Rigidity-controllable material oriented to material increase manufacturing technology and manufacturing method thereof

A technology of additive manufacturing and rigidity, which is applied in the field of materials with controllable stiffness for additive manufacturing technology and its preparation, can solve the problems of simple molding structure, easy deviation of molding size, and difficult-to-shape parts, etc., to achieve simple manufacturing process , the effect of high forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a material with controllable stiffness for additive manufacturing technology provided by the present invention comprises the following steps:

[0031] 1) The types of UV curing forming raw materials include stationary phase materials, reversible phase materials, and UV photoinitiators in materials with controllable stiffness. According to the mass parts of each component in the material formula, acrylate oligomer, alkyl acrylate, and ultraviolet light photoinitiator were mixed in sequence, placed in a water bath at 50-60°C and heated for 2-5 minutes, stirred evenly, and prepared into a light Curing raw materials; and acrylate oligomer is the stationary phase material, and alkyl acrylate is the reversible phase material;

[0032] Among them, the acrylate oligomers are aromatic acid methacrylate half ester, polyethylene glycol dimethacrylate, novolac epoxy acrylate, water-soluble polyester acrylic acid, alkyl epoxy-triacrylate, polybutylene dimethac...

Embodiment 1

[0039] Stiffness controllable material device spiral tube:

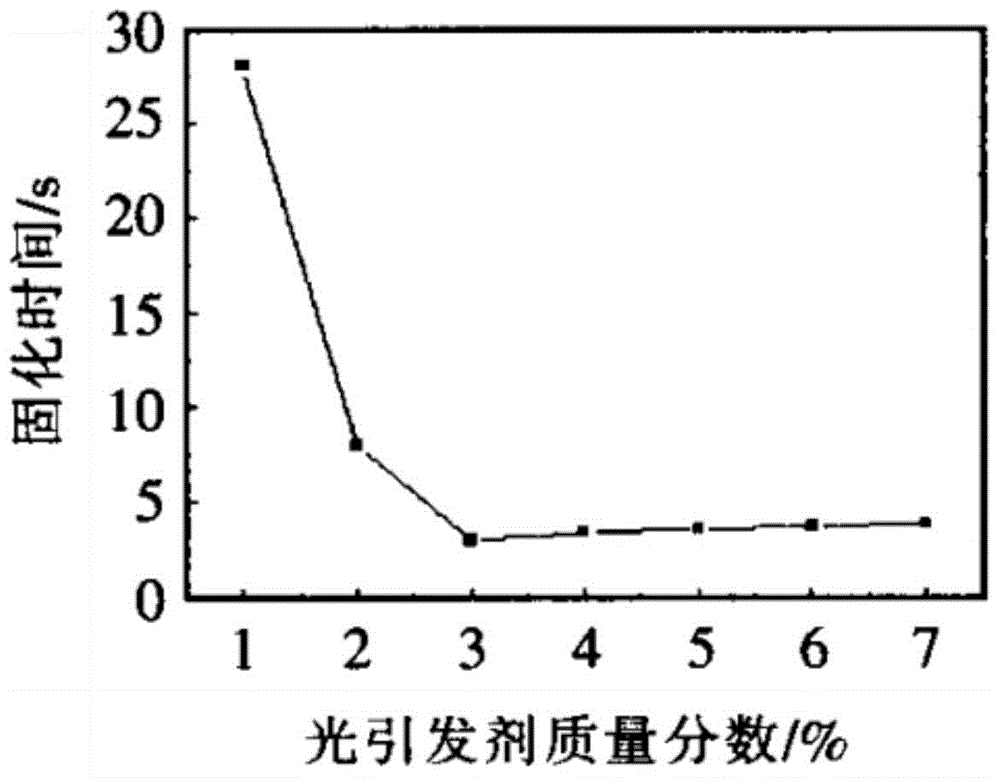

[0040] 1) In parts by mass, 10 parts of polyethylene glycol dimethacrylate, 87 parts of tert-butyl acrylate, and 3 parts of 2,2-dimethoxy-phenylacetophenone were mixed successively, Place in a water bath at 50°C and heat for 5 minutes, stir evenly to form a light-curing raw material; since 2,2-dimethoxy-phenylacetophenone has a great influence on the speed of light-curing forming, 2,2-dimethoxy The content of methoxy-phenylacetophenone is based on figure 1 The curing speed of the shown photosensitive material is determined by the change curve of the content of 2,2-dimethoxy-phenylacetophenone;

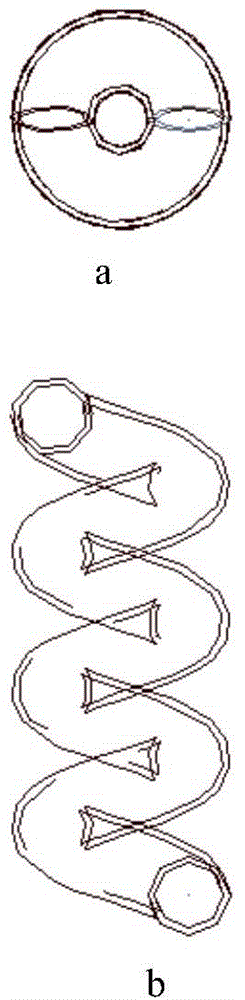

[0041] 2) Use UG software to create a three-dimensional model of a spiral tubular material device with controllable stiffness, such as image 3As shown, the model size data: the outer diameter of the circular pipe is 12mm, the inner diameter is 10mm, and the pitch is 8mm; the surface of the 3D model is discretized, and the ...

Embodiment 2

[0044] 1) In terms of parts by mass, 37 parts of aromatic acid methacrylate half ester, 60 parts of lauryl acrylate, and 1 part of 2,2-dimethoxy-phenylacetophenone were mixed successively, Put it in a 60°C water bath and heat for 2 minutes, stir evenly to form a light-curing raw material; since 2,2-dimethoxy-phenylacetophenone has a great influence on the speed of light-curing forming, so, 2,2-dimethoxy-phenylacetophenone The content of methoxy-phenylacetophenone is based on figure 1 The curing speed of the shown photosensitive material is determined by the change curve of the content of 2,2-dimethoxy-phenylacetophenone;

[0045] 2) Use UG software to create a three-dimensional model of a spiral tubular material device with controllable stiffness, such as image 3 As shown, the model size data: the outer diameter of the circular pipe is 12mm, the inner diameter is 10mm, and the pitch is 8mm; the surface of the 3D model is discretized, and the triangle tolerance and adjacent t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com