Polydimethylsiloxane/liquid metal composite material and preparation method and application thereof

A technology of polydimethylsiloxane and dimethylsiloxane, applied in polydimethylsiloxane/liquid metal composite material and its preparation, polydimethylsiloxane/liquid metal composite material in The application field of magnetorheological stiffness joints can solve the problems of load resistance and inability to apply magnetorheological stiffness mechanisms, etc., and achieve the effects of fast response speed, outflow prevention, and large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the above polydimethylsiloxane / liquid metal composite material, the steps are as follows:

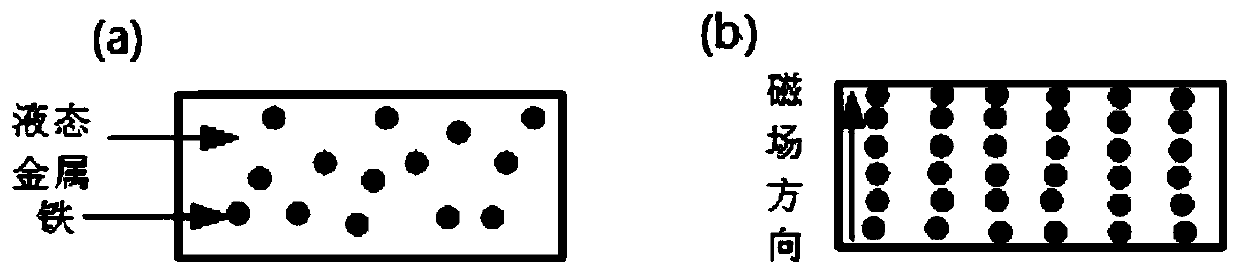

[0043] Step 1. Weigh the iron particles and the gallium indium tin liquid metal according to the ratio, dissolve them in the hydrochloric acid ethanol solution, stir at 800-1000rpm for 5-8min, filter, and obtain the magnetorheological material. The effect diagram is as follows Figure 4 Shown

[0044] Step 2: Embedding the magnetorheological material in the cavity of the housing 1 to obtain a polydimethylsiloxane / liquid metal composite material.

[0045] In the above technical solution, the stirring speed is preferably 1000 rpm and the stirring time is 6 minutes; the stirring equipment usually adopts a high-speed mixer.

[0046] In the above technical scheme, the hydrochloric acid ethanol solution can be obtained commercially, and the concentration of the hydrochloric acid is 1 mol / L.

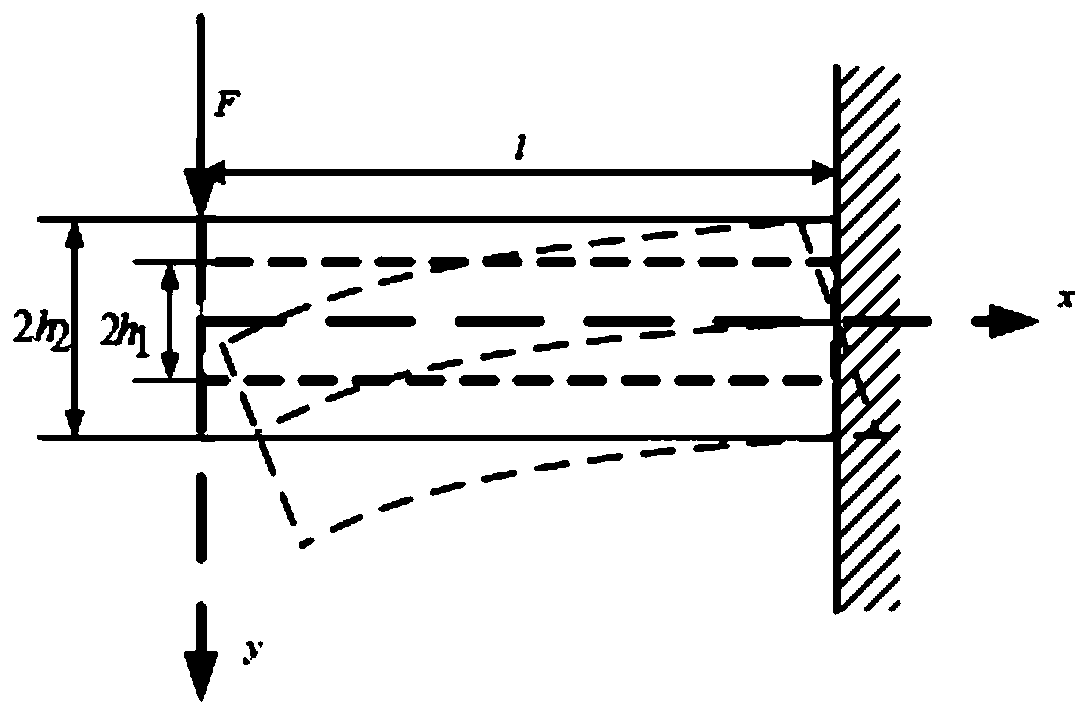

[0047] The present invention also provides the application of the above-mentio...

Embodiment 1

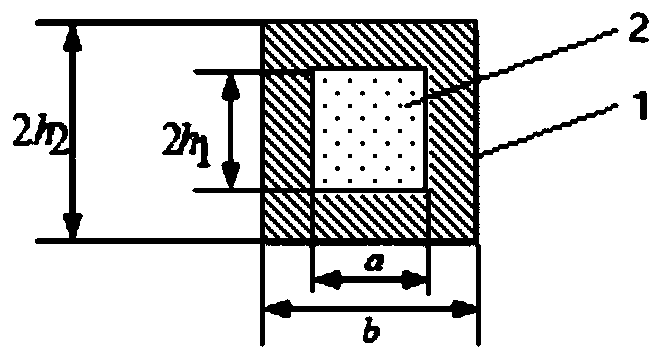

[0050] Polydimethylsiloxane / liquid metal composite material, composed of shell 1 and core 2; shell 1 is a rectangular tube (length, width, and thickness: 100mm, 20mm, 8mm), and the material of shell 1 is poly Dimethylsiloxane; the core 2 is a solid cube (length, width, and thickness: 100mm, 16mm, 6mm, respectively), and the size of the outer contour matches the size of the cavity of the shell 1, and can fit into the cavity , The material of the housing 1 is a magnetorheological material, by dissolving iron particles (100 microns) and gallium indium tin liquid metal (gallium 68.5%wt, indium 21.5wt% and tin 10wt%) in a hydrochloric acid ethanol solution, stirring at 1000rpm for 6min , Filter, obtain;

[0051] In the magnetorheological material, the iron particles are 10wt%, 20wt%, 30wt%, 40wt%, 50wt% respectively.

Embodiment 2

[0053] Polydimethylsiloxane / liquid metal composite material, composed of shell 1 and core 2; shell 1 is a rectangular tube (length, width, and thickness: 100mm, 20mm, 8mm), and the material of shell 1 is poly Dimethylsiloxane; the core 2 is a solid cube (length, width, and thickness: 100mm, 16mm, 6mm, respectively), and the size of the outer contour matches the size of the cavity of the shell 1, and can fit into the cavity , The material of the shell 1 is a magnetorheological material, by dissolving iron particles (75 microns) and gallium indium tin liquid metal (gallium 68.5%wt, indium 21.5wt% and tin 10wt%) in a hydrochloric acid ethanol solution, stirring at 1000rpm for 5min , Filter, obtain;

[0054] In the magnetorheological material, the iron particles are 10wt%, 20wt%, 30wt%, 40wt%, 50wt% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com