Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Wide range of stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

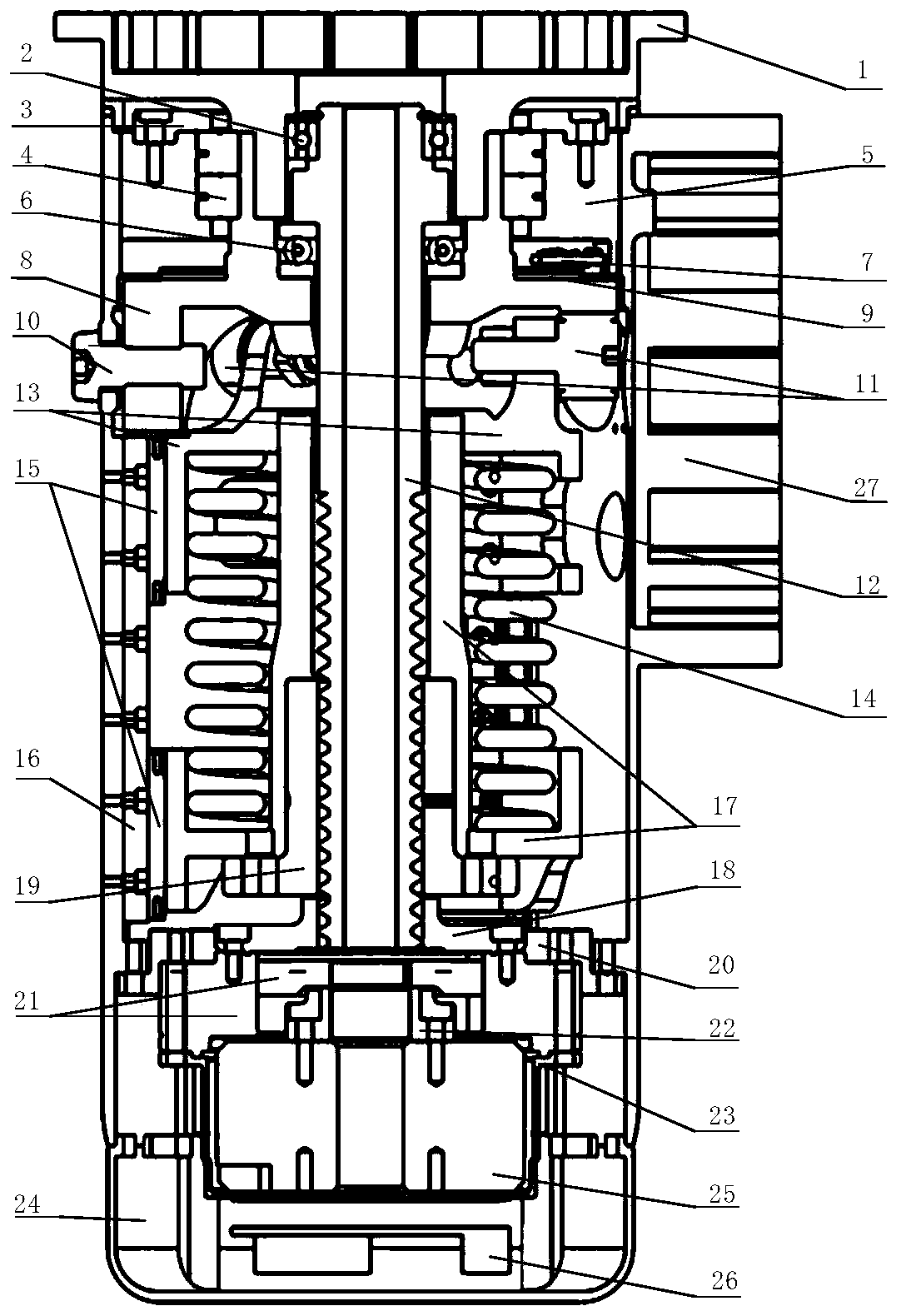

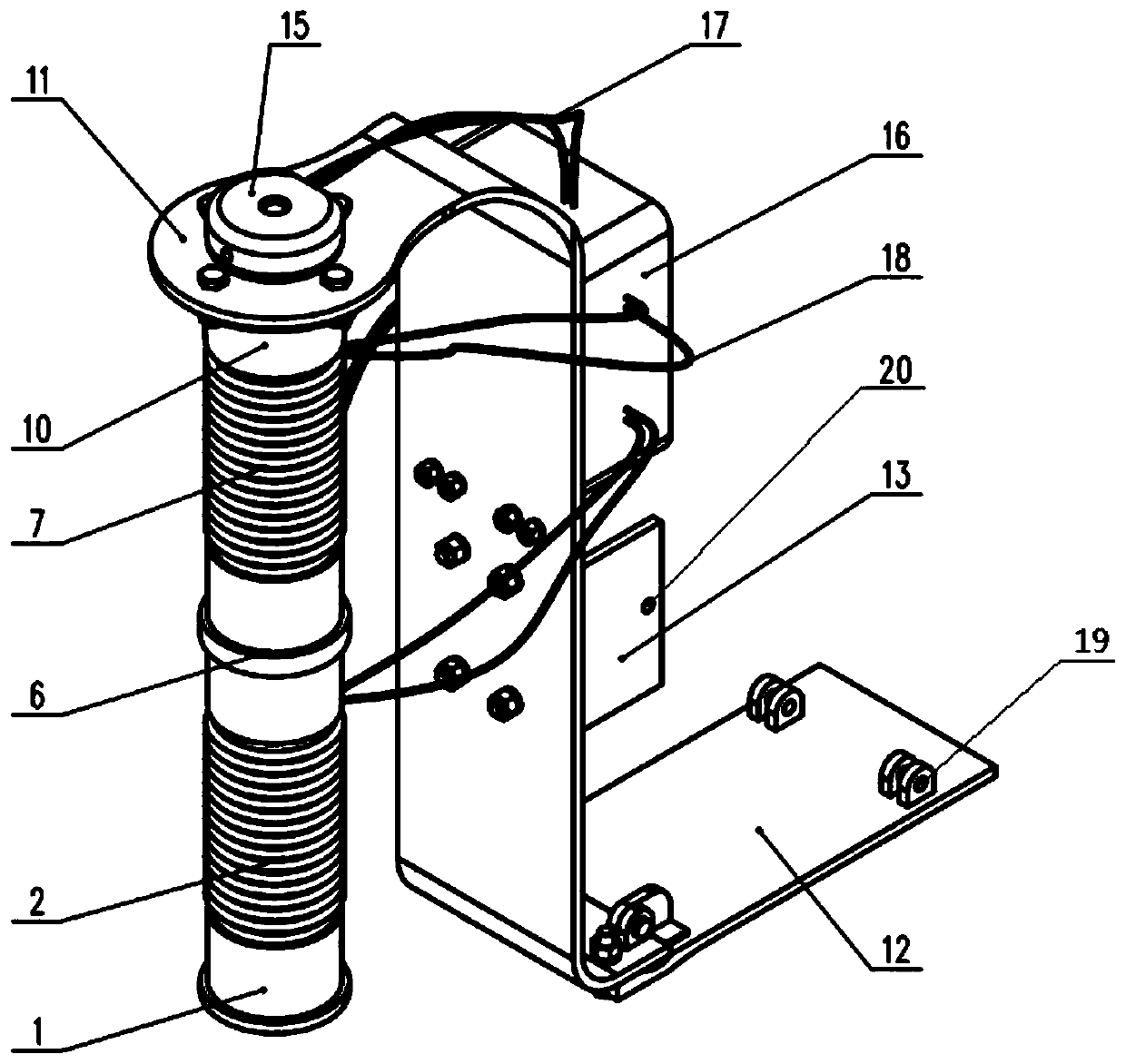

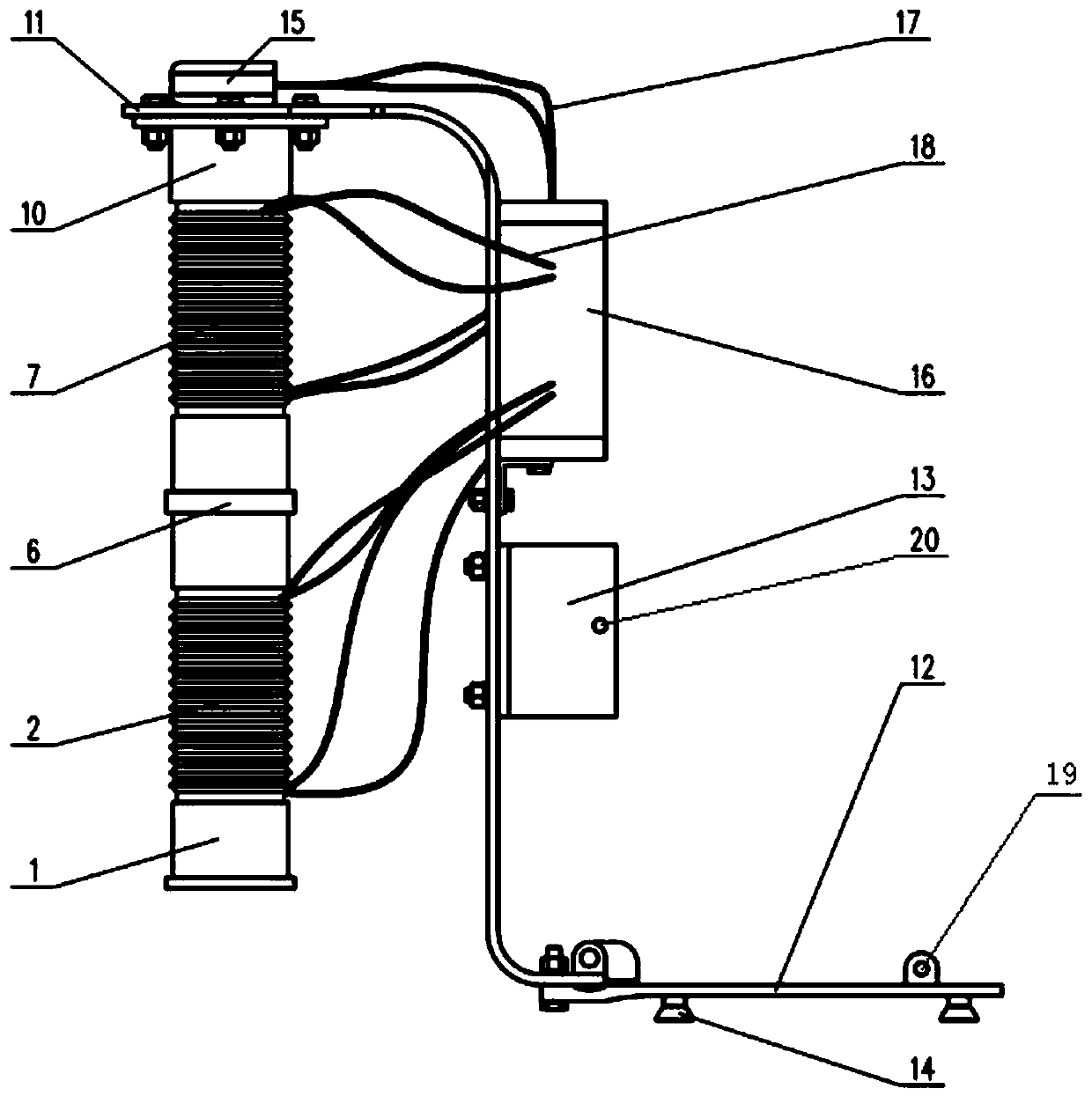

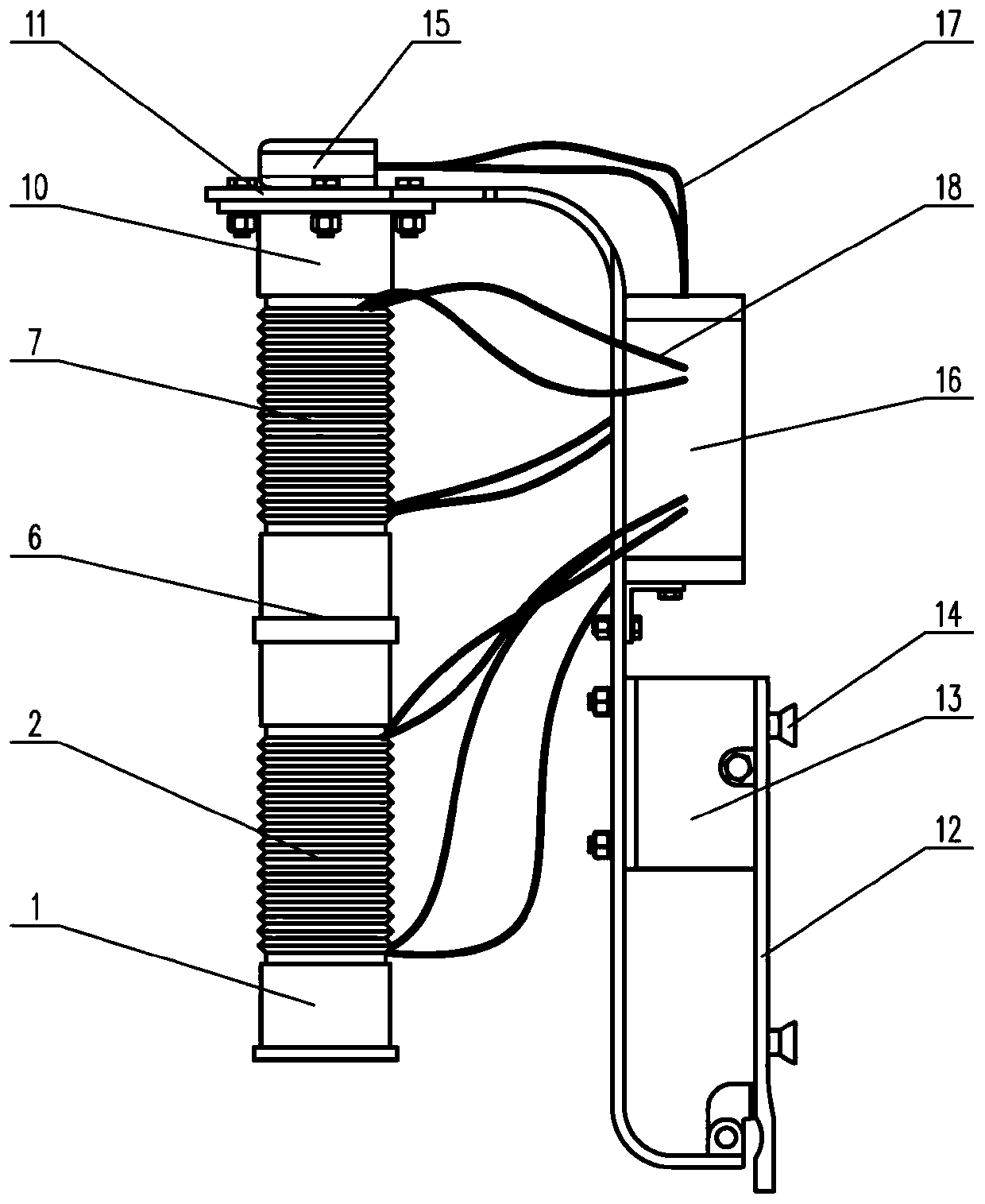

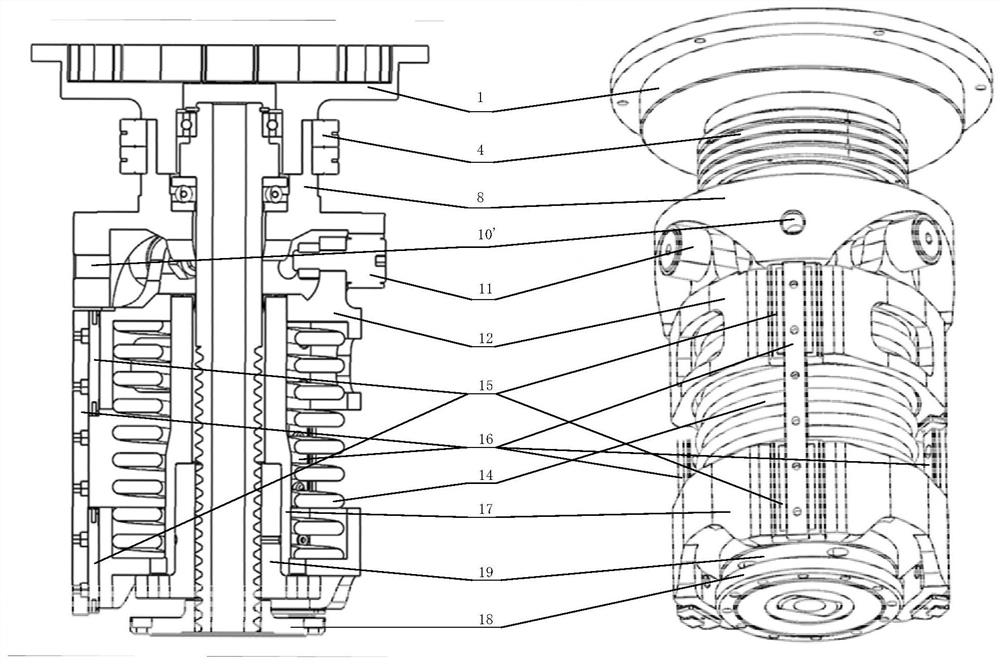

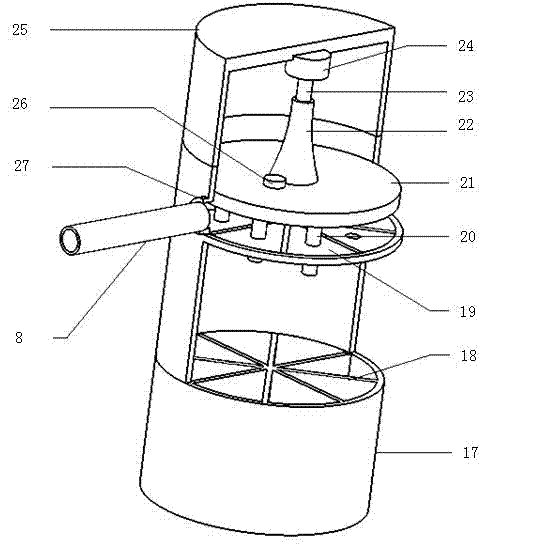

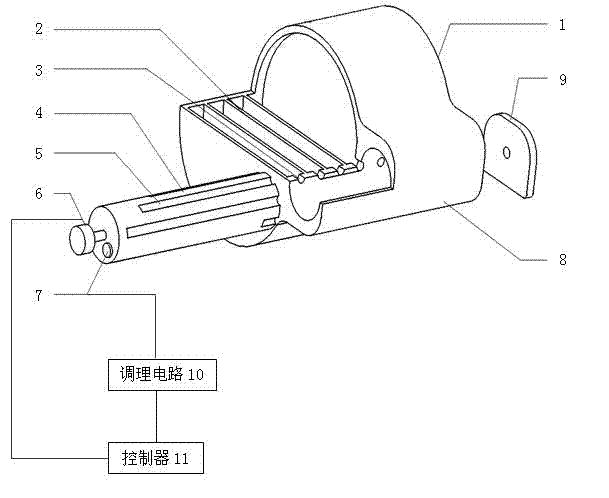

Variable-volume additional air chamber of constant internal pressure air spring

InactiveCN102003488AWide range of stiffnessImprove driving stabilityGas based dampersAir springElectric machinery

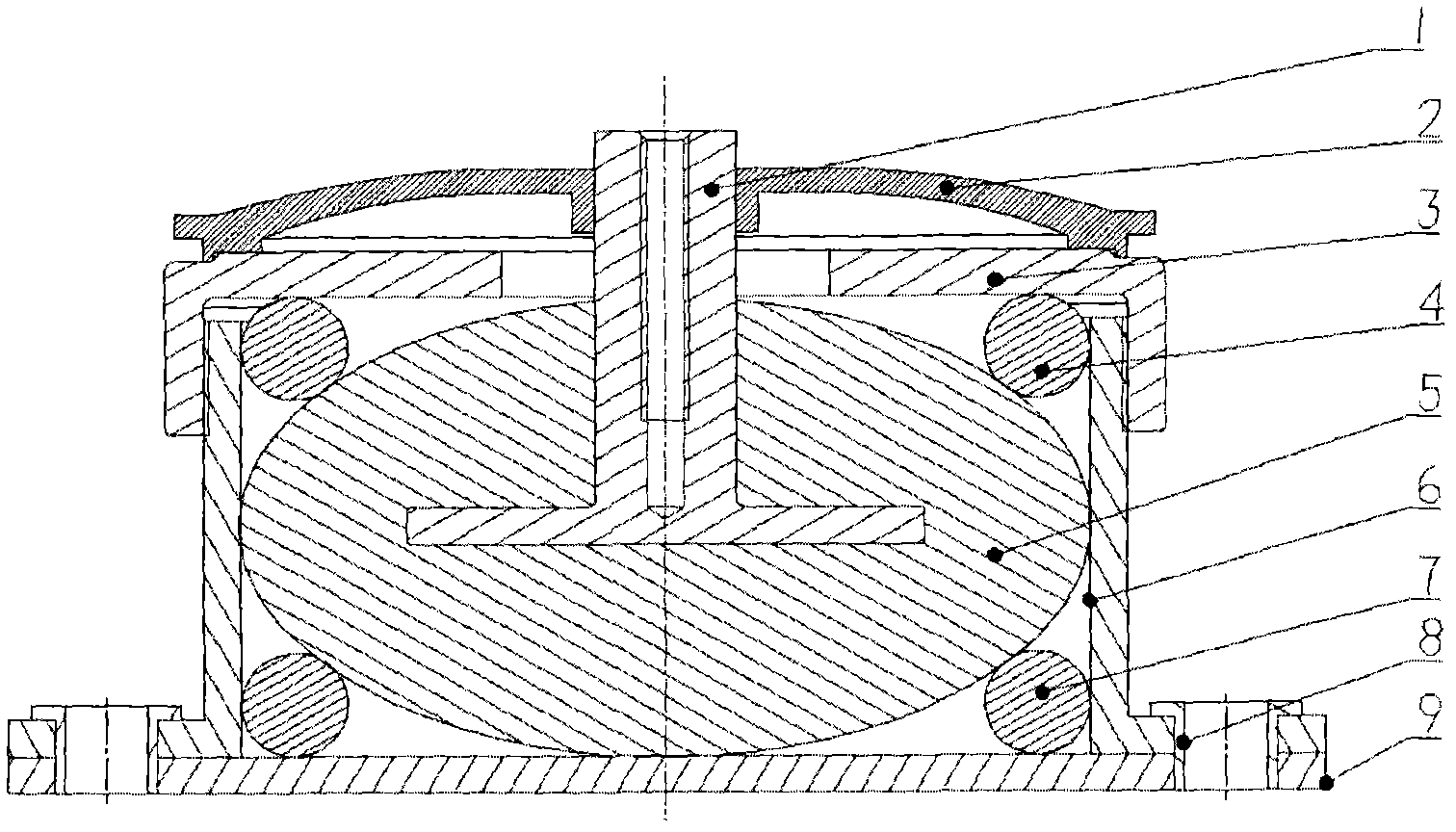

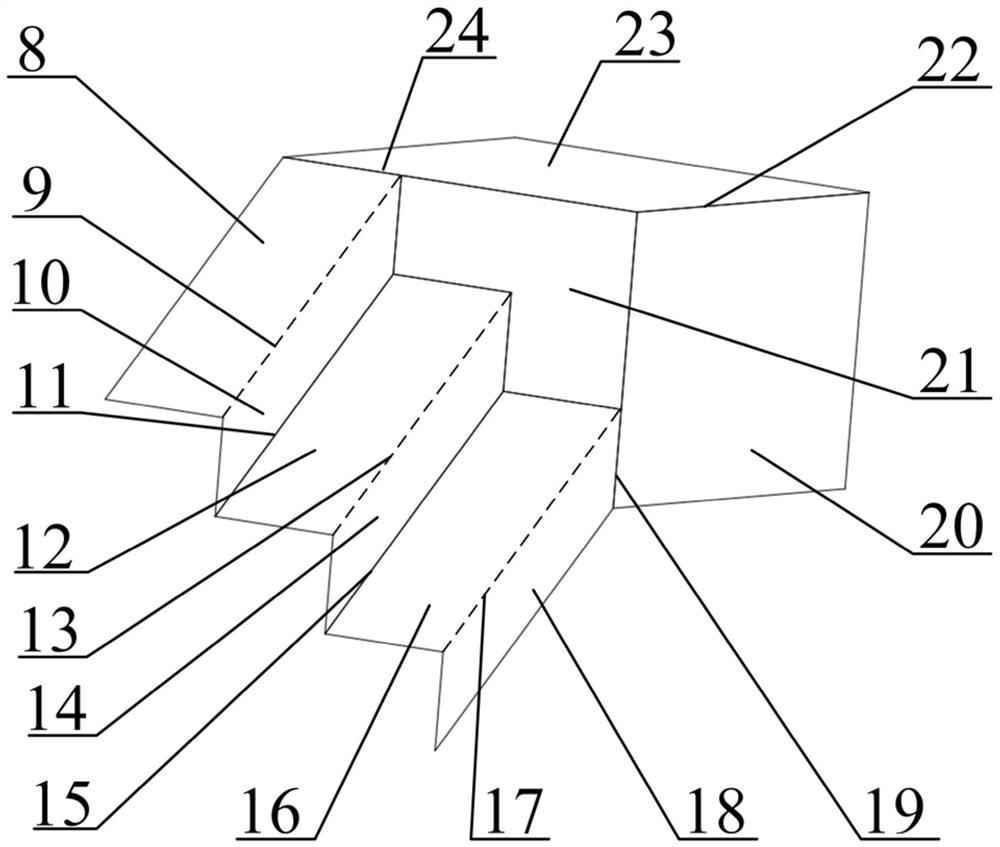

The invention discloses a variable-volume additional air chamber of a constant internal pressure air spring in a vehicle air suspension system. An inner cavity of a cylinder body is uniformly divided into eight layers of cavities by separation plates in the axial direction of the cylinder body, a lug boss extends from the side wall of the cylinder body, a plunger piston which is not communicated with the cavity of the cylinder body is arranged in the lug boss, the bottom of the plunger piston is provided with a sealing cover which seals the bottom of the lug boss, and the sealing cover is connected with a main air chamber of the air spring through a pipeline; the plunger piston axially penetrates to the outside of the top of the lug boss in the axial direction of the lug boss and is connected with a stepping motor at the top, and an angle sensor is arranged on the top end surface of the plunger piston; the side surface of the plunger piston is circumferentially and uniformly distributed with eight semicircular grooves which correspond to the eight layers of cavities in length, small identical holes with eight centers on the same straight line are arranged on the side surface of the cylinder body, and the eight small holes are respectively communicated with the corresponding eight semicircular grooves and the eight layers of cavities; the angle sensor is connected with a controller after being electrically connected with a modulate circuit; and the controller is electrically connected with the stepping motor. The automatic fast change of the volume of the additional air chamber is achieved, thus the air spring obtains a wider rigidity variation range.

Owner:JIANGSU UNIV

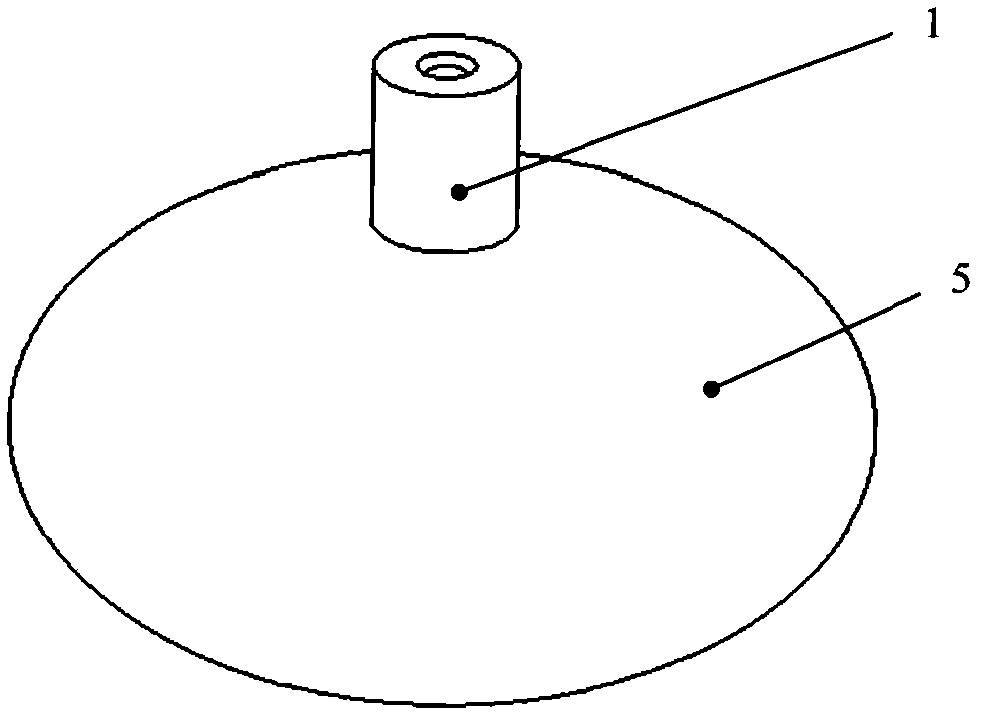

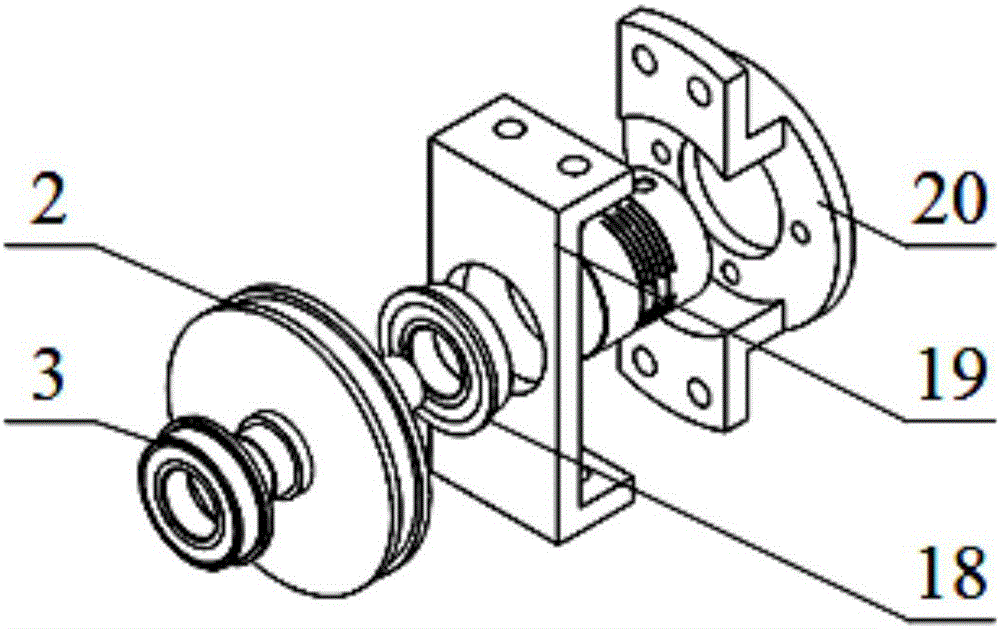

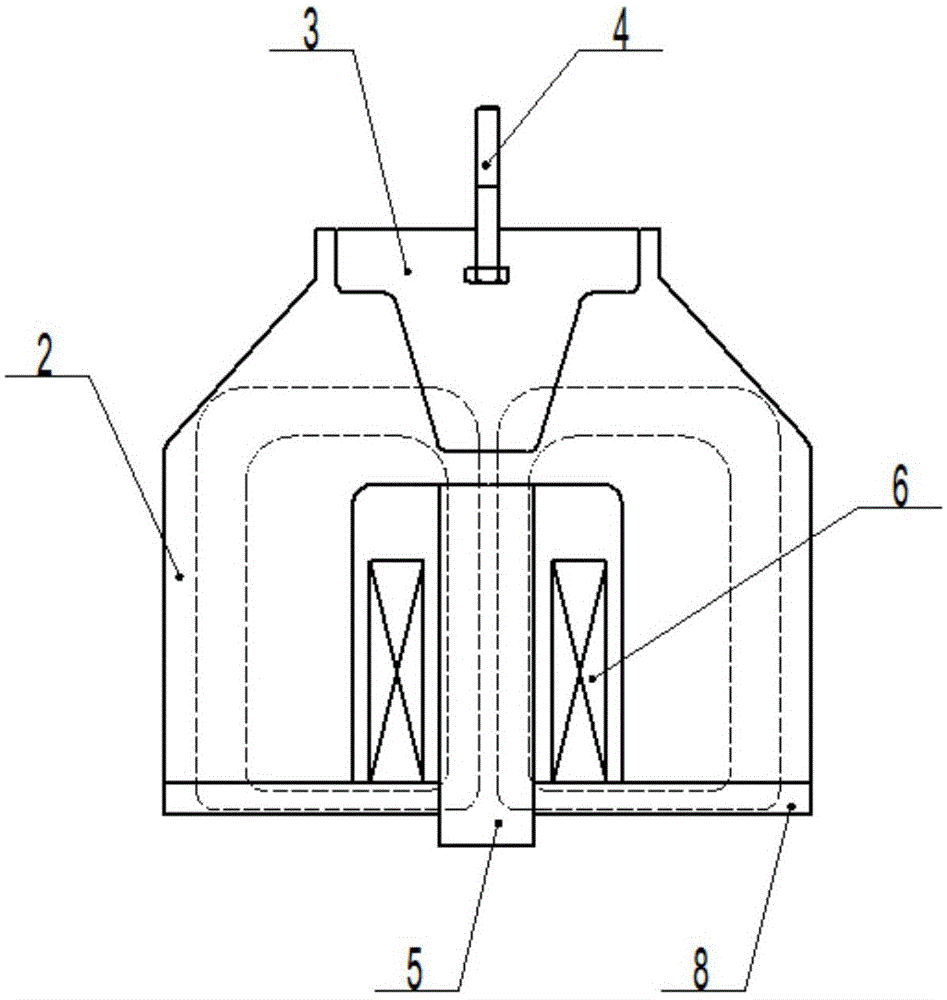

Totally-closed rigidity adjustable type vibration isolator

ActiveCN102518727AExpand the scope of useGood energy consumptionShock absorbersEngineeringRubber ring

The invention relates to a vibration isolation and buffer device for machine-born equipment, in particular to a totally-closed rigidity adjustable type vibration isolator, which comprises a casing, an installation core shaft, a protective rubber cover, an upper rubber ring, a spherical vibration isolation part and a lower rubber ring. The casing is of a sealed structure, the top of the casing is provided with an installation hole where the installation core shaft is arranged, and the spherical vibration isolation part is arranged in the sealed casing and is connected with the bottom of the installation core shaft together. The upper rubber ring is sleeved at the upper portion of a damp rubber ball, and the lower rubber ring is sleeved at the lower portion of the damp rubber ball which is sealed in the casing. The totally-closed rigidity adjustable type vibration isolator adopts a totally-closed structure to have small environment influence, utilizes a combination structure combining the spherical surface and the cylindrical surface to improve vibration isolation and retarding effects, utilizes the structures of the upper rubber ring and the lower rubber ring to limit the swinging of the head of the installation core shaft and improve using safety, and can be suitable for different frequency ranges by rotating the upper cover to adjust the rigidity of the vibration isolator.

Owner:CHINA AIRPLANT STRENGTH RES INST

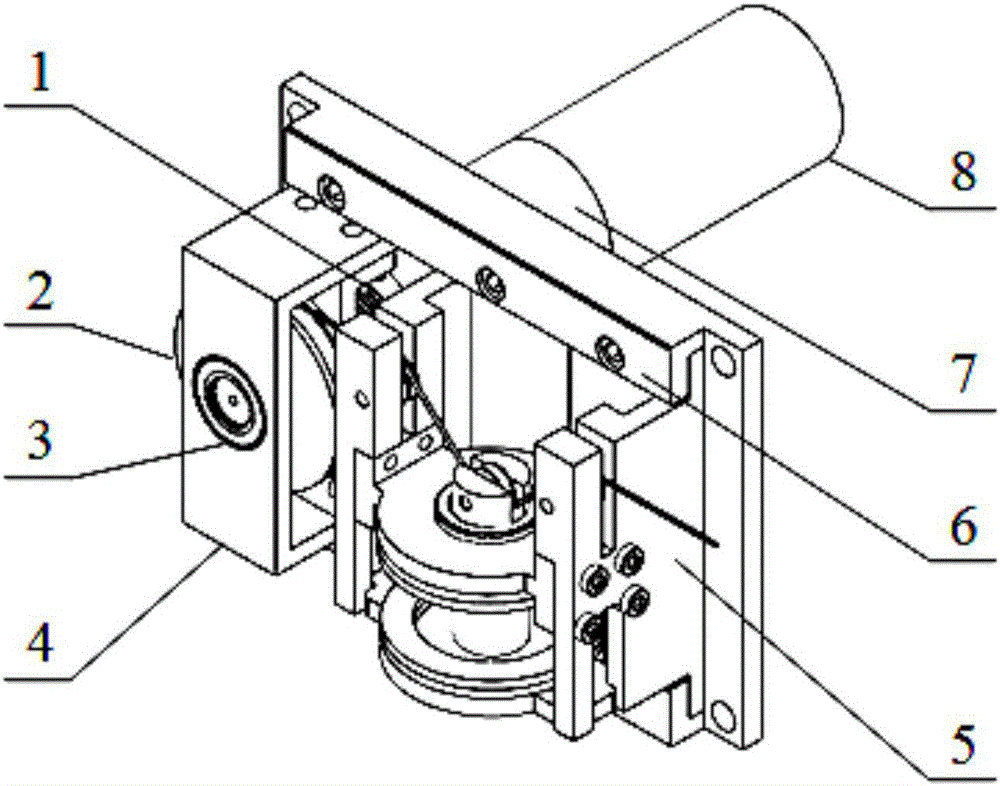

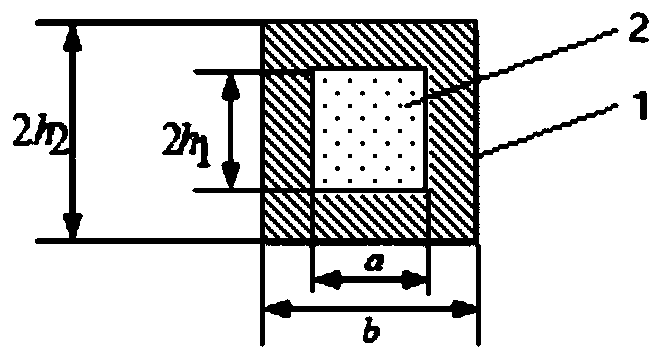

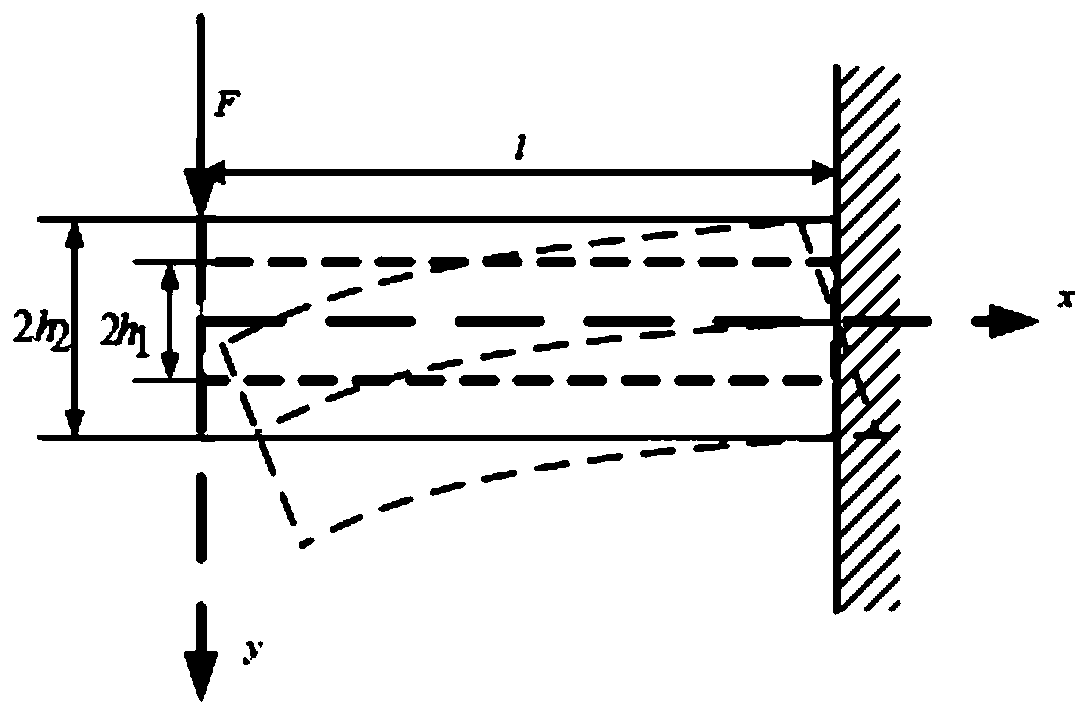

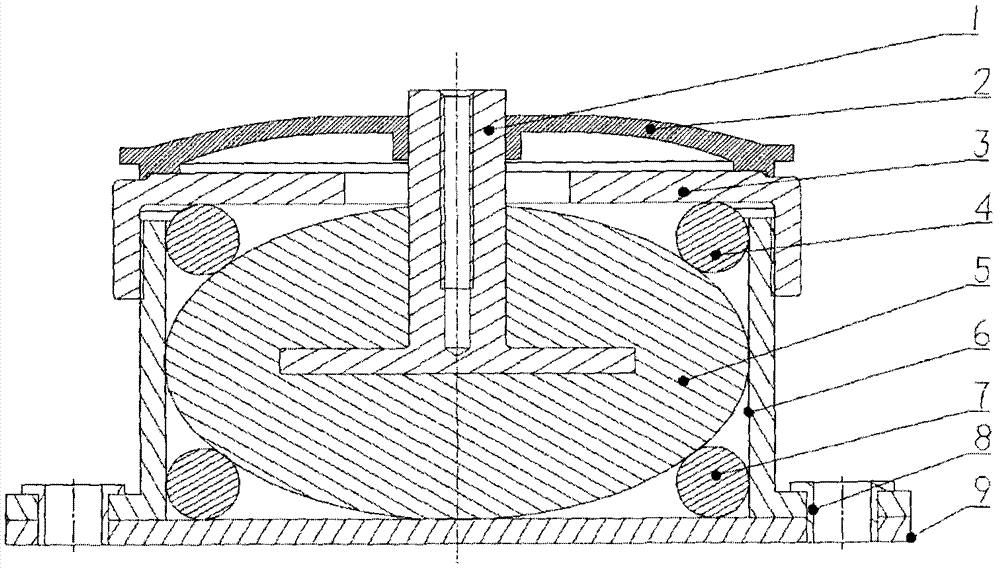

Paralleling model semi-active vibration isolator

ActiveCN104747651AIncrease stiffnessReduce stiffnessSpringsShock absorbersRotary machineMechanical engineering

The invention discloses a paralleling model semi-active vibration isolator. The vibration isolator is characterized in that a cylindrical upper shell is arranged, a rubber main spring is plugged in a top end opening of the upper shell, a main spring framework penetrates through the rubber main spring and is provided with an upper connection stud and a lower connection stud, the upper connection stud is connected with a main vibrating object, the lower connection stud is connected with a column-shaped iron core where an excitation coil is wound, the column-shaped iron core is supported in a magnetism conduction sleeve through a cutting magnetorheological elastomer arranged on the outer circumference of the column-shaped iron core, the two ends of the magnetorheological elastomer are extruded to be connected with the top of a T-shaped support and the bottom end of the iron core, and the T-shaped support penetrates through the magnetism conduction sleeve and is fixedly connected; the upper shell is connected with a lower shell, the lower end of the T-shaped support is fixedly connected with the lower shell, and the bottom of the lower shell is provided with a connection bolt used for being connected with a basal body. By means of the vibration isolator, vibrating energy transmitted by a rotary machine to the basal body can be effectively reduced, vibration of relative parts of the rotary machine is reduced, and the service life of the rotary machine and a system of the rotary machine is prolonged.

Owner:HEFEI UNIV OF TECH

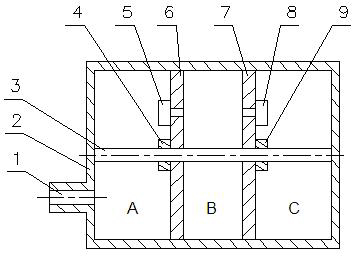

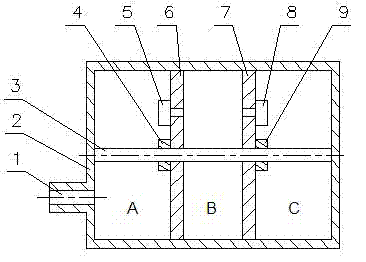

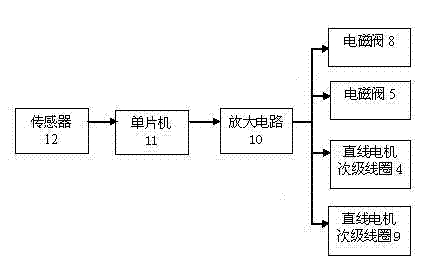

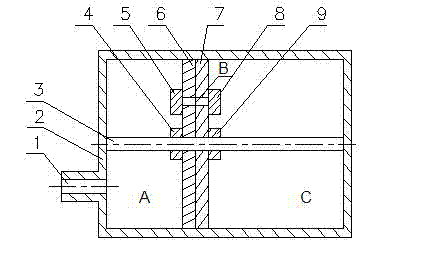

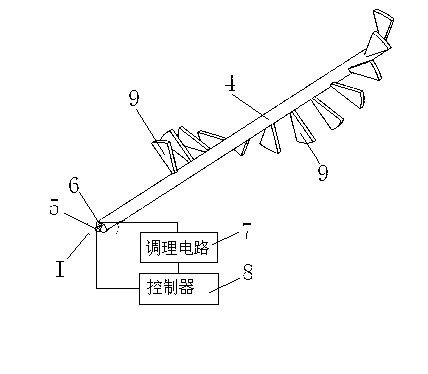

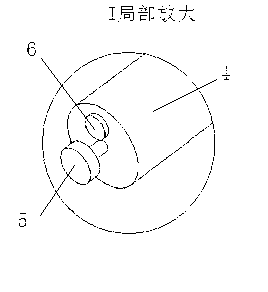

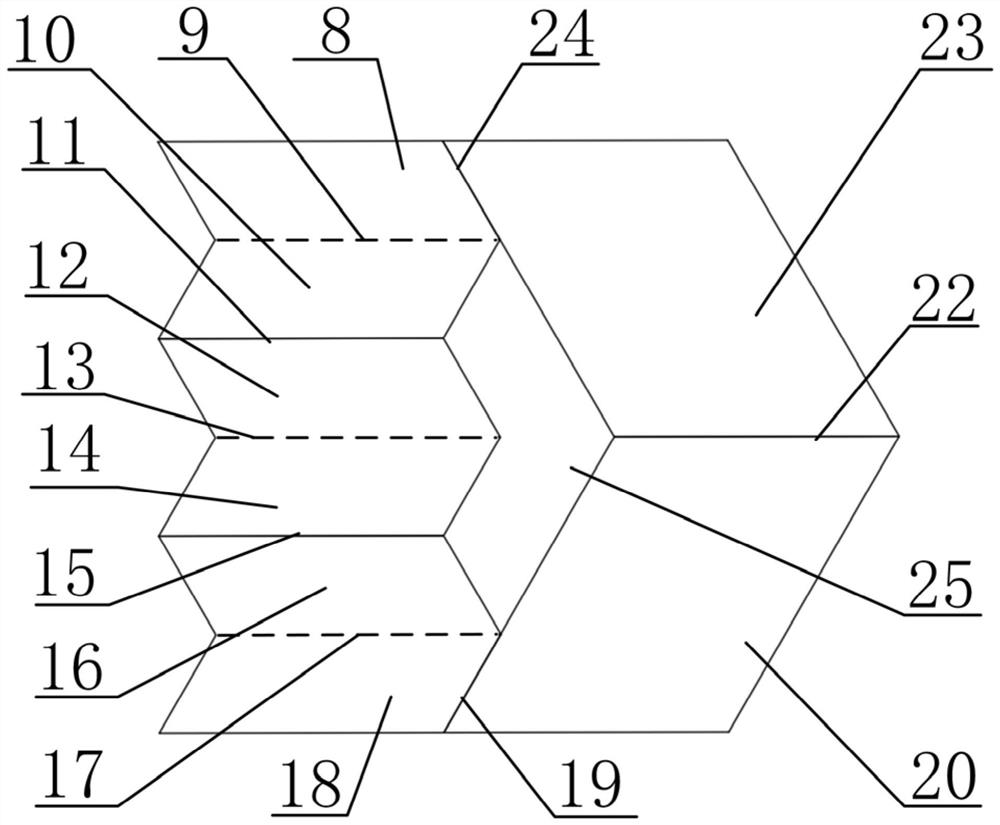

Constant internal pressure air spring additional air chamber with continuously changing volume and working method

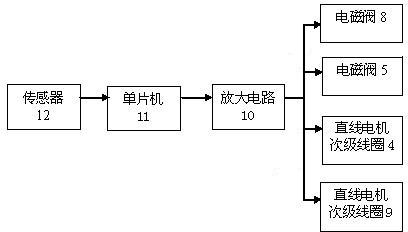

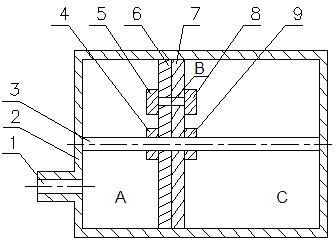

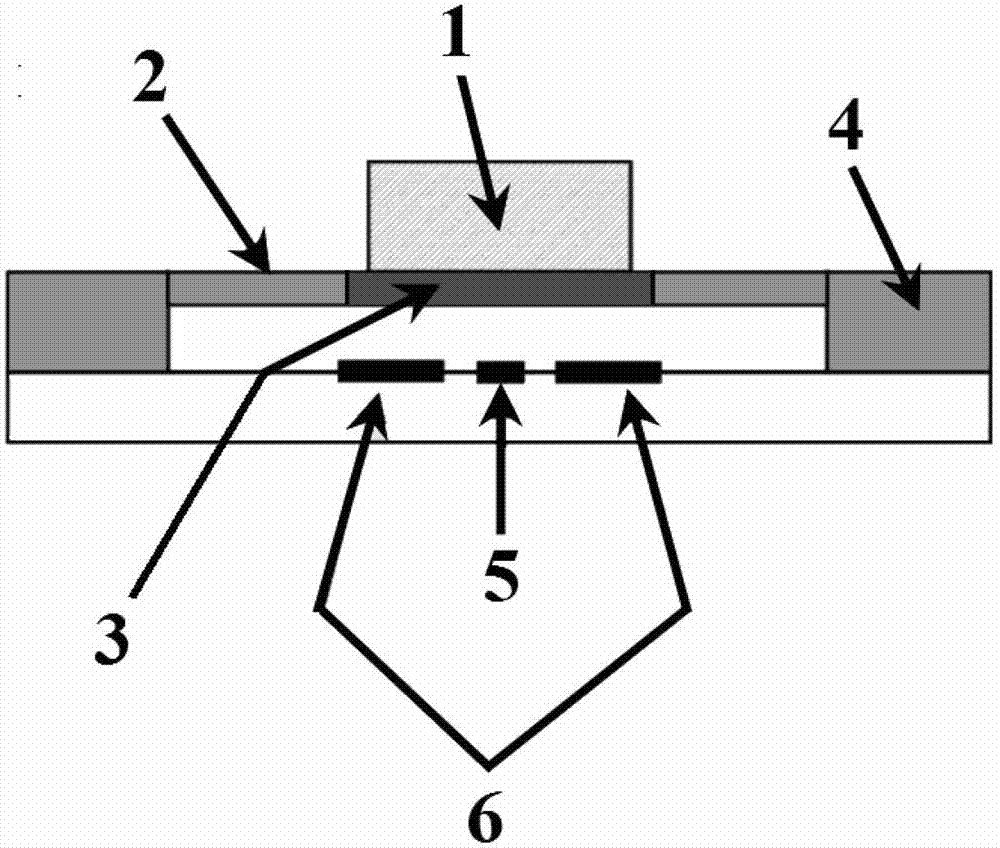

InactiveCN102261417AAutomate rapid changesWide range of stiffnessSpringsGas based dampersSolenoid valveAir spring

The invention discloses a constant internal pressure air spring additional air chamber which is used for air suspension systems of vehicles and of which the volume is changed continuously and an operating method. In the air chamber, two partition plates for dividing the air chamber into three cavities A, B and C in the radial direction of a cylinder body; a dual-secondary linear motor is fixedly connected to the axial directions of the two partition plates; the two secondary coils of the linear motors are connected with the two partition plates respectively; two solenoid valves are arranged at positions where the two partition plates are provided with small holes; the two solenoid valves and the secondary coils of the two linear motors are connected with an amplifying circuit; the amplifying circuit is connected with a sensor by a singlechip; the volume of the three cavities is changed by controlling the two partition plates to move right and left to increase or reduce the stiffness of a spring system, and thus, the volume of the air spring additional air chamber is changed quickly and continuously, so that an air spring has the large stiffness range, the volume of the additional air chamber is changeable but internal pressure keeps constant, and the driving stability and riding comfort of the vehicles are improved.

Owner:JIANGSU UNIV

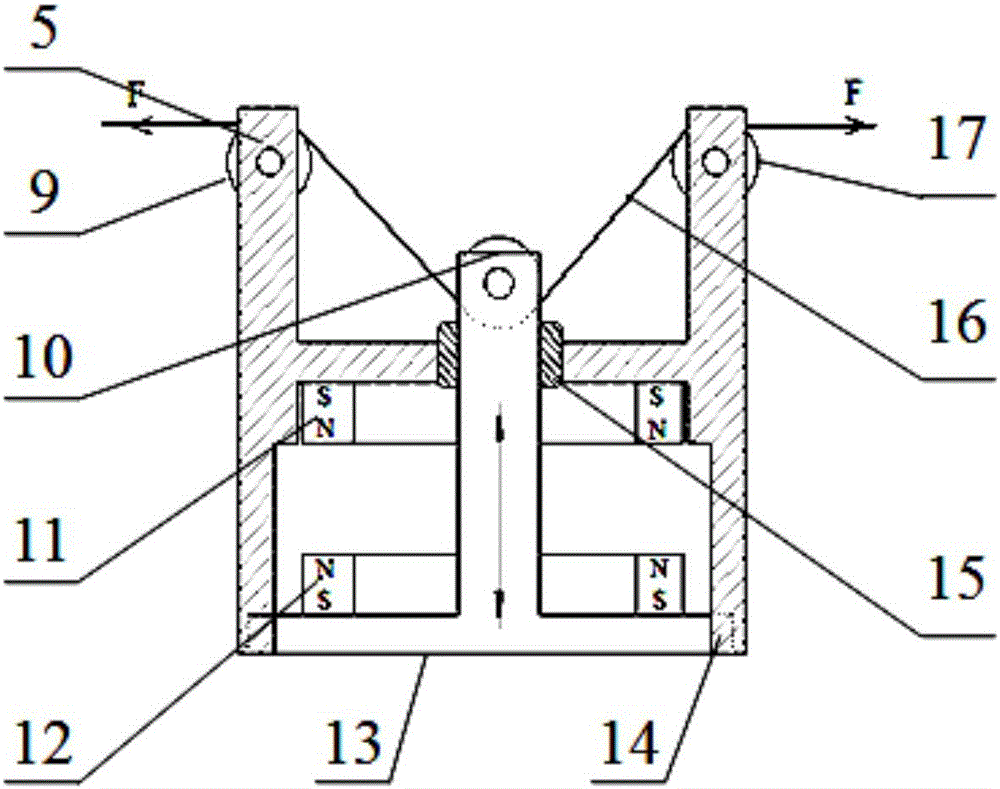

Permanent magnetic rigidity variable drive module for flexible robot

InactiveCN107175657AWide range of stiffnessWide range of stiffness adjustmentProgramme-controlled manipulatorJointsPull forceWinch

A permanent magnetic rigidity variable drive module for a flexible robot is suitable for establishing an antagonistic type flexible rigidity variable robot, especially a multi-freedom-degree flexible parallel rigidity variable robot. Compared with the prior art, the permanent magnetic rigidity variable drive module has the beneficial effect that under the situation that no motor torque is increased, the rigidity adjusting range is enlarged. When the multi-freedom-degree flexible robot is established, a drive unit and a rigidity variable module can be arranged on the rear part, the mass and the inertia of an operation arm are greatly reduced, and therefore the problem that in a traditional series manner, the rigidity change capacity is insufficient as the mass and the inertia are gradually increased is solved. According to the permanent magnetic rigidity variable drive module, one end of a rope is fixed to a rope winch, the rope sequentially penetrates through fixed pulleys, a movable pulley and a rope winch, the rope winch and the fixed pulleys are externally tangent to the same straight line, and the movable pulley is clamped to a symmetrical axis of the two fixed pulleys. The air gap interval between annular permanent magnets is reduced as the distance between a movable sliding base and a fixed base is reduced, and the rope tensile force and the rigidity are improved. The permanent magnetic rigidity variable drive module for the flexible robot is concise in movement type, easy and convenient to manufacture and easy to operate.

Owner:NORTHEASTERN UNIV

Constant internal pressure air spring additional air chamber whose volume is changed continuously and operating method thereof

InactiveCN102261417BAutomate rapid changesWide range of stiffnessSpringsGas based dampersSolenoid valveAir spring

The invention discloses a constant internal pressure air spring additional air chamber which is used for air suspension systems of vehicles and of which the volume is changed continuously and an operating method. In the air chamber, two partition plates for dividing the air chamber into three cavities A, B and C in the radial direction of a cylinder body; a dual-secondary linear motor is fixedly connected to the axial directions of the two partition plates; the two secondary coils of the linear motors are connected with the two partition plates respectively; two solenoid valves are arranged at positions where the two partition plates are provided with small holes; the two solenoid valves and the secondary coils of the two linear motors are connected with an amplifying circuit; the amplifying circuit is connected with a sensor by a singlechip; the volume of the three cavities is changed by controlling the two partition plates to move right and left to increase or reduce the stiffness of a spring system, and thus, the volume of the air spring additional air chamber is changed quickly and continuously, so that an air spring has the large stiffness range, the volume of the additional air chamber is changeable but internal pressure keeps constant, and the driving stability and riding comfort of the vehicles are improved.

Owner:JIANGSU UNIV

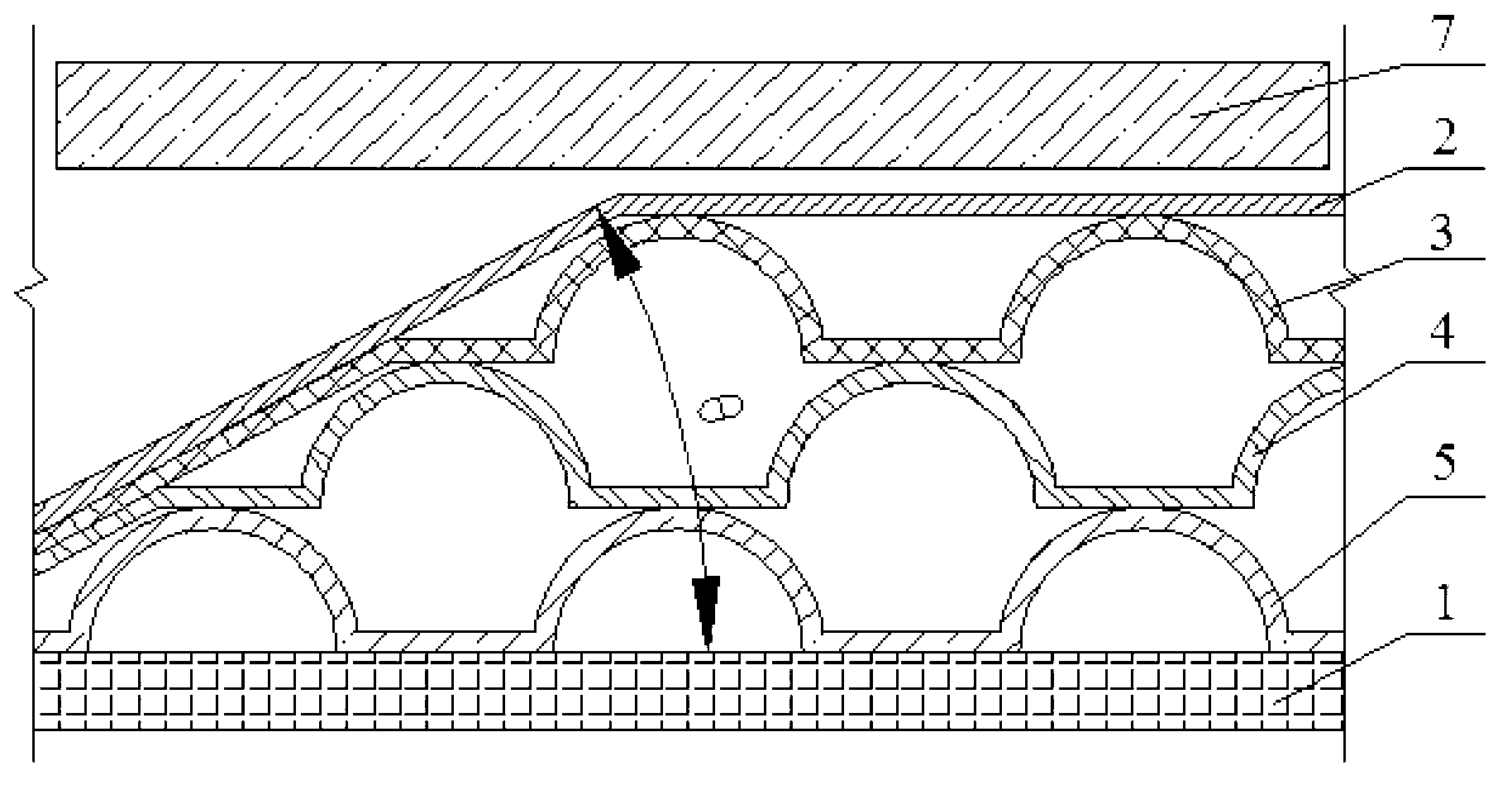

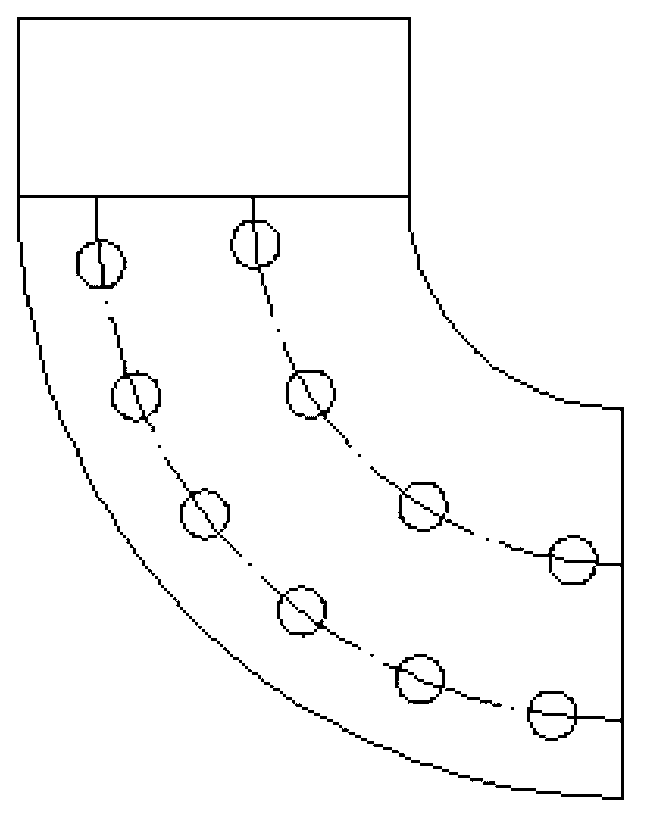

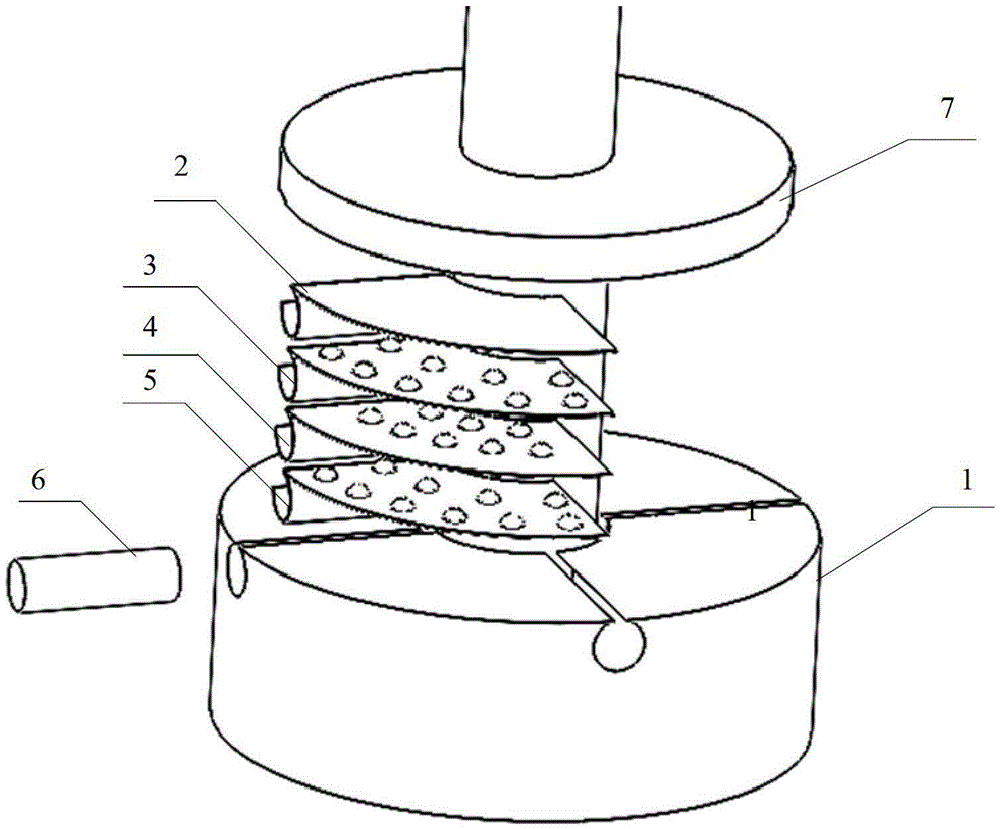

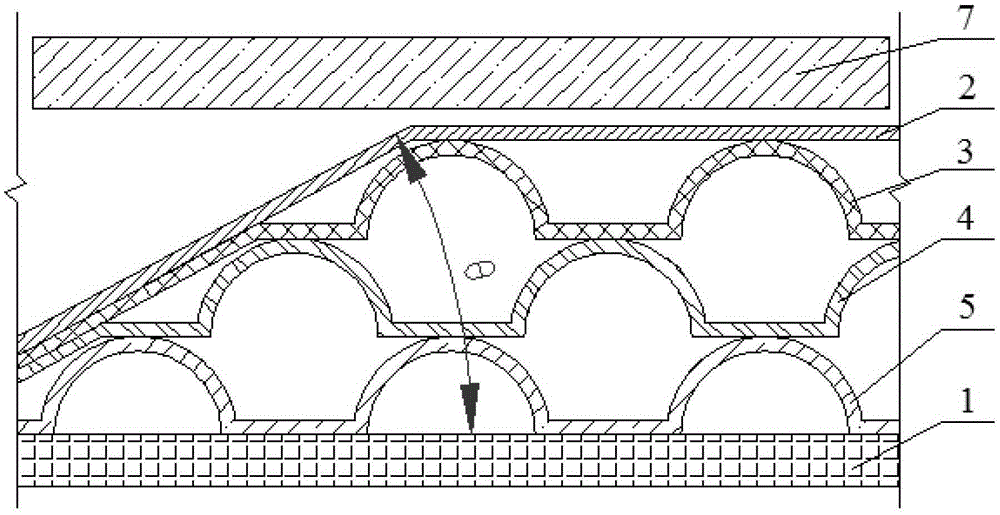

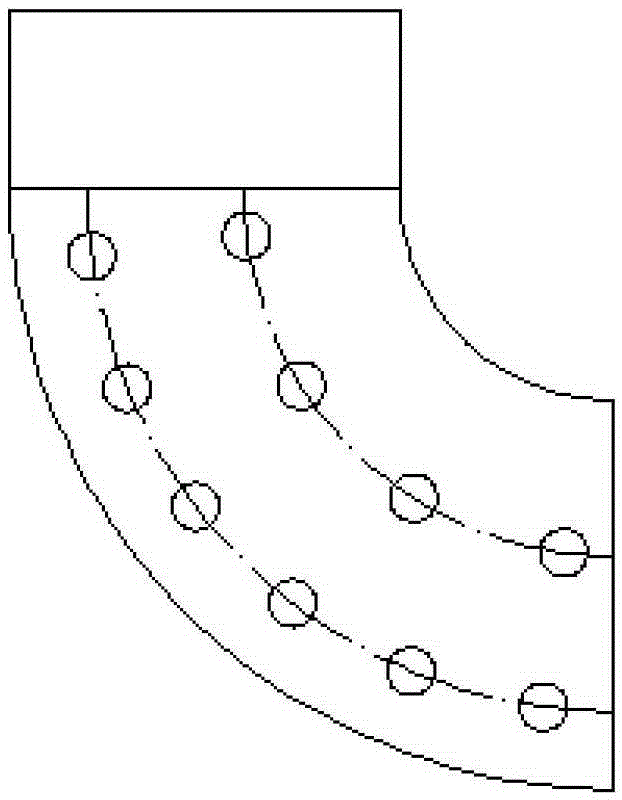

Dynamic pressure gas thrust bearing with multiple layers of bubbling foils

ActiveCN103267062AIncrease stiffnessImprove featuresSliding contact bearingsElastic componentThrust bearing

The invention discloses a dynamic pressure gas thrust bearing with multiple layers of bubbling foils. The dynamic pressure gas thrust bearing comprises a bearing seat and a shaft, wherein the shaft with a rotor thrust plate is arranged in the bearing seat, a plurality of groups of elastic components with the same structure are arranged between the bearing seat and the rotor thrust plate, and the elastic components are uniformly arranged along the circumferential direction of the bearing seat; each elastic component comprises the multiple layers of bubbling foils and a flat foil, the multiple layers of bubbling foils are arranged above the bearing seat, and the flat foil is arranged between a top bubbling foil and the rotor thrust plate and fits with an elastic bubbling foil; bubbling bulges are formed on each bubbling foil; and one end of the elastic component is fixed on the bearing seat by a locating component, and the other end of the elastic component is free. By virtue of the elastic components which are arranged in sections and composed of the flat foils and the bubbling foils, the rigidity distribution and the assembly character of the bearing are improved, and unstable whirling motion of a rotor is effectively restrained. According to the bearing with the multiple layers of bubbling foils, multiple adaptability rigidities are generated by multiple layers of supporting, the rigidity variation range of the bearing is extended, and the rigidity character of the foil bearing is improved.

Owner:XI AN JIAOTONG UNIV

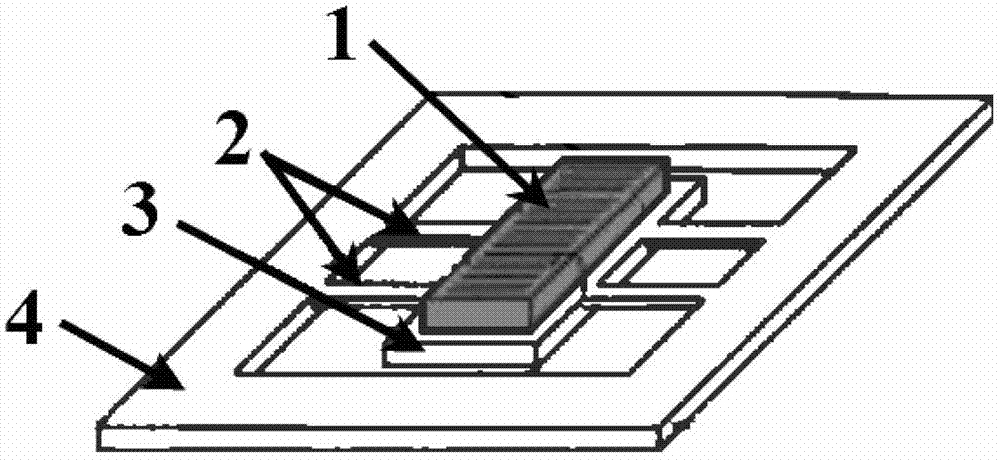

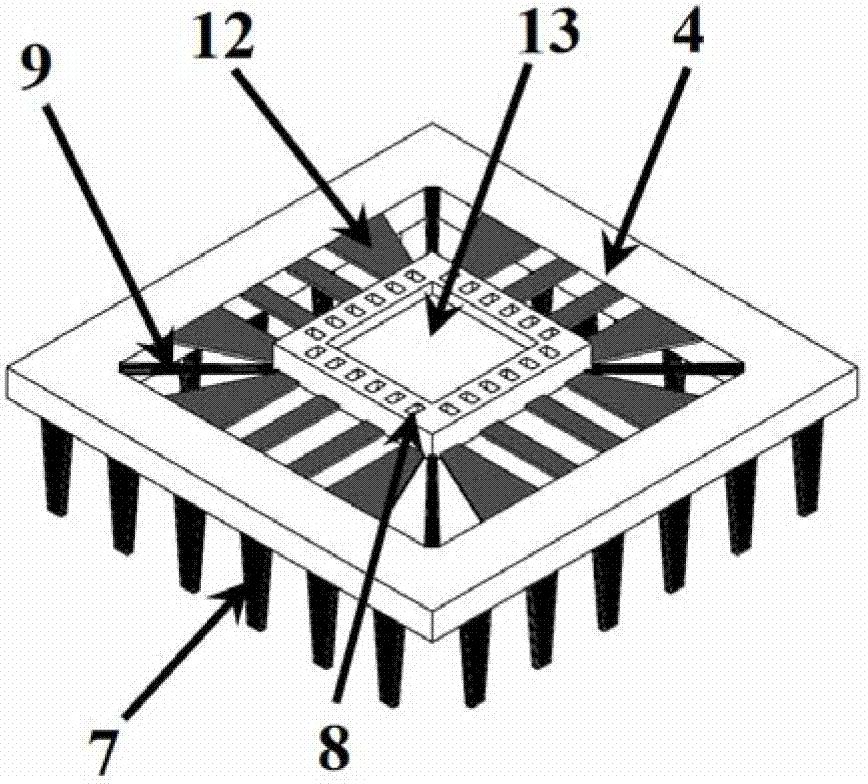

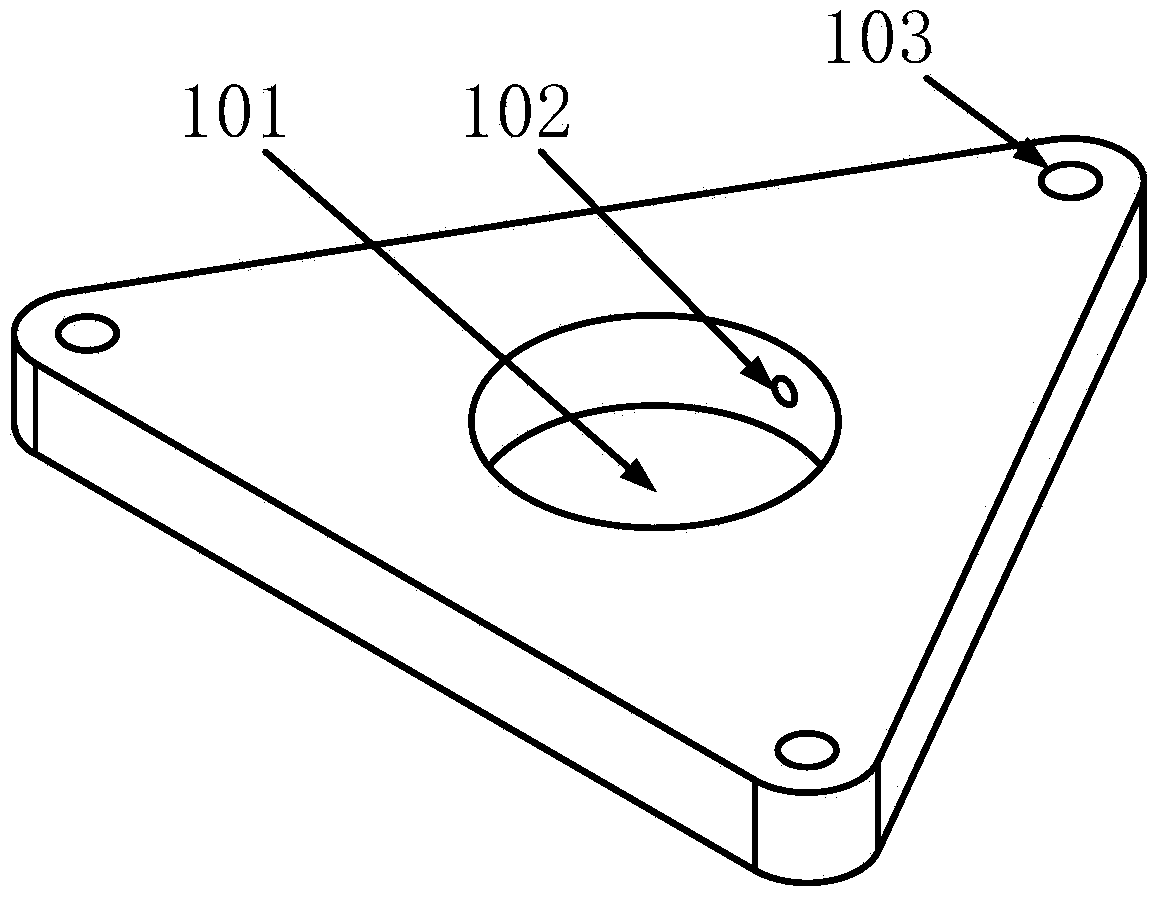

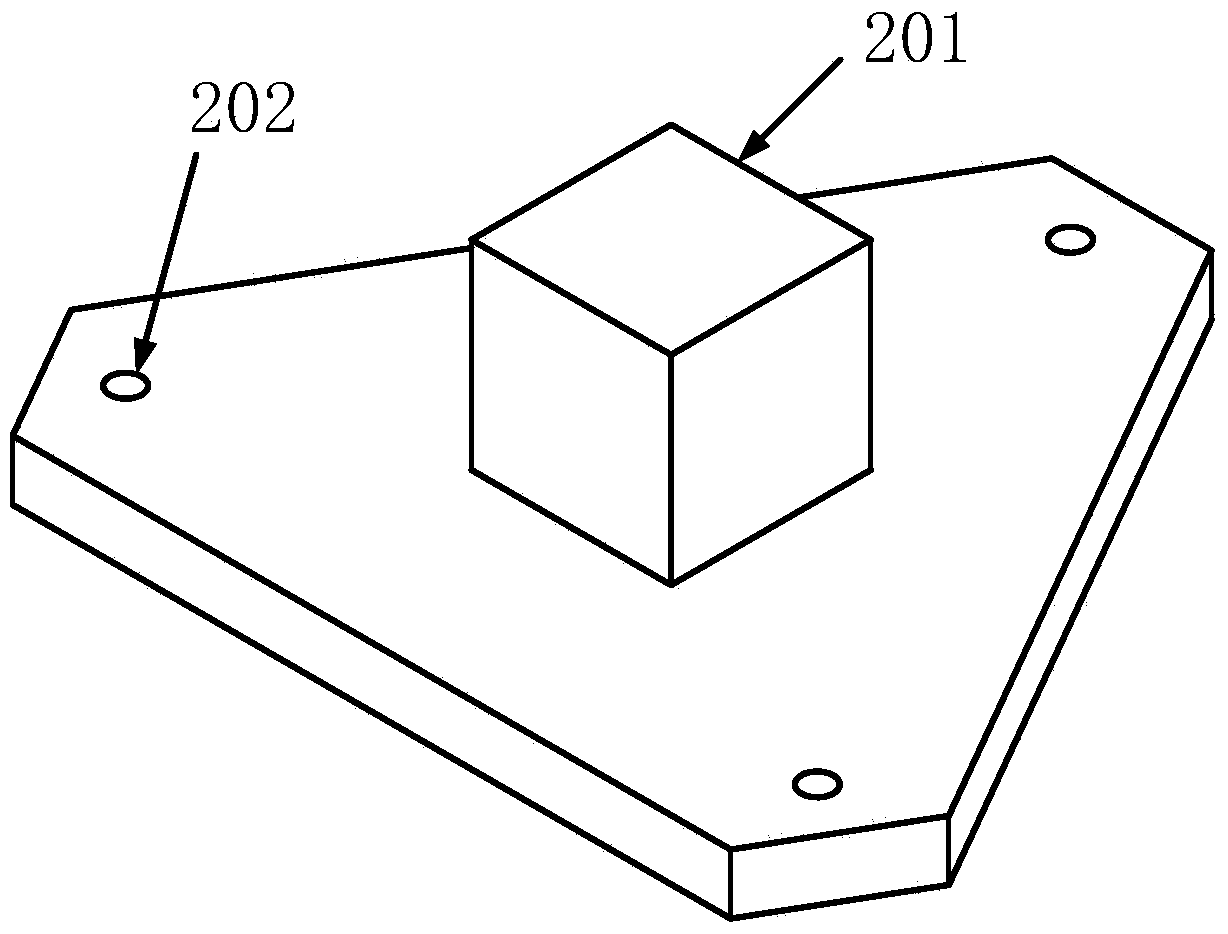

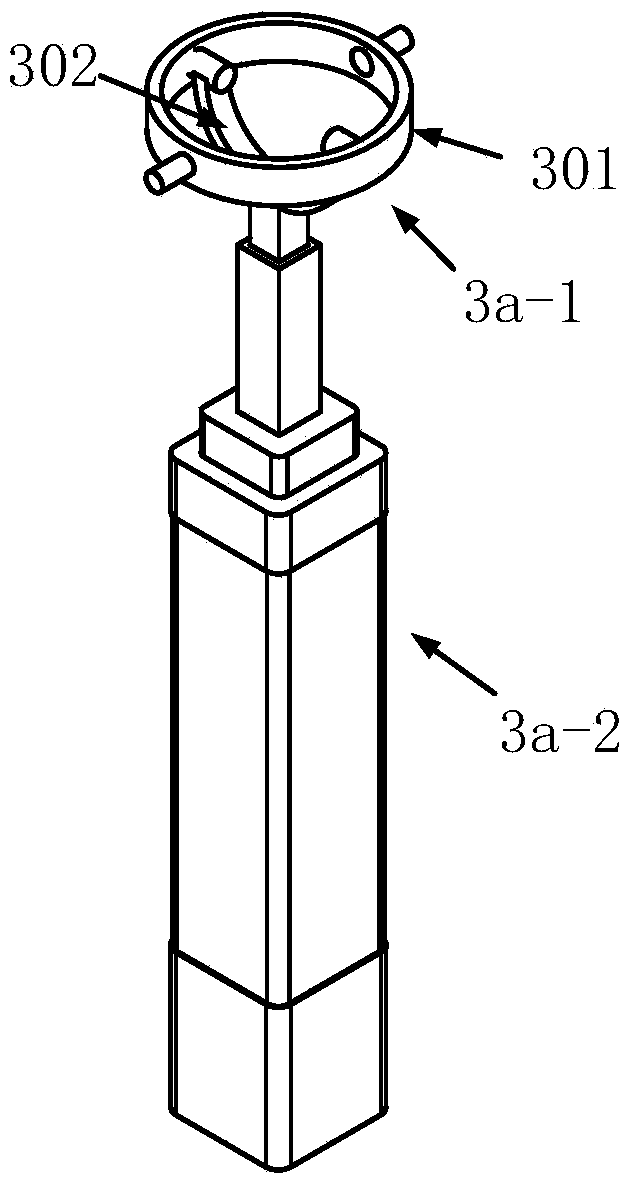

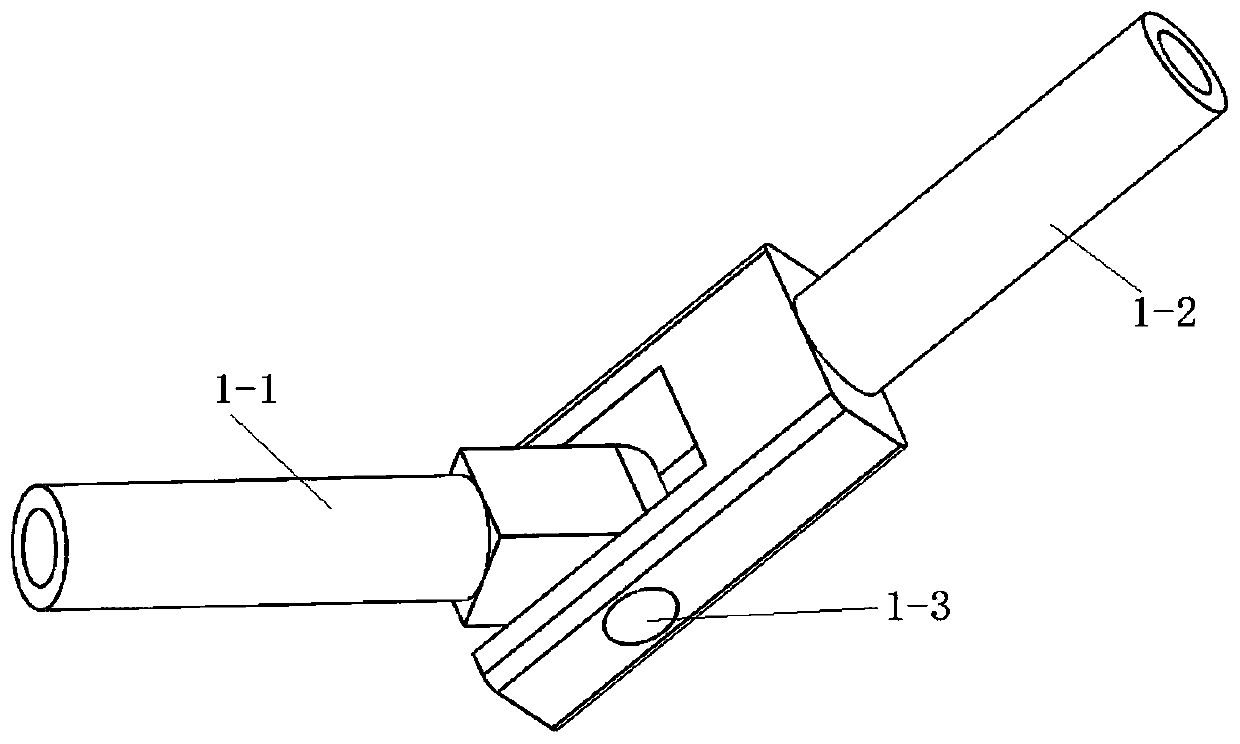

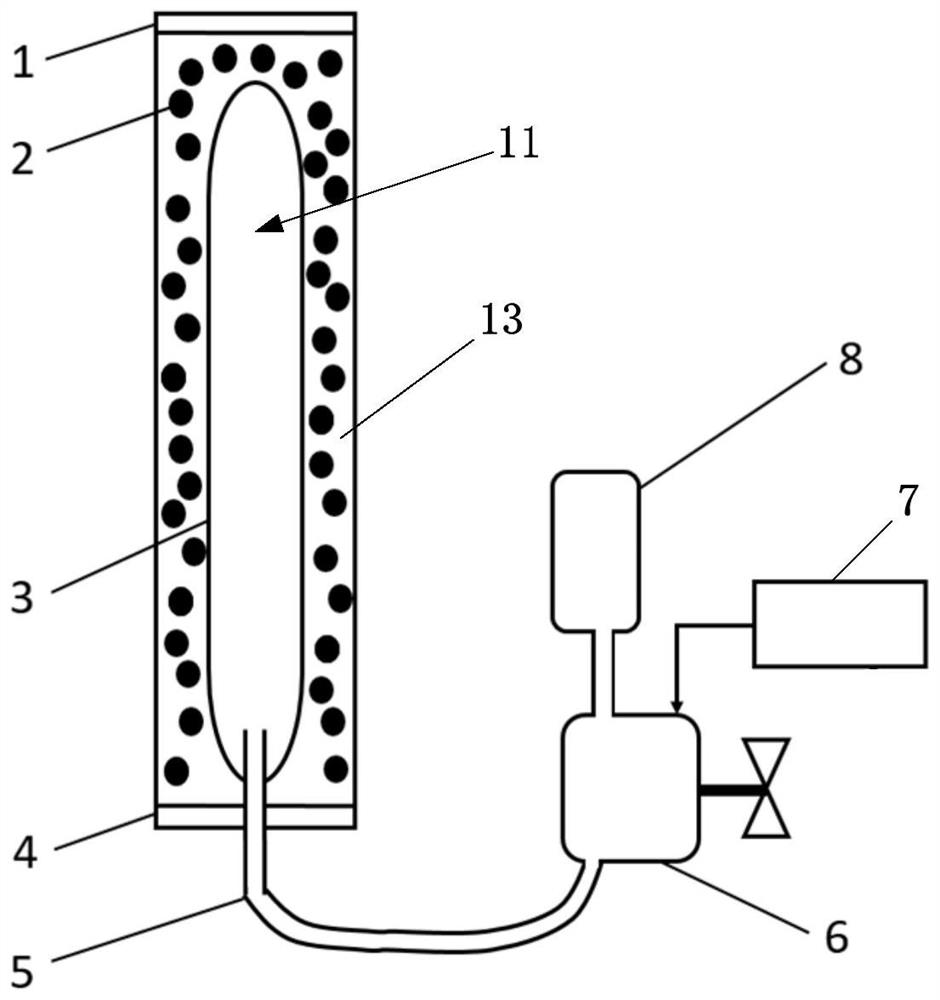

Component-level MEMS (macro-electro-mechanical systems) device active vibration isolator utilizing SMA (shape memory alloy)

InactiveCN103244599AWide range of stiffnessStrong resonant frequency adjustment abilitySolid based dampersControl systemShape-memory alloy

The invention provides a component-level MEMS (macro-electro-mechanical systems) device active vibration isolator utilizing SMA (shape memory alloy). The active vibration isolator is composed of a plurality of SMA micro elastic supports (12), a micro vibration isolating platform (13) with sockets (8), a connecting frame (4) and a plurality of pins (7) connected with the connecting frame (4). Two ends of the SMA micro elastic supports (12) are respectively connected with the micro vibration isolating platform (13) and the connecting frame (4). An MEMS device needed to be isolated from vibration is connected with the sockets (8) on the micro vibration isolating platform (13) through the pins of the active vibration isolator. Pin signals of the active vibration isolator are conducted onto the pins (7) on the connecting frame (4) through four flexible leads (9), and connected with outside circuits through the pins (7). The component-level MEMS device active vibration isolator has large damping and wide rigidity adjusting range, and is simple in structure and control system.

Owner:BEIHANG UNIV

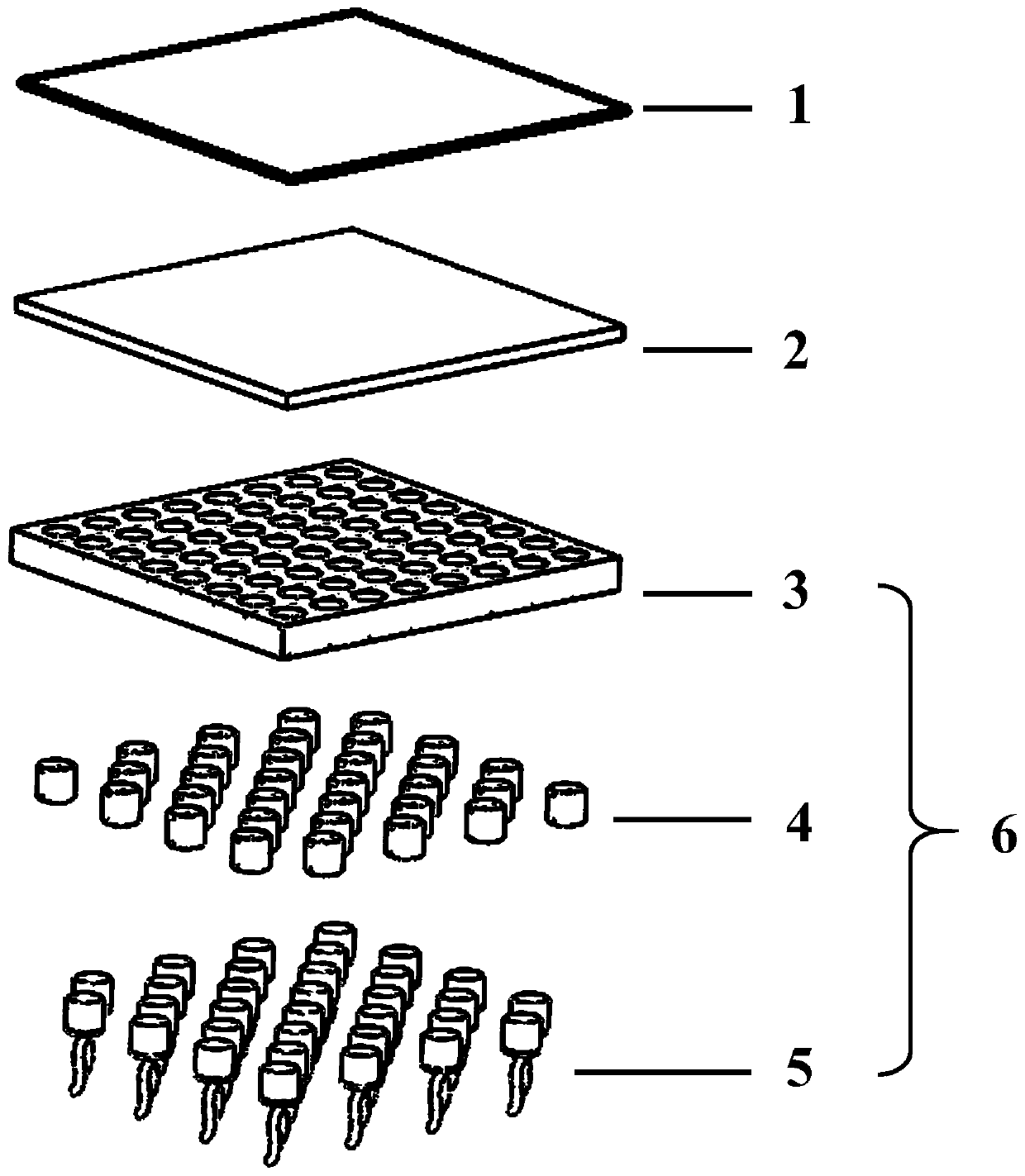

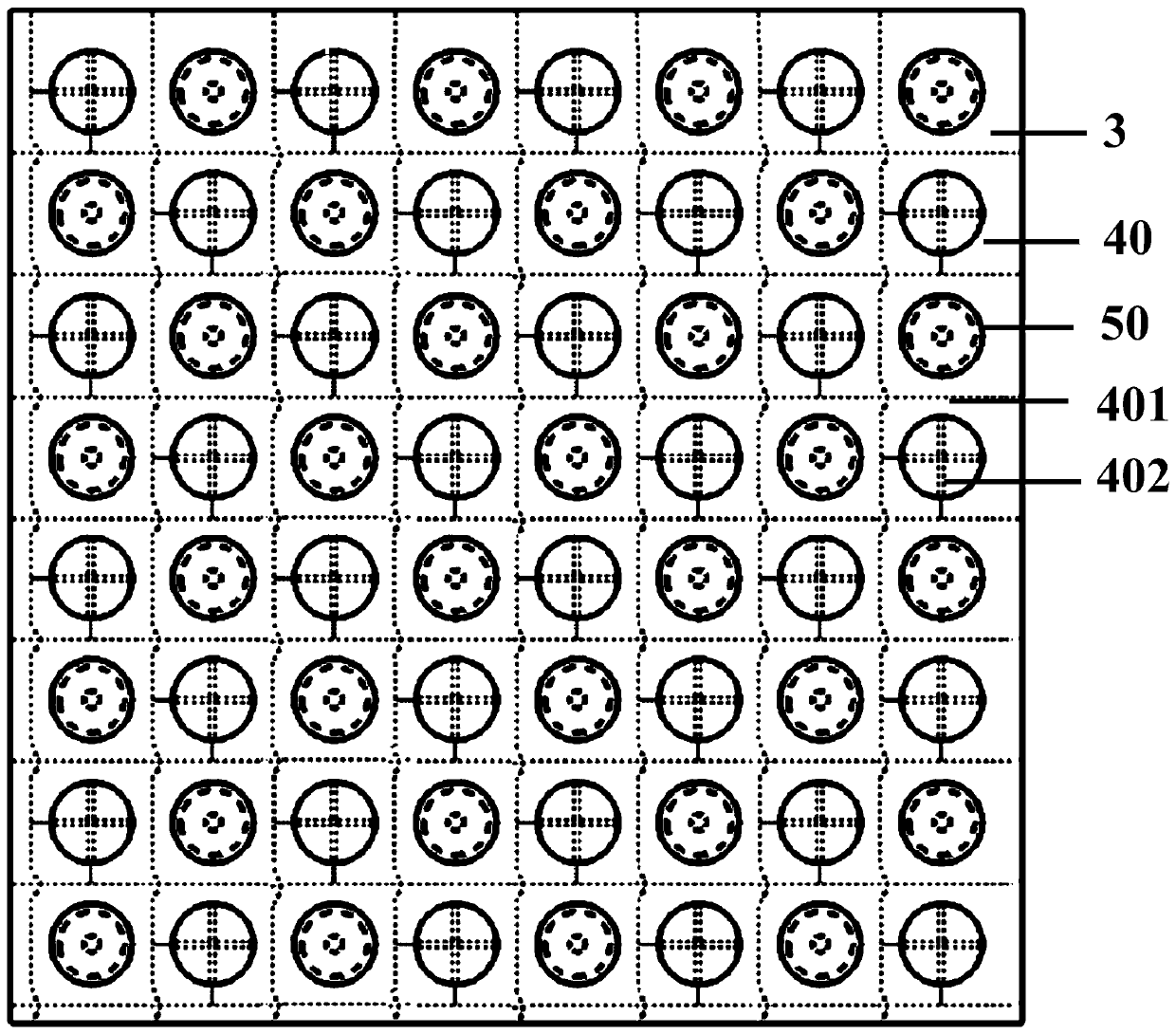

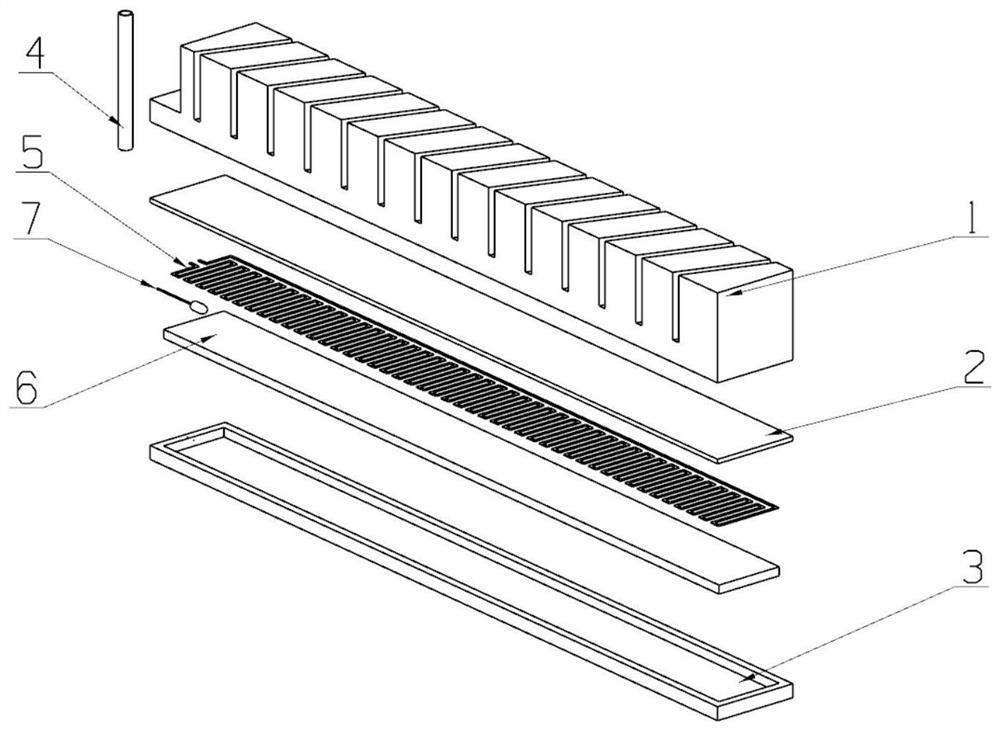

Variable stiffness sensing array based on flexible porous material

ActiveCN110388998ASensitivity changes with changingChange sensitivityForce measurementVariable stiffnessEnergy absorption

The invention discloses a variable stiffness sensing array based on a flexible porous material. The sensing array comprises a dynamic micro-force flexible sensing layer, a static force flexible sensing layer and a packaging layer. The dynamic micro-force flexible sensing layer comprises a flexible porous sensing thin layer prepared by mixing the flexible porous material and a sensitive conductivematerial, and a corresponding conductive electrode; the static force flexible sensing layer comprises flexible sensing units, silica gel air chambers and a flexible substrate wrapping the flexible sensing units and the silica gel air chambers and playing a role in connection; two output ends are led out to serve as electrical signal transmission channels after two ends of all the flexible sensingunits are connected in series, and breather pipes penetrate through the bottoms of all the silica gel air chambers. The packaging layer is composed of a textile thin layer sprayed with an insulating material. The sensing array disclosed by the invention has the functions of adjustable sensitivity and adjustable rigidity of the sensing array; the silica gel air chambers and the flexible porous material have the advantages of safety, buffering and energy absorption, and also have the characteristics of replaceability and personalized installation.

Owner:ZHEJIANG UNIV

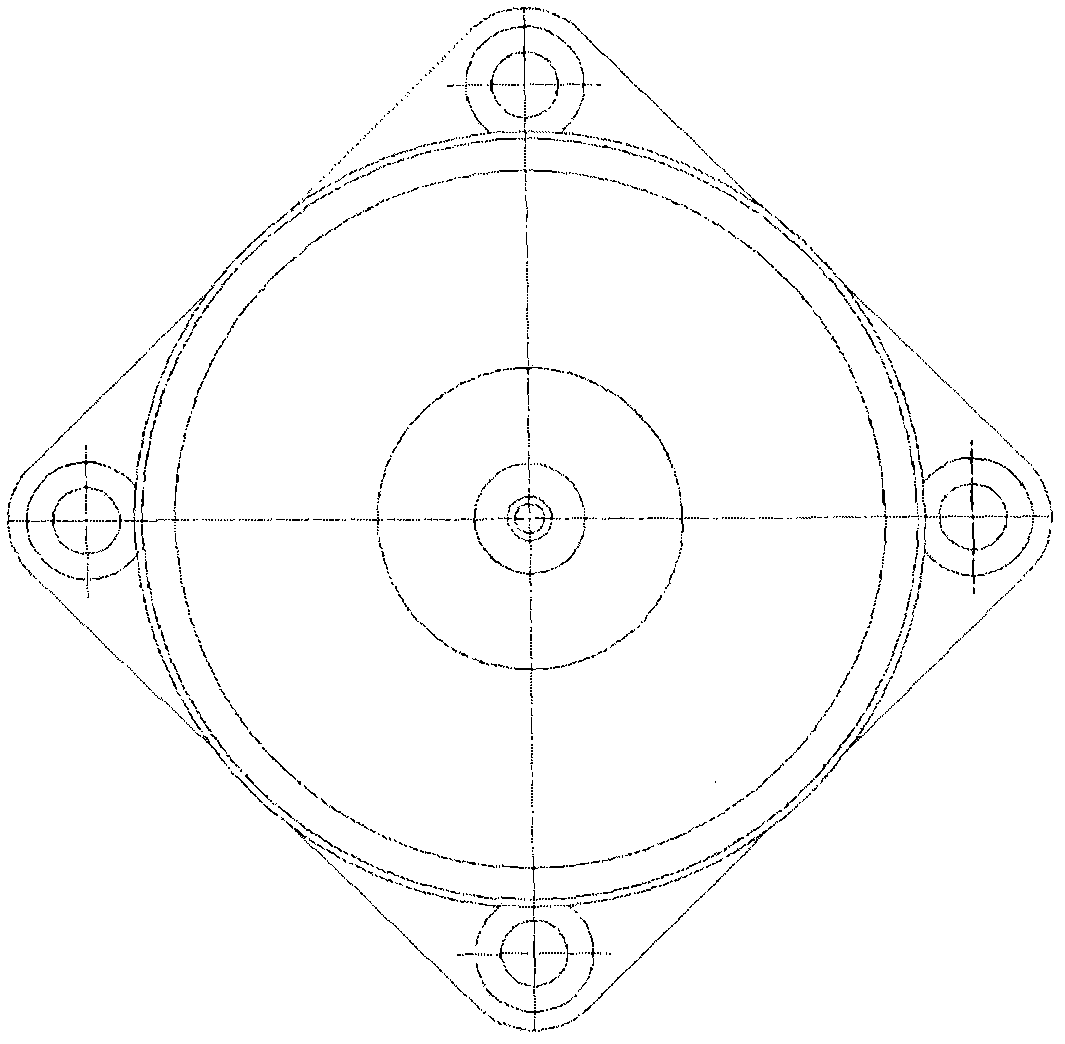

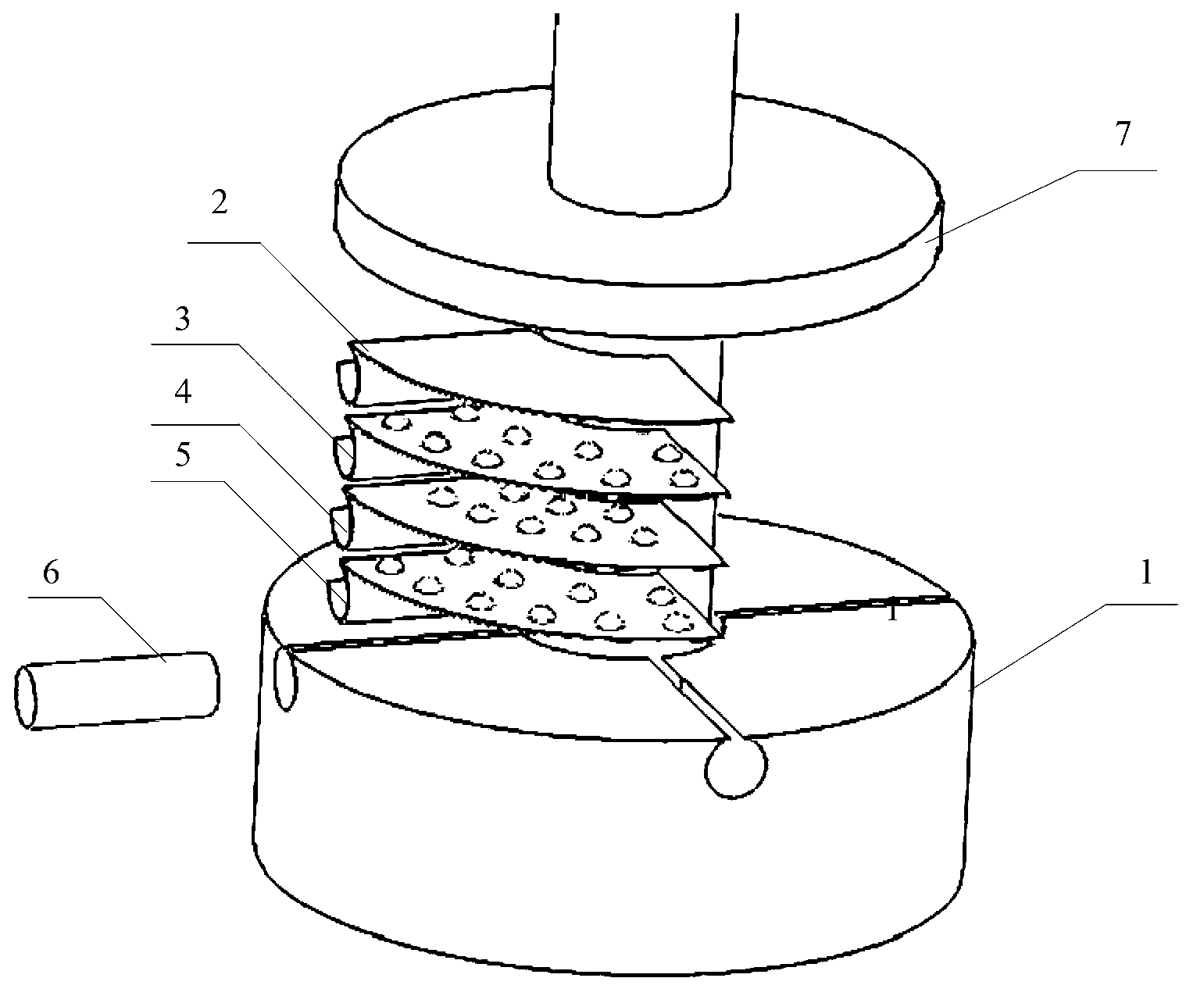

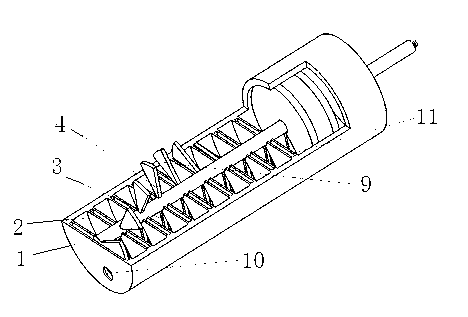

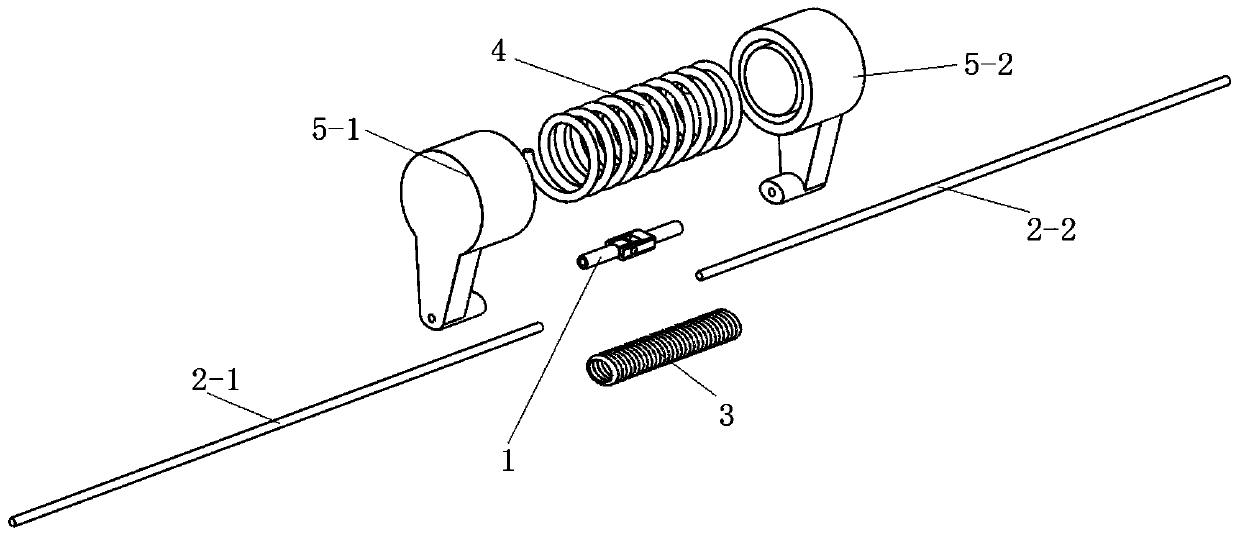

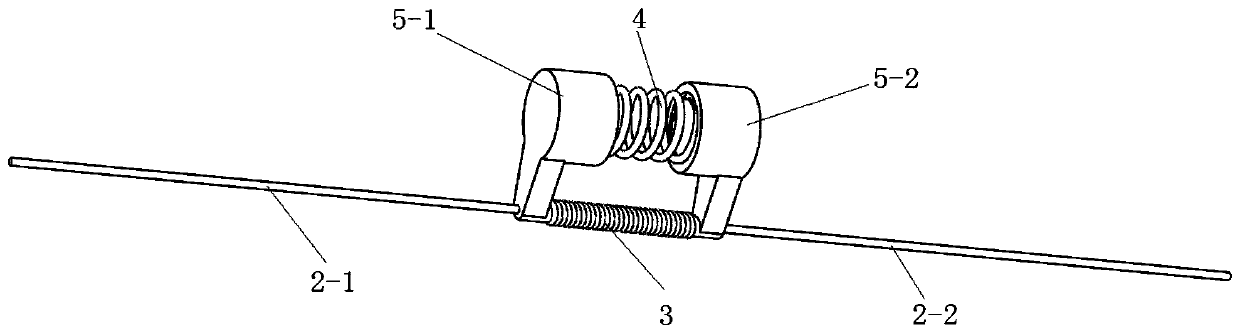

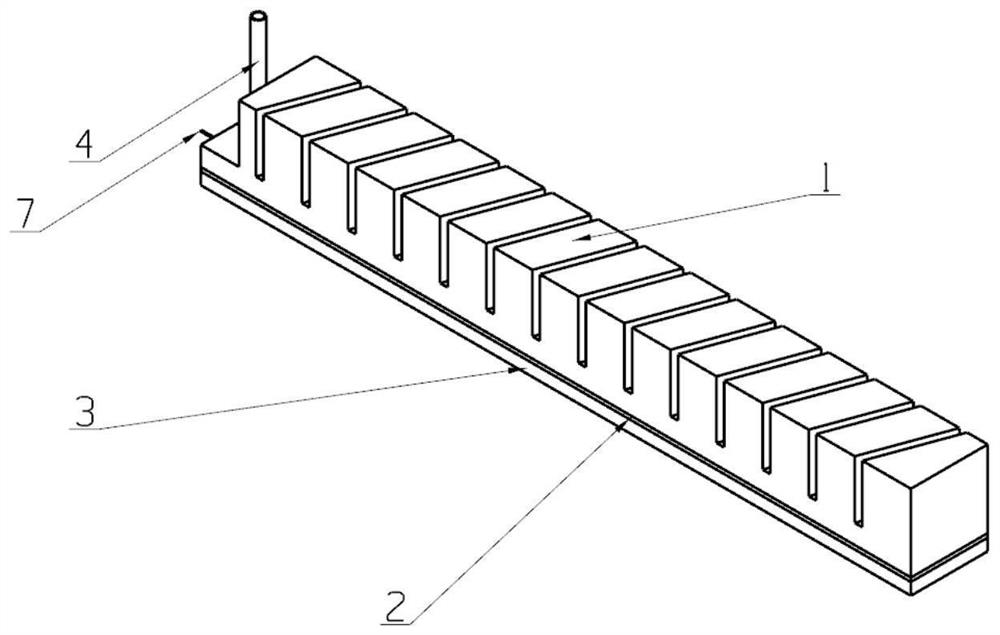

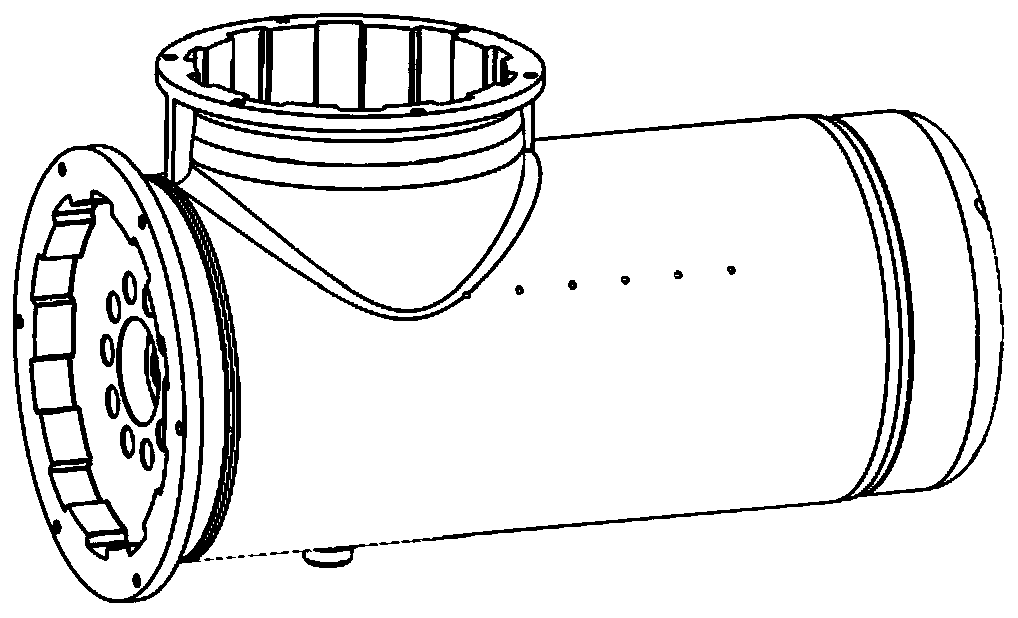

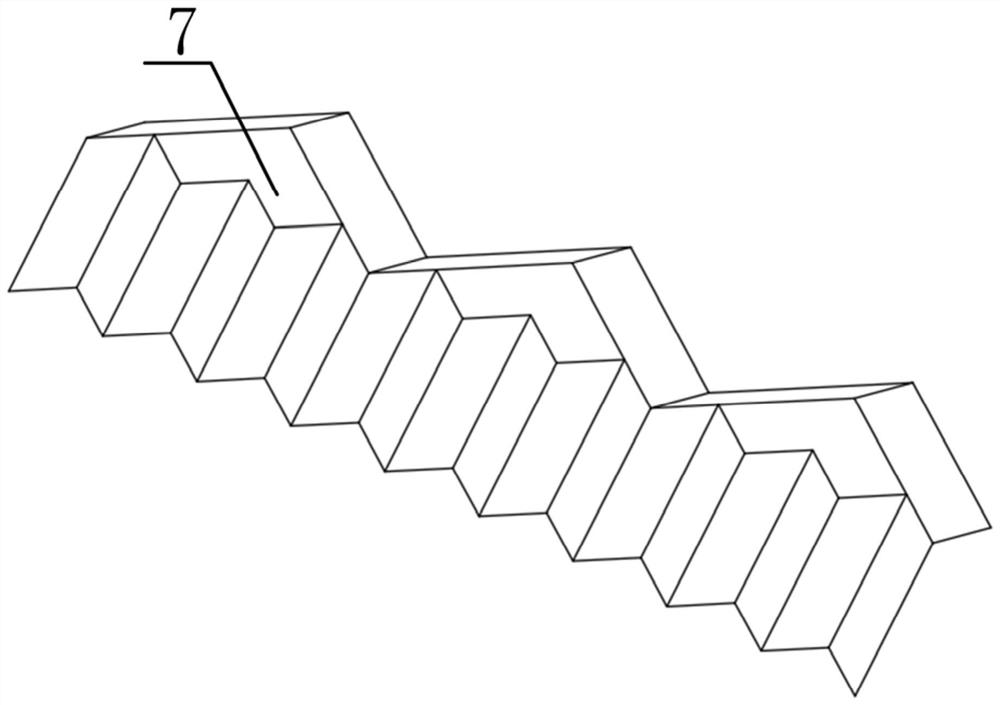

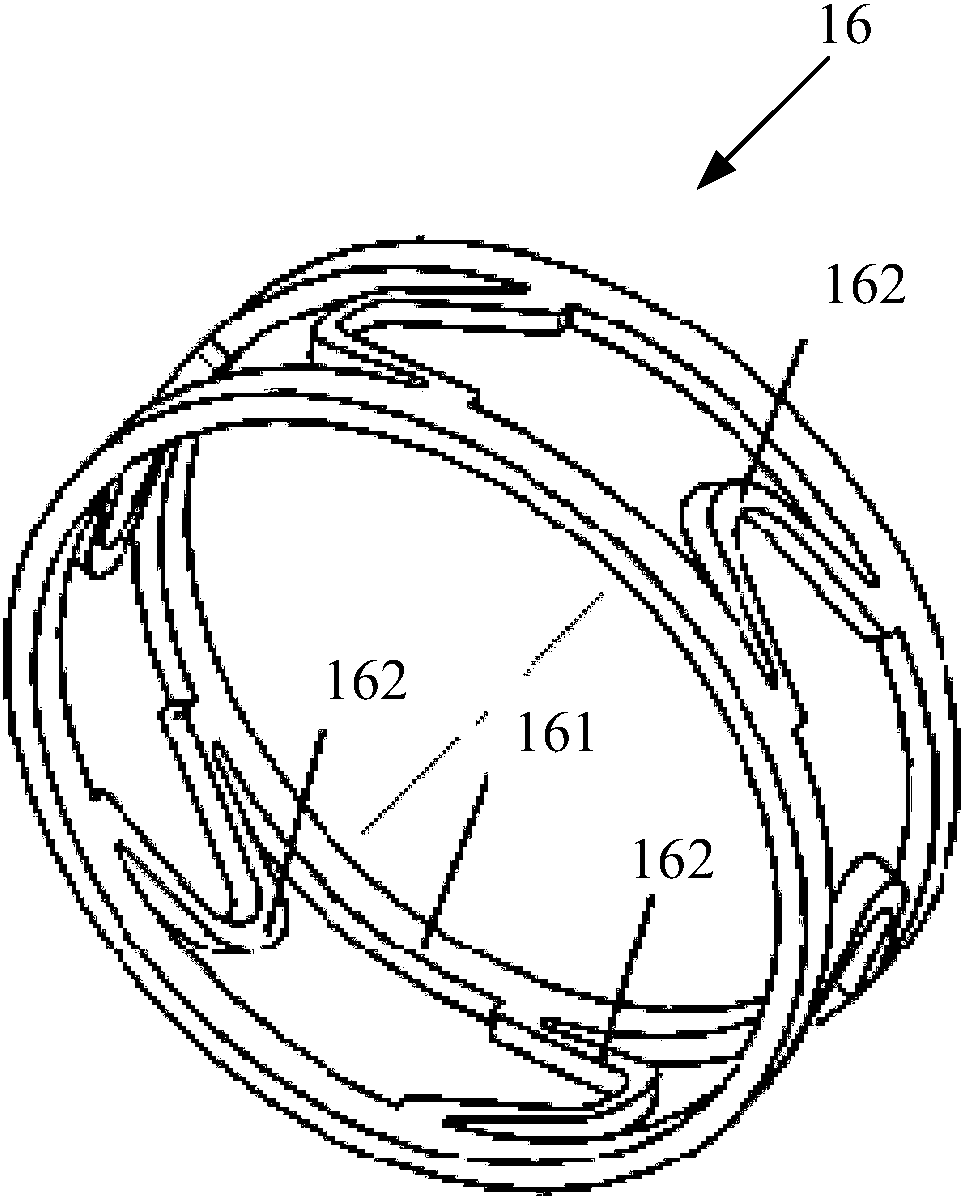

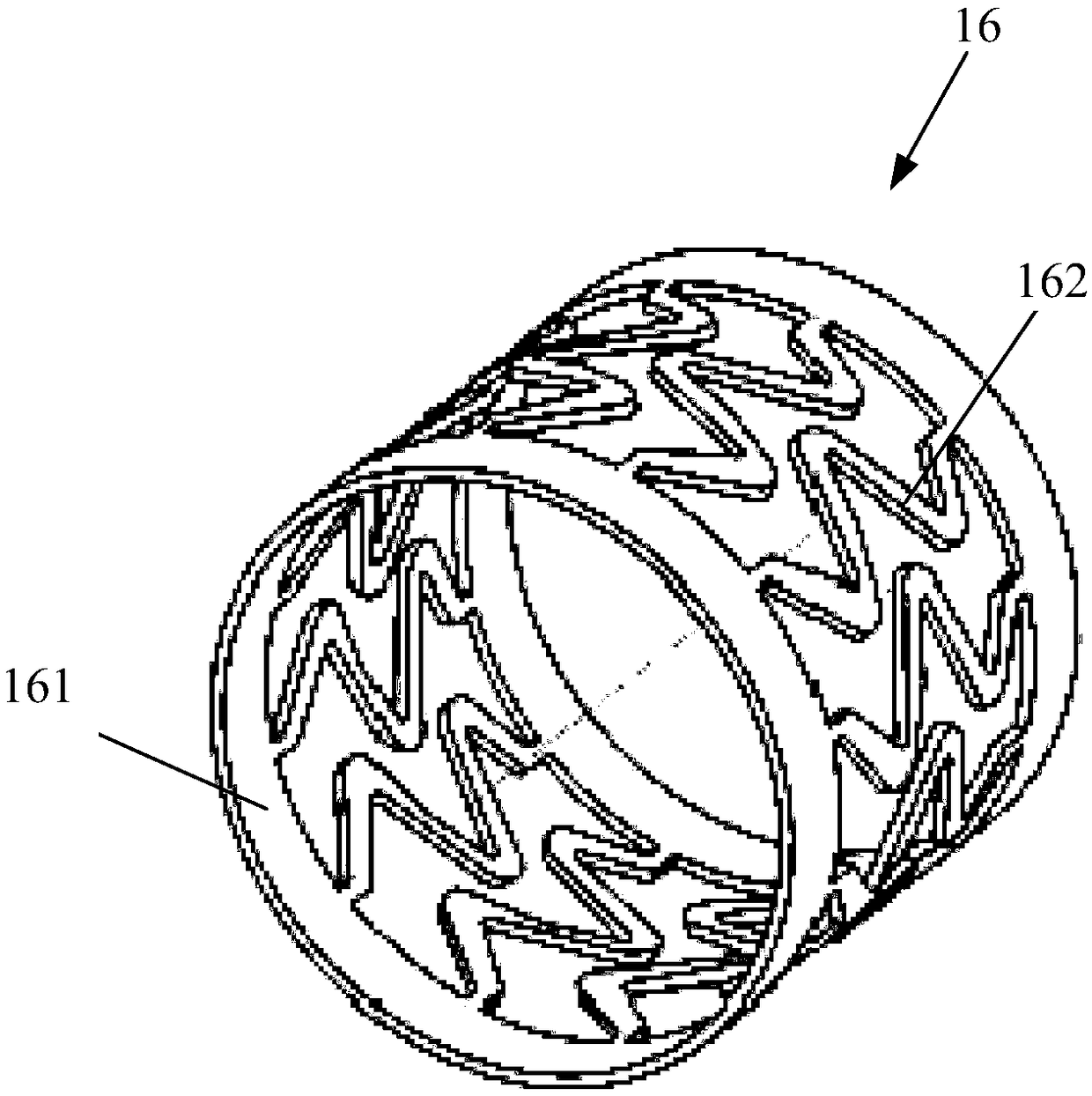

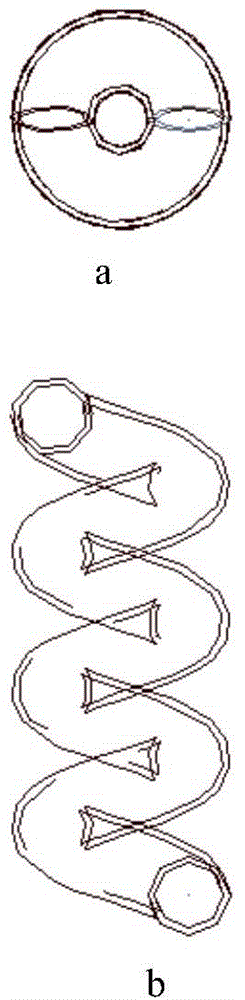

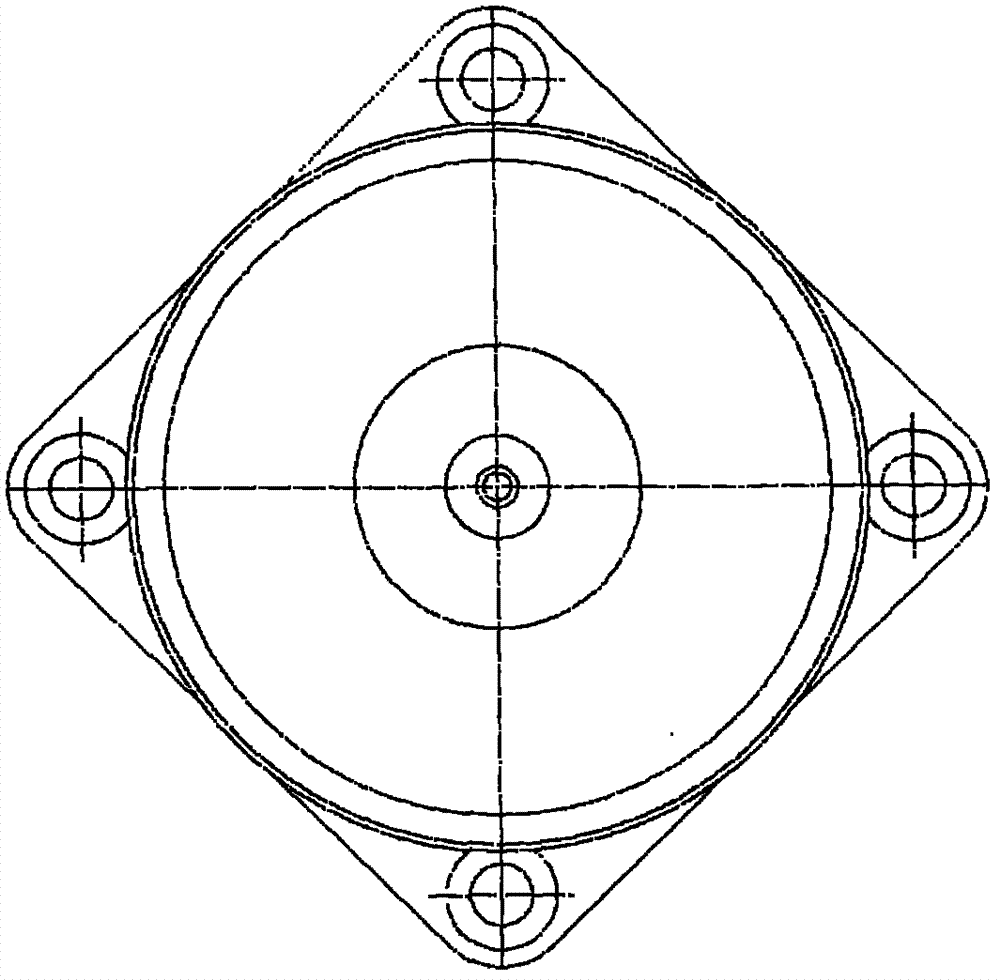

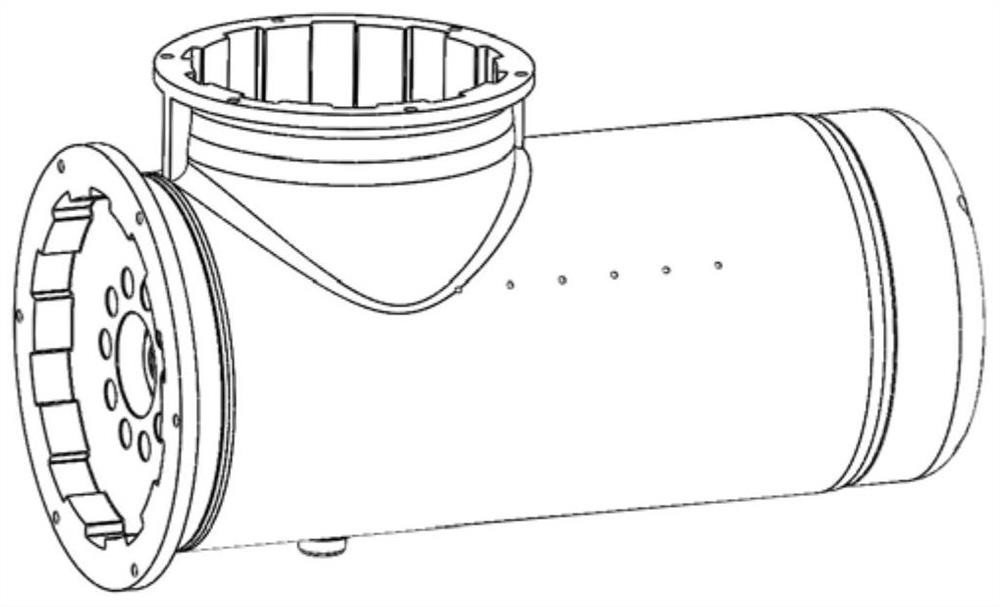

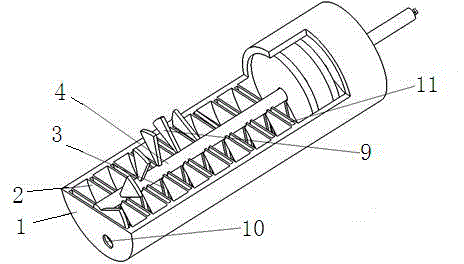

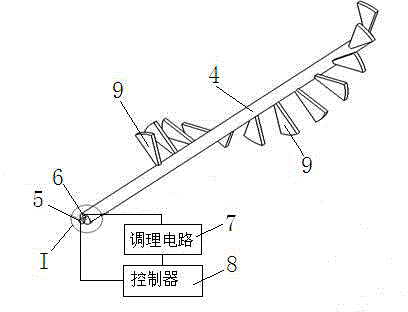

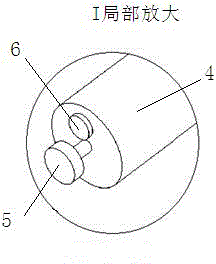

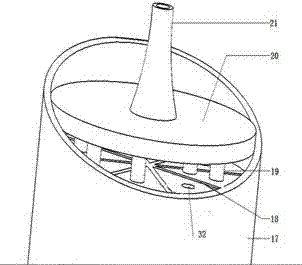

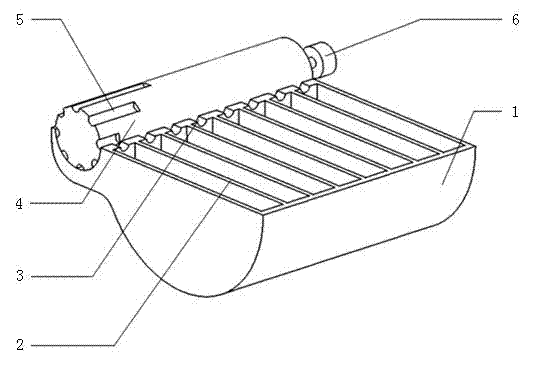

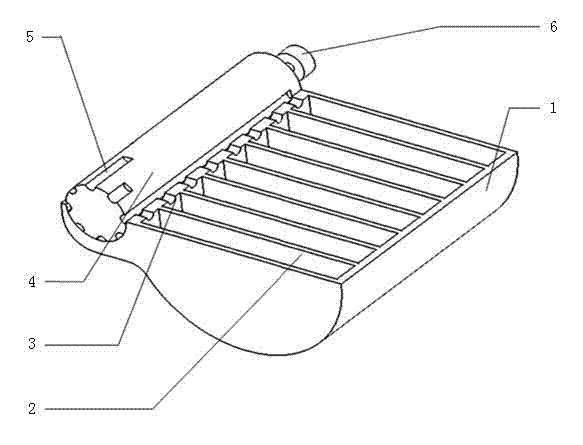

Air spring auxiliary chamber with variable air volume

InactiveCN103016593AWide range of stiffnessMeet the precision requirementsSpringsGas based dampersAir springAir suspension

The invention discloses an air spring auxiliary chamber of a vehicle air suspension, which has a variable volume. N separators are arranged in a cylindrical cylinder body to uniformly divide a cylinder body inner cavity into n small chambers along the axial direction; a center shaft extends into the cylinder body from the outside of one end of the cylinder body and is inserted in center holes of the n separators; the first separator is tightly attached to the other end face of the cylinder body; the same position on each separator is provided with a sector through hole which is coaxial with the center holes; the middle of each separator is provided with a cylindrical hollow slot which is coaxial with the center holes; a sector valve plate is arranged in each cylindrical hollow slot; all the sector valve plates are axially in rigid connection with the center shaft in a spiral manner along the center shaft; one end of the center shaft positioned outside the cylinder body is connected with a stepping motor and an angle sensor is arranged on the end face of the one end of the center shaft; and when the center shaft rotates by a certain angle every time, different sector valve plates are driven to seal the corresponding sector through holes, so that automatic and rapid change of the volume of the auxiliary chamber is implemented and an air spring obtains a large rigid variation range.

Owner:JIANGSU UNIV

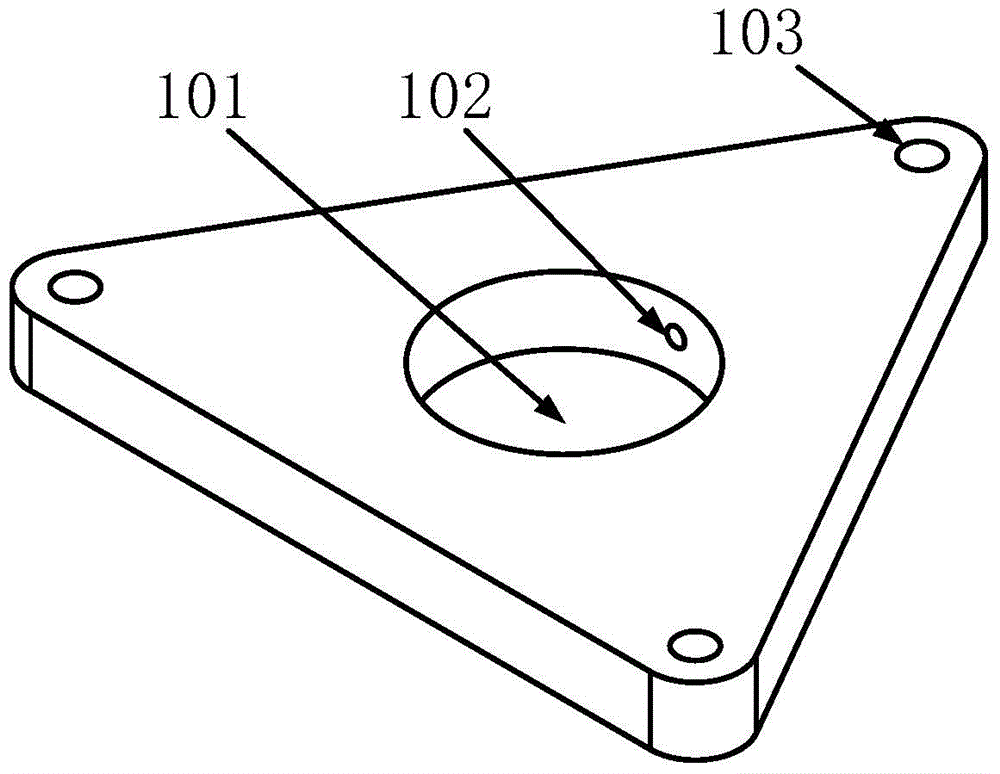

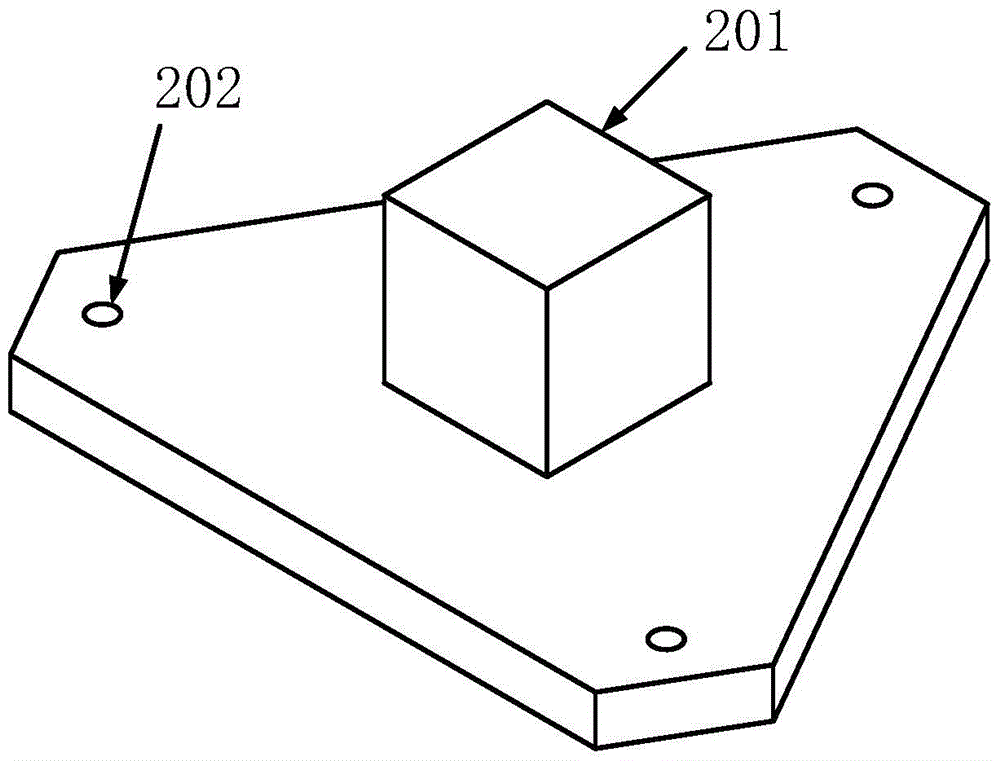

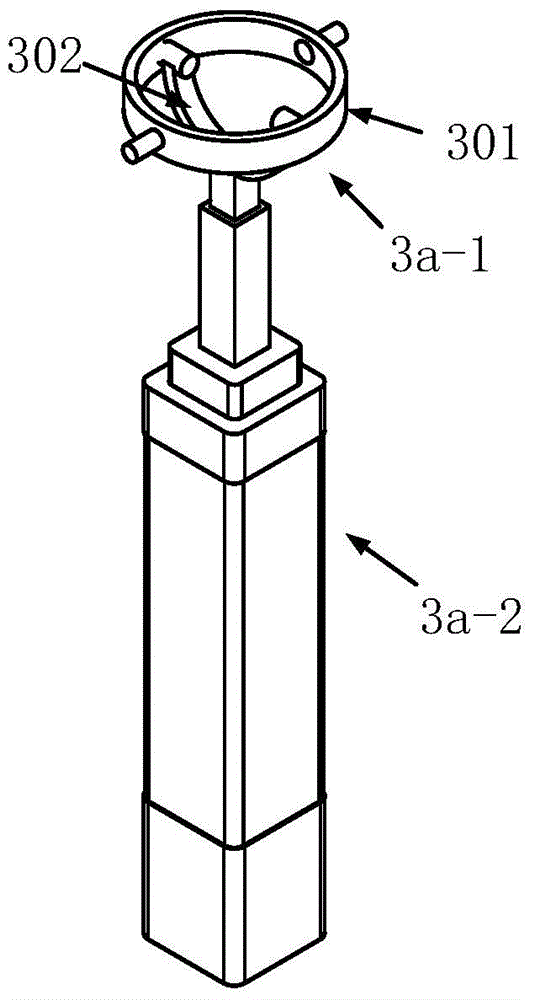

Composite load simulator for achieving multidimensional pure bending moment and tensile pressure

InactiveCN103884373ALarge working spaceWide range of stiffnessMeasurement devicesPure bendingBorn rigidity

The invention discloses a composite load simulator for achieving multidimensional pure bending moment and tensile pressure. The composite load simulator can achieve pure bending moment loading, tensile pressure loading and pure bending moment and tensile pressure composite loading in any direction. The simulator comprises a moving platform, a fixed base and moving branch chains. The moving platform is fixedly connected with a loaded test piece, and the moving branch chains comprise the central moving branch chain and the uniformly-distributed moving branch chains, wherein the uniformly-distributed moving branch chains are of six different structures. The uniformly-distributed moving branch chains of the different structures, the central moving branch chain, the fixed base and the moving platform can form six kinds of different bending moment-tensile pressure composite load simulator structures. The composite load simulator has the advantages that the composite load simulator can achieve multidimensional pure bending moment load output and can output composite loads of the bending moment and the tensile pressure; due to the fact that the branch chains exist, the structure has high bearing rigidity, decoupling can be achieved through output of the tensile pressure and the bending moment, and the composite load simulator is convenient to control, simple to manufacture and convenient to install.

Owner:BEIHANG UNIV

Variable-rigidity flexible mechanical arm

ActiveCN109877858AWide range of stiffnessRealize multi-level regulationProgramme-controlled manipulatorGripping headsFinger jointShape-memory alloy

The invention provides a variable-rigidity driving structure. The structure comprises a rotating structure, wherein the two ends of the rotating structure are both fixedly provided with super-elasticshape memory alloy wires, the rotating structure is sleeved with a corrugated pipe, a low-melting-point alloy is injected in the corrugated pipe, the two ends of the corrugated pipe are sealed throughspring supports, the spring supports are fixedly connected to the super-elastic shape memory alloy wires, a shape memory alloy spring is further fixed between the two spring supports, the low-melting-point alloy is heated and cooled, so that the rotating structure can be switched between a rotating state and a locked state, and the rigidity change range of the variable-rigidity driving structureis greatly expanded. The invention further provides a finger joint comprising the variable-rigidity driving structure and a variable-rigidity flexible mechanical arm.

Owner:WUHAN UNIV OF TECH

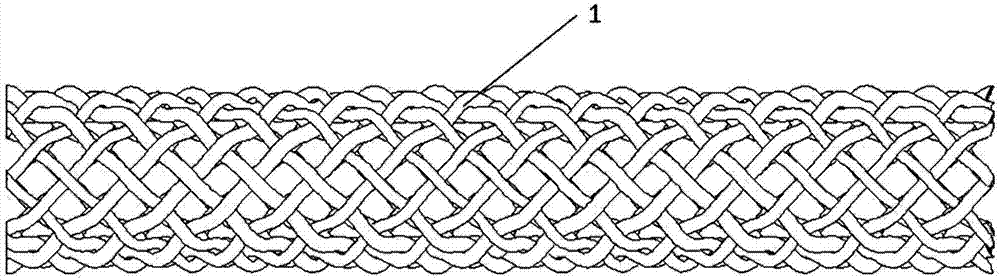

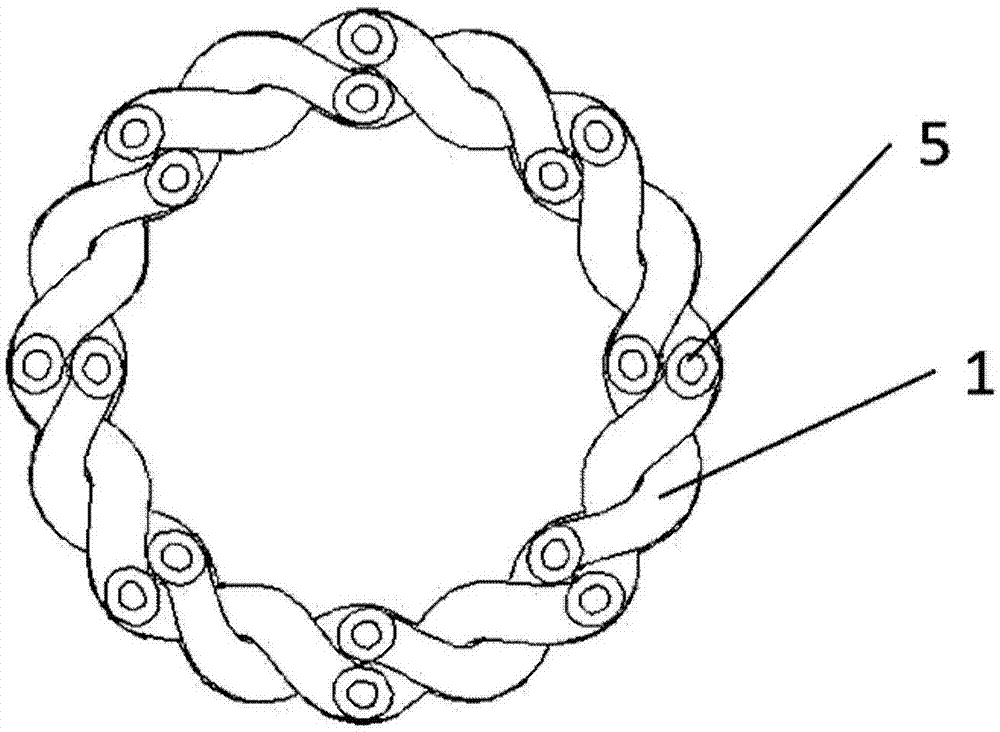

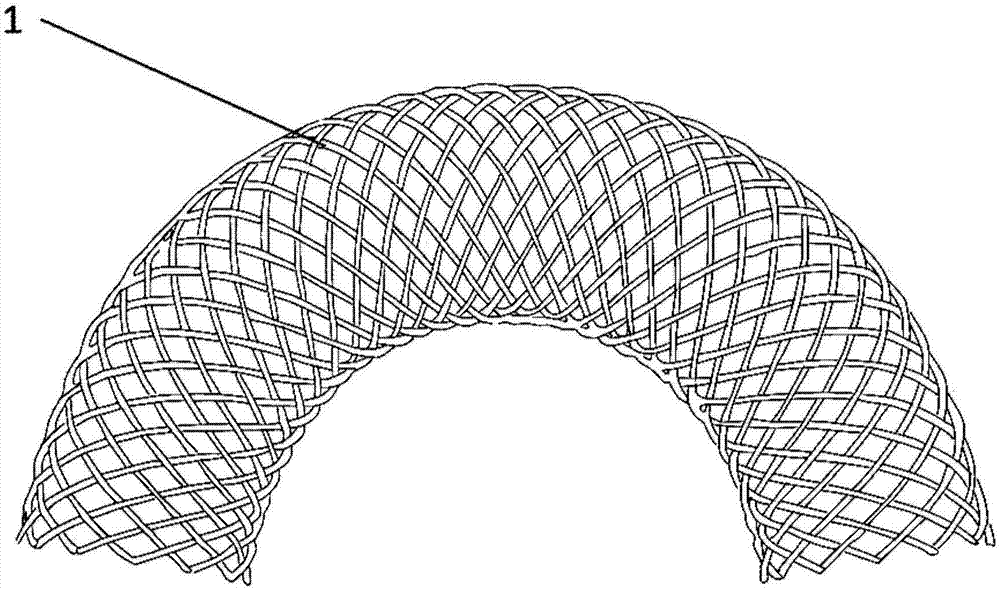

Variable-stiffness protective sheath for natural cavity operation and application method thereof

ActiveCN107280716AImprove flexibilityStrong environmental abilityDiagnosticsSurgeryVariable stiffnessAlloy

The invention discloses a variable-stiffness protective sheath for a natural cavity operation. The protective sheath comprises a braided tube, the braided tube is formed by spirally winding and intersecting multiple hoses, and the interiors of the hoses are filled with alloy with a low melting point. The invention further provides a method for applying the variable-stiffness protective sheath to the natural cavity operation. The method comprises the steps that the alloy with the low melting point in the hoses is powered on and melted, and the braided tube is in a flexible and small-diameter state; the braided tube is put into a natural cavity; the diameter of the braided tube is increased, the alloy with the low melting point is solidified at the human-body temperature, and the braided tube is in a rigid and large-diameter state; an operation tool is put into the braided tube for the operation; after the operation, the alloy with the low melting point in the hoses is powered on, and the braided tube is restored to be the flexible state and drawn out of the natural cavity. The structural stiffness of the braided tube of the variable-stiffness protective sheath is changed through the adoption of a phase transformation technology of the alloy with the low melting point, it can be ensured that the variable-stiffness protective sheath has a relatively large stiffness changing range, and the human cavities are protected from being scratched and stabbed by the operation tool.

Owner:TIANJIN UNIV

Double-layer pneumatic spiral soft body actuator with variable stiffness

InactiveCN113276144AFlexibleHuman-Computer Interaction SafetyProgramme-controlled manipulatorGripping headsTemperature controlActuator

The invention discloses a double-layer pneumatic spiral soft body actuator with variable stiffness. The soft body actuator comprises a pneumatic soft body actuator body, an air guide pipe and a variable stiffness module. The air guide pipe is fixedly installed at the end of the pneumatic soft body actuator body, and the variable stiffness module is fixedly installed at the bottom of the pneumatic soft body actuator body. The soft body actuator is connected with an outer auxiliary device through the air guide pipe, the outer auxiliary device is used for providing and controlling the air pressure needed by spiral deformation of the soft body actuator, the soft body actuator is electrically connected with a temperature control device through the variable stiffness module, and the temperature control device is used for controlling the temperature influencing the stiffness of the soft body actuator. The variable stiffness module is more tightly attached to an object, various objects with complex surface shapes are grabbed through more flexible deformation of the spiral soft body actuator, and spiral grabbing, thin-stick-shaped object grabbing and the like are achieved.

Owner:ZHEJIANG UNIV

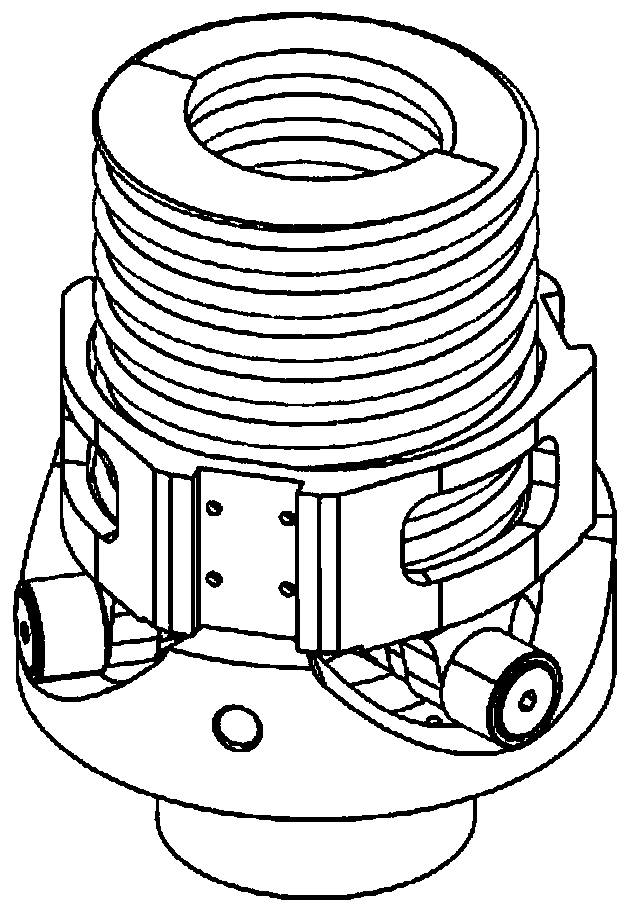

Novel universal variable rigidity manipulator joint

The invention discloses a novel universal variable rigidity manipulator joint. The output of a harmonic reducer is fixedly connected with a threaded end of a trapezoidal lead screw; when the trapezoidal lead screw rotates, a lead screw nut and the trapezoidal lead screw can produce relative axial movement; the lead screw nut is fixedly connected with a lead screw nut fixing disc; the lead screw nut fixing disc and a roller bearing disc can perform axial movement relative to a joint shell along a guide rail fixed to the inner side of the joint shell; a mould spring is mounted between the lead screw nut fixing disc and the roller bearing disc in a sleeving manner; an arc-shaped wheel disc is mounted between the roller bearing disc and a horizontal end of the trapezoidal lead screw; the arc-shaped wheel disc is mounted on the trapezoidal lead screw in the sleeving manner; the horizontal end of the trapezoidal lead screw positions the trapezoidal lead screw in the radial direction througha bearing, bears the acting force of the mould spring and transfers the acting force of the mould spring to the arc-shaped wheel disc; the arc-shaped wheel disc is fixedly connected to an output flange, and is supported to rotate relative to the joint shell through the bearing; and the arc-shaped wheel disc is matched with a roller bearing mounted on the roller bearing disc, so that the external acting force acting on an output flange is converted into compression force acting on the spring.

Owner:BEIJING INST OF CONTROL ENG

Stacked paper folding structure with variable stiffness characteristic

ActiveCN112208677AWith variable stiffnessIncrease stiffnessPaper/cardboard articlesRailway componentsBuckling instabilityPaperboard

The invention discloses a stacked paper folding structure with variable stiffness characteristics, which comprises a plurality of layers of paper folding tubes stacked up and down, each paper foldingtube comprises two symmetrically arranged paper folding plates, each paper folding plate comprises a plurality of basic units, the basic units are connected in sequence, each basic unit comprises n small planes and two large planes, n is an even number greater than 2, the width ratio of the large plane to the small plane is n / 2, and the large plane and the small plane are parallelograms. Due to the fact that all layers of paper folding pipes of the stacked paper folding structure are different in rigidity, when the stacked paper folding structure is subjected to compression force from top to bottom, the stacked paper folding structure generates a layer-by-layer progressive buckling instability process, firstly, the paper folding pipe with the minimum rigidity is subjected to buckling instability, and then the paper folding pipe with the second small rigidity is triggered to be subjected to buckling instability; therefore, the paper folding pipe with the maximum rigidity is obtained through recursion, and then the variable rigidity characteristic of the stacked paper folding structure is achieved. According to specific requirements, multiple layers of paper folding pipes with different rigidities can be stacked, and multiple variable stiffness characteristics are achieved.

Owner:GUANGZHOU UNIVERSITY

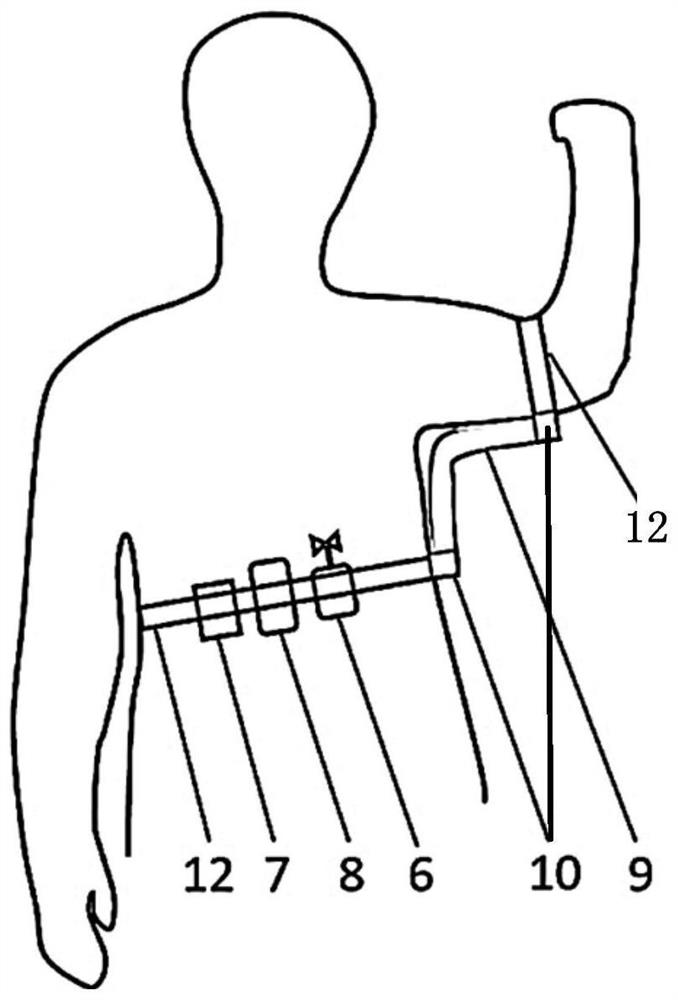

Variable-rigidity wearing system for positive pressure particle congestion

ActiveCN113084781ALow costEasy to operateProgramme-controlled manipulatorHuman bodyControl engineering

The invention provides a variable-rigidity wearing system for positive pressure particle congestion. The variable-rigidity wearing system comprises a variable-rigidity module, a control module, a driving module and a structural part, wherein the variable-rigidity module is worn on a human body and comprises a rigid state and a flexible state; the control module outputs a control command; the driving module executes the control command and can drive the variable-rigidity module to be switched between the rigid state and the flexible state; and the control module, the driving module and the variable-rigidity module are worn on the human body through the structural part. The variable-rigidity wearing system adopts a brand-new particle congestion variable-rigidity wearing system design, utilizes the characteristic that particles are mutually extruded after being pressed and cannot mutually move to form rigidity increase and recover flexibility after extrusion is relieved, easily realizes assistance to different joints of the human body by controlling the pressure in a flexible capsule, and has the advantages of low cost, convenience in operation and good durability.

Owner:UNIV OF SCI & TECH OF CHINA

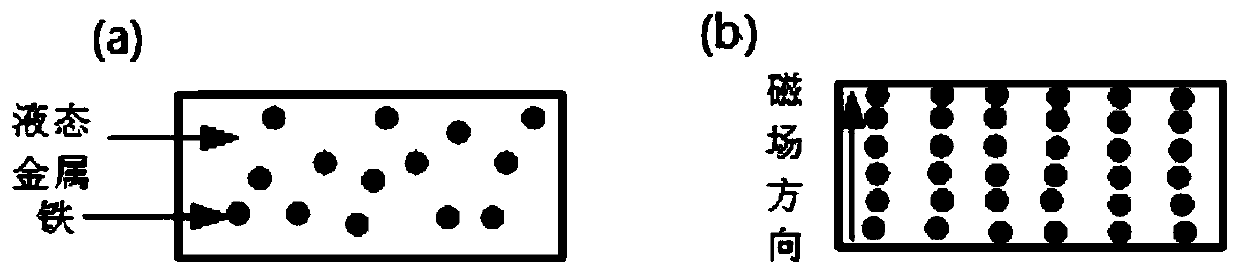

Polydimethylsiloxane/liquid metal composite material and preparation method and application thereof

The invention relates to a polydimethylsiloxane / liquid metal composite material and a preparation method and application thereof, and belongs to the technical field of composite materials. The technical problems are solved that an existing magnetorheological material is viscous and not resistant to loads and cannot be applied to a magnetorheological rigidity variation mechanism. The composite material is composed of a core body and a shell. The shell from polydimethylsiloxane is of a cylindrical structure. The core body is of a solid structure, the size of the outer contour of the core body ismatched with the size of a cavity of the shell, the core body can be exactly embedded into the cavity, and the core body is made from a magnetorheological material composed of iron particles and gallium-indium-tin liquid metal. According to the composite material, the rigidity range of the composite material can be adjusted by adjusting the percentage of the iron particles and the magnetic fieldintensity, the adjusting range is large, the response speed is high, the needed time is only based on millisecond, reversible change can be rapidly achieved, and the composite material is suitable forpreparing magnetorheological rigidity-variable joints.

Owner:BEIHANG UNIV

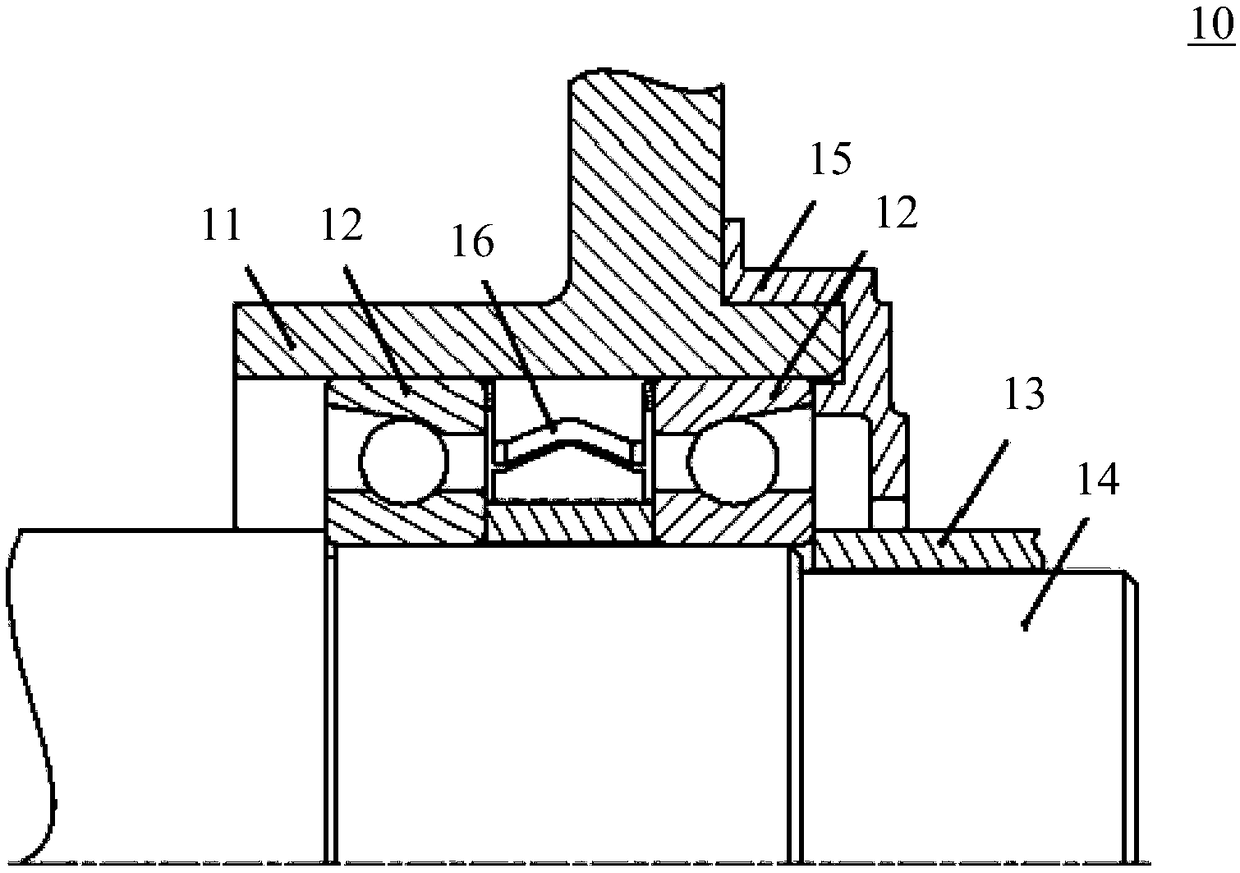

Bearing pre-tightening device

InactiveCN109505872AApply to achieveWide range of stiffnessBearing unit rigid supportMechanical engineeringEngineering

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

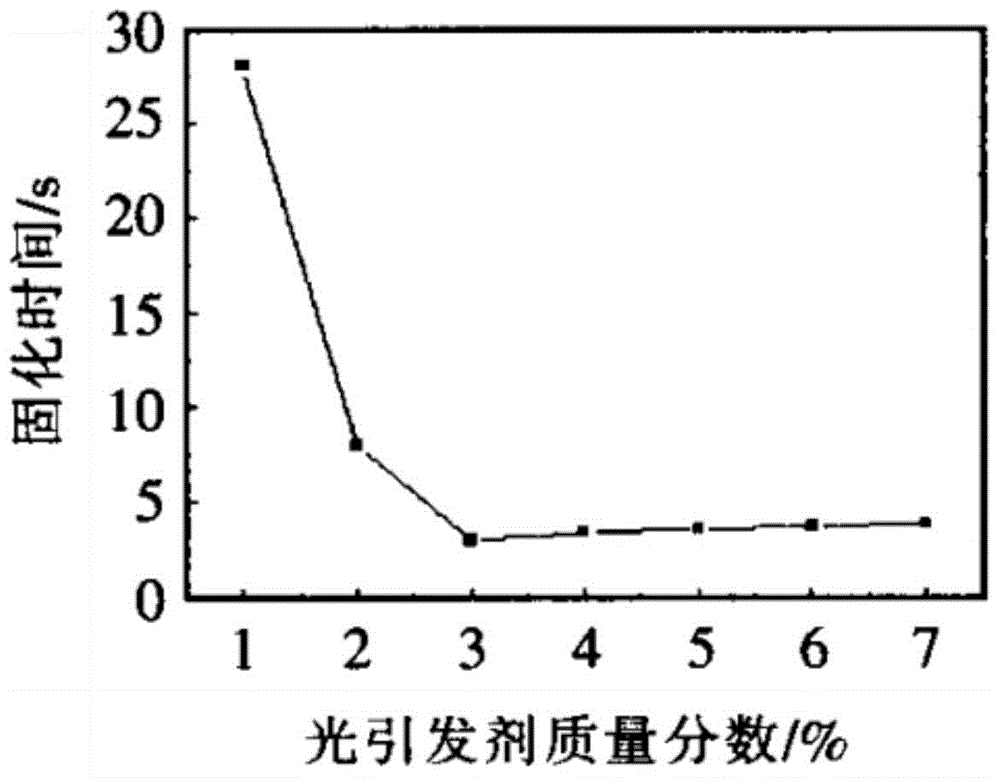

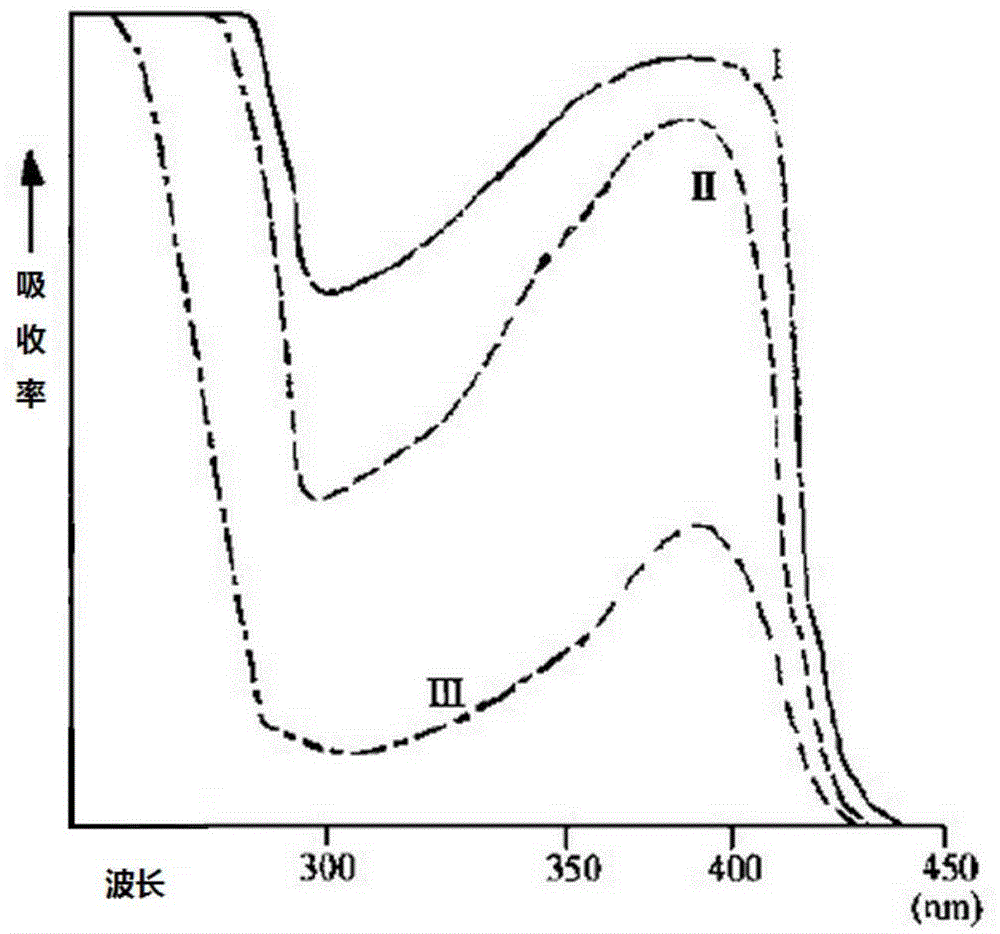

Rigidity-controllable material oriented to material increase manufacturing technology and manufacturing method thereof

InactiveCN104693381ARealize processingHigh forming precisionManufacturing technologyUltraviolet lights

The invention relates to a rigidity-controllable material oriented to a material increase manufacturing technology and a manufacturing method thereof. The rigidity-controllable material comprises, by mass, 10-40 parts of acrylic oligomer, 60-90 parts of alkyl acrylate and 0.1-3 parts of ultraviolet light photoinitiator, and the acrylic oligomer, wherein the alkyl acrylate and the ultraviolet light photoinitiator are sequentially mixed and evenly stirred to prepare a photocuring raw material; a three-dimensional model for a rigidity-controllable material device is built, discretization is carried out on the surface of the three-dimensional model to generate a three-dimensional digital model file, and a machining file capable of being identified by a material increase manufacturing device is led out after supporting adding, model layered discretization and machining path generation are carried out on the three-dimensional digital model file; the photocuring raw material is manufactured into the rigidity-controllable material device through the ultraviolet light polymerization material increase manufacturing technology. The obtained device is variable in structure, the rigidity controlling performance is excellent, and the rigidity-controllable material has the advantages of being high in efficiency, low in cost and high in accuracy; the glassy state Yang modulus value is approximately 500 times of the rubbery state Yang modulus value, and the response speed of the Yang modulus along with changes of the temperature is high.

Owner:XI AN JIAOTONG UNIV +1

A kind of multi-layer bubbling foil dynamic pressure gas thrust bearing

ActiveCN103267062BIncrease stiffnessImprove featuresSliding contact bearingsElastic componentThrust bearing

Owner:XI AN JIAOTONG UNIV

A Composite Load Simulator Realizing Multidimensional Pure Bending Moment and Tensile Compression

InactiveCN103884373BLarge working spaceWide range of stiffnessMeasurement devicesEngineeringBorn rigidity

The invention discloses a composite load simulator for achieving multidimensional pure bending moment and tensile pressure. The composite load simulator can achieve pure bending moment loading, tensile pressure loading and pure bending moment and tensile pressure composite loading in any direction. The simulator comprises a moving platform, a fixed base and moving branch chains. The moving platform is fixedly connected with a loaded test piece, and the moving branch chains comprise the central moving branch chain and the uniformly-distributed moving branch chains, wherein the uniformly-distributed moving branch chains are of six different structures. The uniformly-distributed moving branch chains of the different structures, the central moving branch chain, the fixed base and the moving platform can form six kinds of different bending moment-tensile pressure composite load simulator structures. The composite load simulator has the advantages that the composite load simulator can achieve multidimensional pure bending moment load output and can output composite loads of the bending moment and the tensile pressure; due to the fact that the branch chains exist, the structure has high bearing rigidity, decoupling can be achieved through output of the tensile pressure and the bending moment, and the composite load simulator is convenient to control, simple to manufacture and convenient to install.

Owner:BEIHANG UNIV

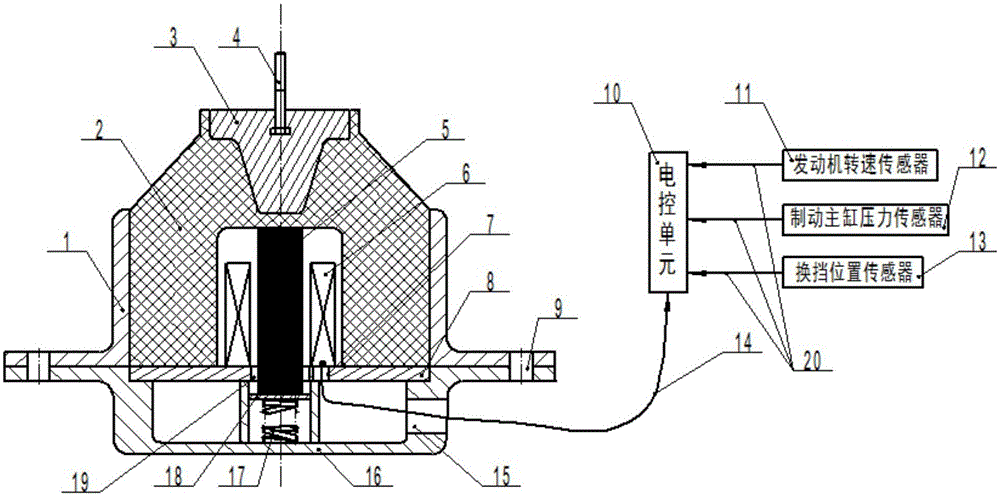

A semi-active magnetic-sensitive rubber automobile engine mount

ActiveCN103660901BSimple structureEasy processing and assemblyJet propulsion mountingInternal combustion mountingSemi activeControl signal

A semi-active magnetic-sensing rubber automobile engine suspension device comprises an upper outer shell, a lower outer shell, a magnetic-sensing rubber main spring, a magnetic-sensing rubber plug block, a center bolt, a field core, a field coil, a platform, an electric control unit, an engine rotating speed sensor, a brake main cylinder pressure sensor, a gear shifting position sensor, a spiral spring and a supporting wafer. The magnetic-sensing rubber main spring and the magnetic-sensing rubber plug block are arranged inside the upper outer shell. The field coil and the field core are arranged in an internal cavity of the magnetic-sensing rubber main spring. The field coil is fixedly connected with the platform. The upper outer shell and the lower outer shell are fixedly connected through connecting holes formed in the upper outer shell and the lower outer shell. The electric control unit is connected with the field coil through a control line, judges the working condition of an engine and an automobile according to signals input by the engine rotating speed sensor, the brake main cylinder pressure sensor and the gear shifting position sensor and sends a control signal to the field coil, so that magnetic-sensing rubber automobile engine suspension is controlled and adjusted, and the riding comfort of the automobile is improved.

Owner:BEIHANG UNIV

Totally-closed rigidity adjustable type vibration isolator

ActiveCN102518727BSolve the problem of vibration isolationReduce consumptionShock absorbersRubber ringEnvironment effect

The invention relates to a vibration isolation and buffer device for machine-born equipment, in particular to a totally-closed rigidity adjustable type vibration isolator, which comprises a casing, an installation core shaft, a protective rubber cover, an upper rubber ring, a spherical vibration isolation part and a lower rubber ring. The casing is of a sealed structure, the top of the casing is provided with an installation hole where the installation core shaft is arranged, and the spherical vibration isolation part is arranged in the sealed casing and is connected with the bottom of the installation core shaft together. The upper rubber ring is sleeved at the upper portion of a damp rubber ball, and the lower rubber ring is sleeved at the lower portion of the damp rubber ball which is sealed in the casing. The totally-closed rigidity adjustable type vibration isolator adopts a totally-closed structure to have small environment influence, utilizes a combination structure combining the spherical surface and the cylindrical surface to improve vibration isolation and retarding effects, utilizes the structures of the upper rubber ring and the lower rubber ring to limit the swinging of the head of the installation core shaft and improve using safety, and can be suitable for different frequency ranges by rotating the upper cover to adjust the rigidity of the vibration isolator.

Owner:CHINA AIRPLANT STRENGTH RES INST

A Continuously Variable Stiffness Flexible Robot

ActiveCN109176489BThe principle is simpleRealize stepless adjustment of stiffnessProgramme-controlled manipulatorEngineeringMagnet

Owner:YANSHAN UNIV

A New General Variable Stiffness Manipulator Joint

A new type of universal variable stiffness manipulator joint, the output of the harmonic reducer is fixedly connected to the threaded end of the trapezoidal screw, when the trapezoidal screw rotates, the screw nut and the trapezoidal screw can produce relative axial movement; the screw nut and the screw The screw nut fixed plate is fixedly connected, the screw nut fixed plate and the roller bearing plate can move axially relative to the joint shell along the guide rail fixed on the inner side of the joint shell; the mold spring is set on the lead screw nut fixed plate and the roller bearing plate between the roller bearing plate and the horizontal end of the trapezoidal screw, the arc-shaped wheel is set on the trapezoidal screw, and the horizontal end of the trapezoidal screw radially positions the trapezoidal screw and the bearing mold through the bearing The spring acts on the force and transmits it to the arc-shaped wheel; the arc-shaped wheel is fixedly connected with the output flange and rotates relative to the joint shell through the bearing support; the arc-shaped wheel and the rollers installed on the roller bearing plate The bearing fits to convert the external acting torque acting on the output flange into the compressive force acting on the spring.

Owner:BEIJING INST OF CONTROL ENG

Air spring auxiliary chamber with variable air volume

InactiveCN103016593BWide range of stiffnessFast and accurate changeSpringsGas based dampersVariable air volumeAir spring

The invention discloses an air spring auxiliary chamber of a vehicle air suspension, which has a variable volume. N separators are arranged in a cylindrical cylinder body to uniformly divide a cylinder body inner cavity into n small chambers along the axial direction; a center shaft extends into the cylinder body from the outside of one end of the cylinder body and is inserted in center holes of the n separators; the first separator is tightly attached to the other end face of the cylinder body; the same position on each separator is provided with a sector through hole which is coaxial with the center holes; the middle of each separator is provided with a cylindrical hollow slot which is coaxial with the center holes; a sector valve plate is arranged in each cylindrical hollow slot; all the sector valve plates are axially in rigid connection with the center shaft in a spiral manner along the center shaft; one end of the center shaft positioned outside the cylinder body is connected with a stepping motor and an angle sensor is arranged on the end face of the one end of the center shaft; and when the center shaft rotates by a certain angle every time, different sector valve plates are driven to seal the corresponding sector through holes, so that automatic and rapid change of the volume of the auxiliary chamber is implemented and an air spring obtains a large rigid variation range.

Owner:JIANGSU UNIV

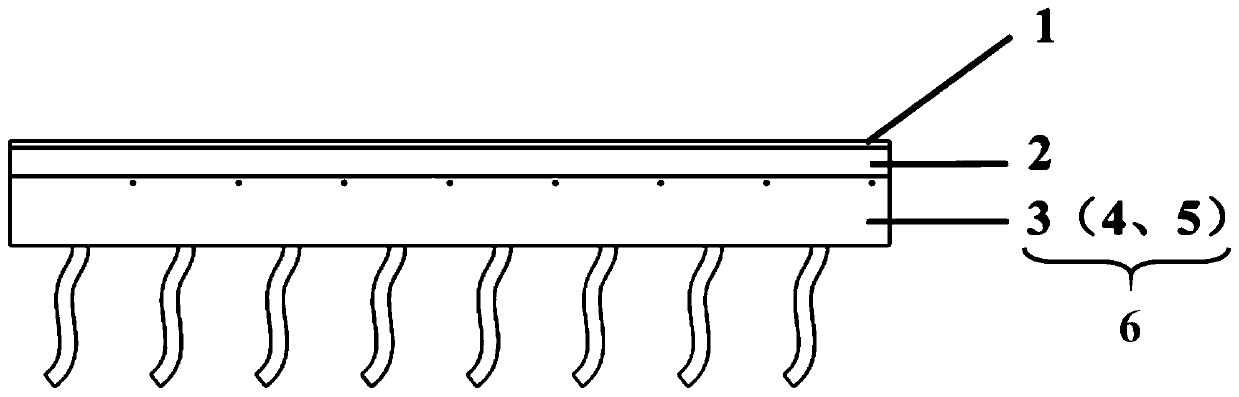

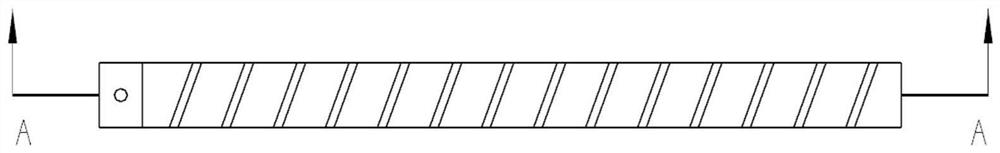

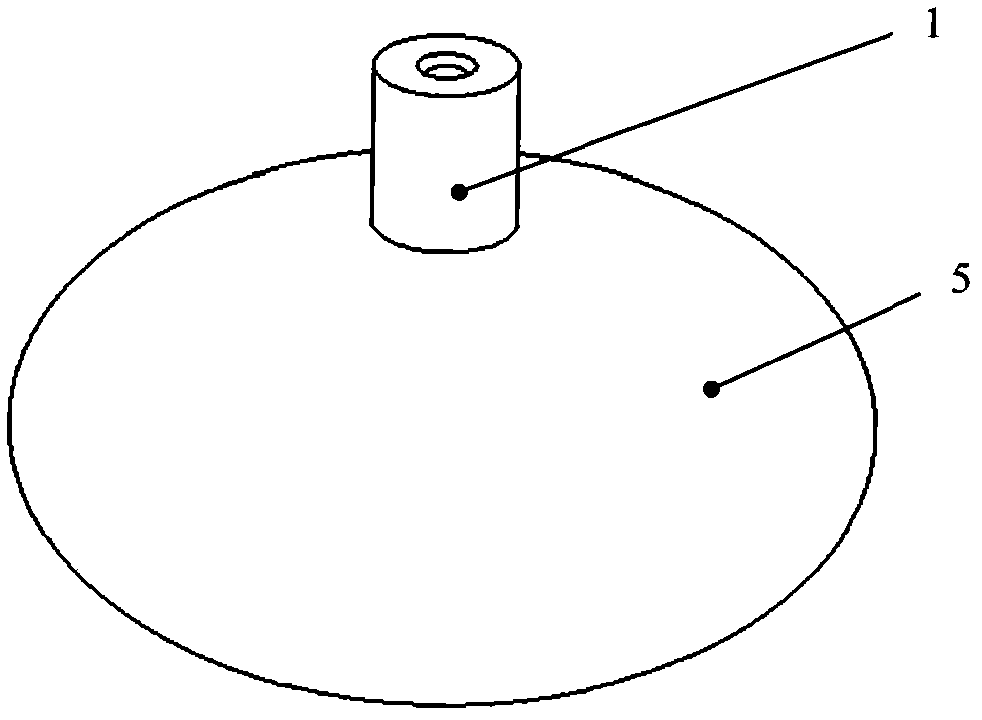

Volume variable air spring auxiliary chamber experiment device and method

InactiveCN102072826BWide range of stiffnessImprove driving stabilityRailway vehicle testingVehicle suspension/damping testingNumerical controlAir spring

The invention discloses a volume variable air spring auxiliary chamber experiment device and a volume variable air spring auxiliary chamber experiment method. Inner cavities of a cylindrical shell of an auxiliary chamber are eight sector cylinder chambers with same volume, which are separated by sector plates circumferentially; a clapboard is enclosed on the upper end face of the eight sector cylinder chambers, and is provided with eight small holes opposite to the eight sector cylinder chambers; a movable cover plate is arranged on the upper layer of the cylindrical shell, and is provided with a height sensor; the lower end face of the movable cover plate is vertically fixedly connected with eight plunger pistons respectively in sealed fit with the eight small holes, and the lengths of the eight plunger pistons form an arithmetic progression in turn; an air spring system is connected with a computer through a numerical control electrohydraulic servo vibration testing system; and withthe increase of the heights of the eight plunger pistons, the eight sector cylinder chambers are opened in turn, the influence of different volumes of the auxiliary chamber on the characteristics of the air spring is measured, the air spring can obtain a wider rigidity change range, and the running stability and riding comfortability of a sedan are improved.

Owner:JIANGSU UNIV

A Parallel Mode Semi-Active Vibration Isolator

ActiveCN104747651BWide range of stiffnessIncrease stiffnessSpringsShock absorbersSemi activeEngineering

The invention discloses a paralleling model semi-active vibration isolator. The vibration isolator is characterized in that a cylindrical upper shell is arranged, a rubber main spring is plugged in a top end opening of the upper shell, a main spring framework penetrates through the rubber main spring and is provided with an upper connection stud and a lower connection stud, the upper connection stud is connected with a main vibrating object, the lower connection stud is connected with a column-shaped iron core where an excitation coil is wound, the column-shaped iron core is supported in a magnetism conduction sleeve through a cutting magnetorheological elastomer arranged on the outer circumference of the column-shaped iron core, the two ends of the magnetorheological elastomer are extruded to be connected with the top of a T-shaped support and the bottom end of the iron core, and the T-shaped support penetrates through the magnetism conduction sleeve and is fixedly connected; the upper shell is connected with a lower shell, the lower end of the T-shaped support is fixedly connected with the lower shell, and the bottom of the lower shell is provided with a connection bolt used for being connected with a basal body. By means of the vibration isolator, vibrating energy transmitted by a rotary machine to the basal body can be effectively reduced, vibration of relative parts of the rotary machine is reduced, and the service life of the rotary machine and a system of the rotary machine is prolonged.

Owner:HEFEI UNIV OF TECH

Variable-volume additional air chamber of constant internal pressure air spring

InactiveCN102003488BWide range of stiffnessImprove driving stabilityResilient suspensionsGas based dampersAir springElectric machine

The invention discloses a variable-volume additional air chamber of a constant internal pressure air spring in a vehicle air suspension system. An inner cavity of a cylinder body is uniformly divided into eight layers of cavities by separation plates in the axial direction of the cylinder body, a lug boss extends from the side wall of the cylinder body, a plunger piston which is not communicated with the cavity of the cylinder body is arranged in the lug boss, the bottom of the plunger piston is provided with a sealing cover which seals the bottom of the lug boss, and the sealing cover is connected with a main air chamber of the air spring through a pipeline; the plunger piston axially penetrates to the outside of the top of the lug boss in the axial direction of the lug boss and is connected with a stepping motor at the top, and an angle sensor is arranged on the top end surface of the plunger piston; the side surface of the plunger piston is circumferentially and uniformly distributed with eight semicircular grooves which correspond to the eight layers of cavities in length, small identical holes with eight centers on the same straight line are arranged on the side surface of the cylinder body, and the eight small holes are respectively communicated with the corresponding eight semicircular grooves and the eight layers of cavities; the angle sensor is connected with a controller after being electrically connected with a modulate circuit; and the controller is electrically connected with the stepping motor. The automatic fast change of the volume of the additional air chamber is achieved, thus the air spring obtains a wider rigidity variation range.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com