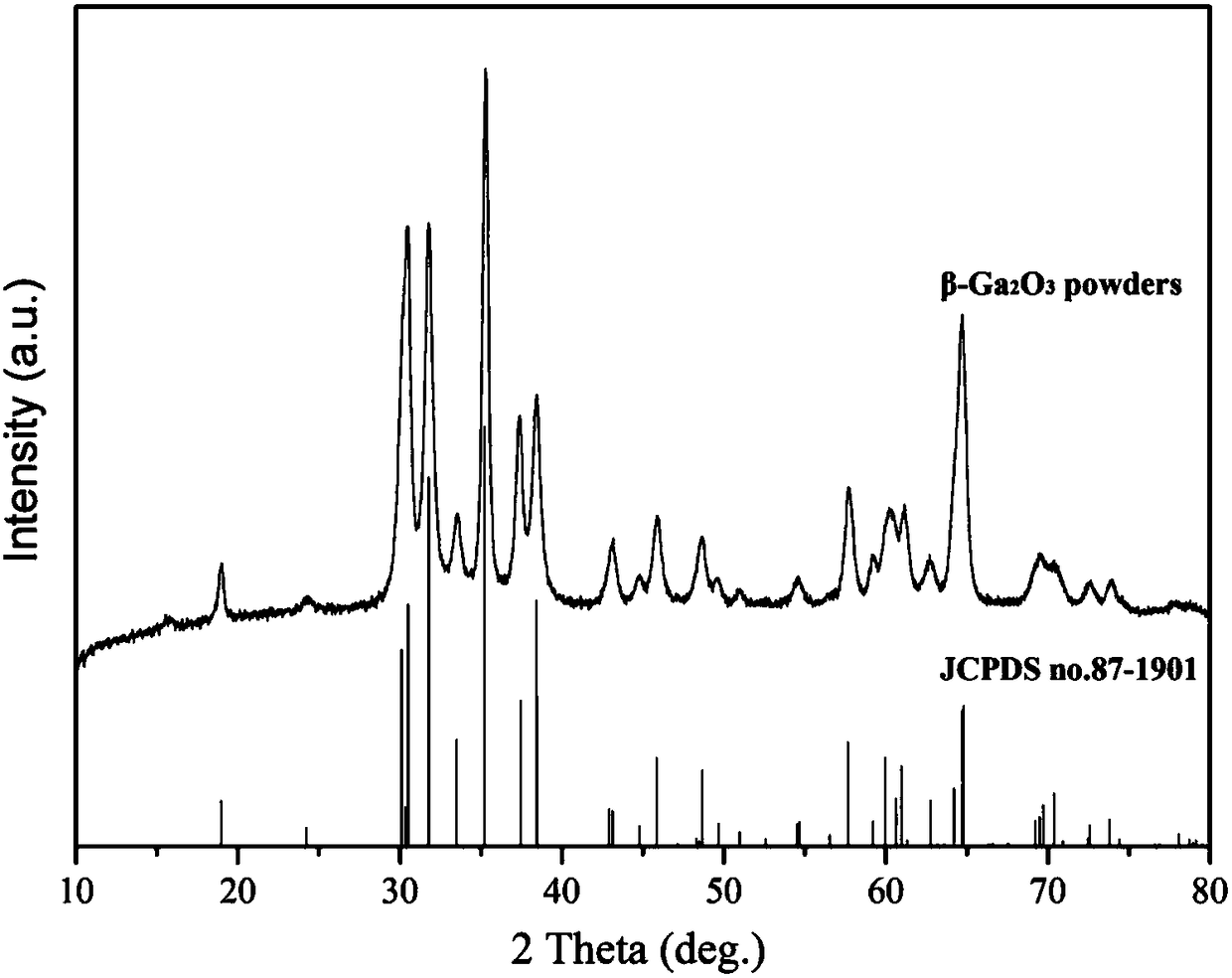

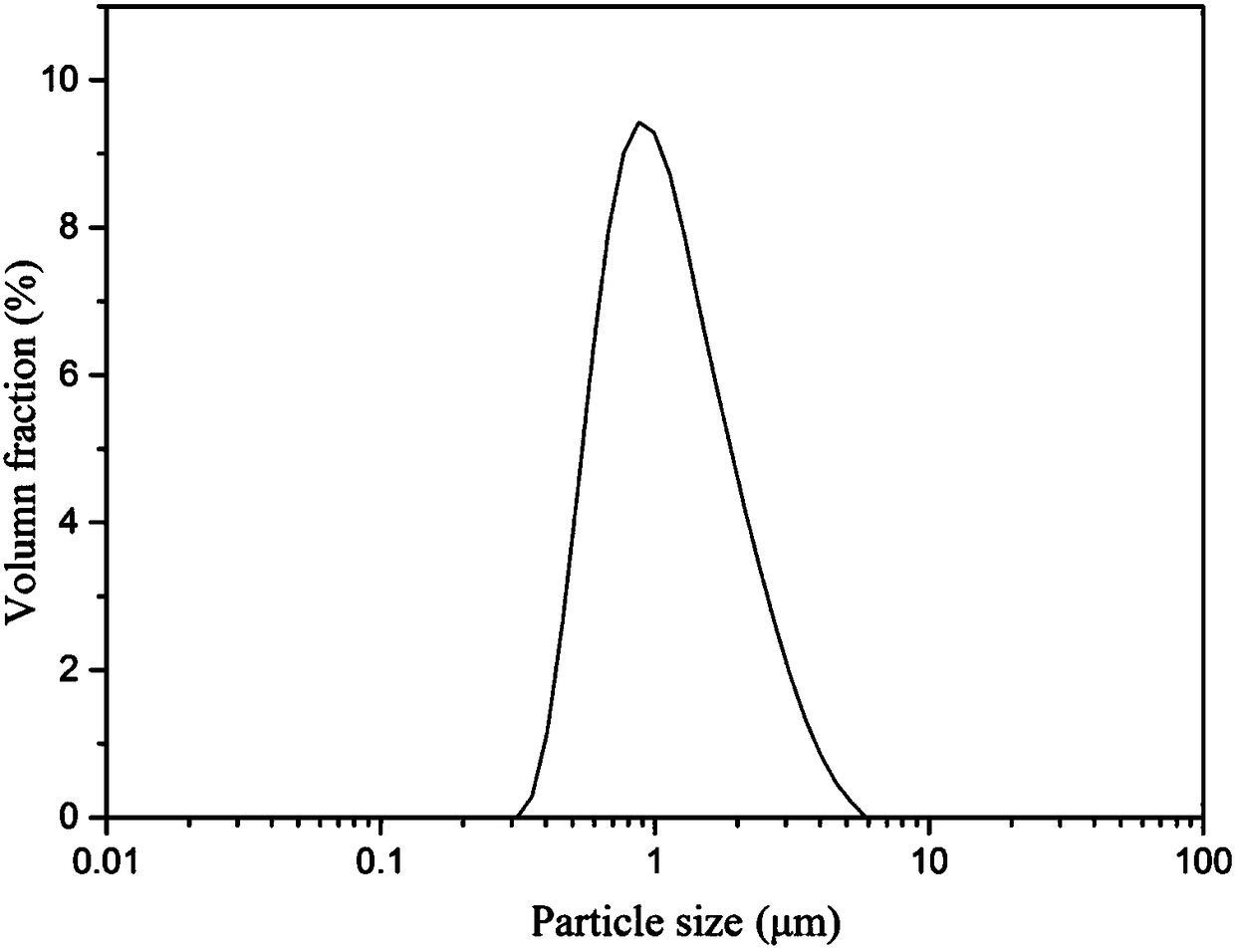

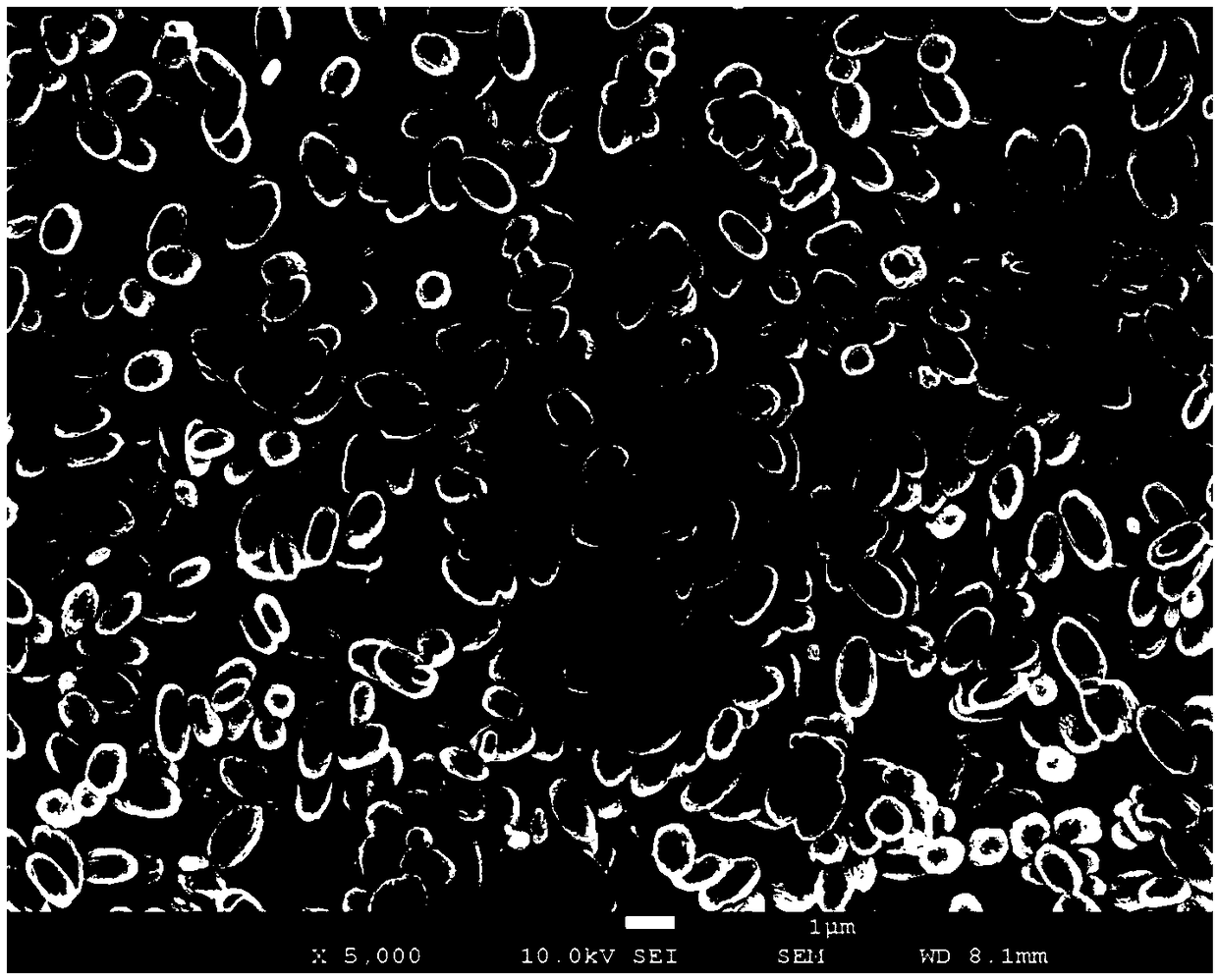

Mono-disperse gallium oxide powder and method for preparing high-density ceramic targets from mono-disperse gallium oxide powder

ActiveCN107010654ASimple processEasy to operateGallium/indium/thallium compoundsCompression moldingHigh density

The invention discloses mono-disperse gallium oxide powder and a method for preparing high-density ceramic targets from the mono-disperse gallium oxide powder. The method includes dissolving metal gallium materials with the purity higher than 99.99% in acid and preparing clear gallium salt solution; adding precipitants into the clear gallium salt solution to generate precipitates; washing, filtering, drying and calcining the obtained precipitates to obtain the mono-disperse ultrafine gallium oxide powder; carrying out compression molding and cold isostatic pressing strengthening on the synthesized mono-disperse gallium oxide powder to obtain gallium oxide green bodies; sintering the green bodies in high-temperature furnaces to obtain the high-density gallium oxide ceramic targets with uniform microscopic structures. The mono-disperse gallium oxide powder and the method have the advantages of simple process, convenience in operation, high yield, applicability to industrial production and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

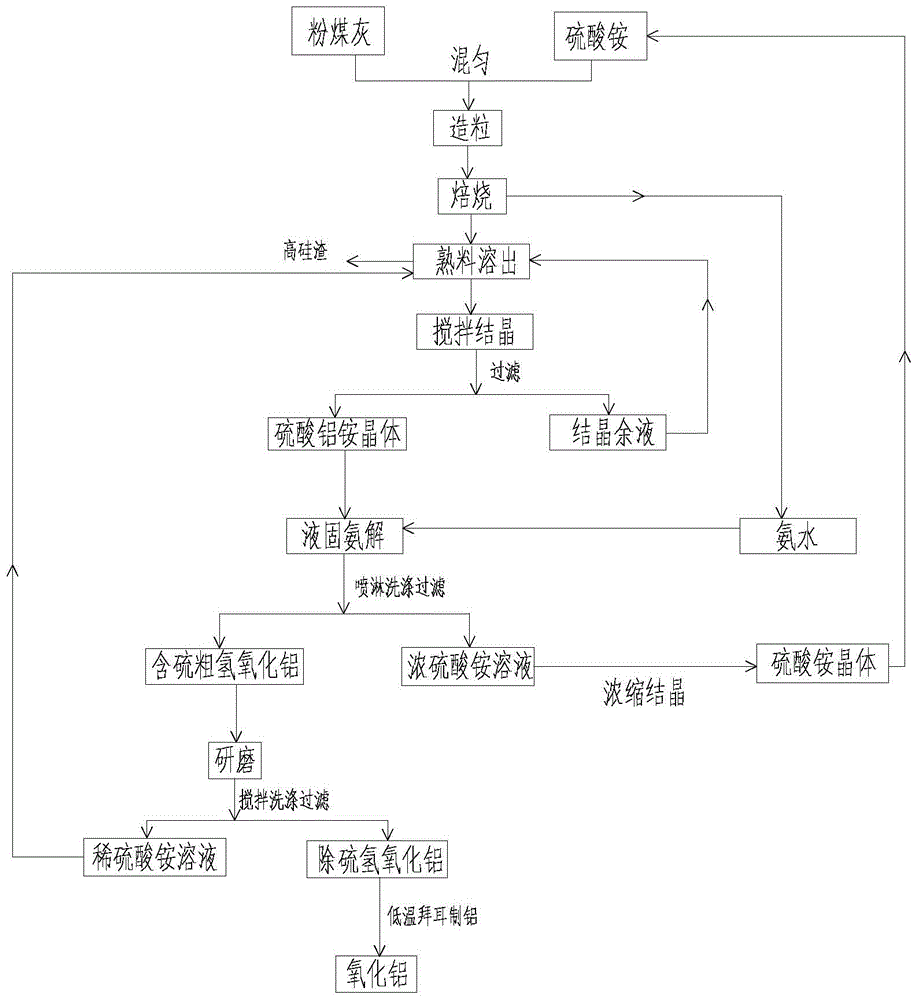

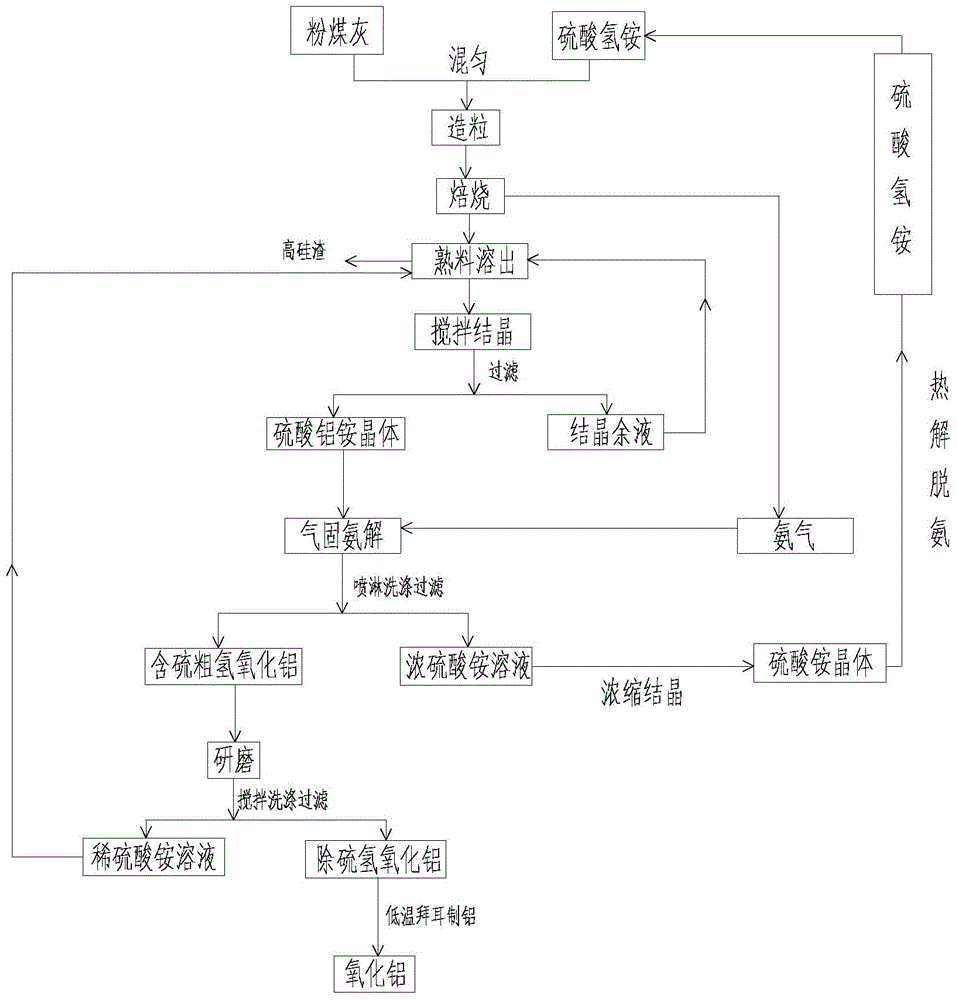

Method for producing metallurgy-grade alumina by taking pulverized fuel ash and recycled ammonium salt as raw materials

InactiveCN104628020AReduce solubilityReduce evaporationSolid waste disposalAluminium oxides/hydroxidesStrong acidsAluminium

The invention discloses a method for producing metallurgy-grade alumina by taking pulverized fuel ash and recycled ammonium salt as raw materials. The method comprises the following steps: (1) preparing materials; (2) roasting; (3) dissolving; (4) crystallizing; (5) carrying out a liquid-solid ammonolysis reaction; (6) grinding and removing sulfur; and (7) performing low-temperature Bayer aluminum production. The method disclosed by the invention has the advantages that an aluminum salt ammonolysis method suitable for strong acid and weak base is adopted, namely liquid-solid or gas-solid ammonolysis is performed, the production efficiency is improved by over 60 percent compared with that a liquid-liquid ammonolysis method, the process conditions of the ammonolysis method are optimized, optimal process parameters are determined, the obtained product, namely crude aluminum hydroxide, is easy to filter and wash, the model selection of equipment is simple, and industrial mass production can be realized.

Owner:NORTH UNITED POWER +1

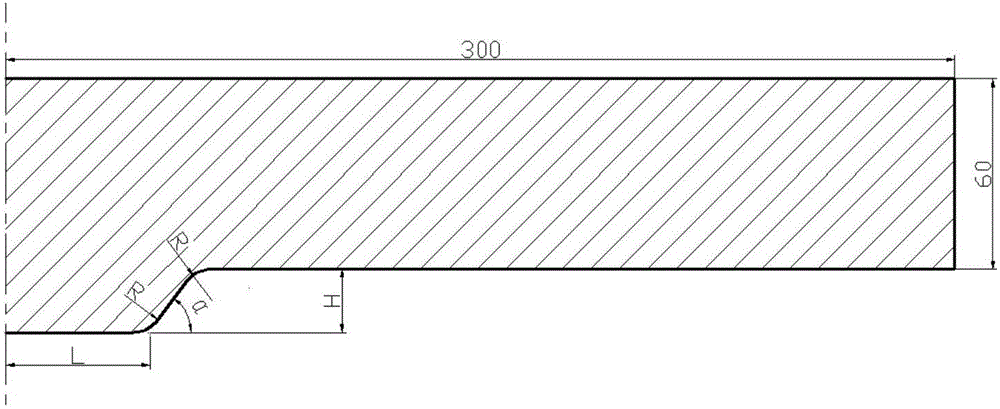

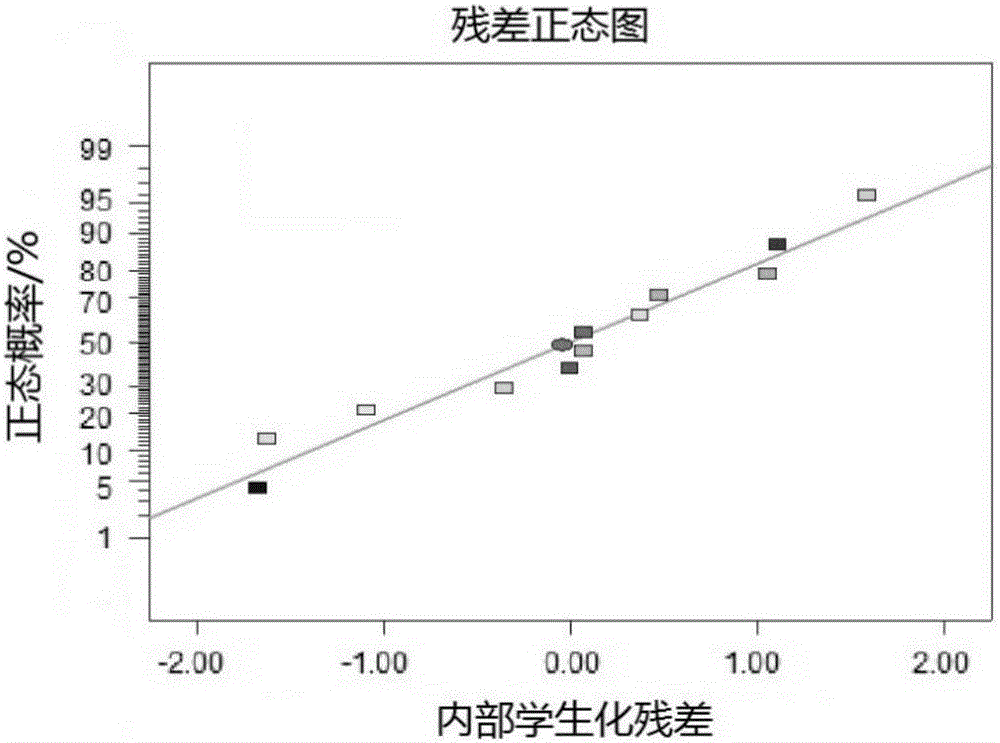

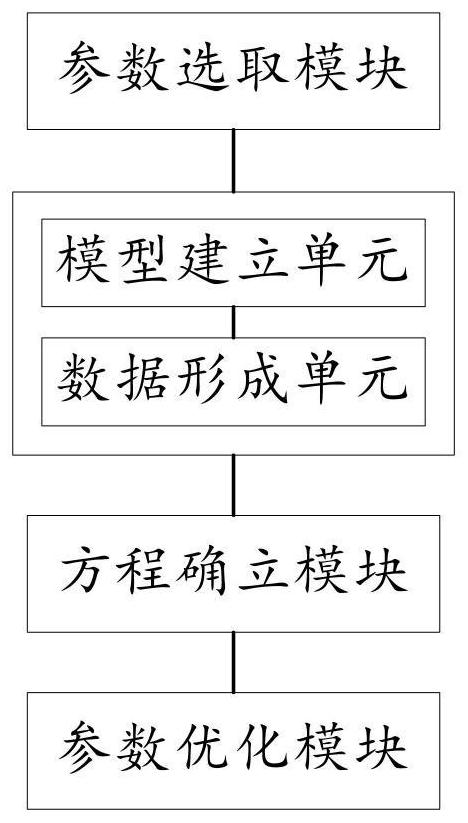

Optimization design method for preforming technology of turbine disk forgings

InactiveCN106599462AExcellent process parametersGeometric CADDesign optimisation/simulationEngineeringForging

The invention discloses an optimization design method for preforming of turbine disk forgings. The method comprises the steps that 1, the geometrical shape of a preforming die is designed, the size of the preforming die is parameterized, and a Plackett-Burmans (PB) experiment design method is utilized to determine key influence parameters; 2, the key influence parameters determined in the step 1 are used as optimization parameters, and a general rotary combination design method is adopted to determine experiment schemes; 3, a finite element method is adopted to perform simulation on all the schemes to obtain an experiment result, a second-order response surface model is utilized to fit out a response surface, optimizing is performed based on an optimization objective function for optimizing to find out an optimal parameter combination. Through the method, the preforging forming technology of turbine disks can be effectively optimized, and it is guaranteed that deformation of the forgings and uniformity of organization are optimal.

Owner:CENT SOUTH UNIV

Method for extracting galla chinensis tannic acid with assistance of radiation pretreatment

InactiveCN103275136AHigh yieldHigh purityEsterified saccharide compoundsSugar derivativesHigh energyGamma ray

The invention relates to a method for extracting galla chinensis tannic acid with the assistance of radiation pretreatment. The method comprises the steps of firstly carrying out radiation pretreatment on galla chinensis, namely a raw material, by adopting Co<60>-gamma rays, and then extracting the galla chinensis tannic acid by adopting a water extraction method. According to the method, the galla chinensis serves as the raw material, and the galla chinensis tannic acid, namely a product, is extracted through the radiation pretreatment of the high-energy Co<60>-gamma rays, so that the yield and purity of the tannic acid are improved in a safe and nontoxic manner; and when the method is applied to industrial production, galla chinensis resources can be utilized more sufficiently, and the high-value utilization and environment-friendly and chemical production of galla chinensis tannic acid resources are embodied sufficiently.

Owner:HUNAN AGRICULTURAL UNIV

Process for recovery and purification of hexagonal boron nitride in cubic boron nitride synthetic tailings

InactiveCN102774817AHigh purityLess investmentNitrogen compoundsProcess equipmentHexagonal boron nitride

The invention discloses a process for recovery and purification of hexagonal boron nitride in cubic boron nitride synthetic tailings. The process includes steps: a, collecting raw materials; b, drying the raw materials; c, ball milling; d, roasting; e, removing metals; f, elutriating; and g, drying. The process is convenient, easy to implement, reduced in waste and improved in economic benefit. The cubic boron nitride synthetic tailings are used, the process which is rational and easy to implement is adopted to recover and purify the hexagonal boron nitride, process parameters reach the optimum, process steps are concise, investment and consumption of process equipment are small, and the purity of recovered and purified hexagonal boron nitride is higher and reaches more than 96%, so that the process for recovery and purification of the hexagonal boron nitride in the cubic boron nitride synthetic tailings has higher economic returns.

Owner:ZHENGZHOU ZHONGNAN JETE SUPERABRASIVES

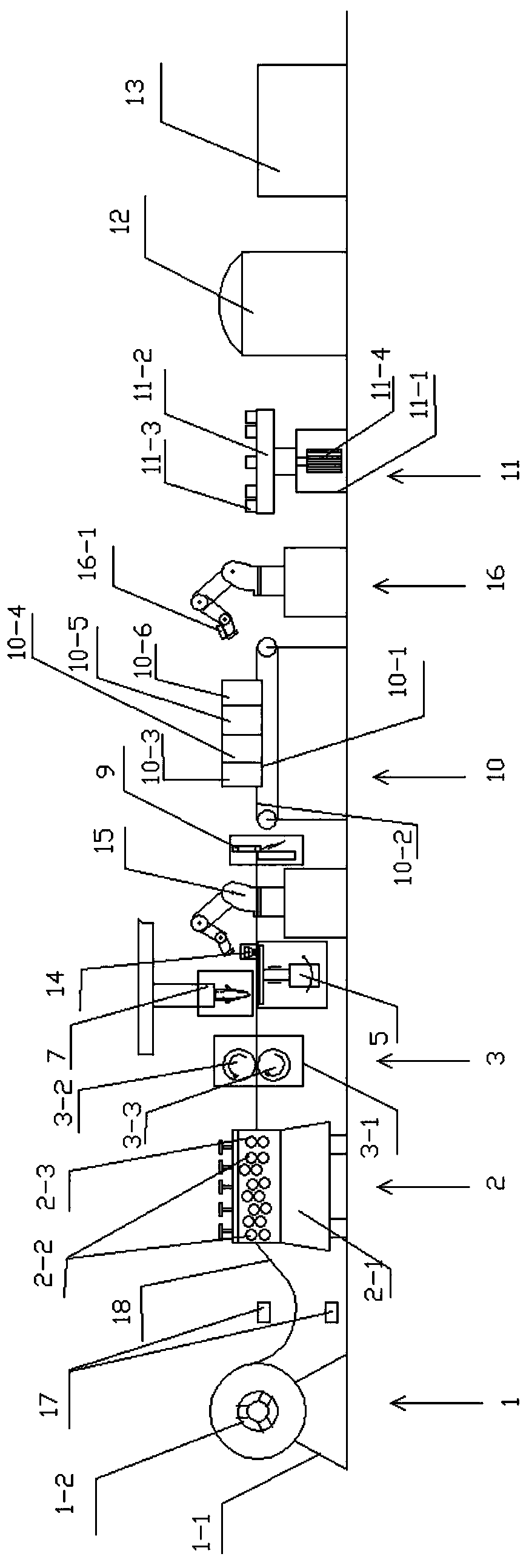

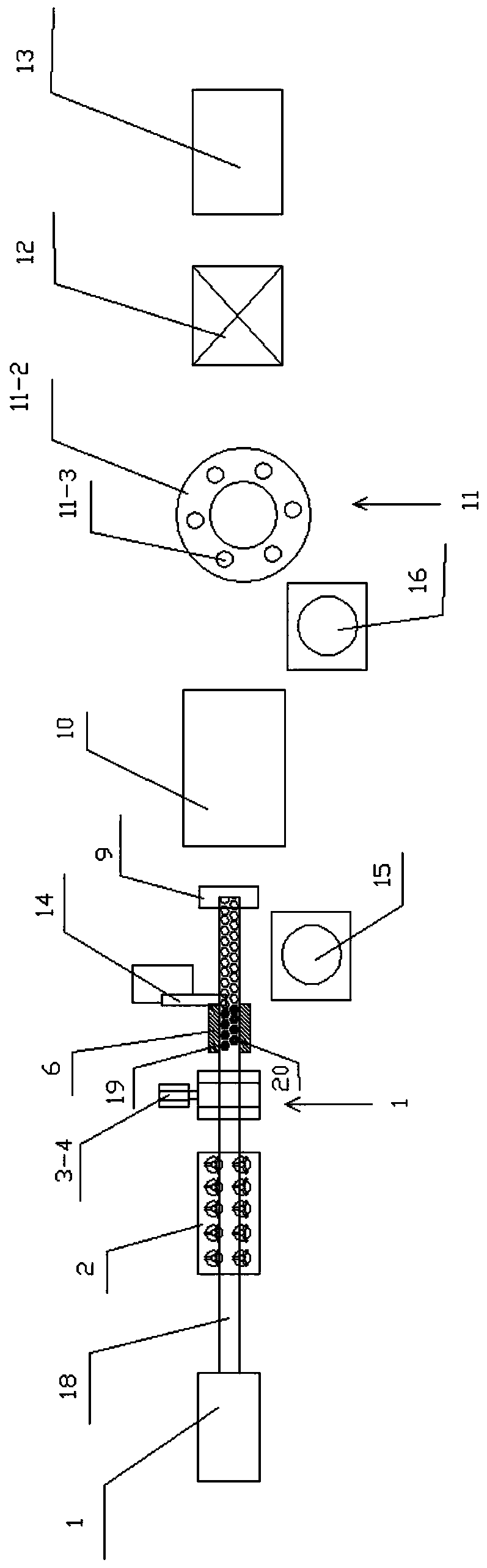

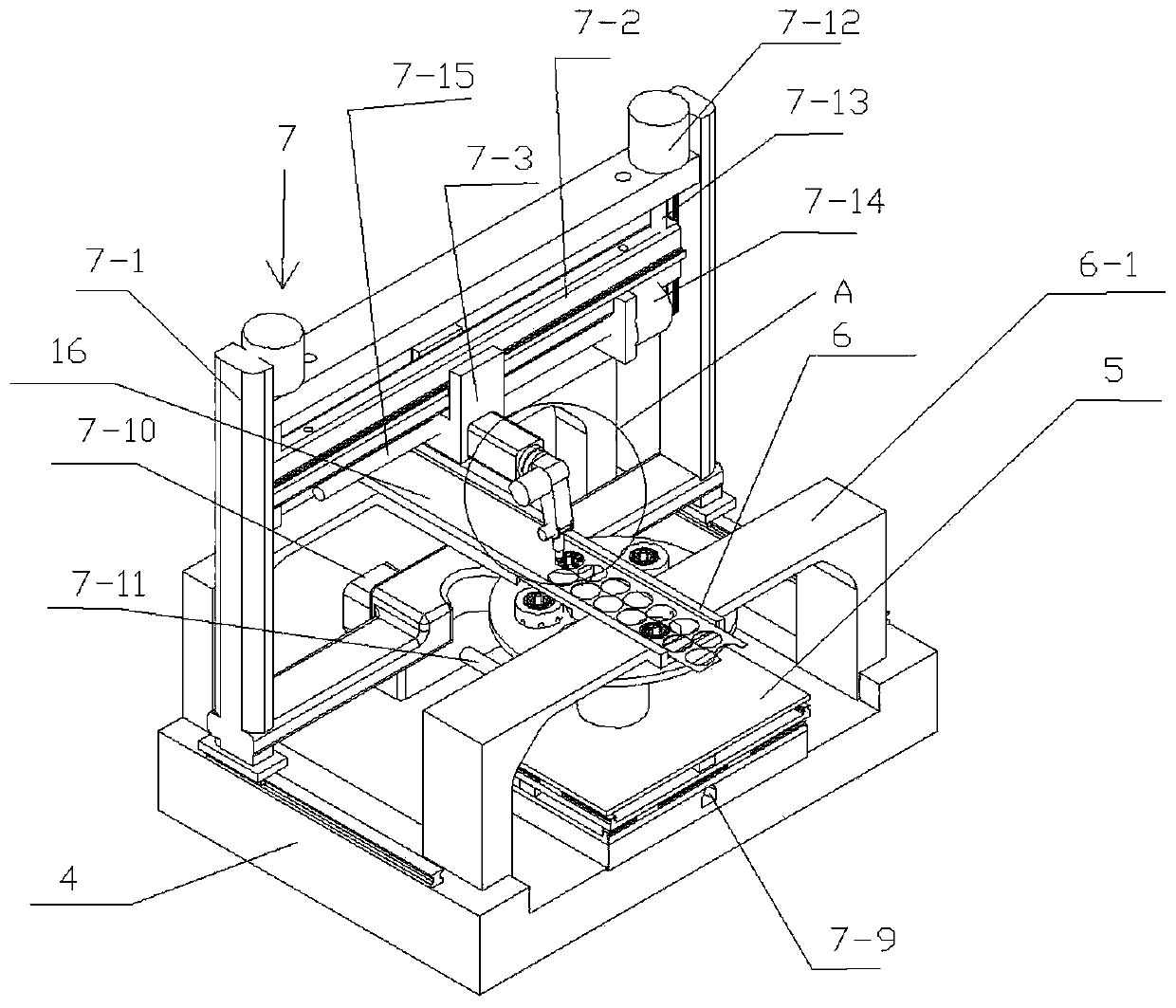

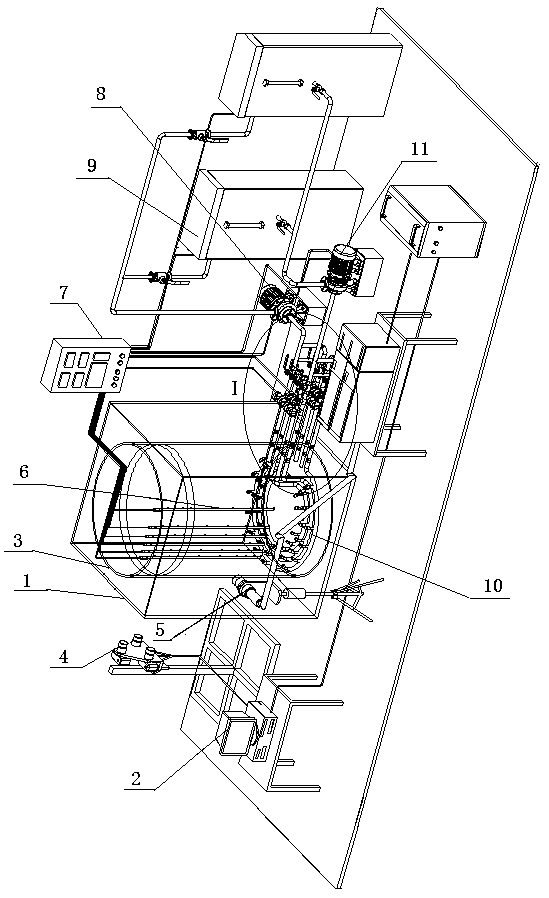

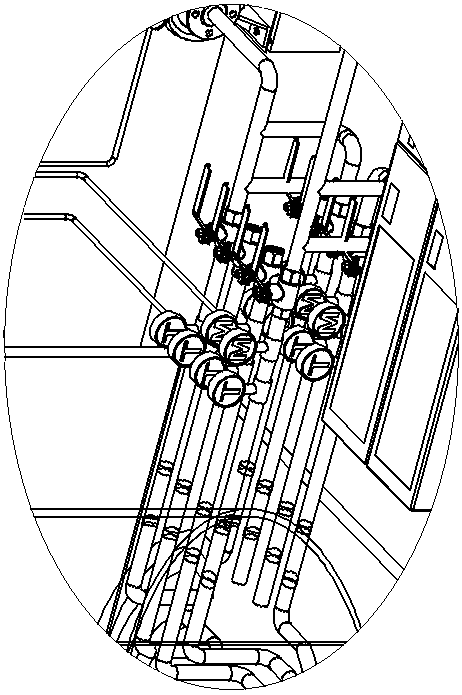

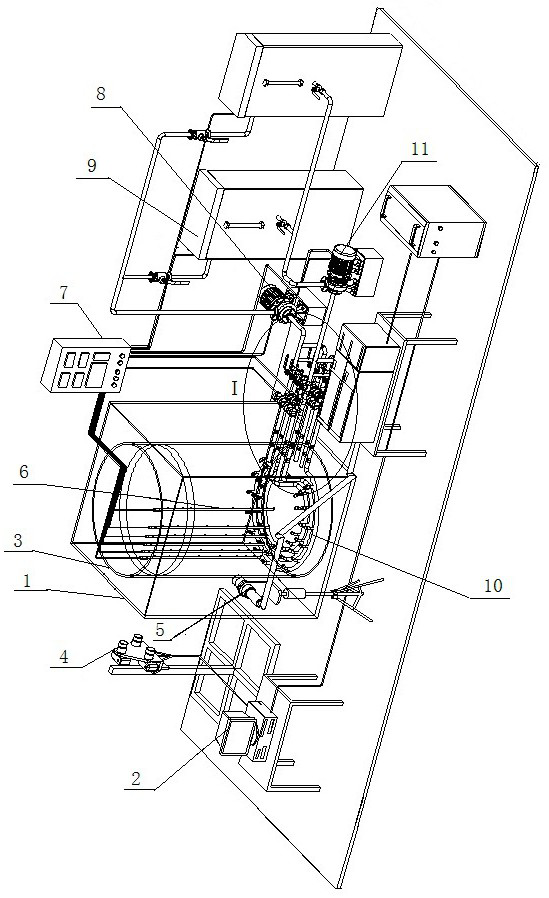

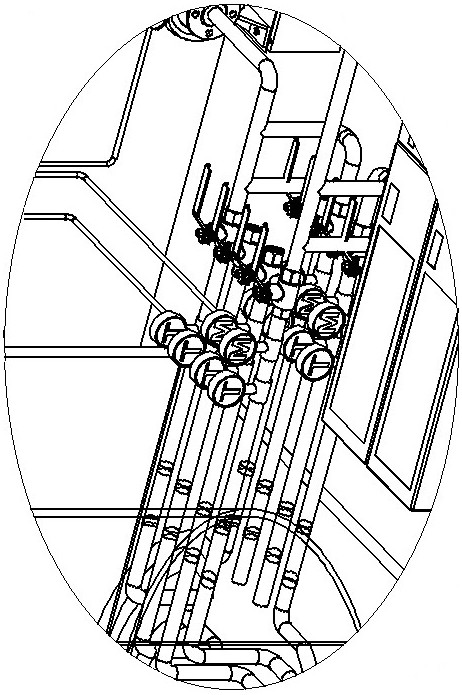

Iron-based amorphous iron core production system and preparation method thereof

PendingCN111478529ARealize stamping superposition productionSolve the problem of thermal crystallizationManufacturing stator/rotor bodiesPunchingProcess engineering

The invention relates to an iron-based amorphous iron core production system and a preparation method thereof. The system comprises a discharging mechanism, a leveling mechanism, a feeding mechanism,a jet flow cutting device, a waste recycling mechanism, a tunnel type annealing furnace, a forming overlying mechanism, a gum dipping device and a curing oven which are sequentially arranged from leftto right in the conveying direction. A workpiece cleaning device and a first transfer robot are arranged between the jet cutting mechanism and the waste recovery mechanism, and the cleaning device and the first transfer robot are arranged on the two sides of a strip correspondingly; and a second transfer robot is arranged between the tunnel type annealing furnace and the forming overlying mechanism. Continuous production of the iron core is achieved, annealing and forming stacking are conducted in sequence, defective punching sheets can be found earlier, and the defective rate of finished products is reduced.

Owner:宁波吉兆电气科技有限公司

Cordyceps militaris culture medium polysaccharide, and separation and purification method and application thereof

ActiveCN108546306APerfect residue treatment processIn line with the concept of green environmental protectionAntibacterial agentsOrganic active ingredientsPurification methodsDrug biological activity

The invention discloses a cordyceps militaris culture medium polysaccharide, and a separation and purification method and application thereof. The polysaccharide comprises the following monosaccharides by molar percentage: 0.11% of ribose, 0.11% of rhamnoside, 0.45% of arabinose, 0.13% of xylose, 14.50% of mannose, 83.96% of glucose and 0.73% of galactose. Through the adoption of the extraction method provided by the invention, the biological activity of the cordyceps militaris culture medium polysaccharide P1 is not influenced, the obtained polysaccharide pure product P1 has high purity and stable property, has obvious effects in the aspects of anti-oxidation, uric acid reduction and bacteriostasis, and is beneficial to human metabolism. The cost is low, and the polysaccharide P1 pure product can be further used for the development of health products, medicines and cosmetics.

Owner:SOUTH CHINA NORMAL UNIVERSITY

A preparation method of monodisperse gallium oxide powder and its high-density ceramic target

ActiveCN107010654BSimple processEasy to operateGallium/indium/thallium compoundsCompression moldingHigh density

The invention discloses mono-disperse gallium oxide powder and a method for preparing high-density ceramic targets from the mono-disperse gallium oxide powder. The method includes dissolving metal gallium materials with the purity higher than 99.99% in acid and preparing clear gallium salt solution; adding precipitants into the clear gallium salt solution to generate precipitates; washing, filtering, drying and calcining the obtained precipitates to obtain the mono-disperse ultrafine gallium oxide powder; carrying out compression molding and cold isostatic pressing strengthening on the synthesized mono-disperse gallium oxide powder to obtain gallium oxide green bodies; sintering the green bodies in high-temperature furnaces to obtain the high-density gallium oxide ceramic targets with uniform microscopic structures. The mono-disperse gallium oxide powder and the method have the advantages of simple process, convenience in operation, high yield, applicability to industrial production and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

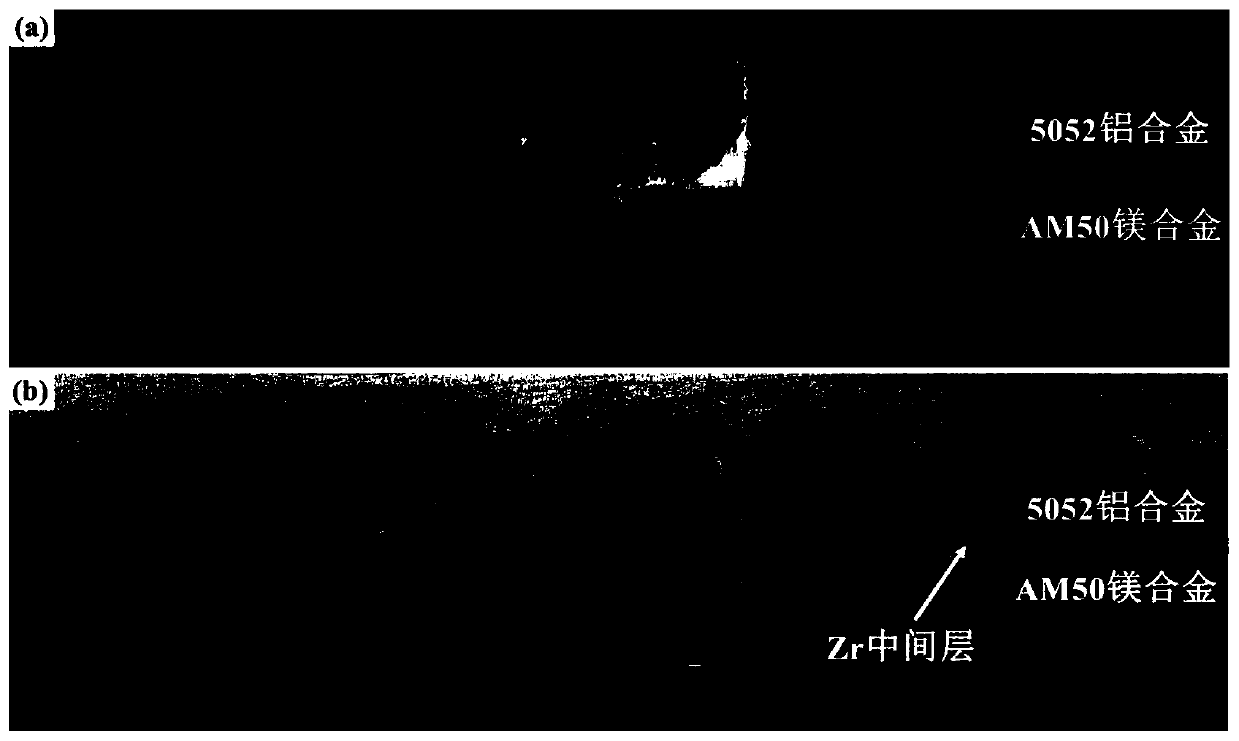

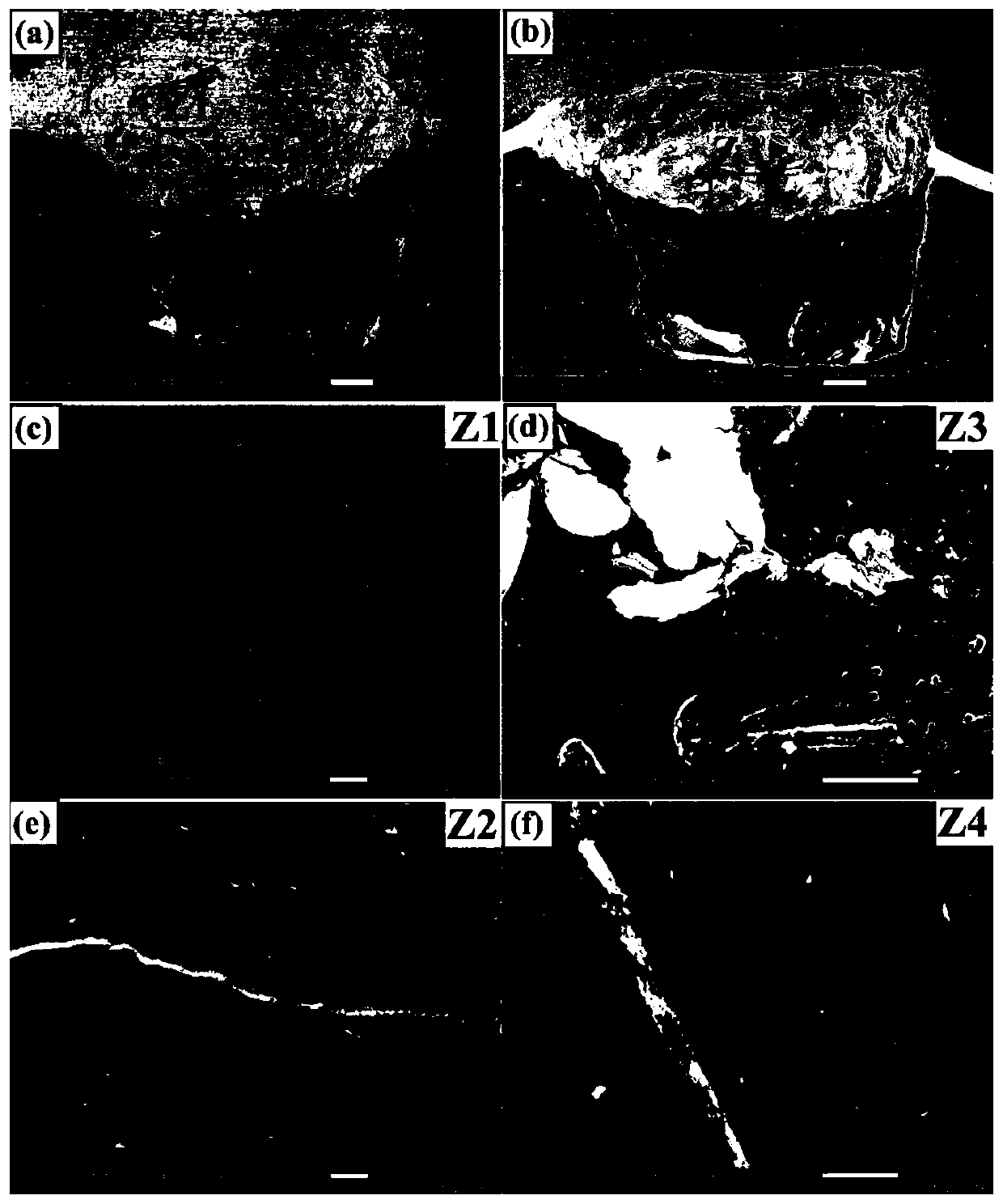

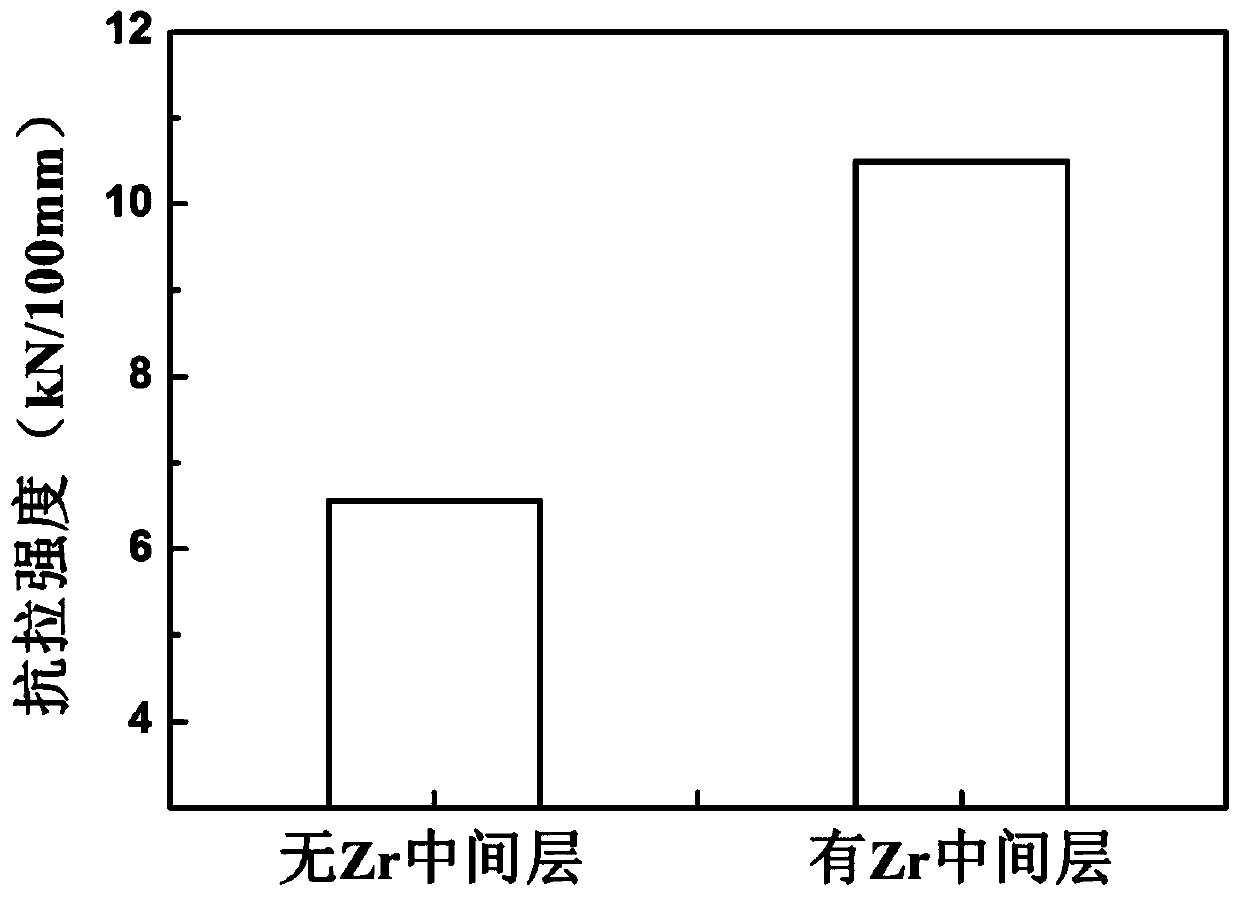

High-strength aluminum/magnesium dissimilar alloy connector containing intermediate layer, and preparation method thereof

InactiveCN109986231AReduce welding heat inputImprove organizational structureWorkpiece edge portionsNon-electric welding apparatusSolid phasesHigh intensity

The invention relates to a high-strength aluminum / magnesium dissimilar alloy connector containing an intermediate layer, and a preparation method thereof. The connector sequentially comprises an aluminum alloy, a Zr intermediate layer and a magnesium alloy from top to bottom, wherein the intermediate layer is a Zr foil with the thickness ranging from 0.05 to 0.25mm. According to the preparation method, the combined action of a solid-phase welding technology, the intermediate layer and environment cooling is adopted for preparing a dissimilar light metal connector, namely, the aluminum / magnesium dissimilar alloy connector containing the Zr intermediate layer is prepared in a water-cooling environment by utilizing a friction stir welding technology, so that the target dissimilar alloy is obtained. According to the high-strength aluminum / magnesium dissimilar alloy connector containing the intermediate layer, and the preparation method thereof provided by the invention, the welding heat input is reduced, and a tissue structure of the connector is improved, so that a mechanical property of the connector is improved.

Owner:HEBEI UNIV OF TECH

Reduction control device and method for N2O produced in denitrification dephosphorization process

ActiveCN102849850BAutomatic control of online recording dataExcellent process parametersTreatment with aerobic and anaerobic processesTotal factory controlPeristaltic pumpActivated sludge

The invention provides a reduction control device and method for N2O produced in the denitrification dephosphorization process and belongs to the technical fields of automatic control of an activated sludge process treatment system and wastewater biological denitrification dephosphorization by means of a sequencing batch reactor (SBR) process. Aiming at solving the technical problem that sodium nitrite adopted to serve as an electron acceptor produces N2O in the denitrification dephosphorization process in the existing SBR process, the device uses an SBR as a main body and comprises a water distribution tank, a peristaltic pump, a magnetic stirring apparatus, an acid adding system, an alkali adding system, an on-line control system connected with a computer and a N2O on-line detecting system. The on-line control system is connected with a water inlet peristaltic pump, a mud discharging system, the acid adding system, the alkali adding system, a temperature control device, the stirring apparatus, a drain valve, a relay on a magnetic valve of a nitrogen aerating system, an oxidation reduction potential (ORP) sensor, a pH sensor and a dissolved oxygen sensor. The N2O on-line detecting system is connected with a N2O microelectrode. The whole process is automatically finished through a programmable logic controller (PLC) of the computer, and the N2O on-line detecting system performs quantitative analysis to the nitrogen conversion condition to confirm dominant mechanism and influencing factors for the N2O production in the denitrification dephosphorization process.

Owner:SDIC XINKAI WATER ENVIRONMENT INVESTMENT CO LTD

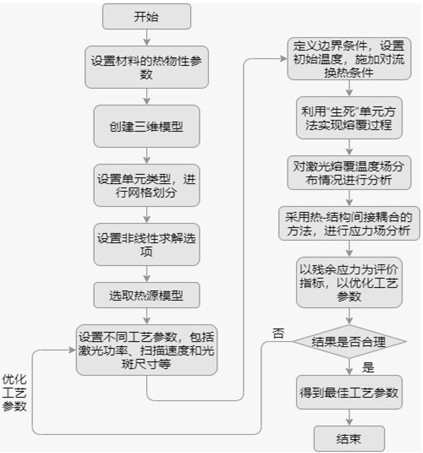

Optimization method of process for repairing axial surface wear part by laser cladding

PendingCN111859735AGuaranteed reliabilityFew coupled equationsDesign optimisation/simulationSpecial data processing applicationsHeat transfer processPowder

The invention discloses an optimization method of a process for repairing an axial surface wear part by laser cladding, which realizes the analysis of a nonlinear problem of a material by defining thermophysical parameters of the material changing along with temperature and ensures the reliability of an analysis process. A heat source model is defined as a body heat generation rate model, so thata molten powder heat transfer process in a coaxial powder feeding mode can be accurately simulated; by adopting an APDL programming mode under a cylindrical coordinate system, the simulation process of laser cladding on the axial surface of the part can be realized; calculation is carried out by adopting an indirect sequential thermal-structural coupling mode, advanced temperature field calculation is carried out, then stress field calculation is carried out, the number of coupling equations is small, and convergence is easy.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

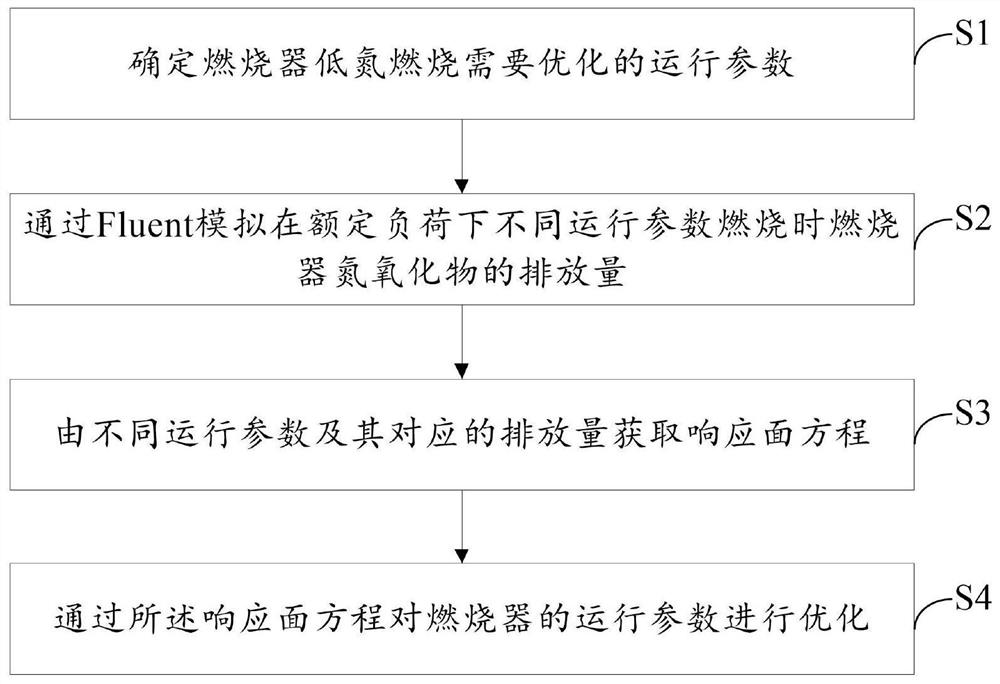

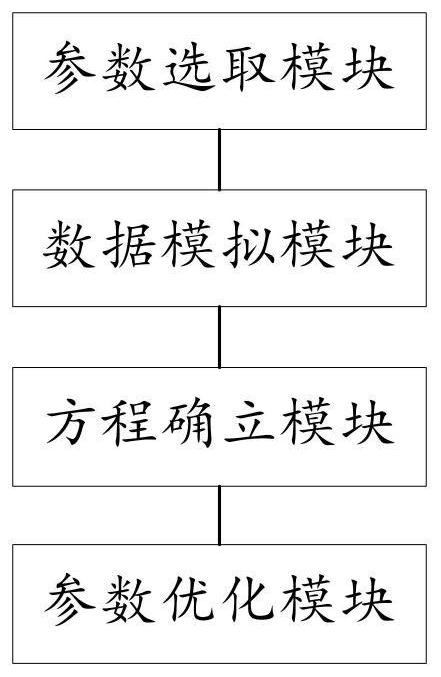

Method and device for optimizing nitrogen oxide emission of combustor

PendingCN111737842AEmission reductionExcellent process parametersDesign optimisation/simulationNitrogen oxidesCombustor

The invention discloses a method and device for optimizing the nitrogen oxide emission of a combustor. The method comprises the steps that S1, operating parameters needing to be optimized for low-nitrogen combustion of the combustor are determined; s2, simulating the discharge amount of nitrogen oxide of a combustor through Fluent when different operating parameters are combusted under a rated load; s3, obtaining a response surface equation according to the different operation parameters and the corresponding discharge amounts; and S4, optimizing the operation parameters of the combustor through the response surface equation. According to the method, a design experiment is carried out on simulation through a response surface method, the influence of multiple factors on the emission amountof nitrogen oxide (NOx) of the combustor is considered, and therefore the optimal technological parameters are obtained, and the emission amount of nitrogen oxide (NOx) of the gas combustor can be effectively reduced.

Owner:XINAO SHUNENG TECH CO LTD

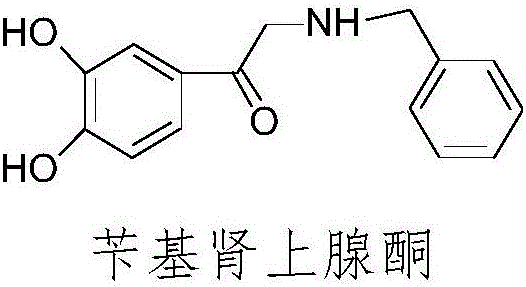

Preparation method of adrenalone hydrochloride

ActiveCN106748835AIncrease contact areaReduce generationOrganic chemistryOrganic compound preparationAlcoholReaction speed

The invention relates to a preparation method of adrenalone hydrochloride. In a process of preparing the adrenalone hydrochloride from chloracetyl catechol and methylamine, reaction is controlled to be carried out in an alcohol solution and tetrabutylammonium bromide or tetrabutylammonium iodide is selected as a phase transfer catalyst. According to the method provided by the invention, the reaction is controlled to be carried out in the alcohol solution and sufficient proceeding of the reaction is promoted; meanwhile, the tetrabutylammonium bromide or the tetrabutylammonium iodide is added to be used as the phase transfer catalyst, so that the reaction is accelerated, the reaction time is shortened and the accumulation of impurities is reduced. The adrenalone hydrochloride with high quality can be prepared at a single time without the need of refining, and a high-quality intermediate is provided for preparation of L-adrenaline.

Owner:BENGBU BBCA MEDICINE SCI DEV

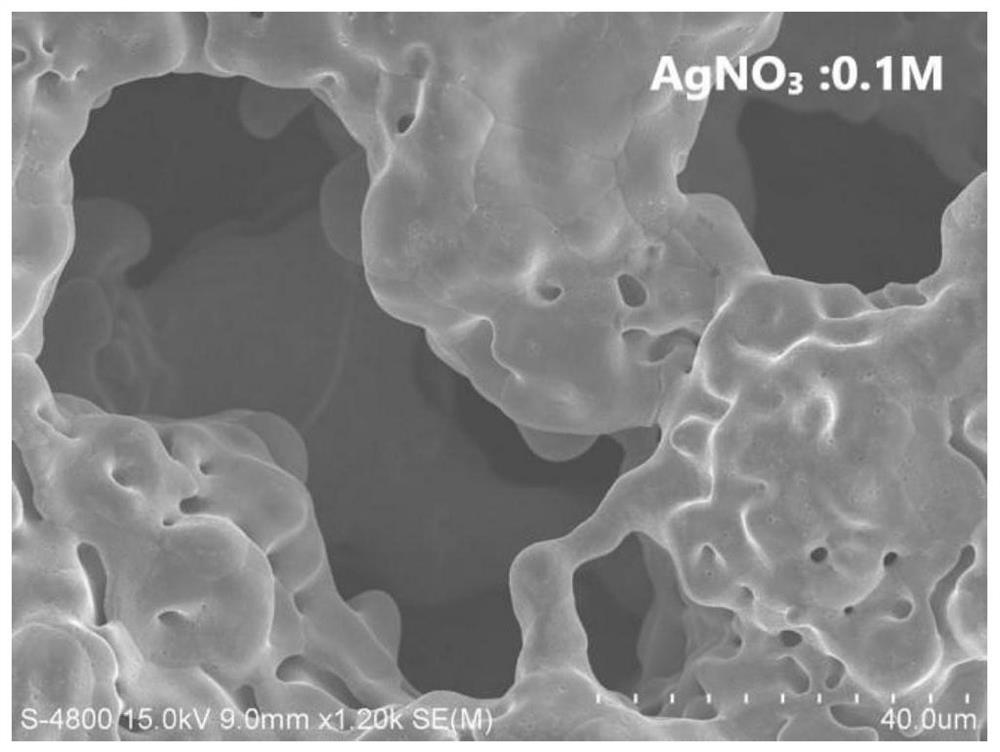

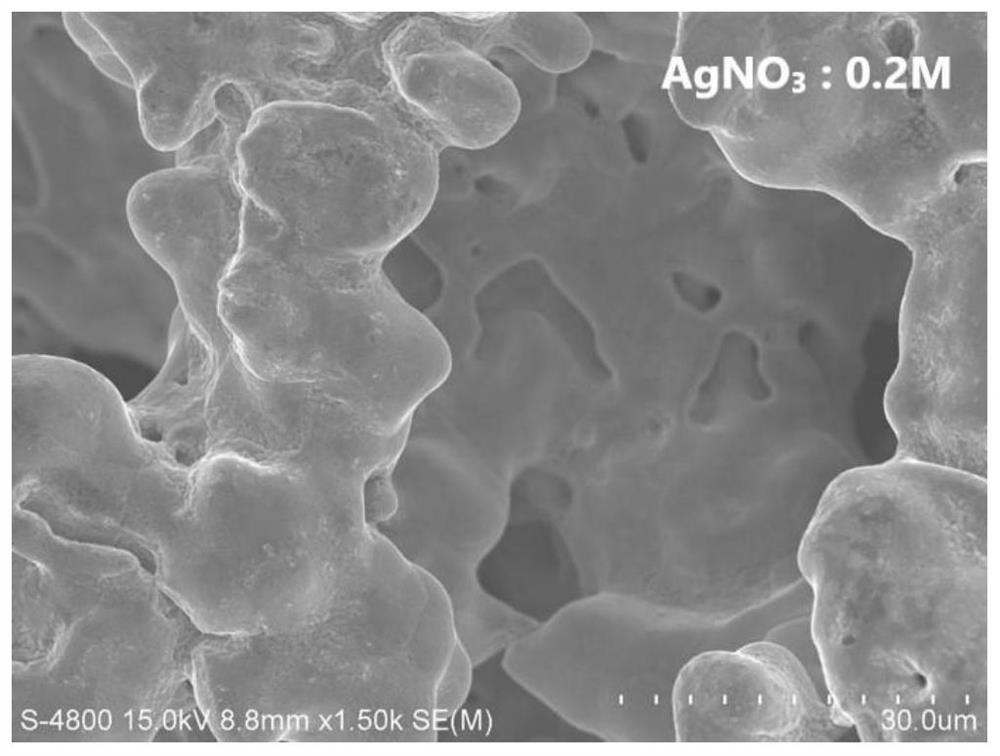

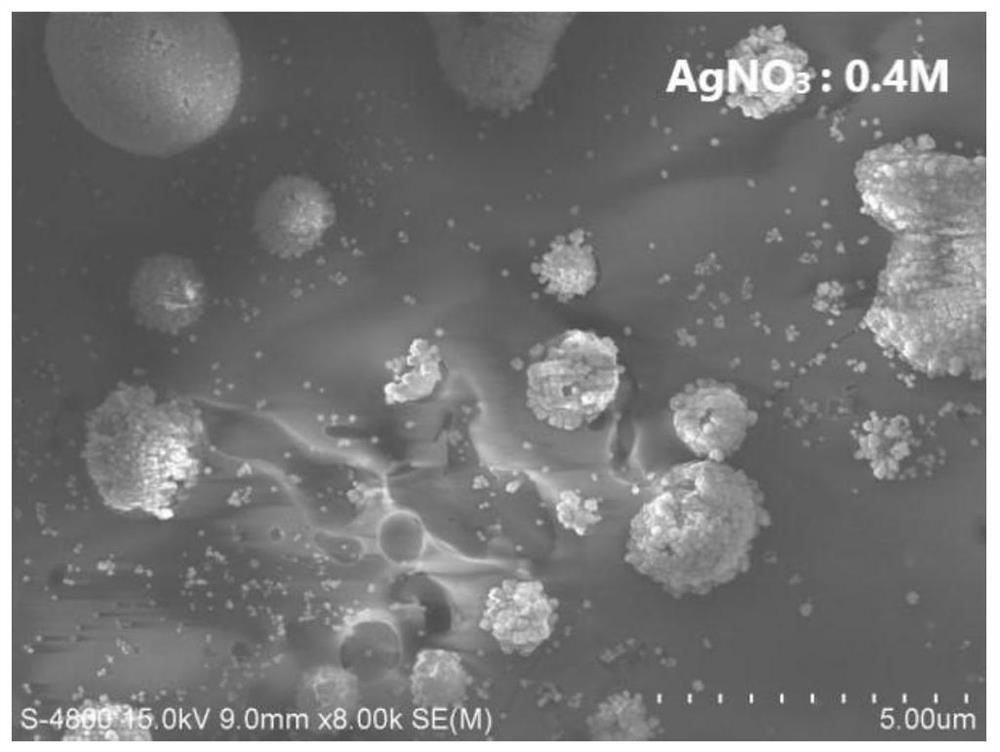

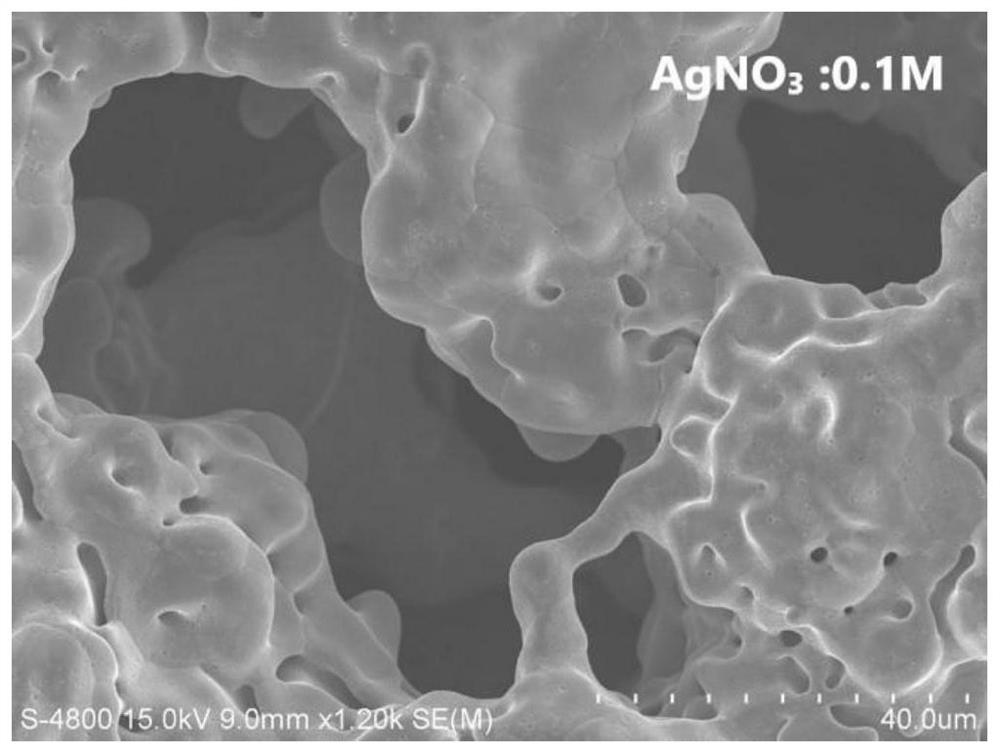

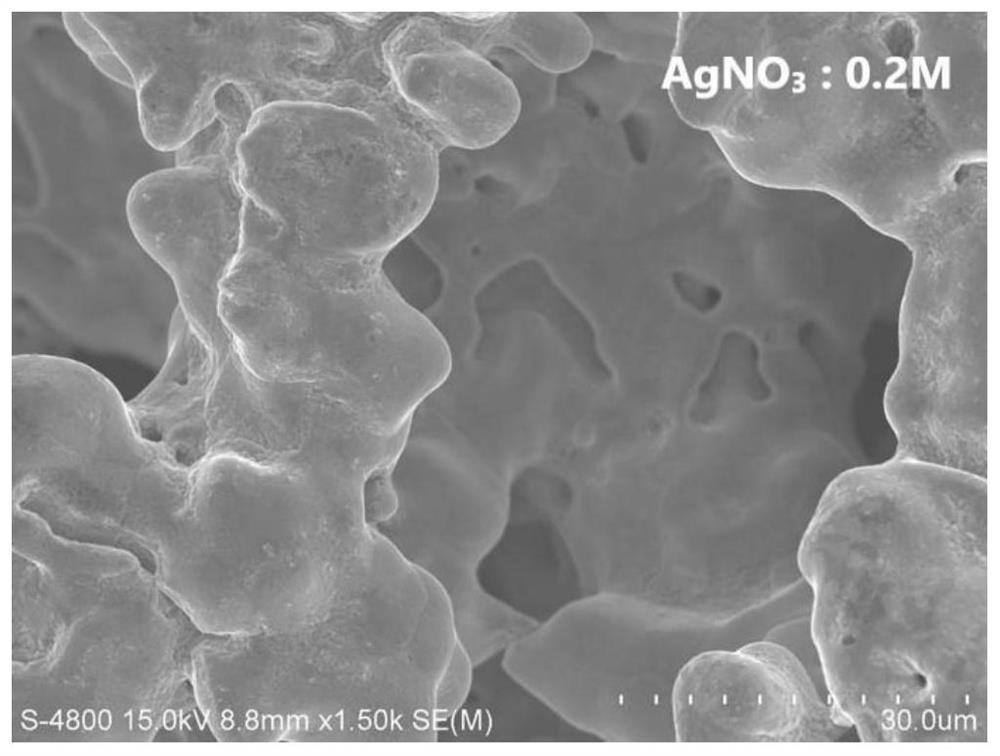

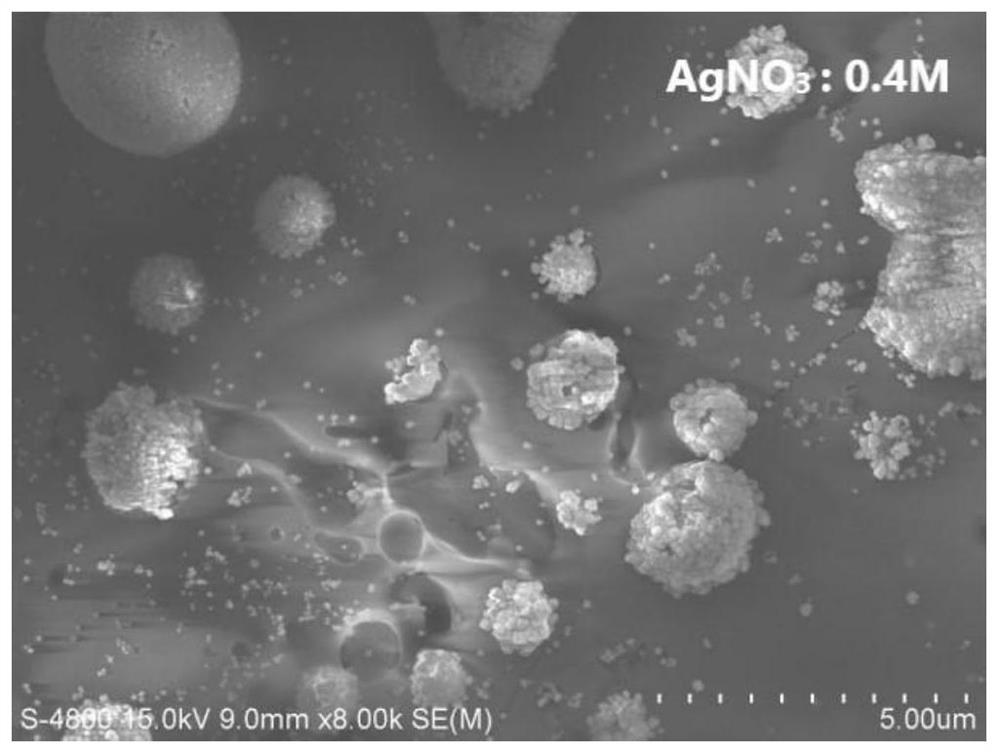

Silver nano / foamed copper material and preparation method and application thereof

ActiveCN113308685AHigh sensitivityRaman enhancementMaterial nanotechnologyRaman scatteringNanofoamAlcohol

The invention discloses a preparation method of a SERS substrate of a silver nano / foamed copper material. The preparation method comprises the steps of firstly immersing a cleaned and dried small foamed copper sheet with appropriate specifications into a dilute hydrochloric acid solution for a period of time, then rinsing the foamed copper sheet with absolute ethyl alcohol and deionized water in sequence, immersing the treated foamed copper sheet in a mixed solution of a silver nitrate solution and a PVP solution prepared in advance for shaking, rinsing the foamed copper sheet with the absolute ethyl alcohol and the deionized water again, putting the foamed copper sheet into a vacuum drying oven for full drying, and obtaining a silver nano / foamed copper substrate after the drying is completed. The prepared SERS substrate of the silver nano / foamed copper material is cheap in material, simple in preparation method, high in stability, storable, and relatively high in sensitivity in Raman detection.

Owner:HUAZHONG AGRI UNIV +2

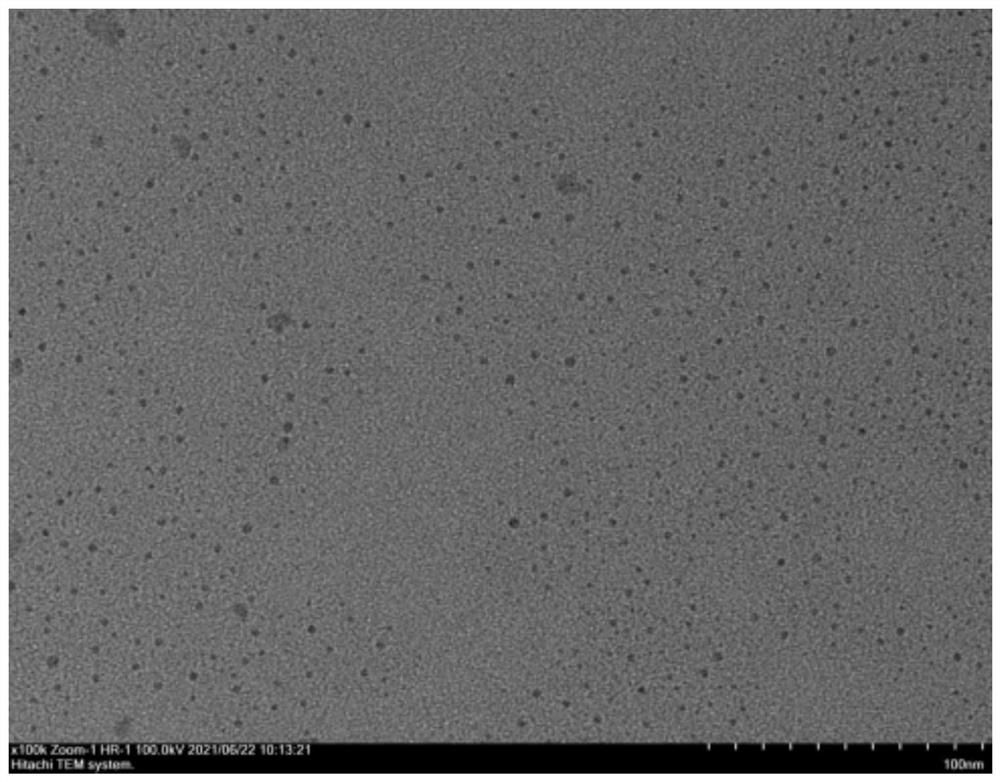

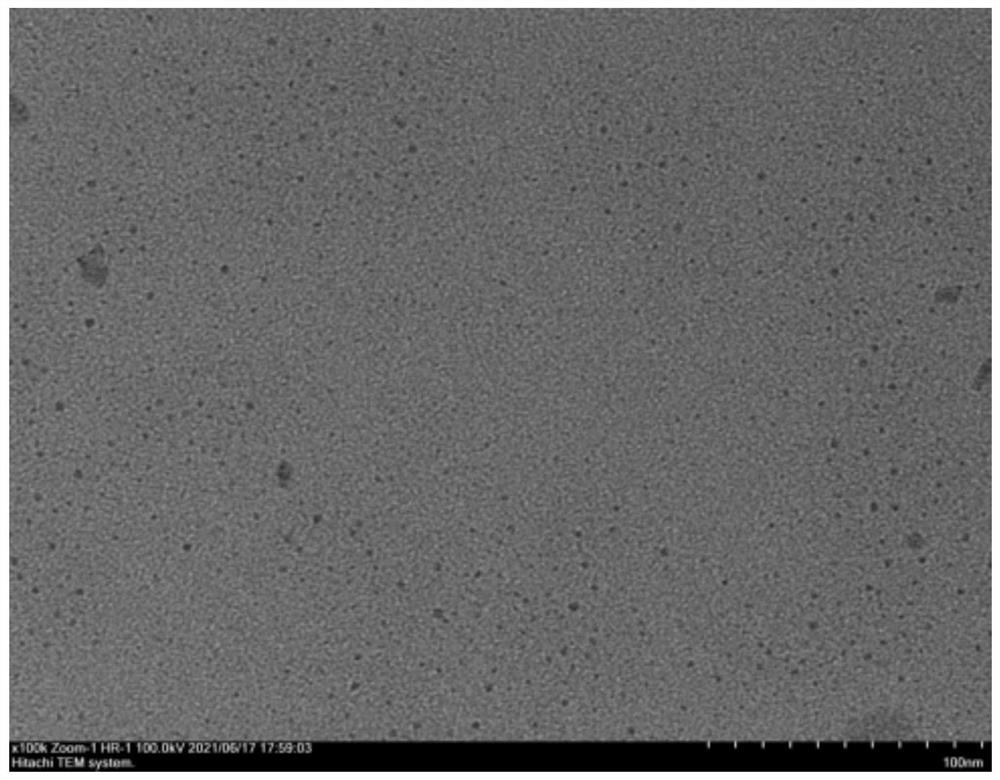

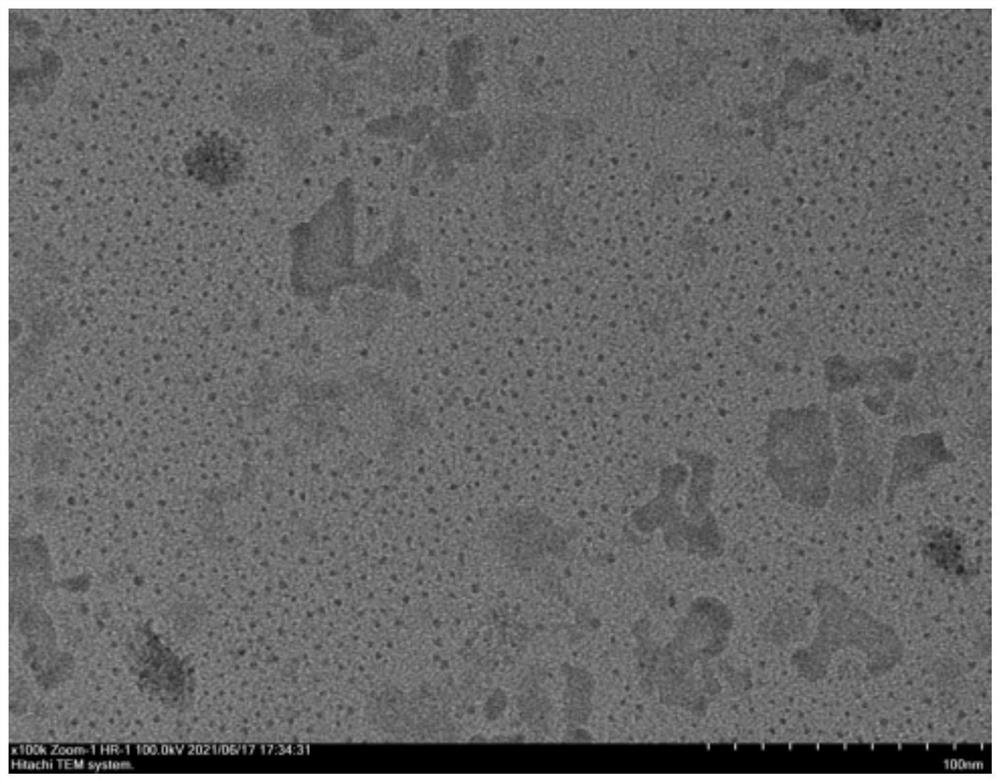

Preparation method of gold nanoparticles as electron microscope developer and obtained gold nanoparticles

PendingCN113732279AExcellent process parametersUniform shapeFlow propertiesNanosensorsGold particlesNanoparticle

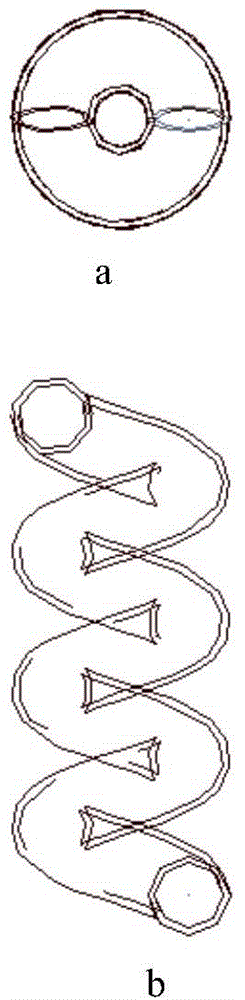

The invention discloses a preparation method of gold nanoparticles as an electron microscope developer and the obtained gold nanoparticles. According to the preparation method, chloroauric acid is used as a precursor material, hexadecyl trimethyl ammonium bromide is used as a stabilizer, sodium borohydride is used as a reducing agent, an oxidation-reduction reaction is carried out in a supergravity rotating packed bed, and the gold nanoparticles are obtained. The invention further provides the gold nanoparticles prepared by the preparation method. According to the preparation method of the gold nanoparticles, better process parameters are obtained by adjusting the feeding flow rate and the rotor rotating speed of the supergravity rotating packed bed, convenience and safety are achieved, continuous production can be achieved, the obtained gold nanoparticles are uniform in morphology and size, the particle size of the gold nanoparticles is 1-3 nm, and the size of the gold nanoparticles is smaller than that of common gold particles; and and the particles are good in dispersity and long in storage time.

Owner:BEIJING UNIV OF CHEM TECH

Nanometer Na/Fe composite type solid acid catalyst and preparation method and application thereof

ActiveCN109621964AIncrease the active siteExcellent process parametersOrganic chemistryCatalyst activation/preparationNano catalystSolid acid

The invention belongs to the technical field of biomass utilization, and particularly discloses a nanometer Na / Fe composite type solid acid catalyst and a preparation method and application thereof. The preparation method of the catalyst comprises the following steps that ferrous chloride and ferric chloride are mixed to be uniform under the action of hydrochloric acid according to the certain ratio, then, sodium hydroxide is dropwise added, and the nanometer Na / Fe composite type solid acid catalyst is prepared through a forward sedimentation method. Biomass and the prepared nanometer catalystare mixed according to the certain ratio, pyrolysis is performed under the inert atmosphere, and the high-selectivity furfural product can be obtained. The catalyst is simple in preparation process,low in cost, high in selectivity, capable of solving the problems that in the prior art, furfural selectivity is low and few by-products are produced, and capable of achieving biomass directional conversion and high-value utilization.

Owner:HUAZHONG UNIV OF SCI & TECH

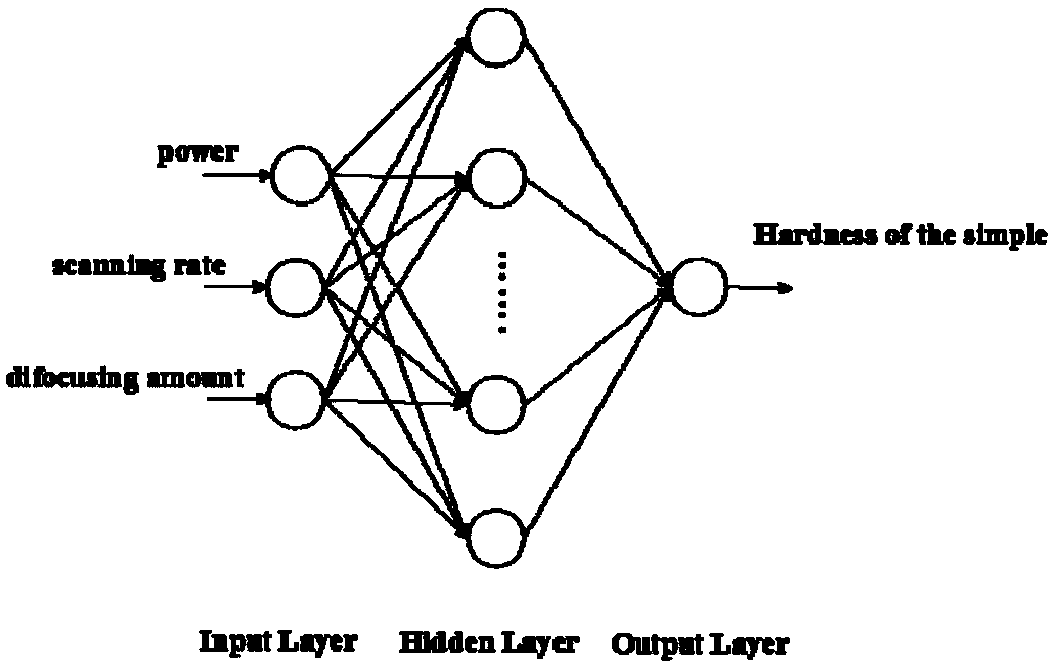

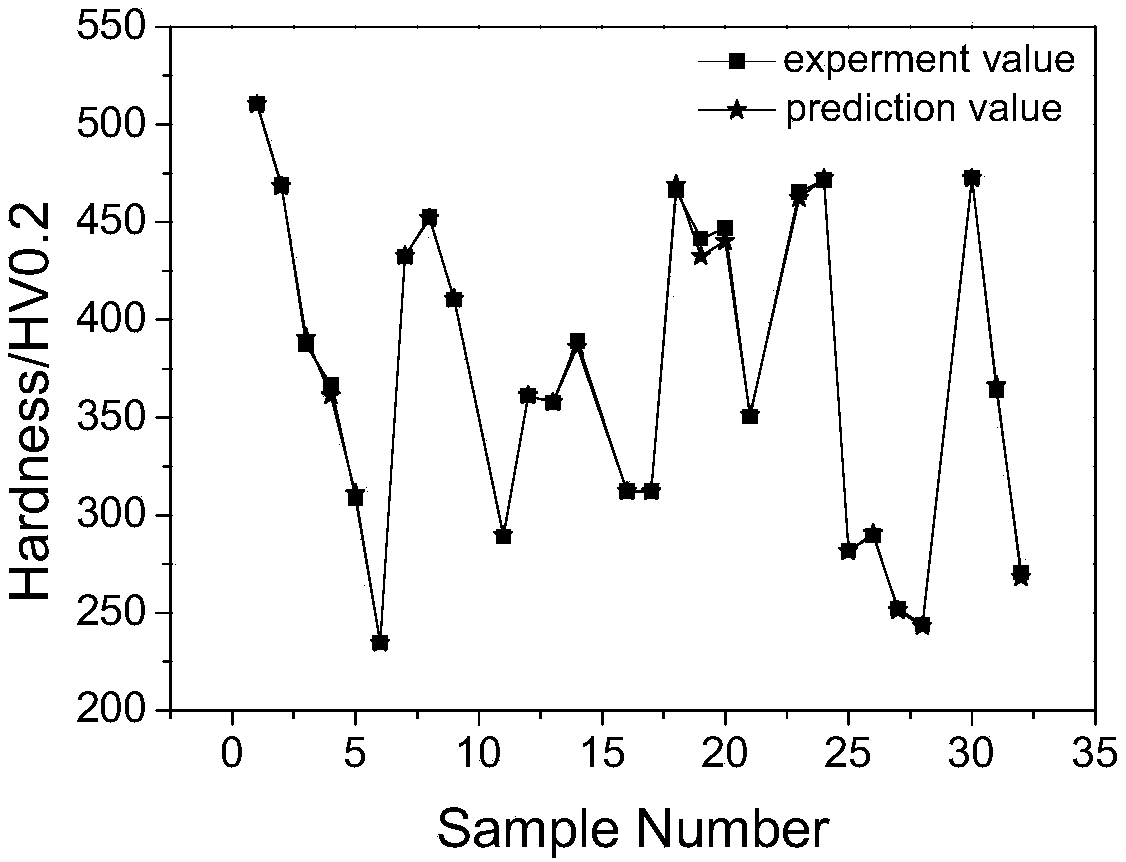

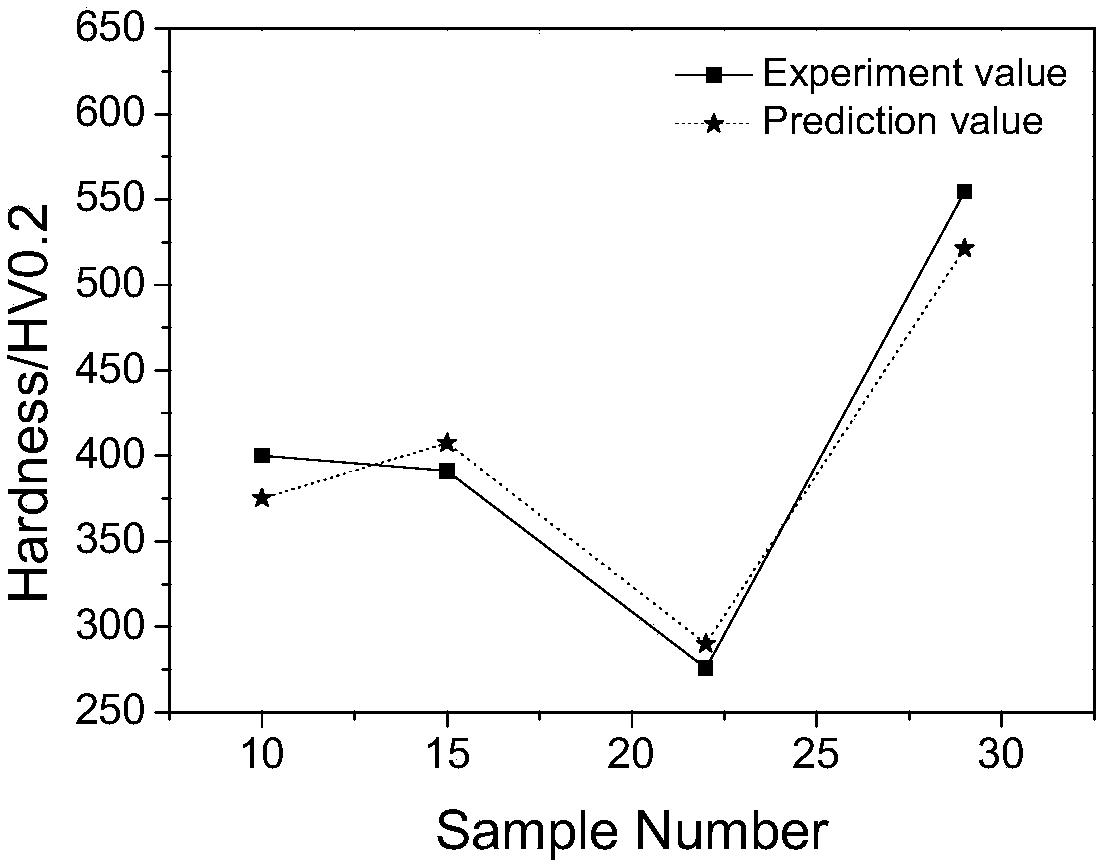

Steel wire cutter body laser heat treatment technological parameter optimization method

InactiveCN108330255AExcellent process parametersReduce the number of trialsFurnace typesHeat treatment process controlGenetic algorithmPrediction methods

The invention discloses a steel wire cutter body laser heat treatment technological parameter optimization method. According to the steel wire cutter body laser heat treatment technological parameteroptimization method provided by the invention, the outstanding fitting ability of an artificial neural network to a multivariate nonlinear mapping relation is firstly utilized, digging and learning are performed from test data, a mapping relation of laser heat treatment technological parameter including the laser power, the scanning speed and the defocusing amount and the corresponding microhardness is established finally, and a prediction method of the steel wire cutter body laser heat treatment technological parameters is established on the basis of the mapping relation; and then a genetic algorithm is adopted to perform operation on artificial neural network prediction data to obtain optimal laser heat treatment technological parameters, and the purpose of optimization is achieved.

Owner:NANJING UNIV OF SCI & TECH

Method for separating and extracting cytidine from fermentation liquor

PendingCN113621010AEliminate the process of obtaining secondary crystallizationReduce dosageSugar derivativesSugar derivatives preparationSilver sulfateFermentation broth

The invention discloses a method for separating and extracting cytidine from fermentation liquor. The method comprises the following steps of adsorbing and eluting liquid containing cytidine by cation exchange resin, and concentrating and crystallizing the obtained eluent to obtain cytidine crystals, wherein the cation exchange resin is obtained by modifying NH-1 resin with silver sulfate and / or sulfuric acid. The cation exchange column used in the method is modified NH-1 resin, the cytidine adsorption capacity of the cation exchange column reaches 0.3 g / g, the resin dosage is reduced, and the acid and alkali dosage and the operation time are indirectly saved.

Owner:NANJING HIGH TECH UNIV BIOLOGICAL TECH RES INST CO LTD +1

Rigidity-controllable material oriented to material increase manufacturing technology and manufacturing method thereof

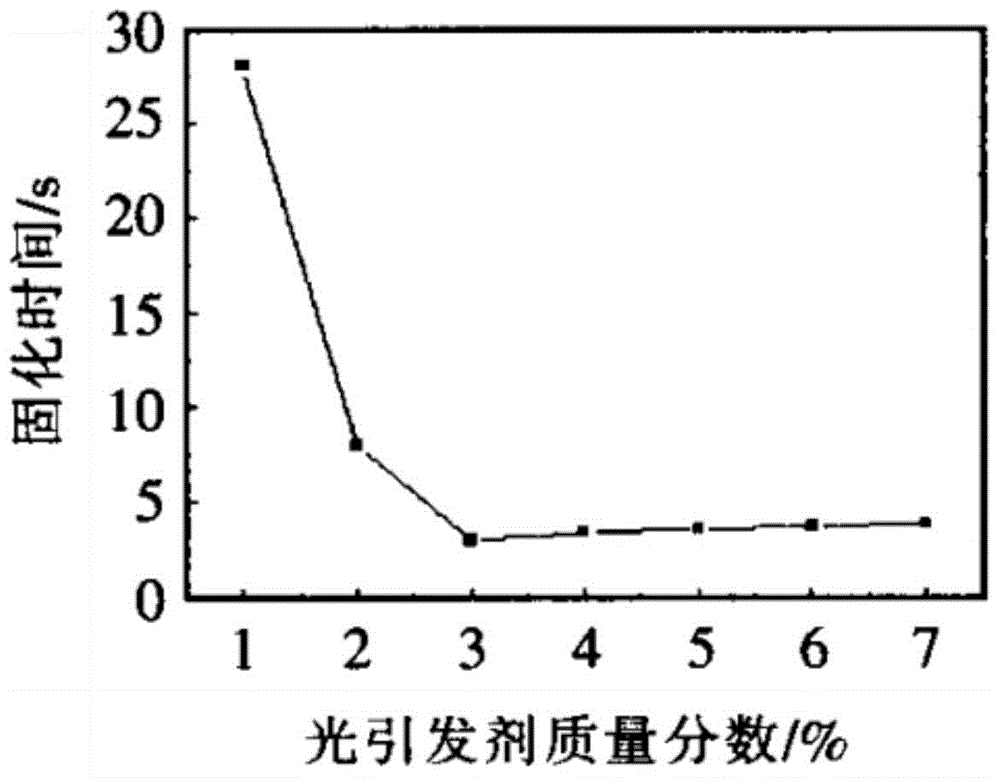

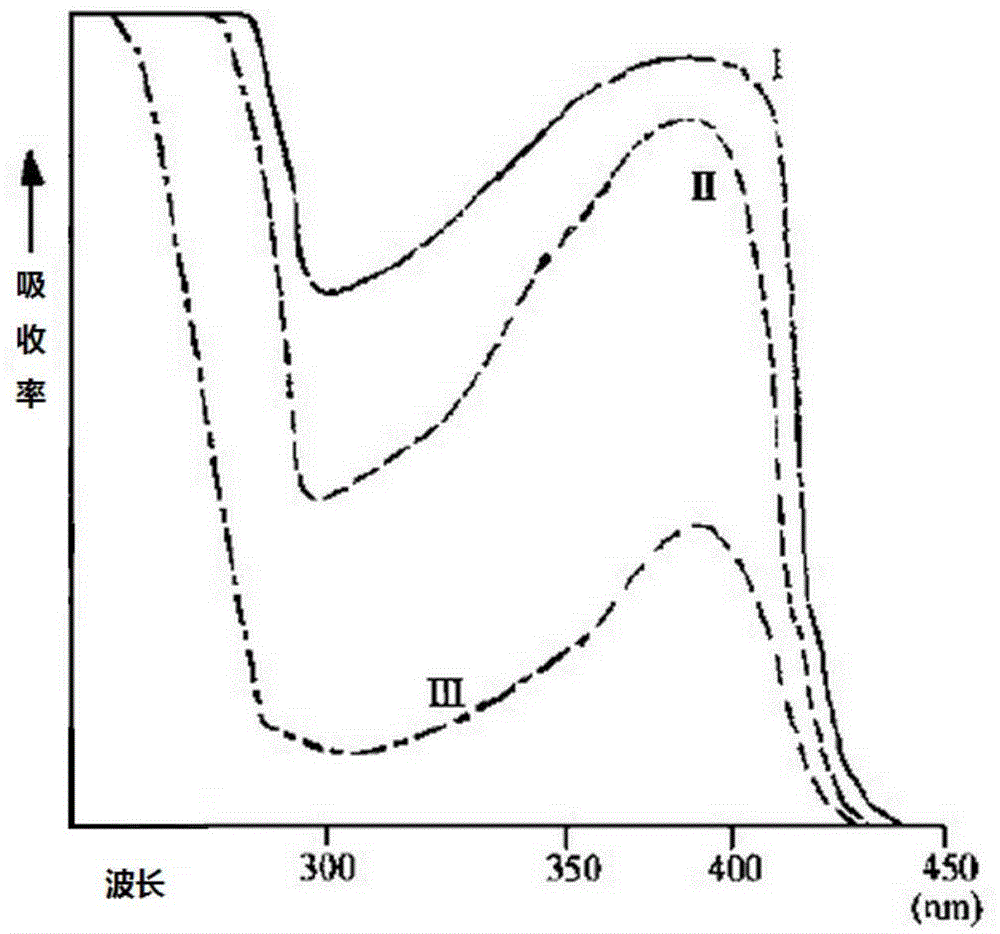

InactiveCN104693381ARealize processingHigh forming precisionManufacturing technologyUltraviolet lights

The invention relates to a rigidity-controllable material oriented to a material increase manufacturing technology and a manufacturing method thereof. The rigidity-controllable material comprises, by mass, 10-40 parts of acrylic oligomer, 60-90 parts of alkyl acrylate and 0.1-3 parts of ultraviolet light photoinitiator, and the acrylic oligomer, wherein the alkyl acrylate and the ultraviolet light photoinitiator are sequentially mixed and evenly stirred to prepare a photocuring raw material; a three-dimensional model for a rigidity-controllable material device is built, discretization is carried out on the surface of the three-dimensional model to generate a three-dimensional digital model file, and a machining file capable of being identified by a material increase manufacturing device is led out after supporting adding, model layered discretization and machining path generation are carried out on the three-dimensional digital model file; the photocuring raw material is manufactured into the rigidity-controllable material device through the ultraviolet light polymerization material increase manufacturing technology. The obtained device is variable in structure, the rigidity controlling performance is excellent, and the rigidity-controllable material has the advantages of being high in efficiency, low in cost and high in accuracy; the glassy state Yang modulus value is approximately 500 times of the rubbery state Yang modulus value, and the response speed of the Yang modulus along with changes of the temperature is high.

Owner:XI AN JIAOTONG UNIV +1

Testing device for simulating flow field in continuous casting crystallizer

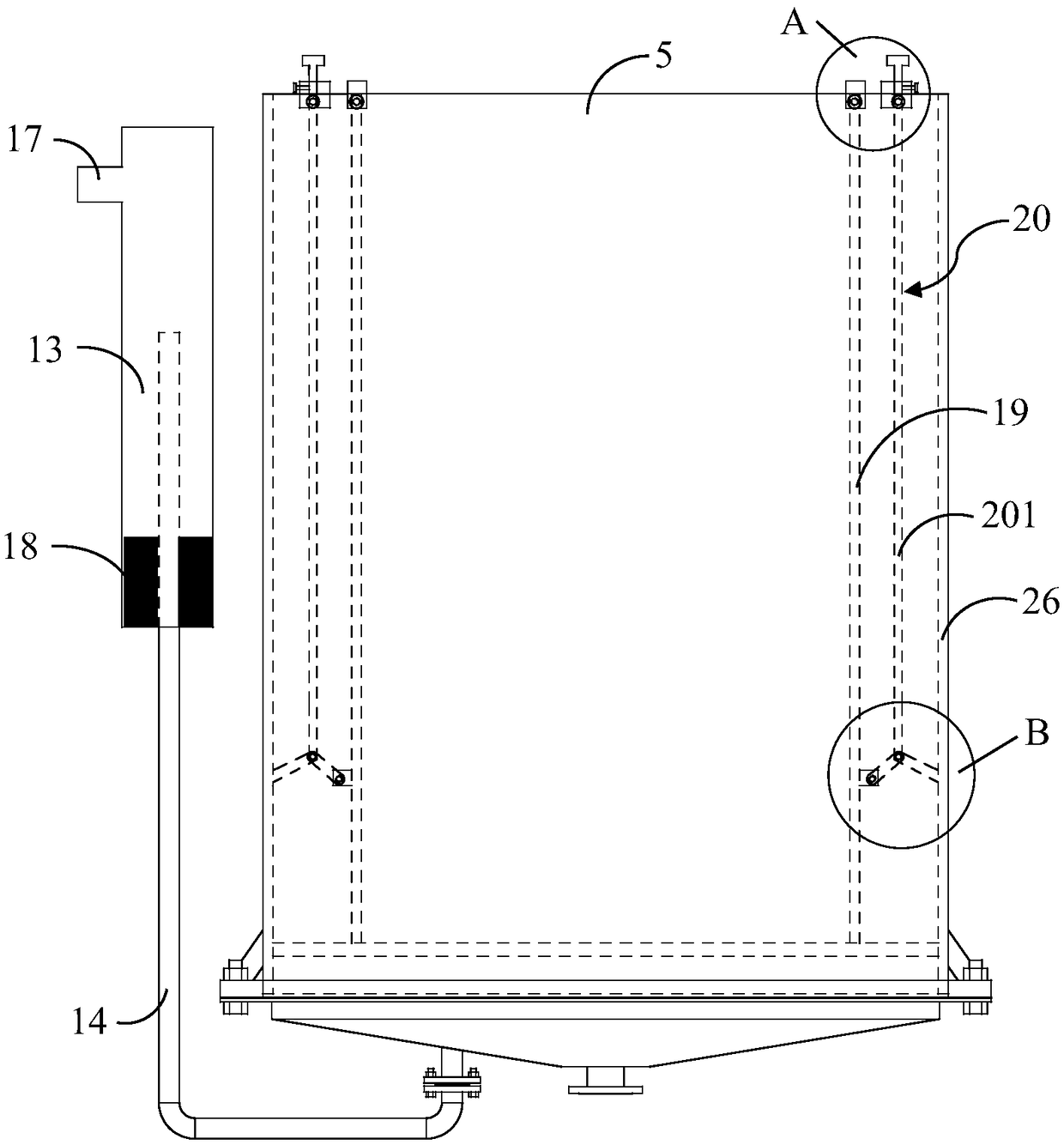

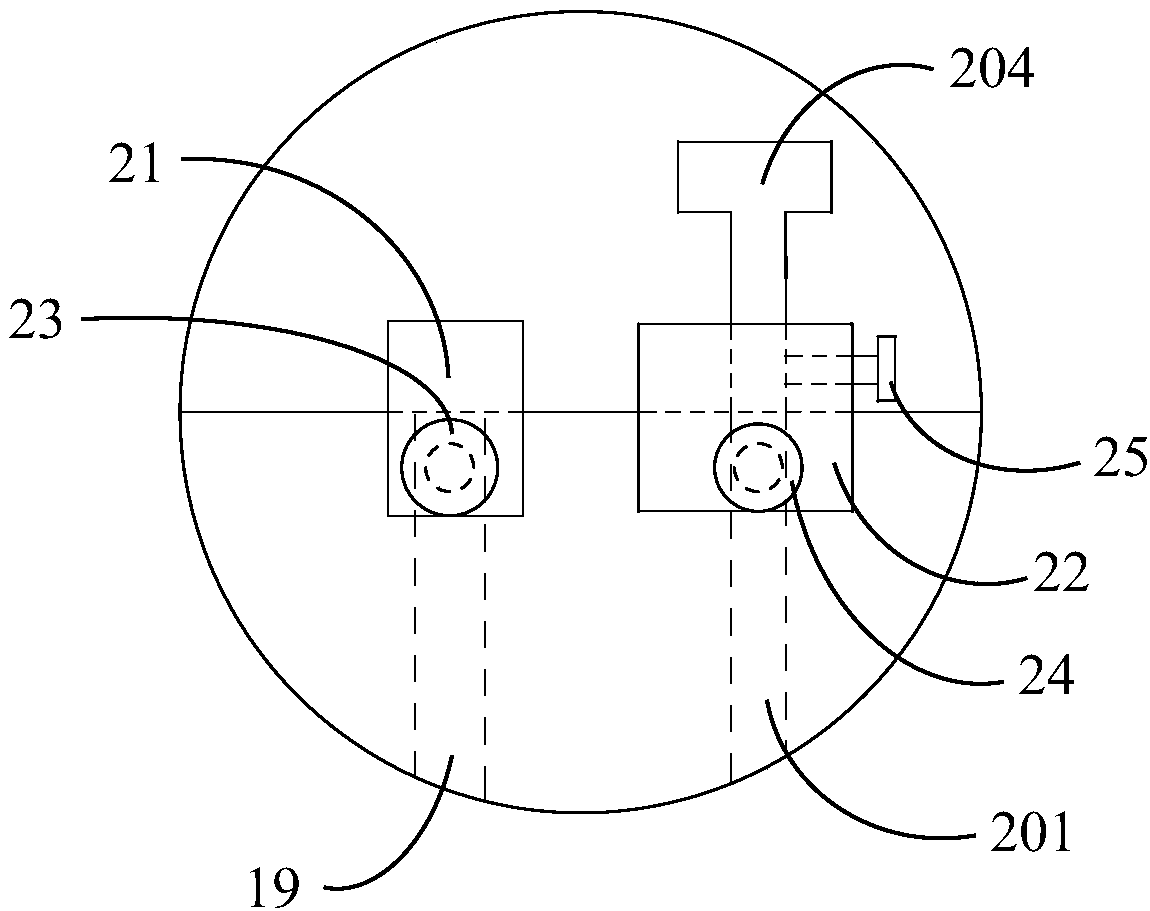

ActiveCN108788030ALiquid level stabilityEasy to controlEducational modelsEngineeringIndustrial water

The invention discloses a testing device for simulating a flow field in a continuous casting crystallizer. The testing device includes a water tank, a crystallizer model and a water recycling tank; wherein an industrial water inlet is formed in the water tank, an immersion water opening is formed in the top of the crystallizer model in an inserted mode, the upper part of the immersion water opening communicates with the water tank, a first flow regulating valve is arranged between the water tank and the immersion water opening, the water recycling tank communicates with the bottom of the crystallizer model and the water tank, and a second flow regulating valve is arranged between the crystallizer model and the water recycling tank; and a self-priming pump is arranged between the water recycling tank and the water tank, a container is arranged on the outer side of the crystallizer model, the bottom of the container communicates with the bottom of the crystallizer model, and an overflowopening is formed in the side of the container. By means of the testing device for simulating the flow field in the continuous casting crystallizer, the liquid level of the crystallizer model can be accurately controlled, and the width of an inner cavity of the crystallizer model and the taper of an inner billet shell of the crystallizer model can be adjusted.

Owner:BAOSHAN IRON & STEEL CO LTD

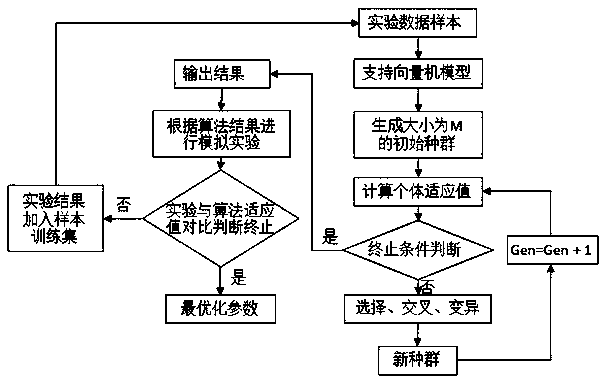

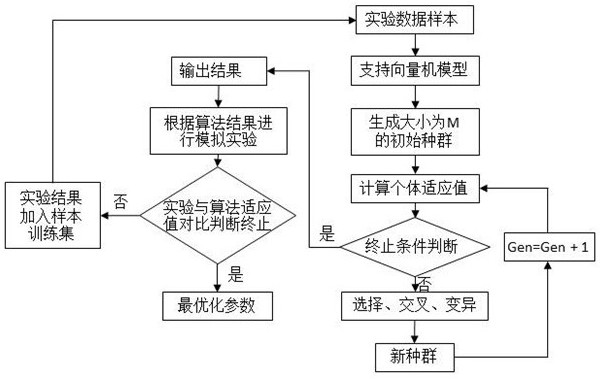

Optimal parameter determination method for researching oil storage tank hot oil spraying heating process

ActiveCN111476417AImprove computing efficiencyGuaranteed calculation accuracyMeasurement devicesForecastingSupport vector machineGenetics algorithms

The invention relates to an optimal parameter determination method for researching the hot oil spraying and heating process of an oil storage tank, and the method comprises the steps: determining a decision variable according to factors affecting the hot oil spraying and heating effect of the oil storage tank in an actual production process; acquiring the actual measurement data of the hot oil spraying and heating process in the experiment storage tank under different parameters, taking the field cooperation angle, the uniformity, the heating efficiency and the average temperature rising speedas indexes for evaluating the heating effect, determining the weight of each index, and obtaining a target function through calculation; establishing a support vector machine model through the decision variable and the target function; generating an initial population with the size of M based on the support vector machine model, and optimizing the target function by adopting a genetic algorithm;taking the optimal variable as an experimental parameter to carry out an indoor simulation experiment to obtain a corresponding target function, and if an error between the target function and a support vector machine result exceeds a certain range, repeating iteration until the error is smaller than the certain range. According to the method, the optimal process parameters can be found, and the calculation precision is ensured to a great extent.

Owner:领航石油化工(天津)有限公司

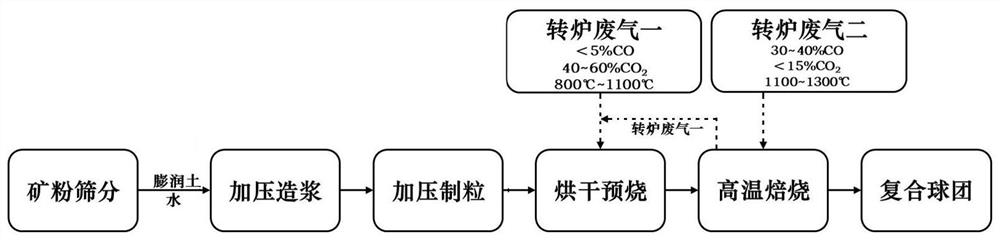

Method for drying-in-shade pelletizing by using converter waste gas

ActiveCN112921172AHigh compressive strengthExcellent process parametersCO2 contentBlast furnace smelting

The invention relates to a method for drying-in-shade pelletizing by using converter waste gas. The method comprises the following steps of S1, preparing raw materials; S2, pressurizing and making slurry; S3, pressurizing and granulating; S4, drying and pre-burning; and S5, high-temperature roasting. All heat of drying and pre-burning in the step S4 comes from first converter waste gas, and high-temperature roasting heat in the step S5 comes from second converter waste gas; and the temperature of the first converter waste gas is lower than that of the second converter waste gas, the CO content in the first converter waste gas is lower than that of the second converter waste gas, and the CO2 content in the first converter waste gas is higher than that of the second converter waste gas. Drying and high-temperature roasting are carried out in the pelletizing process, and compared with a traditional pelletizing process, the technological process is shortened, and the time is shortened; a process technology different from the traditional pelletizing process is provided, so that the production efficiency is improved; and the process parameters of obtained pellets are basically superior to those of traditional pellets, the pelletizing rate is increased, and the requirements of blast furnace smelting are met.

Owner:NORTHEASTERN UNIV

A Method for Determining the Optimal Parameters of Thermal Oil Spraying Heating Process in Oil Storage Tanks

ActiveCN111476417BImprove computing efficiencyGuaranteed calculation accuracyMeasurement devicesForecastingGenetics algorithmsProcess engineering

The present invention relates to a method for determining the optimal parameters of the thermal oil spraying and heating process of the oil storage tank, which includes: determining the decision variable according to the factors that affect the thermal oil spraying and heating effect of the oil storage tank in the actual production process; obtaining different The measured data of the thermal oil spraying heating process in the experimental storage tank under the parameters, the field synergy angle, uniformity, heating efficiency and average heating rate are used as indicators to evaluate the heating effect, the weights of each indicator are determined, and the objective function is calculated; through Decision variable and objective function establish a support vector machine model; based on the support vector machine model, an initial population of size M is generated, and a genetic algorithm is used to optimize the objective function; the optimized variables are used as experimental parameters for indoor simulation experiments to obtain the corresponding objective function , the error with the result of the support vector machine exceeds a certain range, then repeat the iteration until the error is less than a certain range. The invention can find the optimal process parameters, which ensures the calculation accuracy to a great extent.

Owner:领航石油化工(天津)有限公司

A method for producing metallurgical grade alumina from fly ash and recyclable ammonium salt

InactiveCN104628020BEasy to filter washEasy to crystallize outSolid waste disposalAluminium oxides/hydroxidesSulfurStrong acids

The invention discloses a method for producing metallurgy-grade alumina by taking pulverized fuel ash and recycled ammonium salt as raw materials. The method comprises the following steps: (1) preparing materials; (2) roasting; (3) dissolving; (4) crystallizing; (5) carrying out a liquid-solid ammonolysis reaction; (6) grinding and removing sulfur; and (7) performing low-temperature Bayer aluminum production. The method disclosed by the invention has the advantages that an aluminum salt ammonolysis method suitable for strong acid and weak base is adopted, namely liquid-solid or gas-solid ammonolysis is performed, the production efficiency is improved by over 60 percent compared with that a liquid-liquid ammonolysis method, the process conditions of the ammonolysis method are optimized, optimal process parameters are determined, the obtained product, namely crude aluminum hydroxide, is easy to filter and wash, the model selection of equipment is simple, and industrial mass production can be realized.

Owner:NORTH UNITED POWER CO LTD +1

A kind of silver nano/copper foam material and its preparation method and application

ActiveCN113308685BHigh sensitivityRaman enhancementMaterial nanotechnologyRaman scatteringAnhydrous ethanolNanofoam

The invention discloses a method for preparing a SERS substrate of a silver nanometer / copper foam material. Firstly, immerse the cleaned and dried small pieces of foam copper with appropriate specifications in dilute hydrochloric acid solution for a period of time, and then successively wash them with absolute ethanol, deionized Rinse the foamed copper sheet with water, then immerse the processed foamed copper sheet in the mixed solution of silver nitrate solution and PVP solution prepared in advance to shake, rinse the foamed copper sheet with absolute ethanol and deionized water again, and put it in a vacuum It is fully dried in a drying oven, and the silver nano / copper foam substrate can be obtained after drying. The SERS substrate of the silver nanometer / copper foam material prepared by the invention has the advantages of cheap materials, simple preparation method, strong stability, storage resistance, and high sensitivity in Raman detection.

Owner:HUAZHONG AGRI UNIV +2

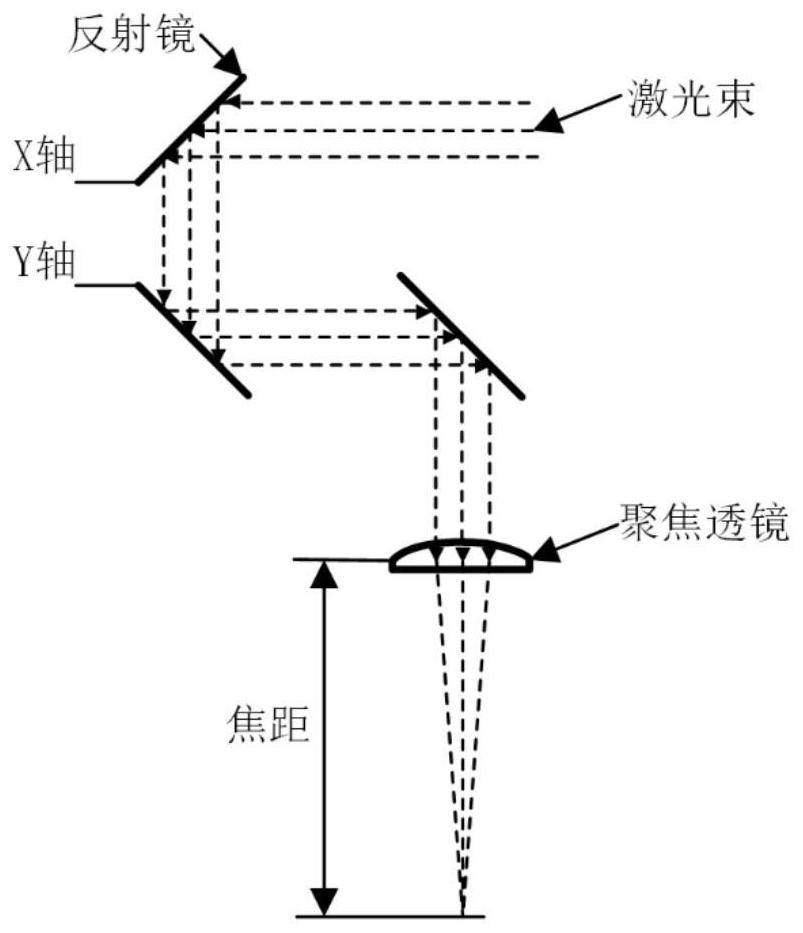

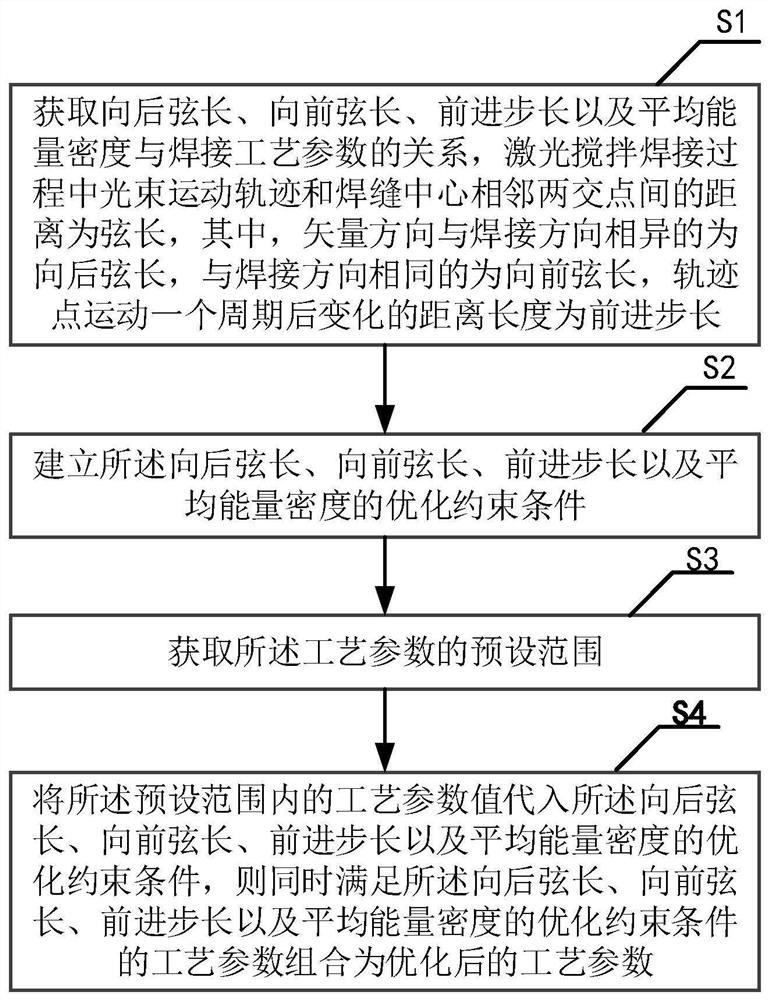

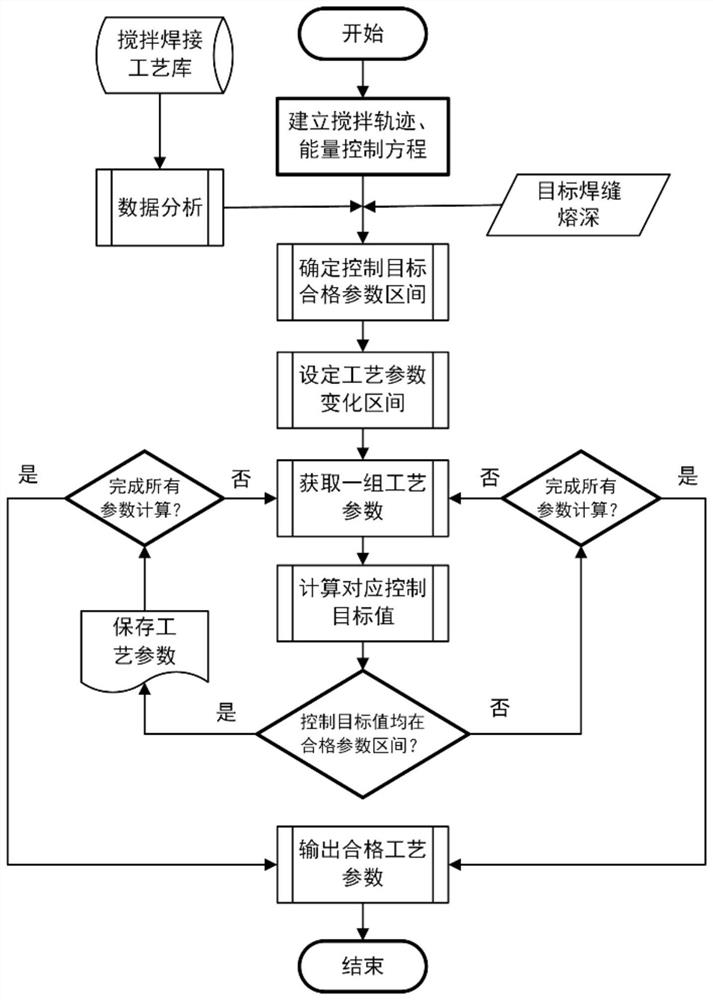

Process parameter optimization method and system for porosity suppression in laser stir welding

ActiveCN113305435BSuppress generationExcellent process parametersLaser beam welding apparatusThermodynamicsEngineering

The invention belongs to the technical field related to laser welding, and discloses a process parameter optimization method and system for suppressing pores in laser stir welding. The method includes: S1, obtaining the backward chord length, forward chord length, forward step length and average The relationship between energy density and welding process parameters, the distance between the laser motion trajectory and the two adjacent intersection points of the weld center in the laser stir welding process is the chord length; S2, establish the backward chord length, forward chord length, forward step length and average The optimization constraints of energy density; S3, obtaining the preset range of process parameters; S4, substituting the process parameter values within the preset range into the optimization constraints of backward chord length, forward chord length, forward step length and average energy density , then the process parameter combination that satisfies the optimization constraints of backward chord length, forward chord length, forward step length and average energy density at the same time is the optimized process parameter. This application optimizes the welding process parameters to achieve welding with large melting depth and few pores.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of ibuprofen sodium salt refining device and process

ActiveCN103880650BExcellent process parametersThe effect of optimal process parameters on the removal of organic matterCarboxylic compound separation/purificationEconomic benefitsTower

The present invention adopts the continuous stripping process based on the heat integration method to remove the organic matter in the sodium salt solution, and provides a device and a process for removing the organic matter in the ibuprofen sodium salt: ibuprofen sodium salt and water in the sodium salt Mix in the dissolving tank, dissolve and enter the filter press for separation, the insoluble matter is discharged from the bottom, the separated solution enters the sodium salt solution receiving tank, and the filtrate enters the stripping tower from the top of the tower after being preheated by the primary condenser through the feeding pump , the top product is condensed by the first-stage condenser and the second-stage condenser, and then enters the distributor, and the extracted product flows out from the upper part of the distributor and enters the distillate receiver to collect; the bottom product enters the stripping receiving tank and enters the next process. This process can not only shorten the treatment time, avoid the generation of waste water with high COD content but also re-use the organic matter. The technology has remarkable treatment effect, low operating cost and can generate certain economic benefits, and has high popularization and application value.

Owner:山东新华医药化工设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com