Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

231 results about "Clamminess" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS20070284255A1Stable cutting edgeReduce torsion fatiguePigmenting treatmentSurgeryWear resistantShape-memory alloy

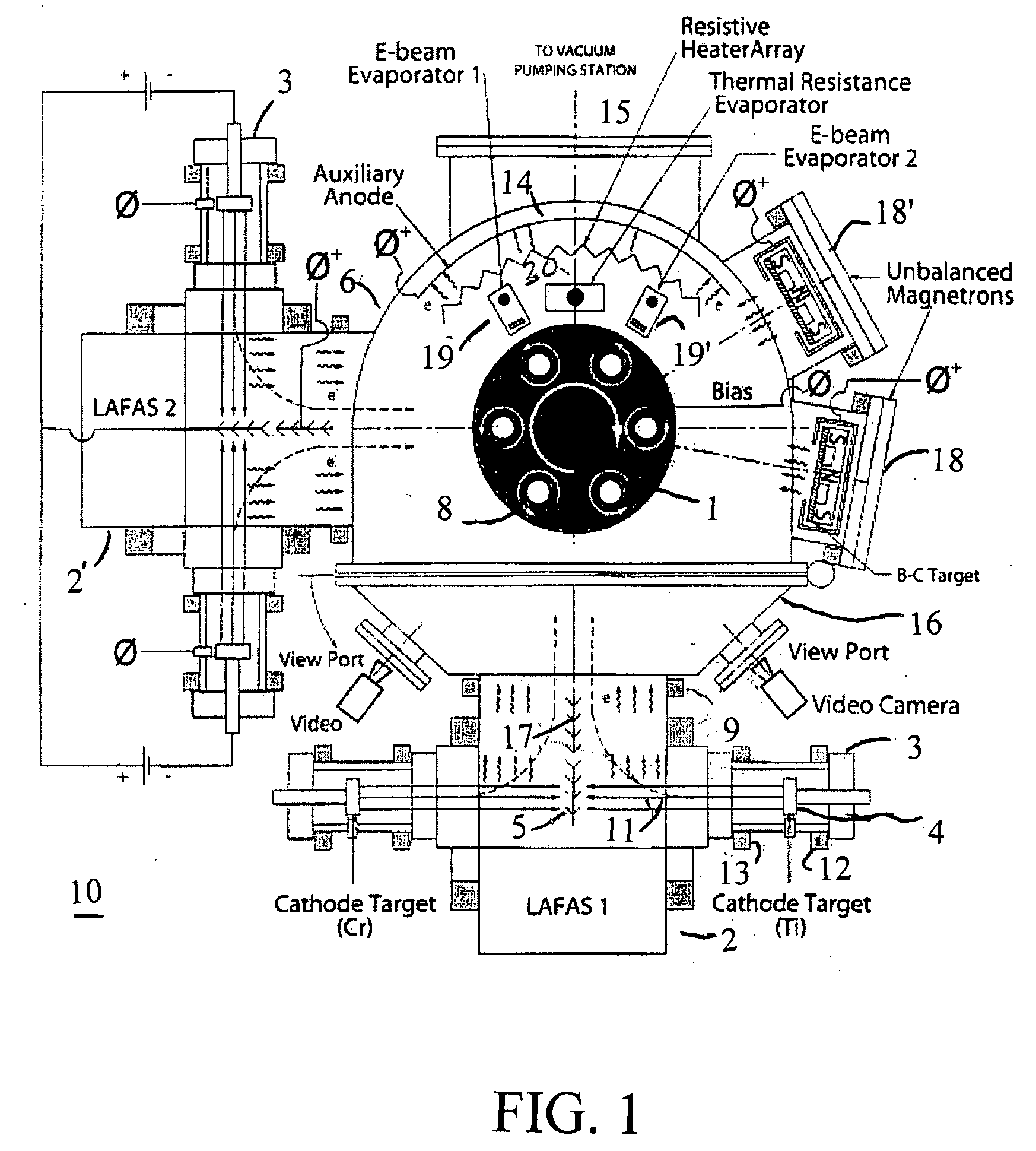

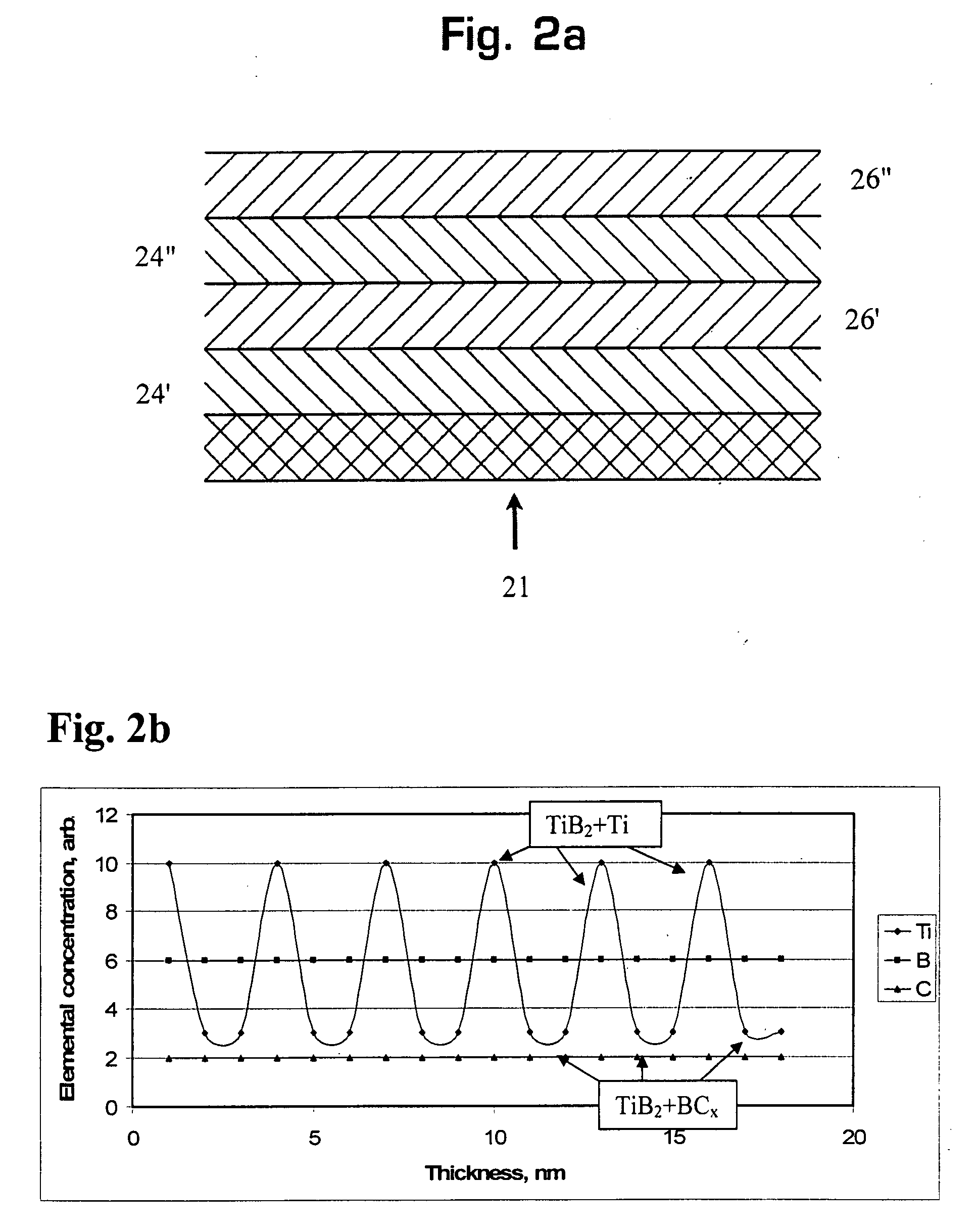

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

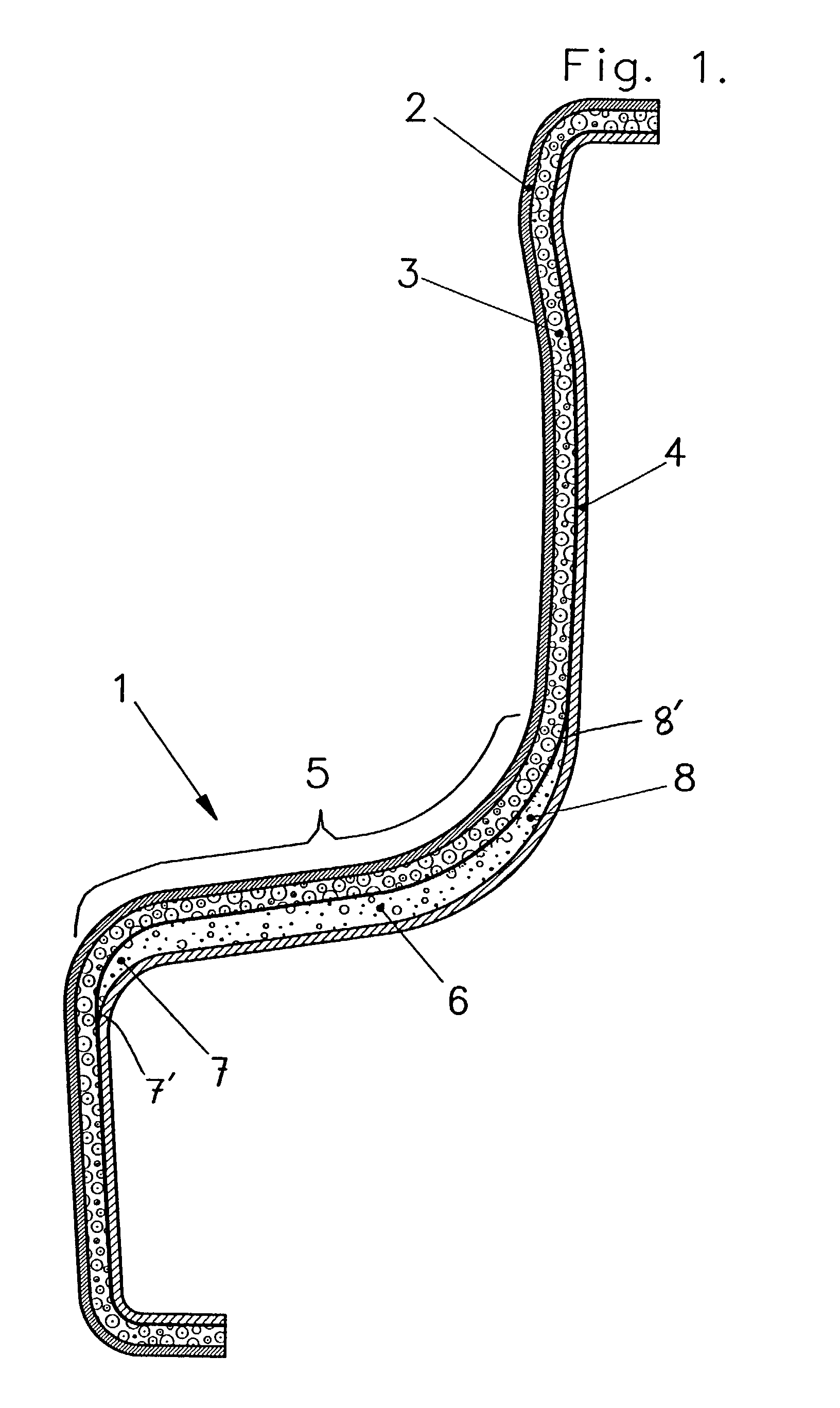

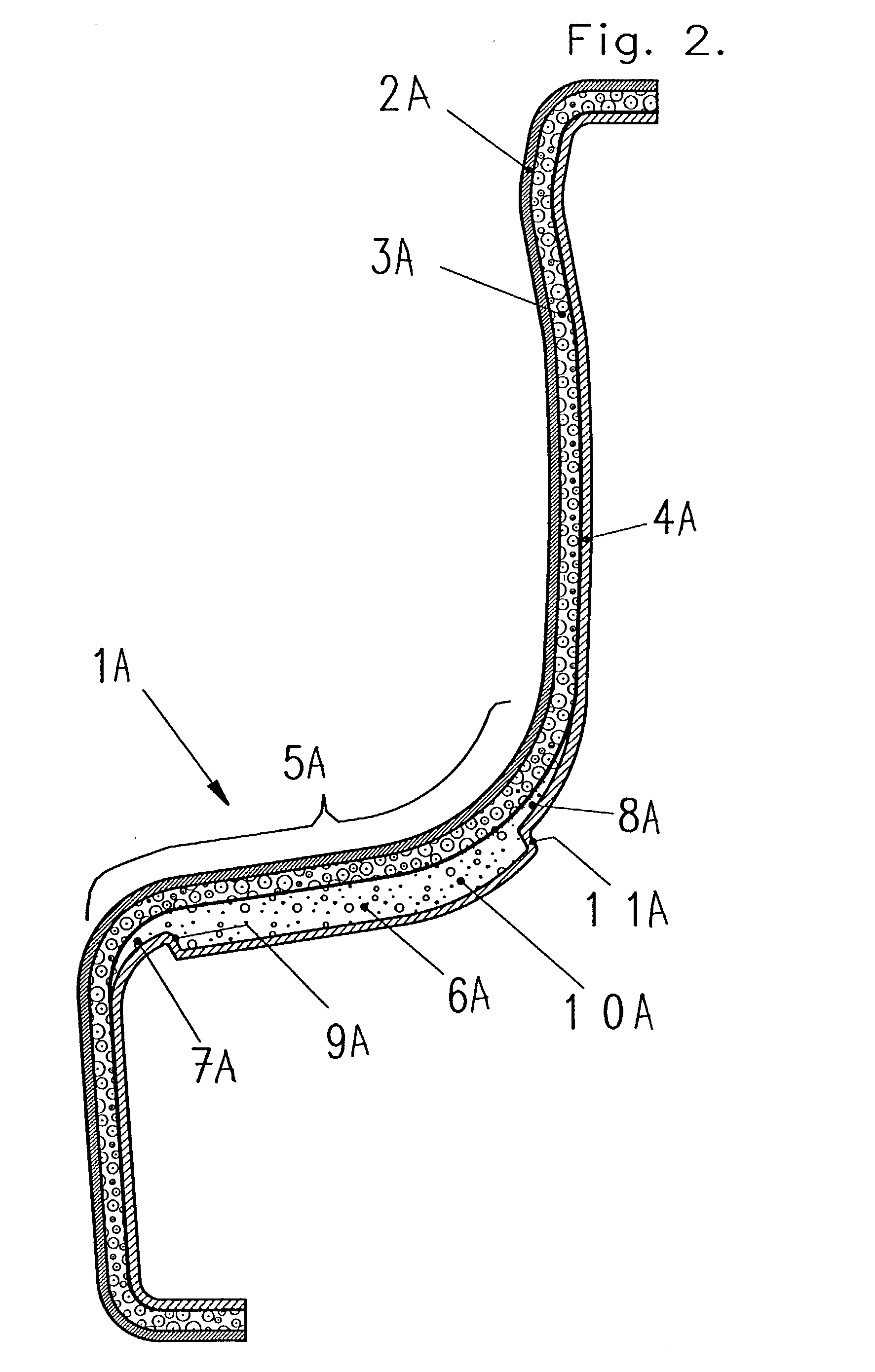

Method and apparatus for making a trim component with a foam core having a smoothly varying thickness

InactiveUS20030041955A1Guaranteed shock absorptionSoftness shockAdhesive processesEngine sealsThermoplasticPolymer science

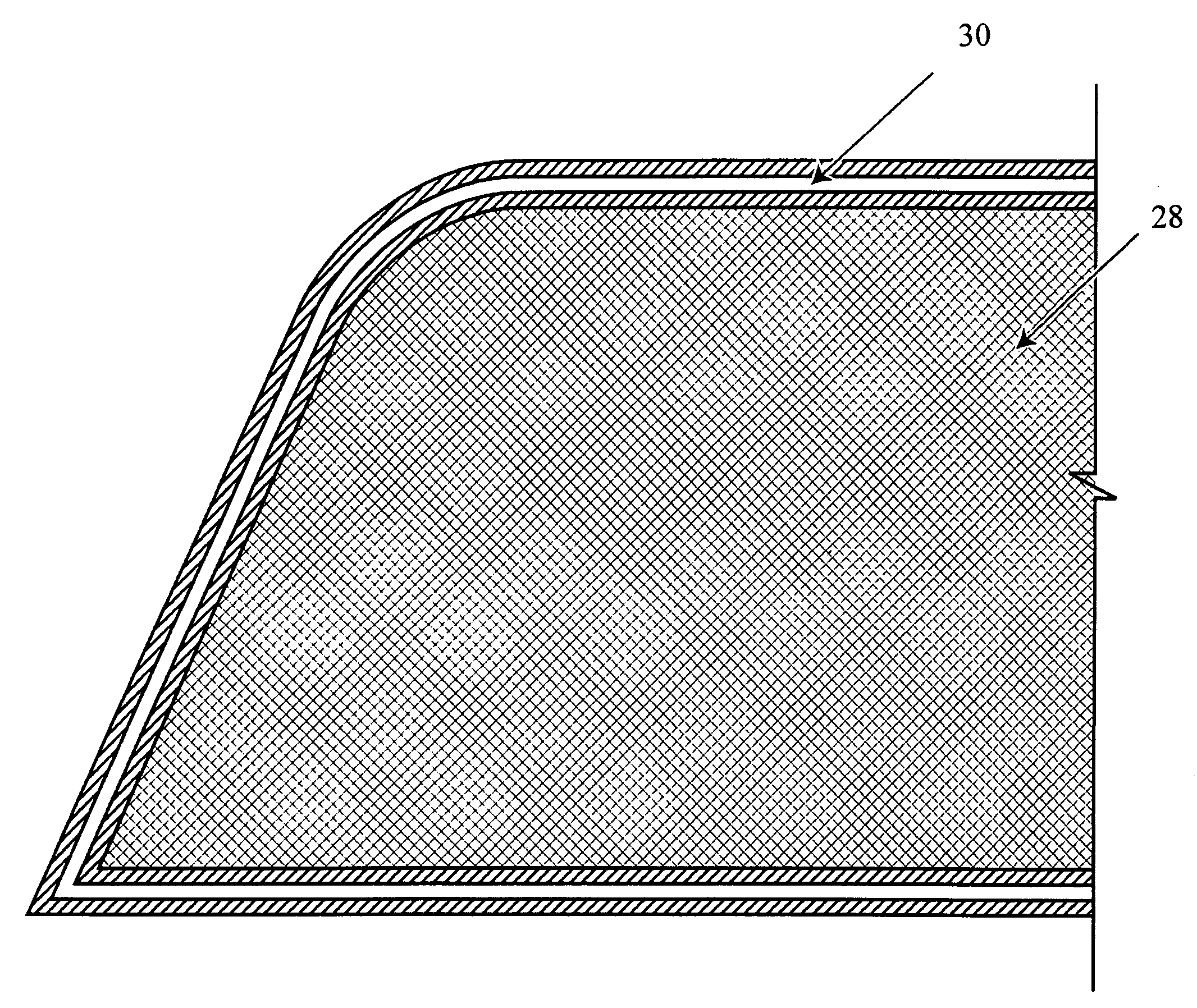

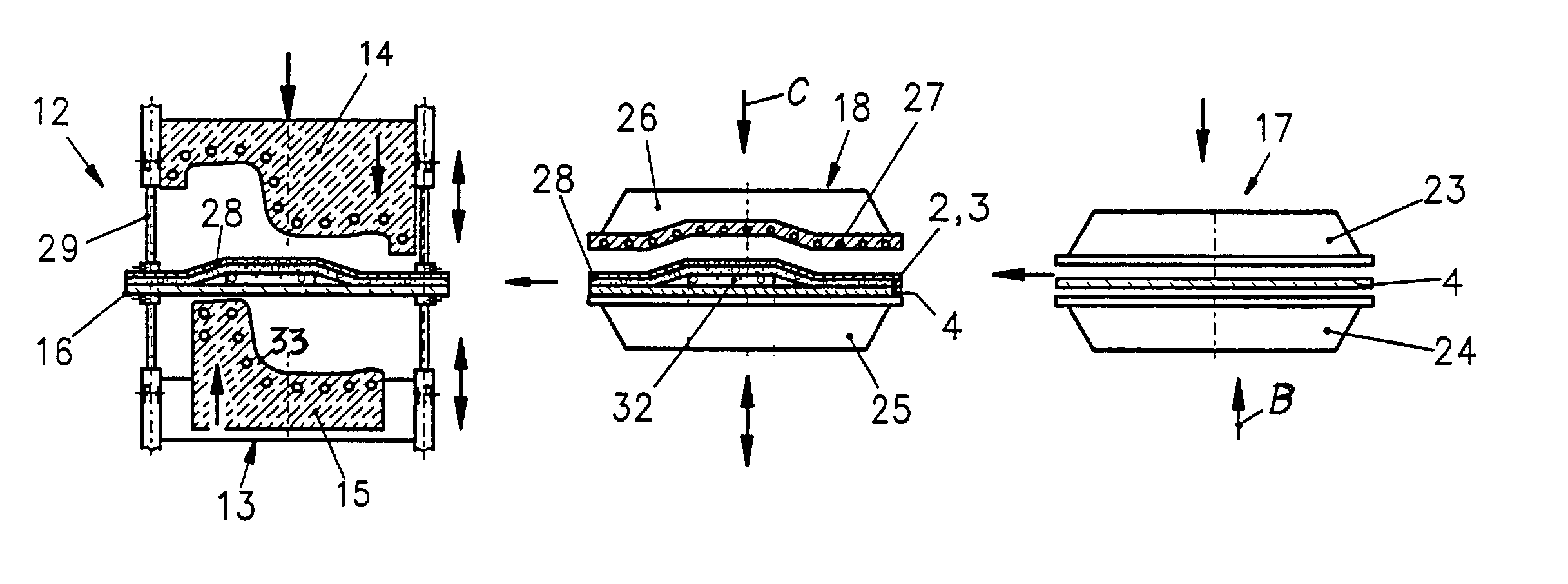

A trim component includes a foam backing layer and a foam pad insert laminated between a cover material and a substrate. The foam pad insert provides an area of enhanced cushioning, and has smoothly tapered edges to ensure a smooth surface contour without a visible edge transition on the cover material. The foam pad insert has a lower melting temperature than the foam backing layer, both of which are thermoplastics. A foam pad insert is positioned and fixed on the back surface of the foam backing layer. A substrate material is heated and then laminated and molded with the foam and the cover material. The heat from the substrate partially softens and melts the foam backing layer and the foam pad insert. The partially melted foam pad insert is viscously deformed to form the tapered edges, as dictated by the smoothly varying mold gap spacing of the forming tools.

Owner:HERBERT OLBRICH

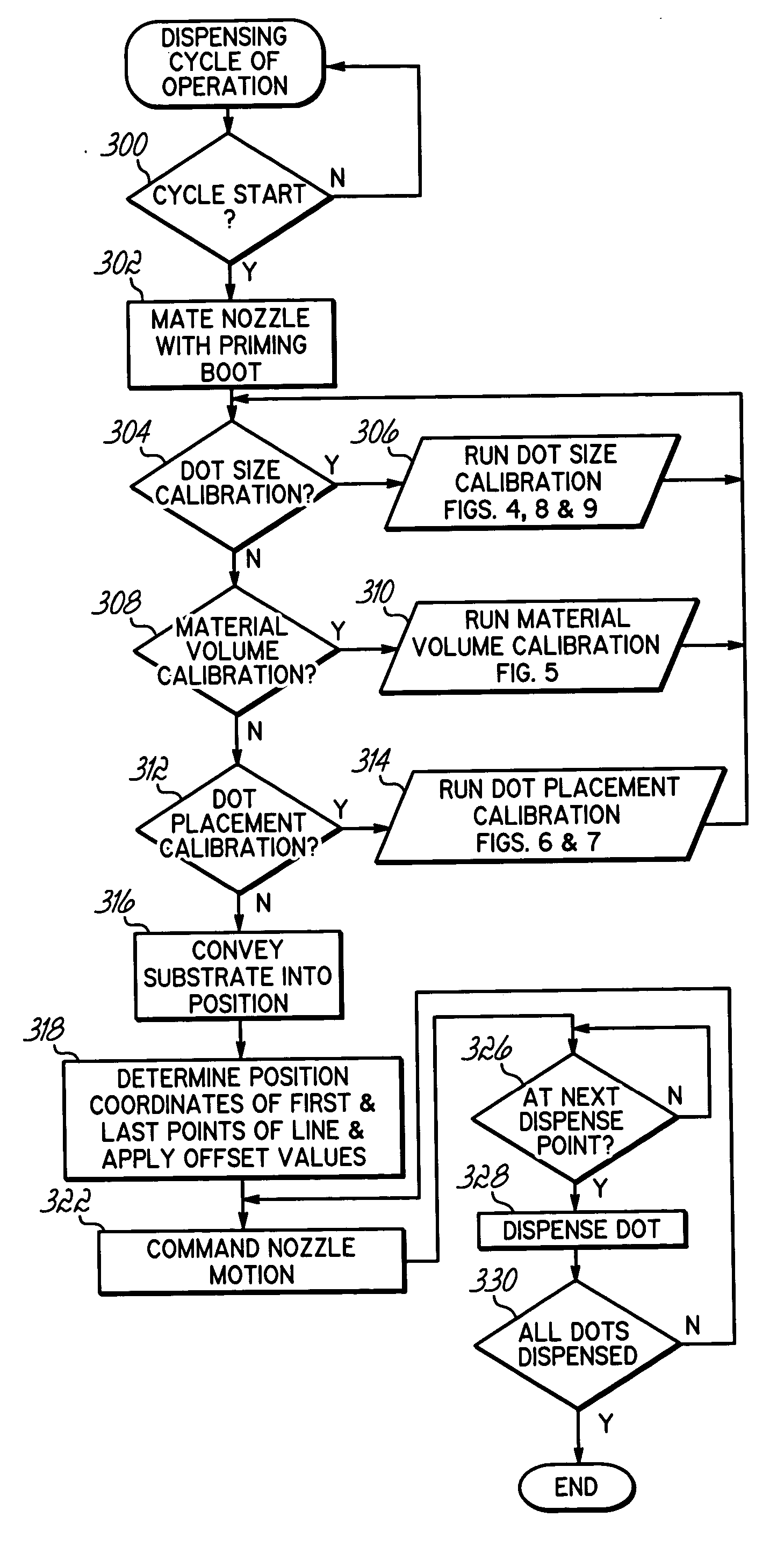

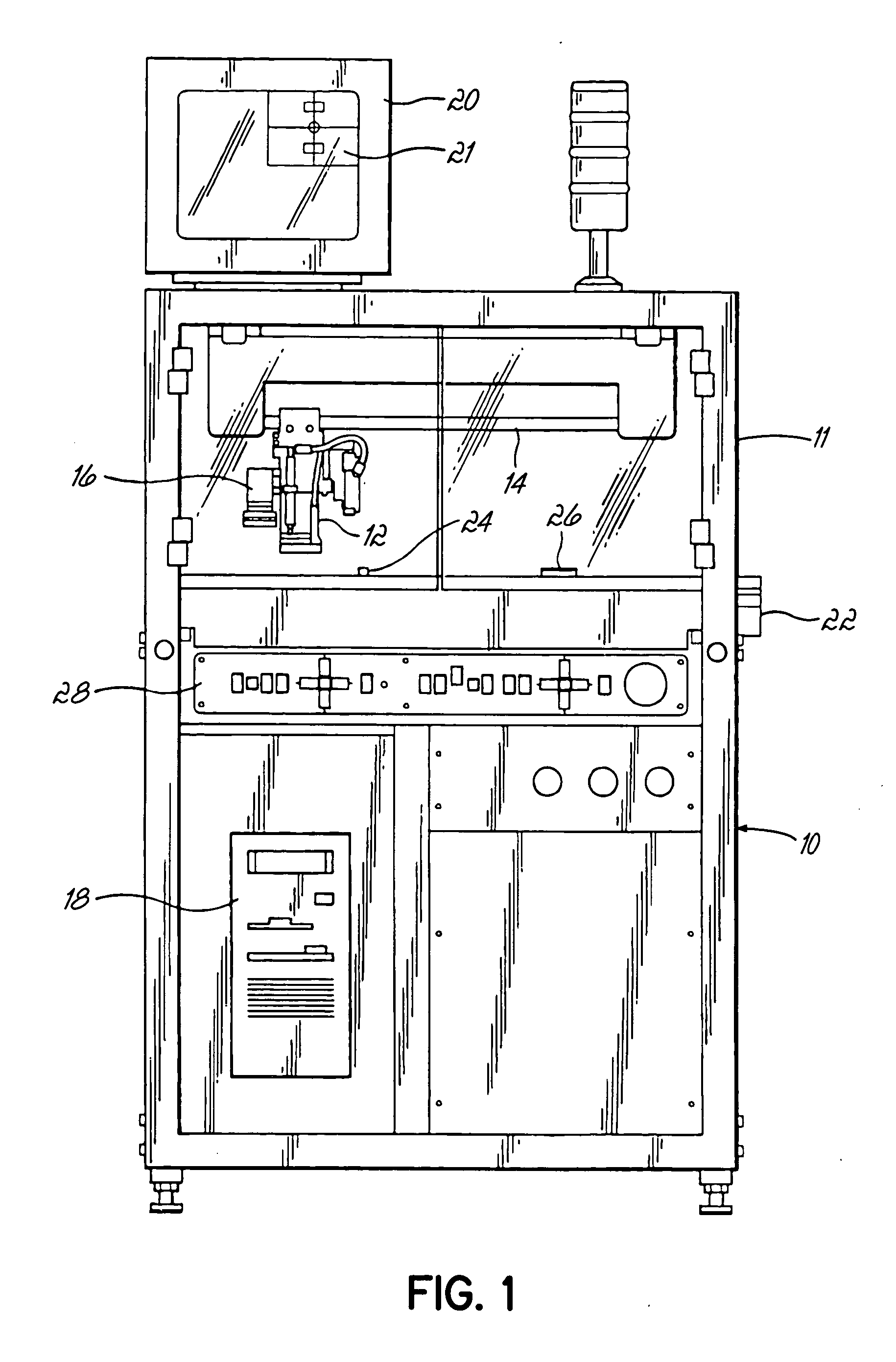

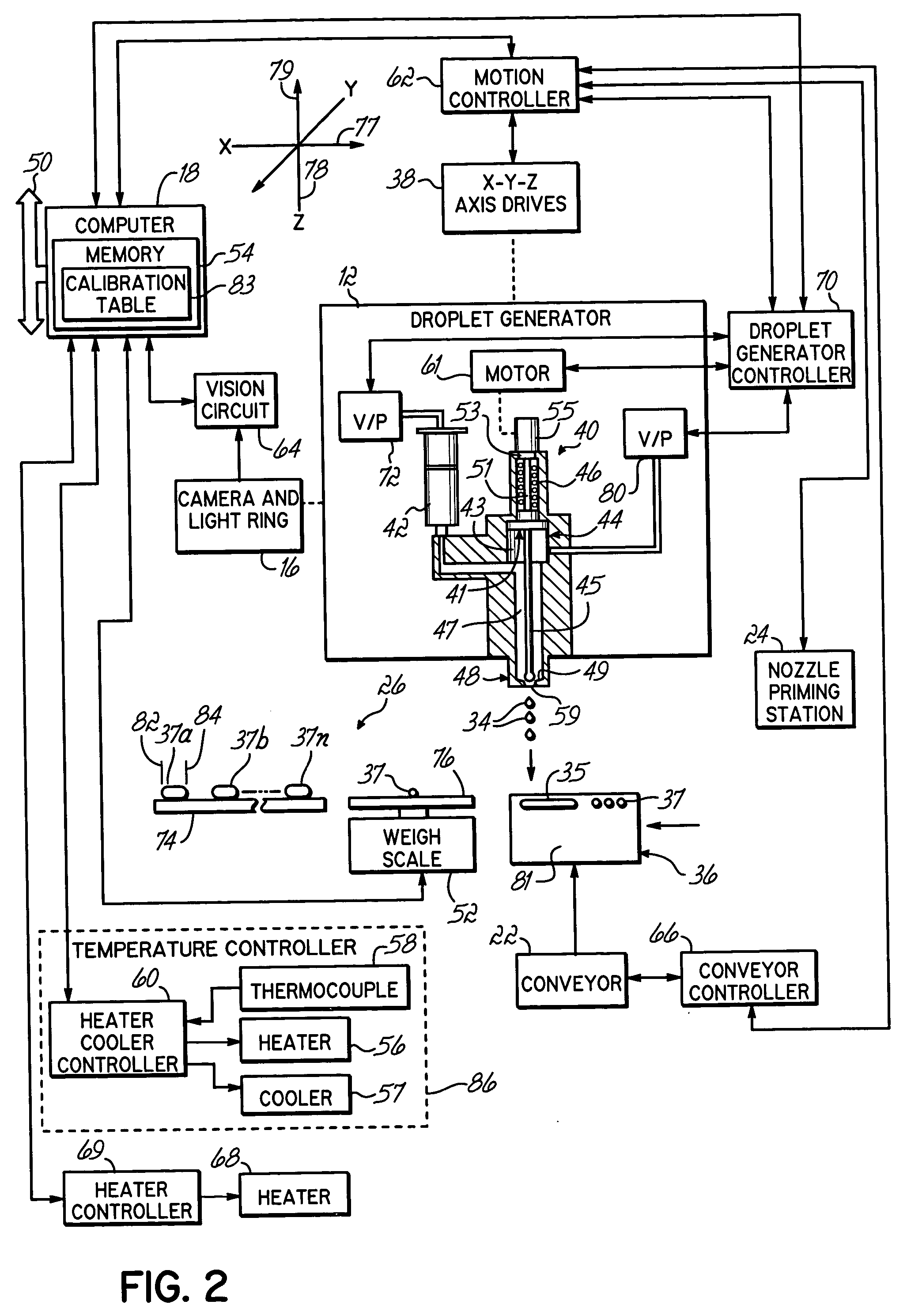

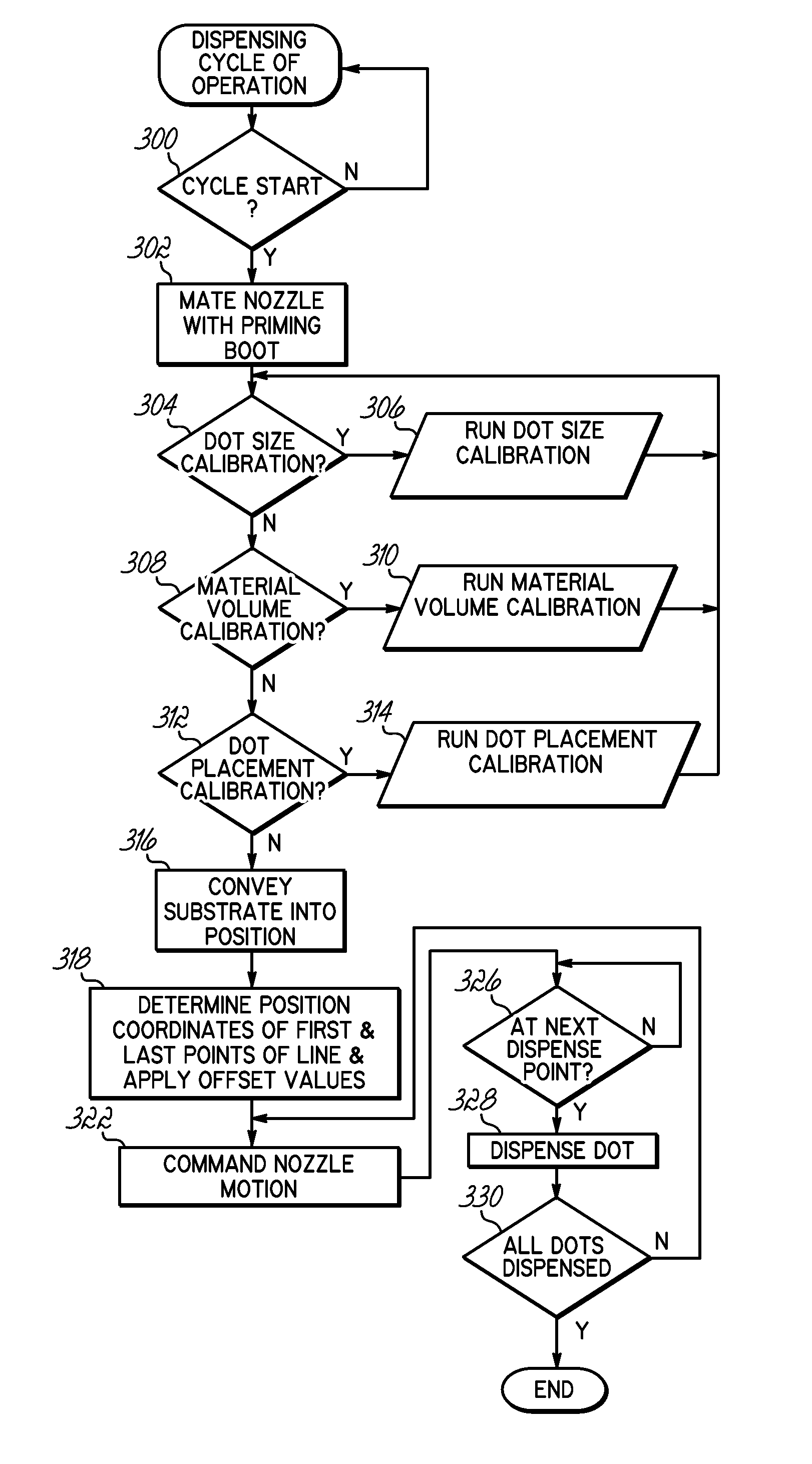

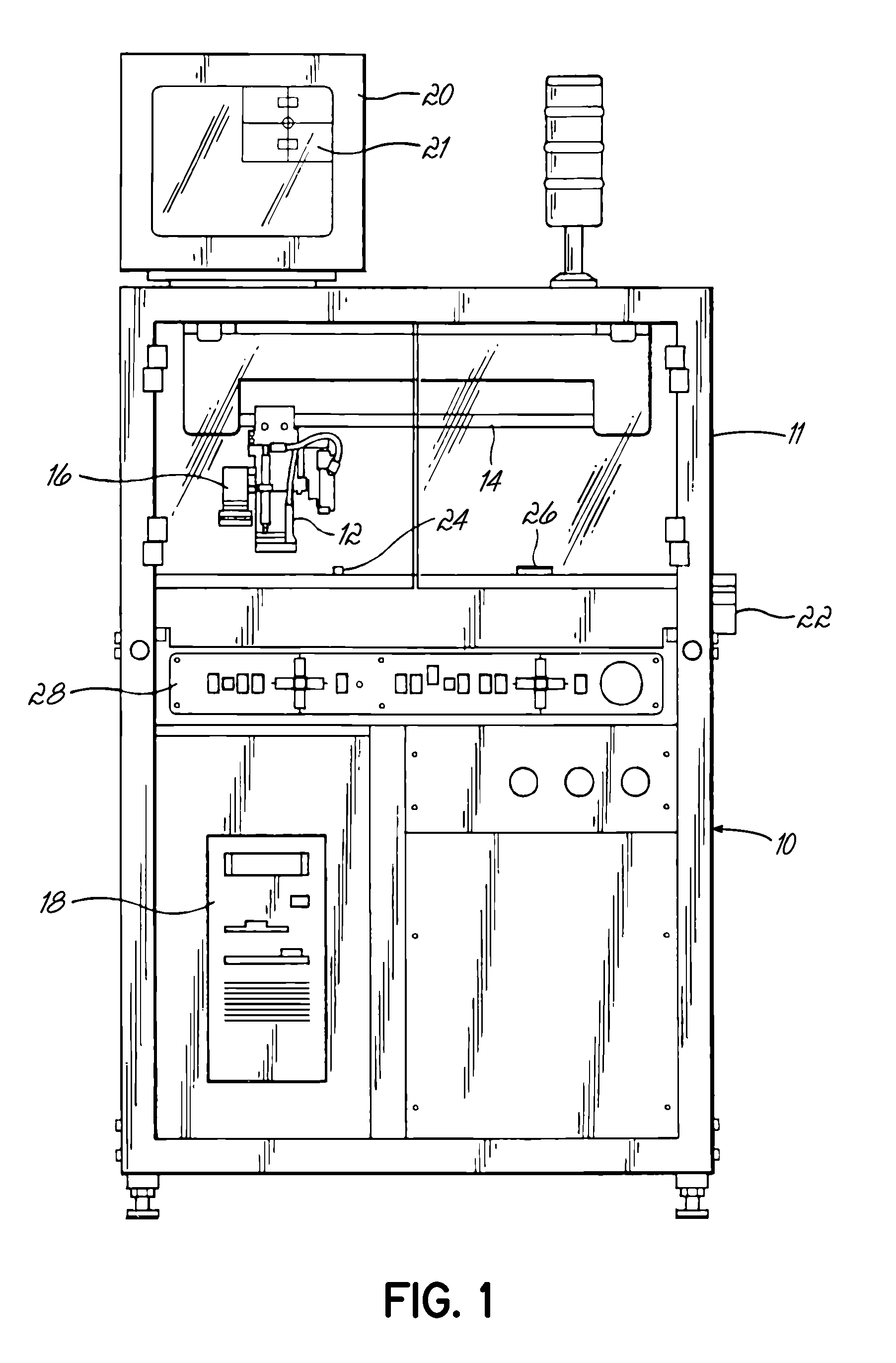

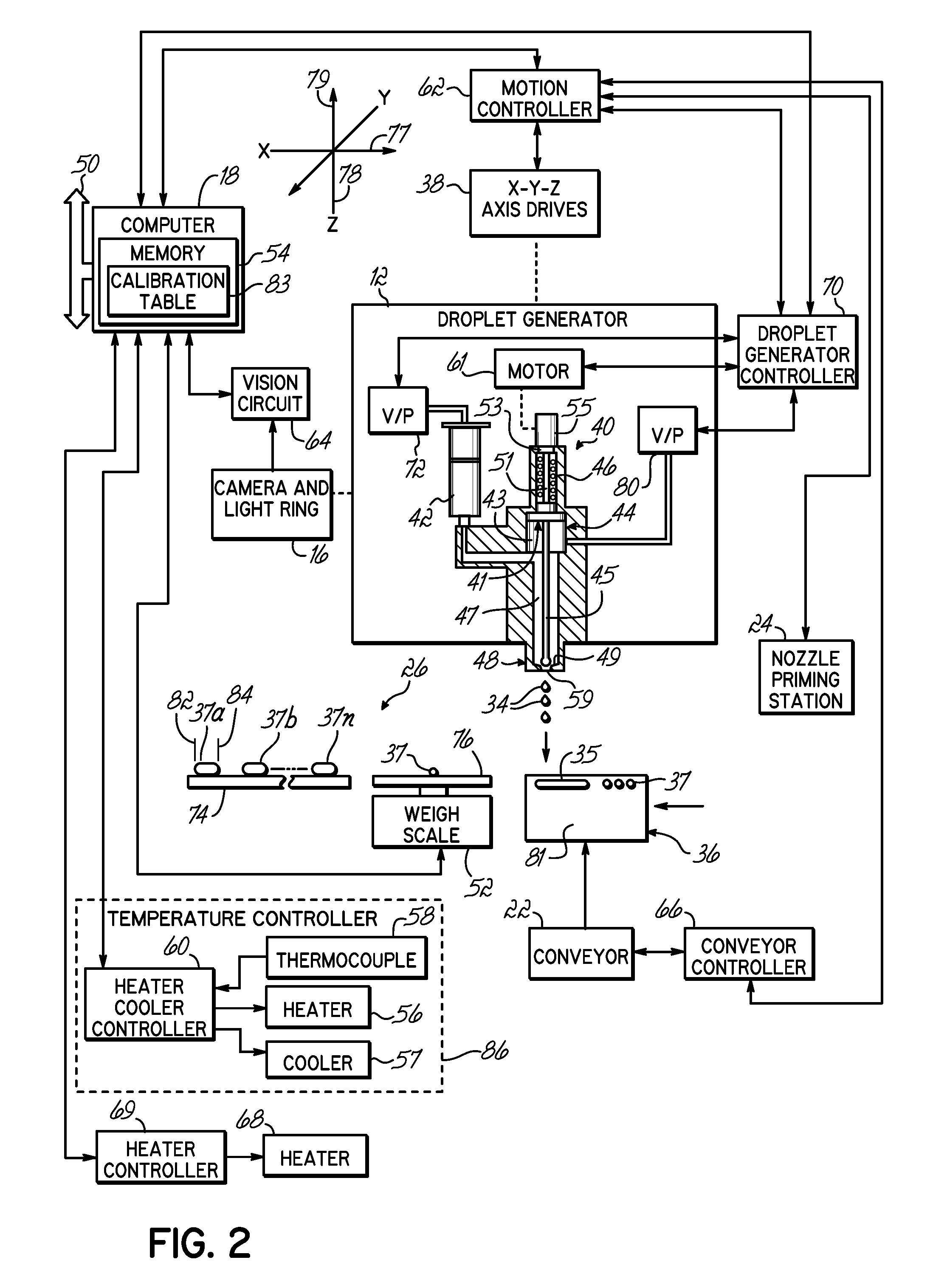

Viscous material noncontact jetting system

InactiveUS20050001869A1Precise applicationSimpler and less-expensivePrinted circuit assemblingSpraying apparatusEngineeringRelative motion

A viscous material noncontact jetting system has a jetting dispenser mounted for relative motion with respect to a surface. A control is operable to cause the jetting dispenser to jet a viscous material droplet that is applied to the surface as a viscous material dot. A device, such as a camera or weigh scale, is connected to the control and provides a feedback signal representing a size-related physical characteristic of the dot applied to the surface. The size-related physical characteristics of subsequently applied dots is controlled by heating and cooling, or adjusting a piston stroke in the jetting dispenser, in response to the size-related physical characteristic feedback. Dispensed material volume control and velocity offset compensation are also provided.

Owner:NORDSON CORP

Mixture containing fluororesin and prepreg prepared from same, and copper clad laminate

ActiveCN106854330AEasy to operateMild preparation conditionsSynthetic resin layered productsGlass/slag layered productsPolymer scienceResin matrix

The invention specifically relates to a mixture containing fluororesin and a preparation method thereof, belonging to the field of communication materials. A prepreg prepared by impregnating a glass fabric in dispersion liquid of the mixture containing fluororesin and then carrying out drying and the like has uniform glue content, good impregnation quality, strong resin adhesion, smooth surface and appropriate toughness and viscosity. The invention also relates to a high-frequency copper clad laminate prepared from the prepreg, or a film or copper foil made of the mixture containing fluororesin. The prepared copper clad laminate has good thermal-mechanical properties, excellent dielectric properties and high copper foil strength, and can meet requirements on the comprehensive properties of substrate materials in the field of high-frequency communication. According to the invention, the processing properties of traditional fluororesin are greatly improved by using fluorine-containing resin with a low melting point; and a coupling agent is cooperatively used, so interaction between an inorganic filling material and glass fabric and a resin matrix is improved, dispersibility of the inorganic filling material, processing aids and the like in the fluororesin is enhanced, and the overall performance of the copper clad laminate is made more stable.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

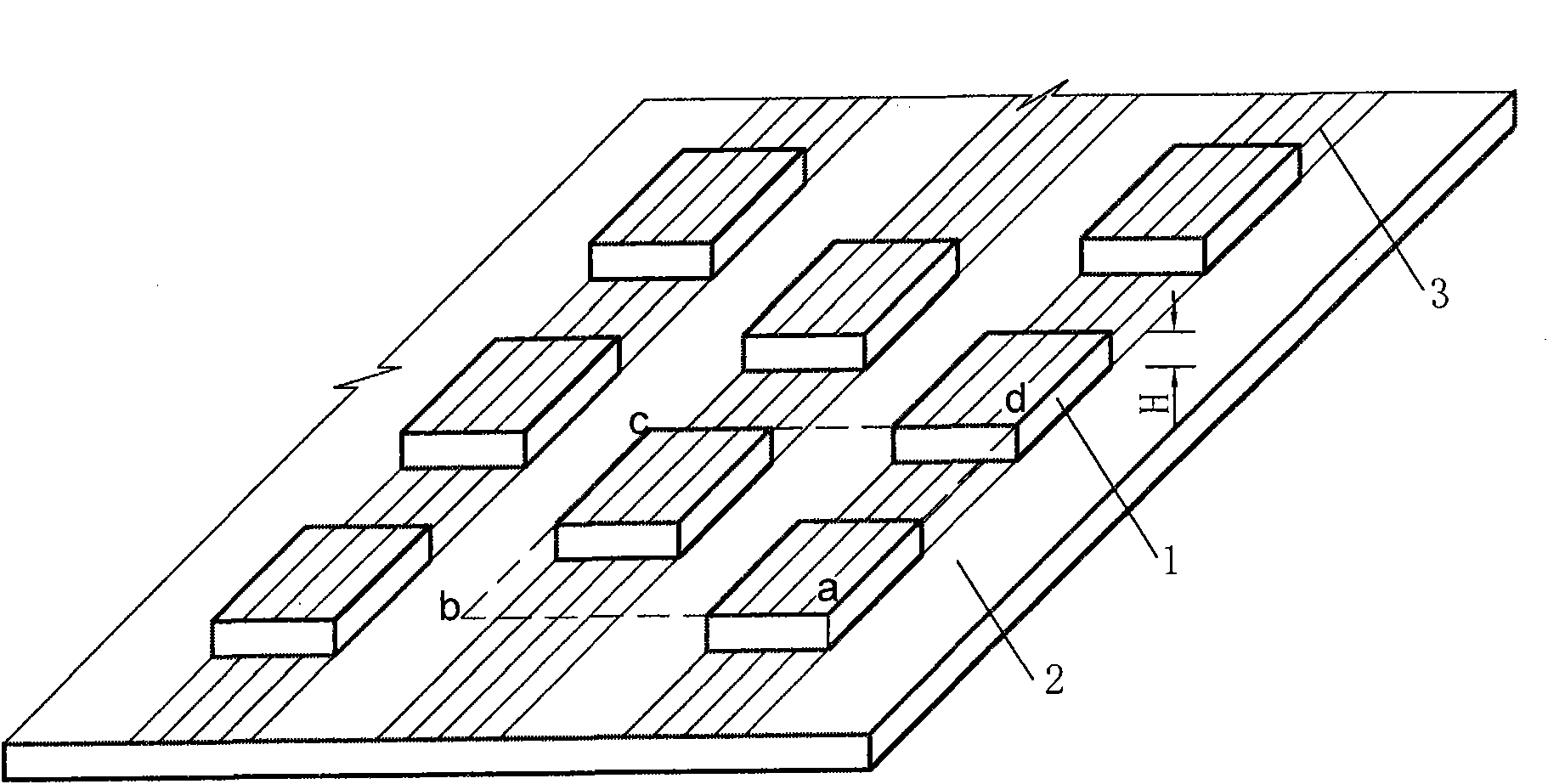

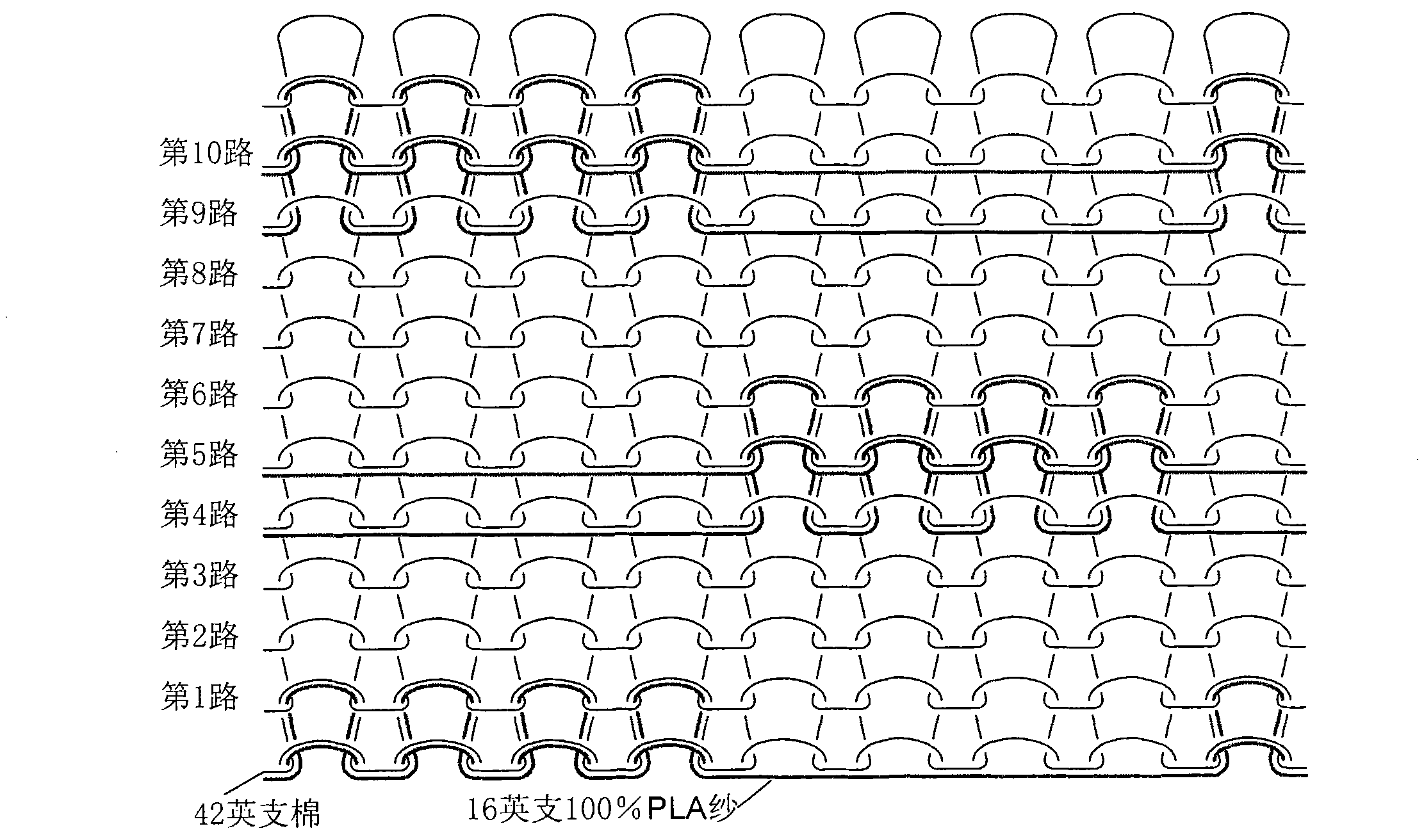

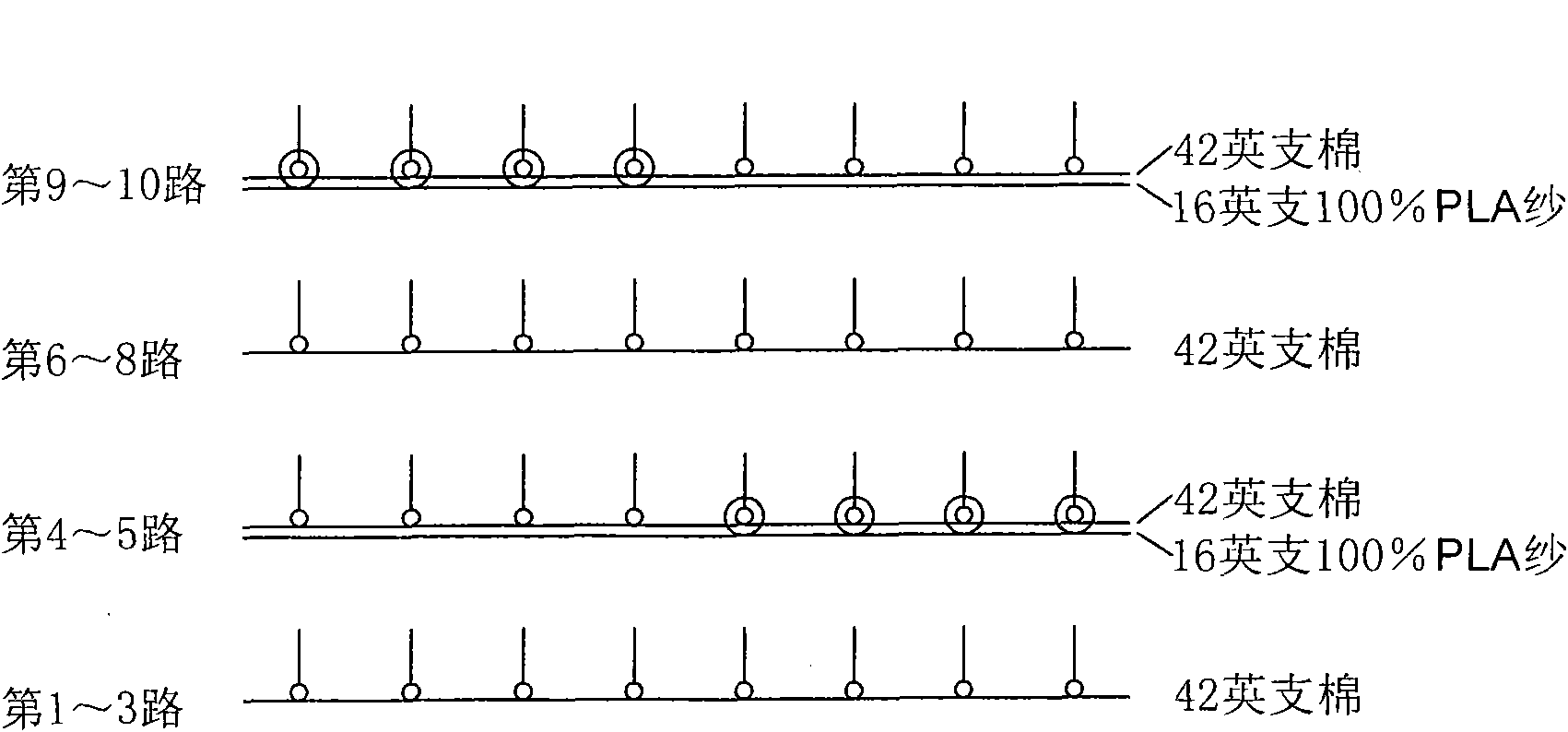

Fabric with function of bidirectional adjustment of heat humidity

The invention discloses a fabric with a function of bidirectional adjustment of heat humidity. In contact with skin, one side of the fabric is a lining that is woven from yarns with official moisture regain below 2%; the other side of the fabric is a surface layer and woven from yarns with official moisture regain above 8%; the lining of the fabric adopts a structure projecting towards the skin side; and the projecting area accounts for 10-60% of the total area of the fabric, and the projecting height is 0.12-1.0mm. The benefits of the fabric are as follows: effectively transmitting thermal heat in a moving state, bringing good thermal insulation effect into play in a static state no matter whether underwear is dry or wet by sweat, consequently preventing sweat upon movement and cold caused by clamminess after sweating, and being stable in performance of eliminating sweat. The fabric can be made into underwears, is especially suitable for use in multilayer dressing, or in high humidity and other situations similar to multilayer dressing. The fabric can also be made into other products such as pillow towels, sweat towels, saliva towels, bandeaux, wrist straps and the like.

Owner:朱建荣

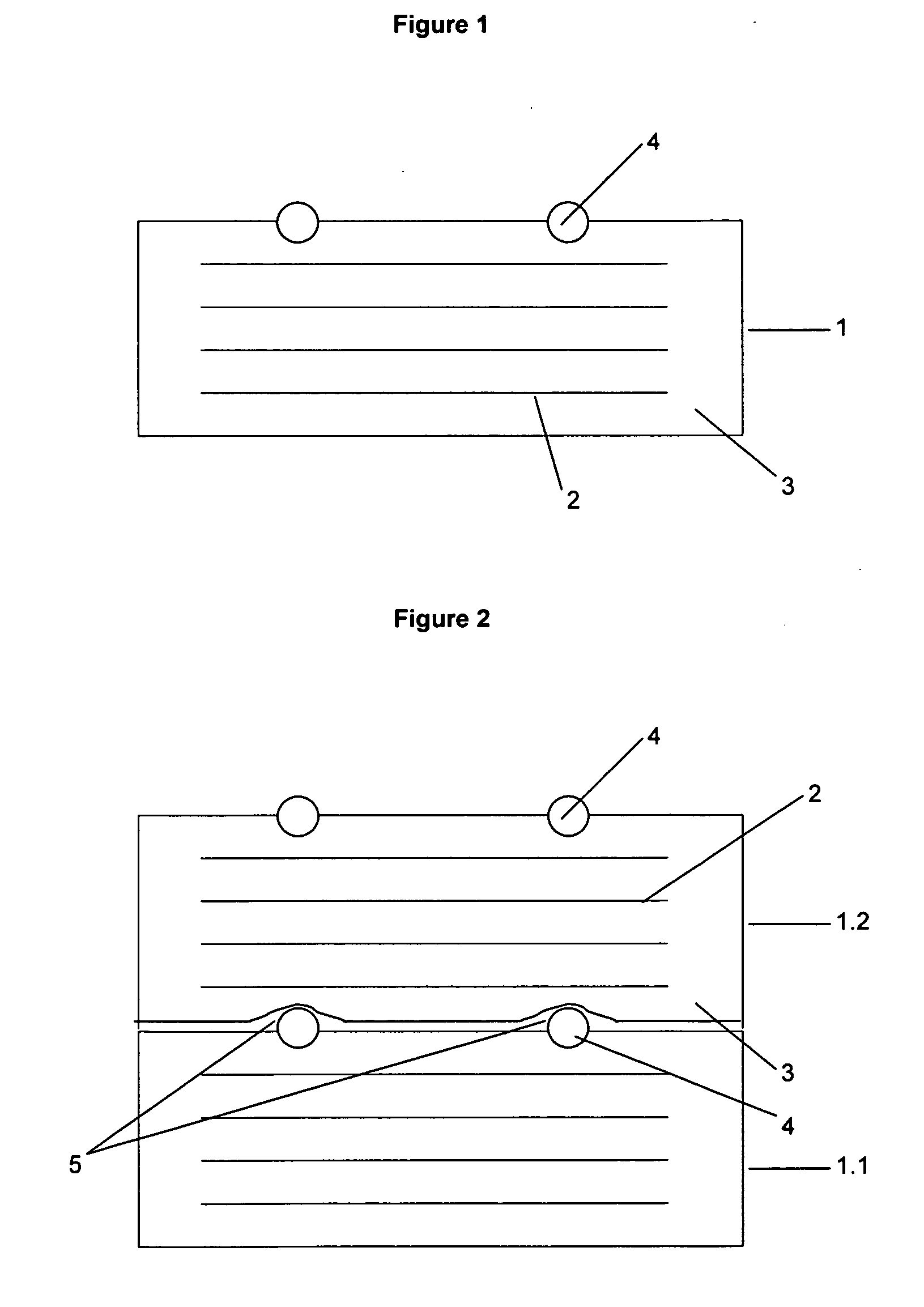

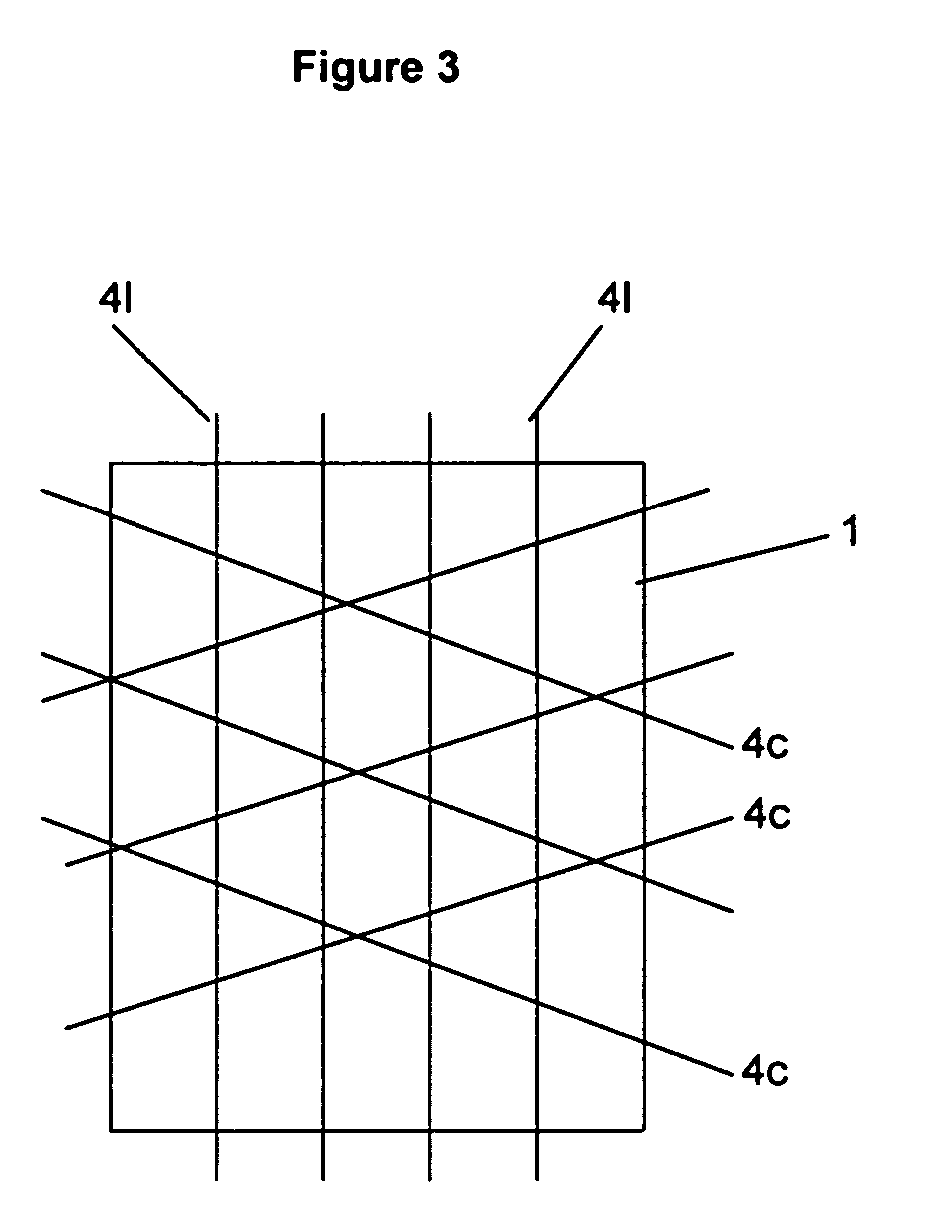

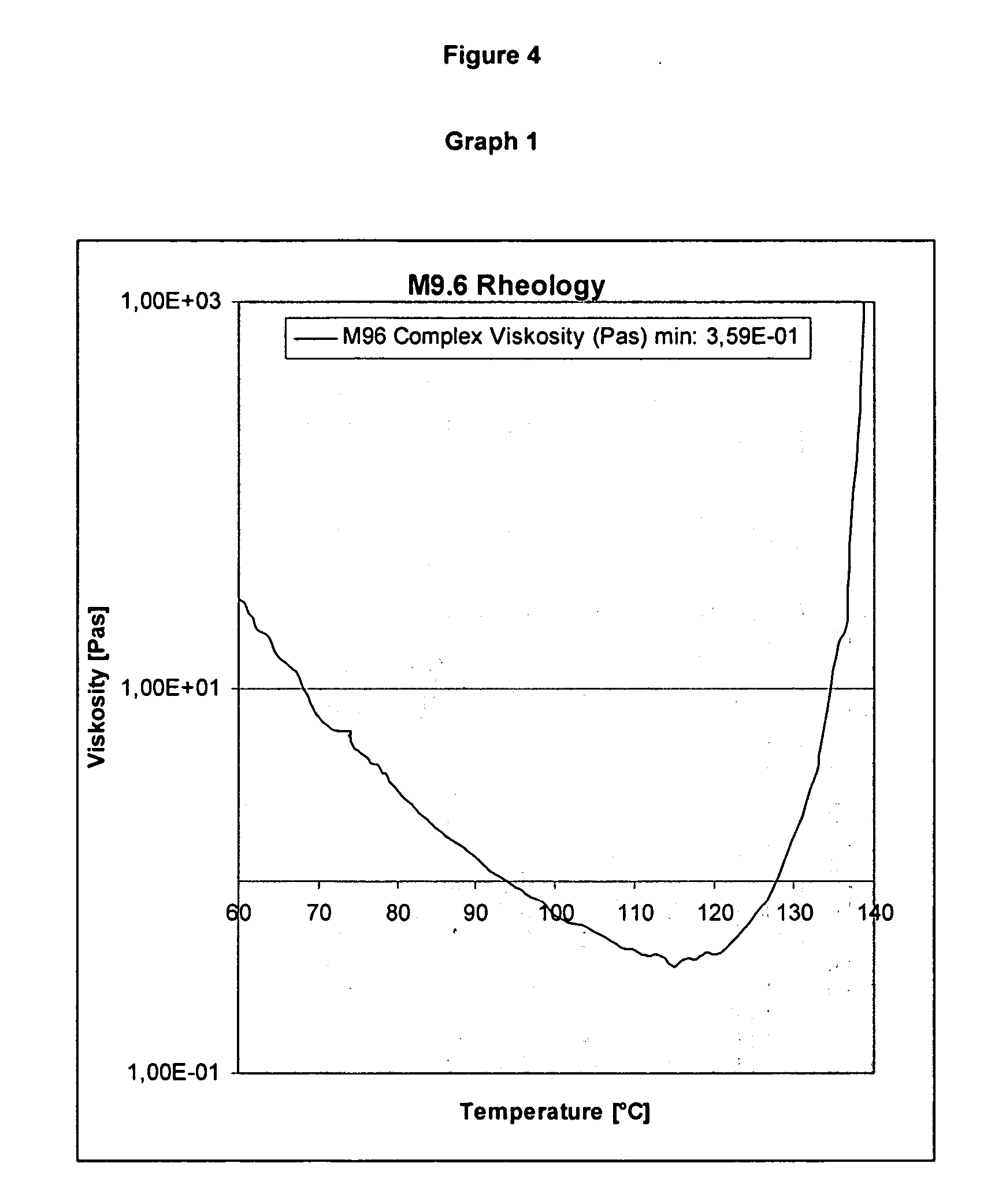

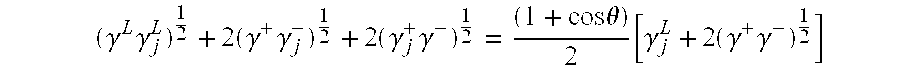

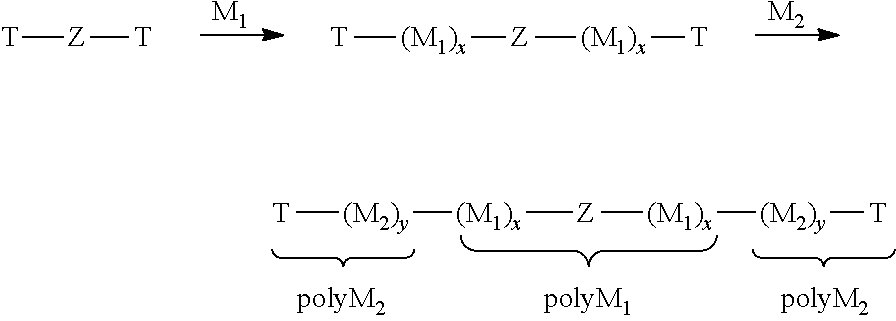

Prepregs for use in building lay-ups of composite materials and processes for their preparation

InactiveUS20050255766A1Reduction in laminate void levelImprove mechanical propertiesSynthetic resin layered productsLaminationPorosityViscosity

The invention concerns a process for making a scrim-reinforced prepreg for use in building low-porosity lay-ups, characterized in that a conventional prepreg is formed of a fibrous reinforcement and a heat-curable resin, the prepreg having suitable viscosity and sufficient tackiness to hold a scrim which is adhered to the prepreg by applying light pressure, so that the scrim is impressed onto the prepreg to such a degree, that less than half of the circumference of the scrim strands becomes coated by the prepreg-resin.

Owner:HEXCEL HLDG

Biaxially-oriented polyester film for fabrication and method of producing the same

InactiveUS6905774B2Improve hygieneEnhancing carnauba wax dispersion propertySynthetic resin layered productsSpecial tyresPolyesterHeat resistance

Biaxially-drawn polyester film for fabrication which is characterized in that it is a film comprising polyester in which ethylene terephthalate units and / or ethylene naphthalate units are the chief structural component, and the melting point of said film is 180-270° C., the angle of contact to water is 70°-120°, and the planar orientation coefficient is 0.08-0.15. This film shows outstanding release properties following repeated use, use after fabrication and use in an aqueous environment and, furthermore, it exhibits stable properties with little variation and, in particular, following lamination to metal sheet such as steel or aluminium, when used as the inner face of a fabricated metal can, it is outstanding in its non-stick properties to the contents, and provides a combination of heat resistance and processability.

Owner:TORAY IND INC

Recipe and prepn. method for application metals-ceramics composite materials as super hardness abrasive tool bond

InactiveCN1903485AOvercome the shortcomings of insufficient toughnessDimensional and shape stableSuperhard materialCeramic composite

Owner:国庆

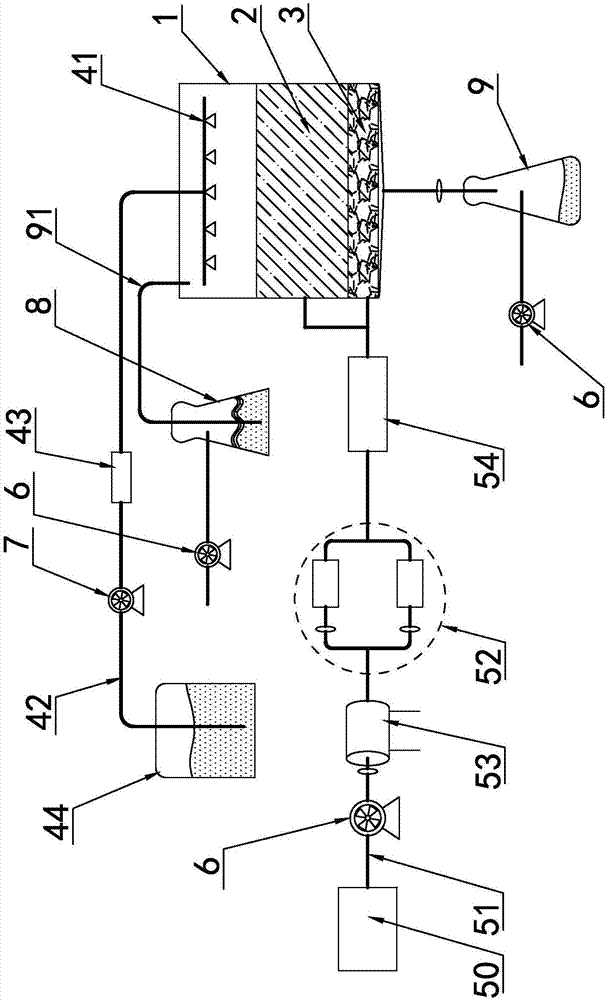

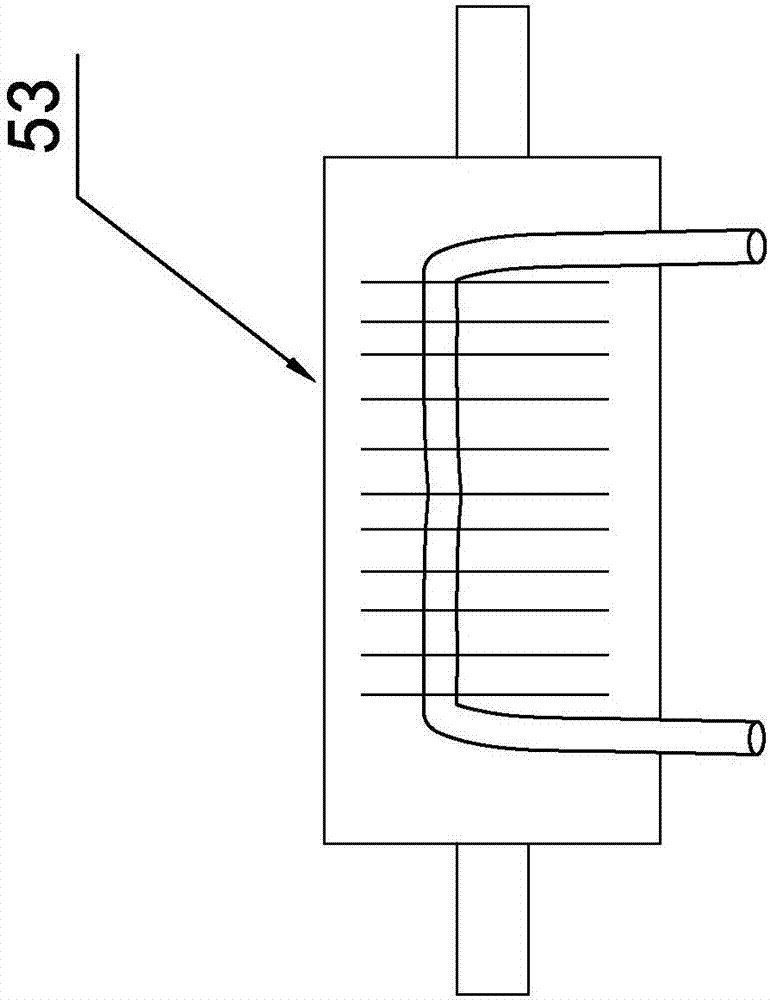

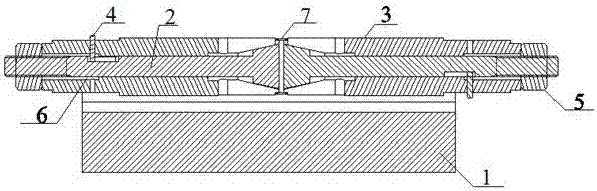

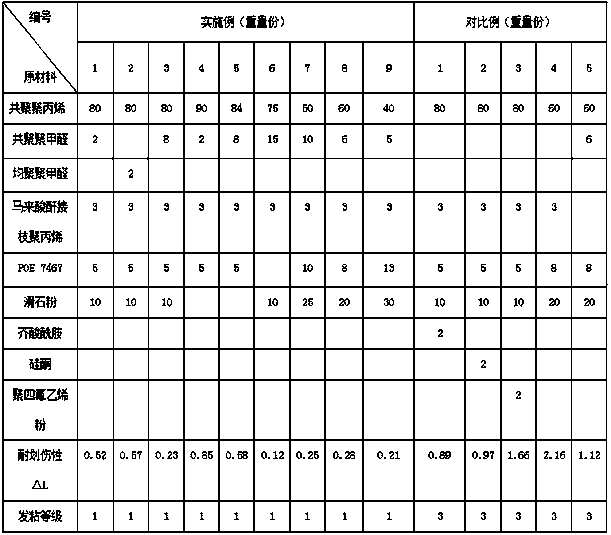

Pneumatic type coupling system for preparing large remolded clay and performing one-dimensional consolidation test

ActiveCN104596817AAvoid interferenceAvoid cumbersomePreparing sample for investigationMaterial strength using tensile/compressive forcesWater dischargeWater volume

The invention discloses a pneumatic type coupling system for preparing large remolded clay and performing one-dimensional consolidation test, which can be used for preparing a large-size cylindrical sample or hollow cylindrical sample of remolded clay in geotechnical engineering, and also can be used for performing one-dimensional consolidation test of a large clay sample. The pneumatic type coupling system comprises a displacement measuring system, a combined pressure cavity, a pore-pressure measuring system, a discharged-water volume measuring system, a pneumatic loading system and an axial tightening member. The pneumatic type coupling system disclosed by the invention has the advantages that the loading is carried out by a pneumatic mode, the pressurization is stable, uniform, measurable and controllable, the loading pressure can be more than 1.6MPa and the defect of difficult application of high pressure in weight loading is effectively overcome; a vertical metal permeable stone is embedded into a rigid and transparent sleeve to form a vertical water discharging channel, so that the defects of single water discharging channel and slow consolidation speed of traditional consolidation equipment are overcome; the pressure cavity of the pneumatic type coupling system is the rigid and transparent sleeve, so that the pneumatic type coupling system has visibility and overcomes the defect of invisibility of a traditional consolidometer.

Owner:WENZHOU UNIVERSITY

Pipe material modified with ultrahigh molecular weight polyethylene and its prepn

The present invention is modified ultrahigh molecular weight polyethylene pipe material and its preparation process. The modified ultrahigh molecular weight polyethylene pipe material consists of ultrahigh molecular weight polyethylene 105-165 weight portions, polyethylene wax 3-7 weight portions, graphite 1.2-4 weight portions, hollow glass bead 3-10 weight portions, antistatic agent 1.2-4.5 weight portions and flame retardant 1.8-5.6 weight portions. It has tensile strength higher than 46 MPa. Its preparation process includes the steps of compounding material, mixing, heating, extruding, forming, biaxial tension, cooling to settle and cutting. The modified ultrahigh molecular weight polyethylene pipe material has low cost, high wear resistance, excellent self-lubricating performance, high impact strength, excellent fire resistance, etc.

Owner:王好占

Viscous material noncontact jetting system

InactiveUS7939125B2Precise applicationFast response timePrinted circuit assemblingMovable spraying apparatusRelative motionPiston

A viscous material noncontact jetting system has a jetting dispenser mounted for relative motion with respect to a surface. A control is operable to cause the jetting dispenser to jet a viscous material droplet that is applied to the surface as a viscous material dot. A device, such as a camera or weigh scale, is connected to the control and provides a feedback signal representing a size-related physical characteristic of the dot applied to the surface. The size-related physical characteristics of subsequently applied dots is controlled by heating and cooling, or adjusting a piston stroke in the jetting dispenser, in response to the size-related physical characteristic feedback. Dispensed material volume control and velocity offset compensation are also provided.

Owner:NORDSON CORP

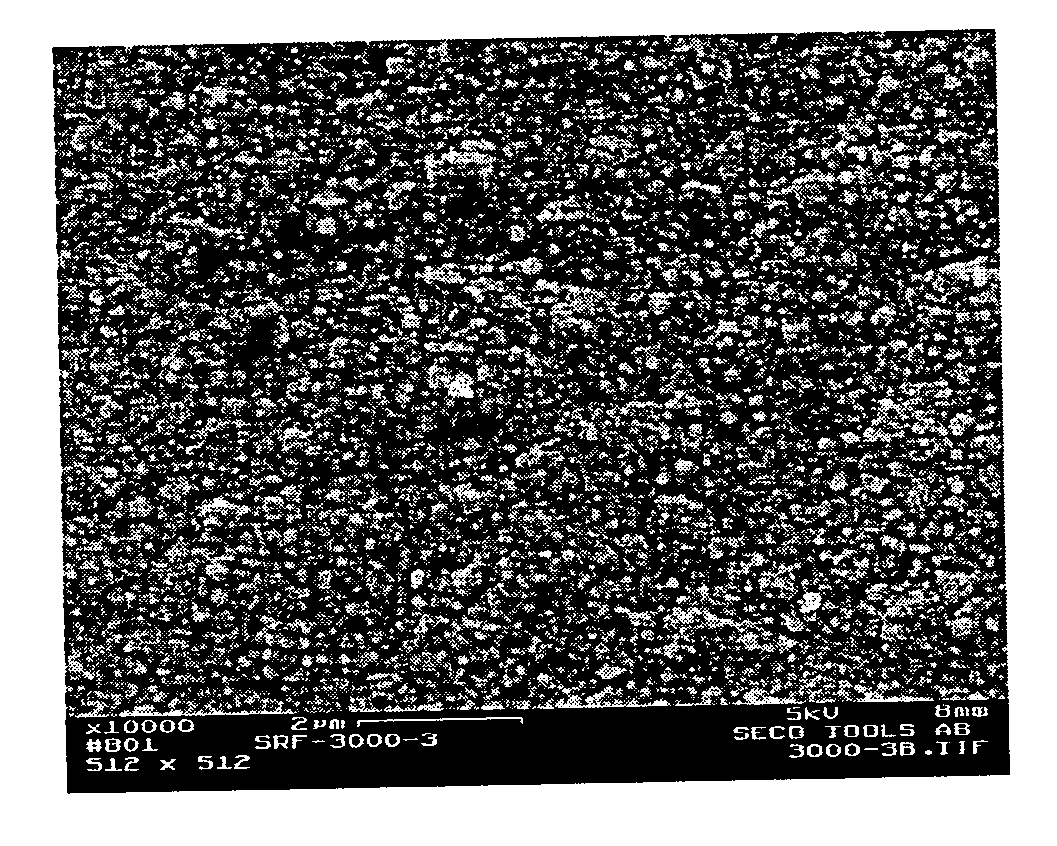

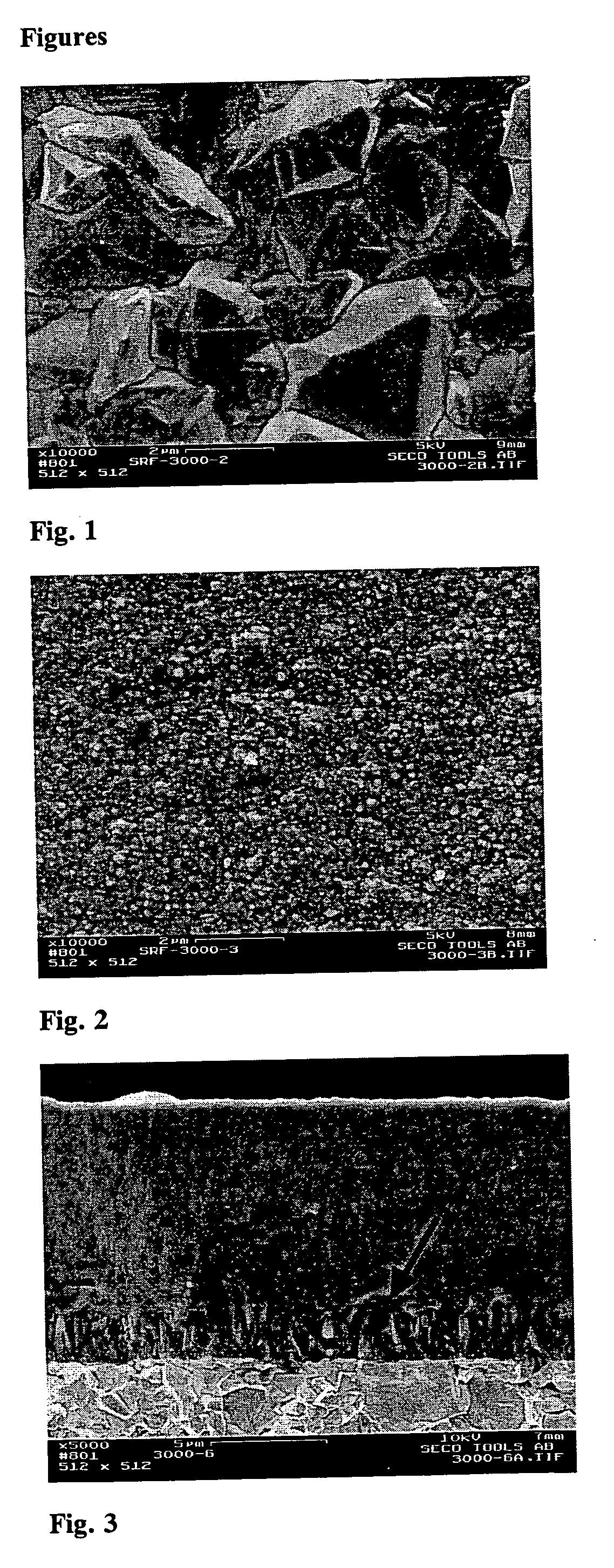

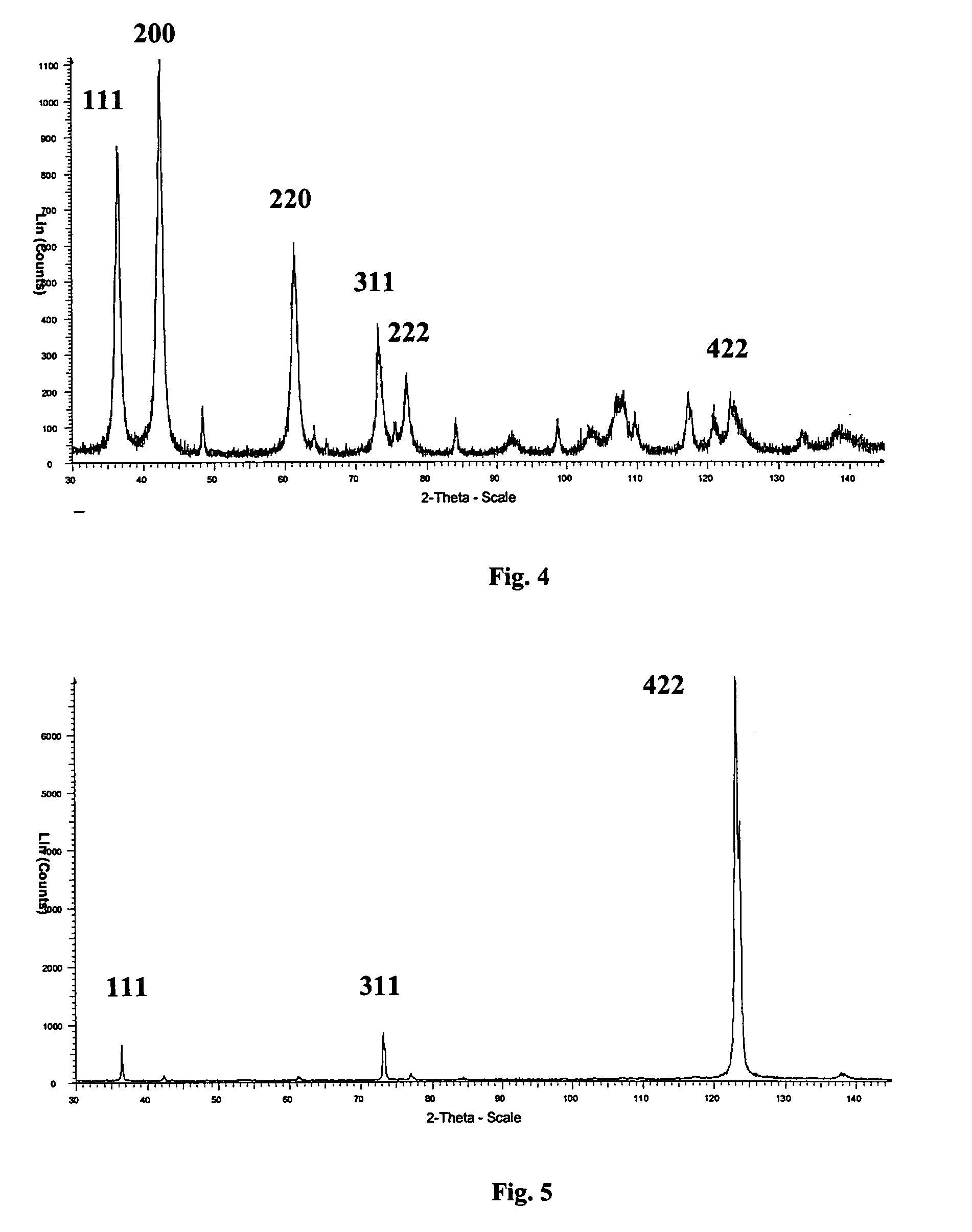

Coating with controlled grain size and morphology for enhanced wear resistance and toughness

InactiveUS20040265541A1Reduce grain sizeImprove toughnessPigmenting treatmentOther chemical processesGranularityWear resistance

Wear resistance of the prior-art Ti(C,N) layers can be considerably enhanced by optimising the grain size and microstructure. This invention describes a method to obtain controlled, fine, equiaxed grain morphology in Ti(C,N) layers produced using moderate temperature CVD (MTCVD). The control of the grain size and shape can be obtained by doping using CO, CO2, ZrCl4 and AlCl3 or combinations of these. Doping has to be controlled carefully in order to avoid nanograined structures and oxidisation. This kind of coatings shows new enhanced wear properties. The fine grain size together with equiaxed grain morphology enhances the toughness of the coating with at least maintained wear resistance, which can be seen especially in sticky steels like stainless steels. The optimum grain size is from about 50 to about 300 nm, preferably from about 50 to about 150. The coatings according to this invention are characterised by the lack of any strong preferred growth orientation, the length-to-width ratio (L / W) around 1 and only with a slight to moderate XRD line broadening.

Owner:SECO TOOLS AB

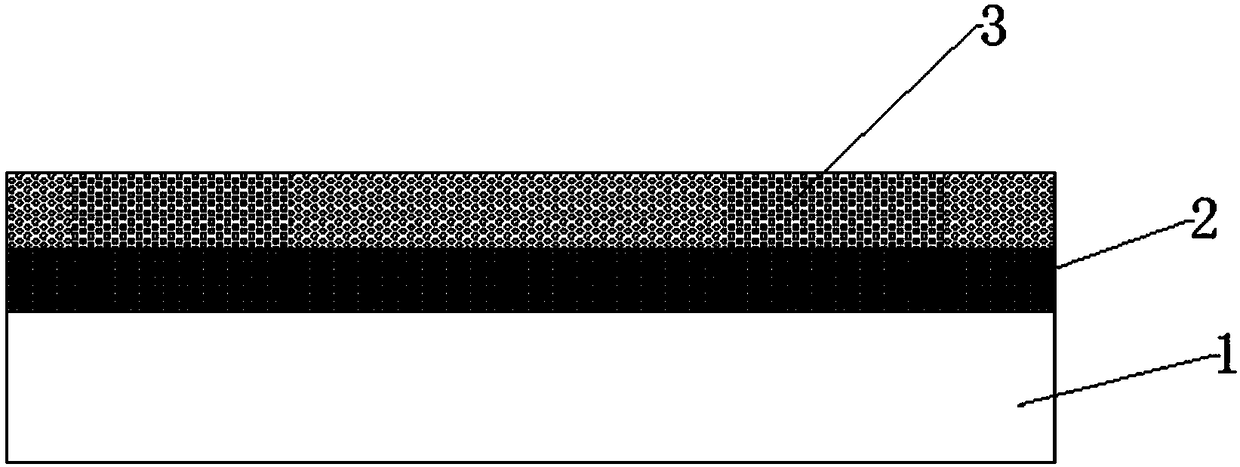

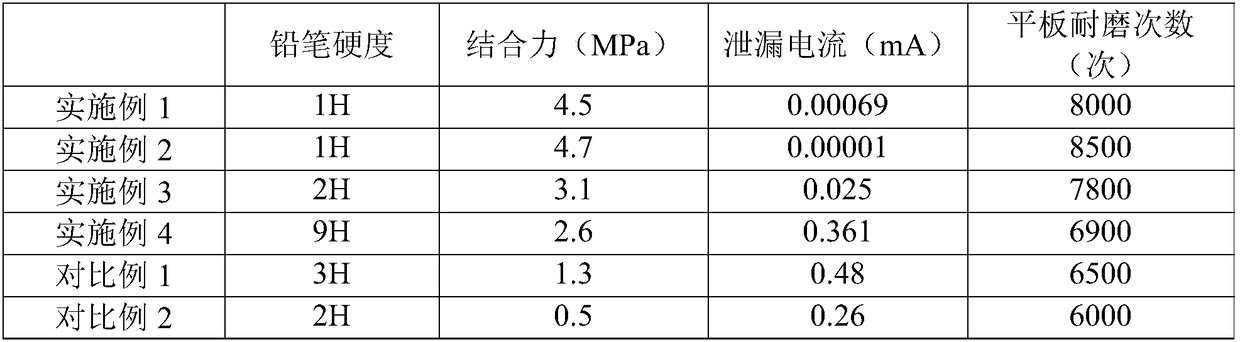

Inorganic ceramic non-stick pan composite coating and manufacturing method thereof

InactiveCN109321007AImprove hydrophobicityGood non-stickCooking-vessel materialsLiquid surface applicatorsCeramic coatingMetallurgy

The invention discloses an inorganic ceramic non-stick pan composite coating and a manufacturing method thereof. The inorganic ceramic non-stick pan composite coating is prepared from a bottom coatingand a surface coating, wherein the bottom coating is an inorganic ceramic coating which is 15 to 50 mum in thickness, is more than or equal to 1.2 and is less than or equal to 3.5 mum in roughness Ra; the surface coating is an inorganic ceramic coating which is 3 to 10 mum in thickness, and is more than or equal to 0.6 and is less than 1.2 mum in roughness Ra. By adopting the inorganic ceramic non-stick pan composite coating, the long-effect non-stick property of the non-stick pan is improved effectively. In particular, when the surface film is slightly damaged, high non-stick property can bekept.

Owner:浙江宇达新材料有限公司

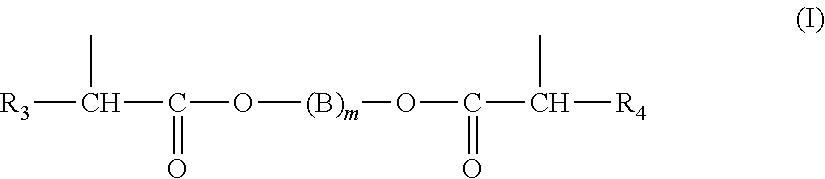

Liquid (METH)acrylic syrup for impregnating a fibrous substrate and method for the production thereof, method for impregnating a fibrous substrate, and composite material produced after polymerisation of said pre-impregnated substrate

ActiveUS20160017138A1High mechanical strengthLower performance requirementsFibre treatmentWood working apparatusViscous liquidMeth-

The invention relates to a liquid (meth)acrylic syrup for impregnating a fibrous substrate. The invention especially relates to a viscous liquid syrup mainly containing methacrylic or acrylic components. The invention also relates to a method for producing such a syrup. The invention relates further to a process for impregnating a fibrous substrate or long fibers with said viscous liquid syrup. The invention also relates to a fibrous substrate preimpregnated with said syrup, which is useful for the production of mechanical or structured parts or products. The invention also relates to a production method for producing mechanical or structured parts or items and to three-dimensional mechanical or structured parts produced by said method. The invention applies to the production of mechanical parts or structural elements made of impact-resistant thermoplastic composite material.

Owner:ARKEMA FRANCE SA

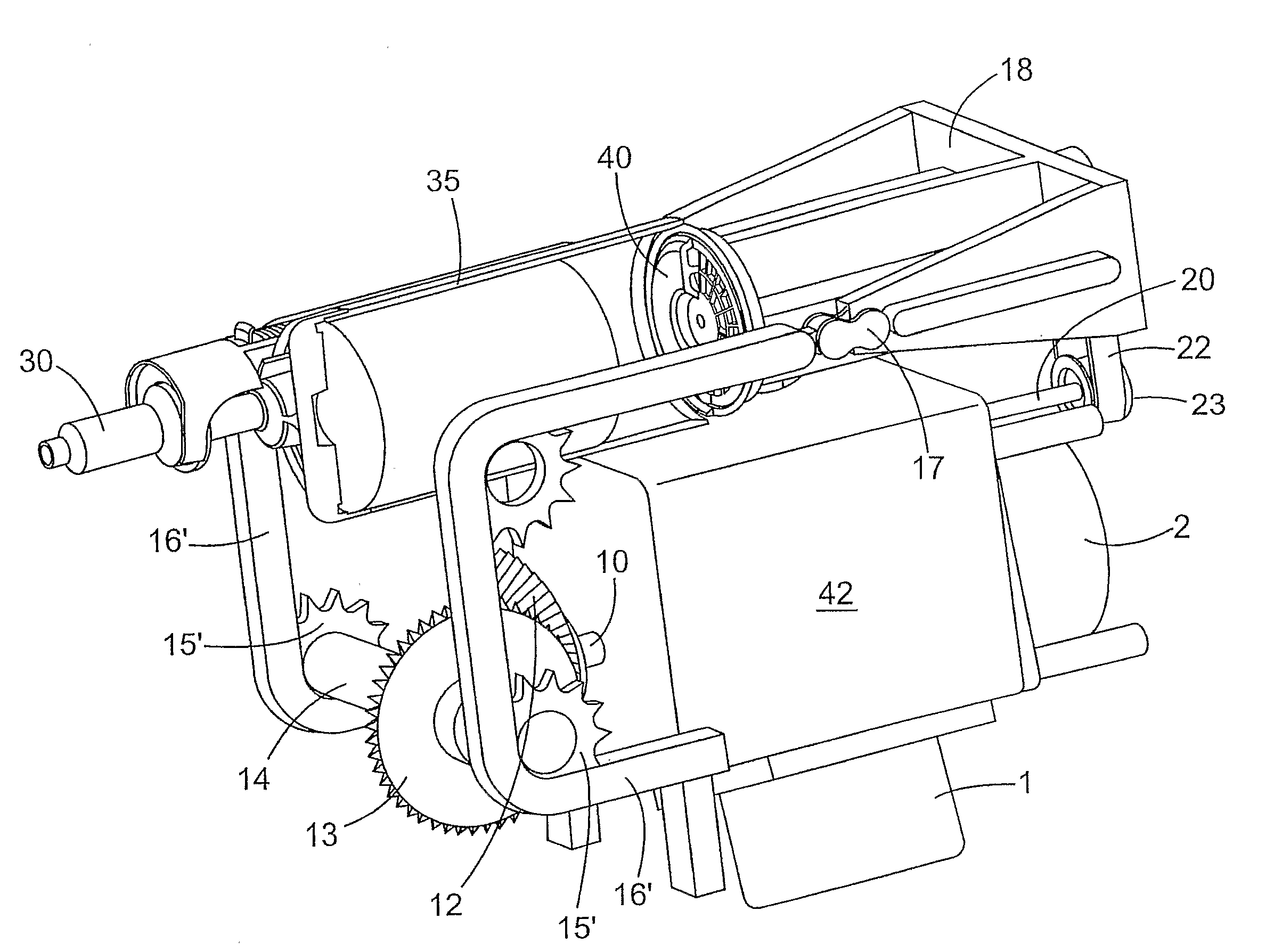

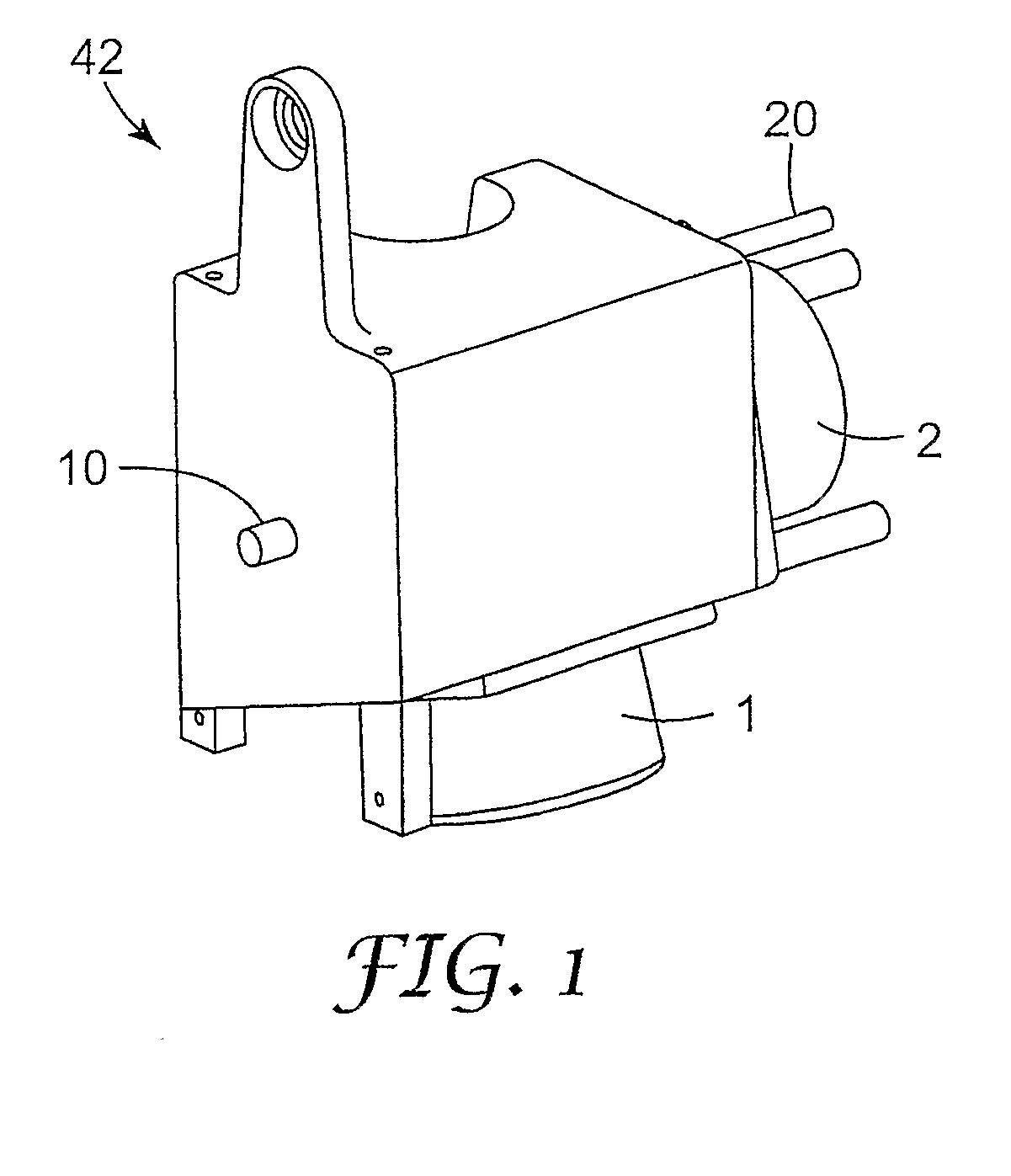

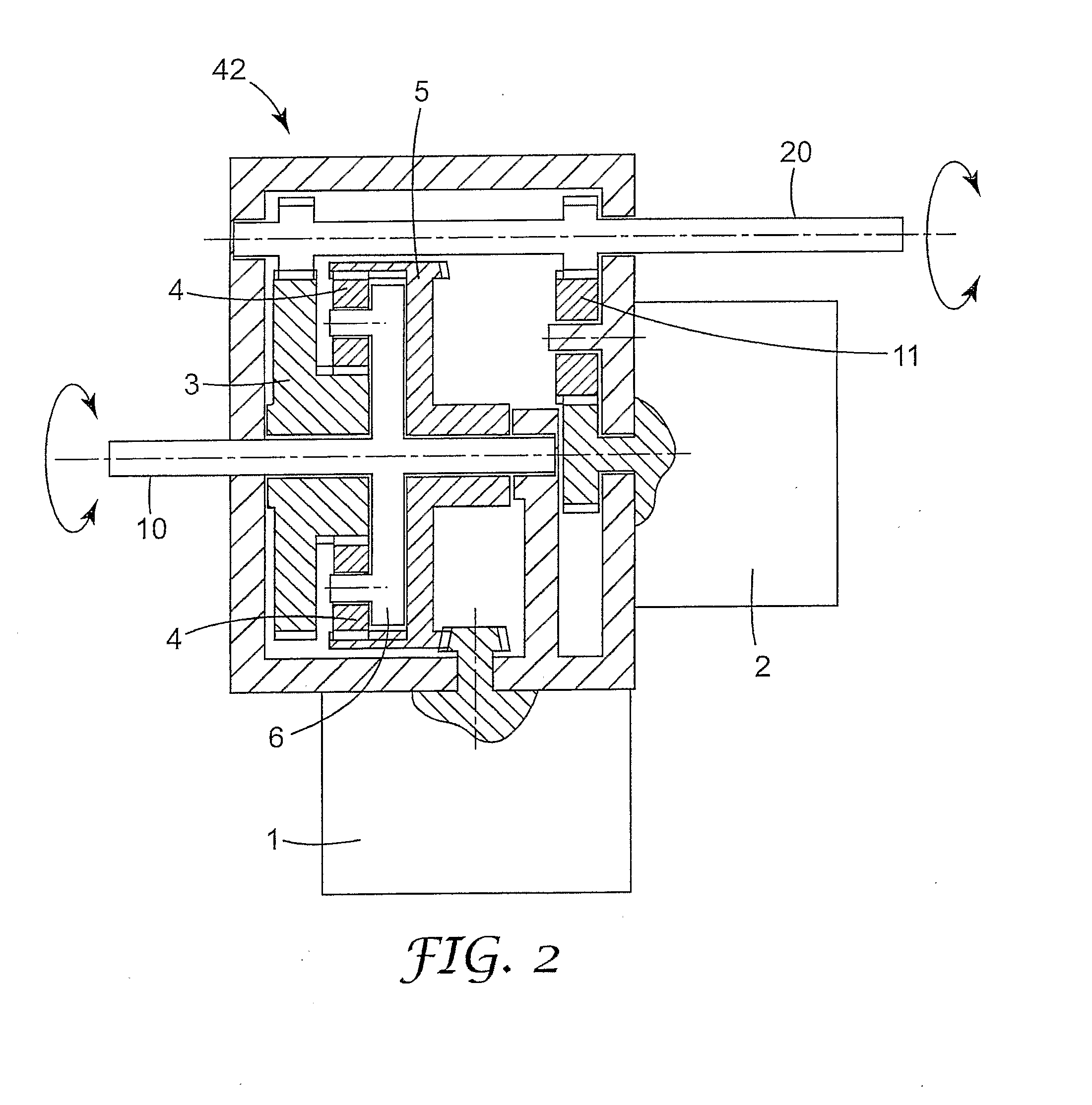

Method of Mixing and Extruding Viscous Materials and Gearbox for Dispensing the Same

InactiveUS20090001096A1Reduce loadIncrease torqueOpening closed containersBottle/container closureElectric machineryPlunger

The present invention relates to a method of mixing and dispensing viscous materials, comprising the steps of: inserting a cartridge containing one or more viscous materials in a chamber; activating a first motor (1) to move a plunger from a first position to a second position within the cartridge and activating a second motor (2) to move the plunger from the second position further within the cartridge to dispense the material.

Owner:3M ESPE

Device for simulating soil pollution release in different soil environment conditions

The invention discloses a device for simulating soil pollution release in different soil environment conditions. The device comprises at least a sample pot used for containing a soil sample, the sample pot is internally provided with a water distribution device, the bottom of the sample pot is provided with a liquid outlet, a lower side of the sample pot is communicated with a gas inlet pipe, an inlet end of the gas inlet pipe is provided with a gas generating device, and the gas inlet pipe is in series connection with a gas flowmeter, a gas temperature control device and a gas moisture control device. The water distribution device is used for simulating the release of pollutants in a sprinkling or rain falling condition, the gas pressure in the sample pot is adjusted by a pressure system,the soil condition in different temperature conditions can be simulated by the gas temperature control device, and the soil condition in different moisture conditions can be simulated by the gas moisture control device; after the gas temperature control device and the gas moisture control device are arranged in series, the device can be better used for simulating multiple soil environment conditions such as dry cold, clamminess, dry heat, wet heat, anaerobism and aerobiosis. The device is used in the field of pollutant simulation tests.

Owner:GUANGDONG PROVINCIAL ACADEMY OF ENVIRONMENTAL SCI

Super-strength non-stick coating and construction method thereof

InactiveCN109575792AHigh strengthGood non-stickLiquid surface applicatorsCoatingsChemical industryUltimate tensile strength

The invention belongs to the technical field of the chemical industry coating, and particularly relates to a super-strength non-stick coating and a construction method thereof. The super-strength non-stick coating is successively provided with a bottom coating and a middle coating from top to bottom. The bottom coating comprises the following raw materials in parts by matching: 8-30 parts of a bonder, 0.5-5 parts of high-temperature resisting pigment, 5-25 parts of high-temperature resisting filler, 0.5-2.5 parts of an assistant, and the balance of water; and the middle coating comprises the following raw materials in parts by matching: 8-25 parts of fluororesin, 8-20 parts of the bonder, 0.5-10 parts of the high-temperature resisting pigment, 0.5-2.5 parts of the assistant, and the balance of the water. The disclosed super-strength non-stick coating and the construction method thereof can be applied to non-stick cookers. The super-strength non-stick coating has an excellent non-stickproperty, and is easy to clean. In addition, because the coating has super-strength, abrasion resistance and scratch resistance are greatly superior to a common non-stick coating.

Owner:浙江青荷新材料有限公司

Preparation method of base material for anion wall plates and floors capable of purifying indoor air

The invention discloses a preparation method of anion wall plates and floors capable of purifying indoor air. The preparation method comprises the steps of preparing materials, wherein polypropylene resin and a performance improving agent are weighed and put into a mixing machine; conducting heating and stirring, so that a material mixture is formed; raising the temperature of the material mixture, conducting stirring, and sending the material mixture into a cold mixing treatment machine for conducting slow stirring and temperature lowering; weighing other raw materials other than the polypropylene resin and the performance improving agent, and putting the materials into the mixing machine; conducting heating, raising the temperature, conducting stirring, and putting obtained materials into an extruder for pressure extrusion; and conducting cooling, traction and cutting on extruded sheets, so that finished products are obtained. The products manufactured through the method are high in surface brightness, free of clamminess, attractive in appearance, firm, durable, free of deformation, good in quality and wide in application scope and has good development prospect.

Owner:SHANDONG XINHAI NEW MATERIAL

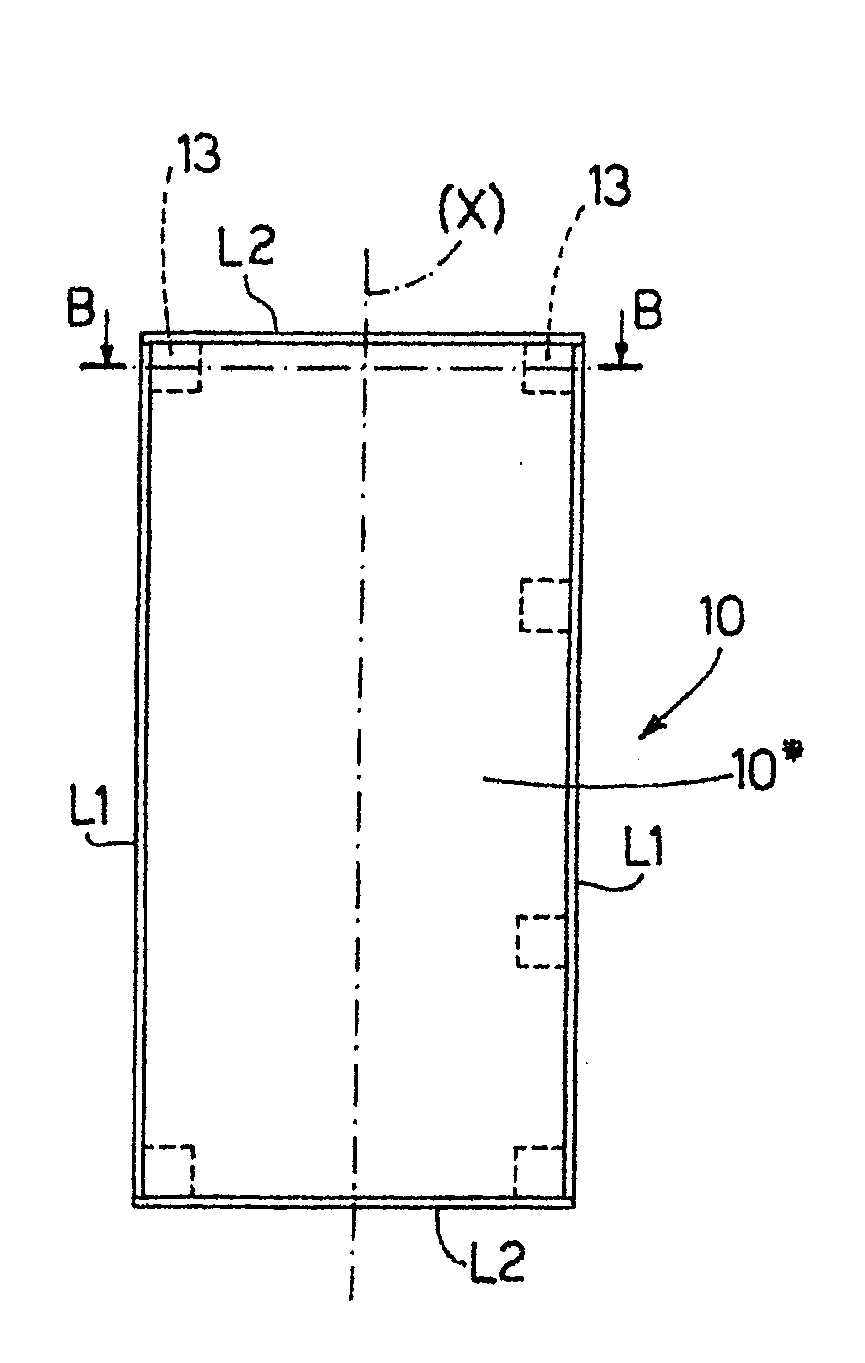

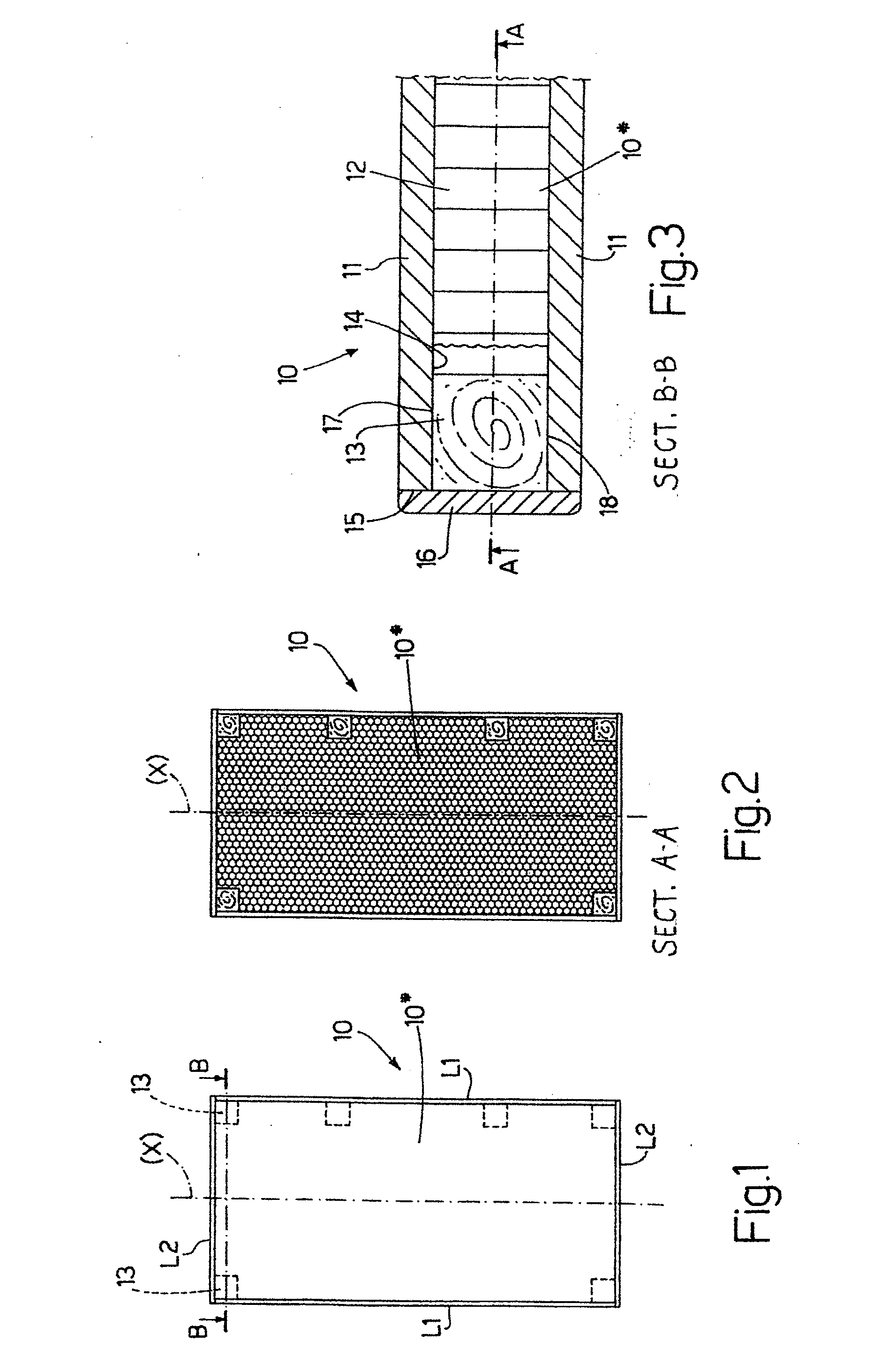

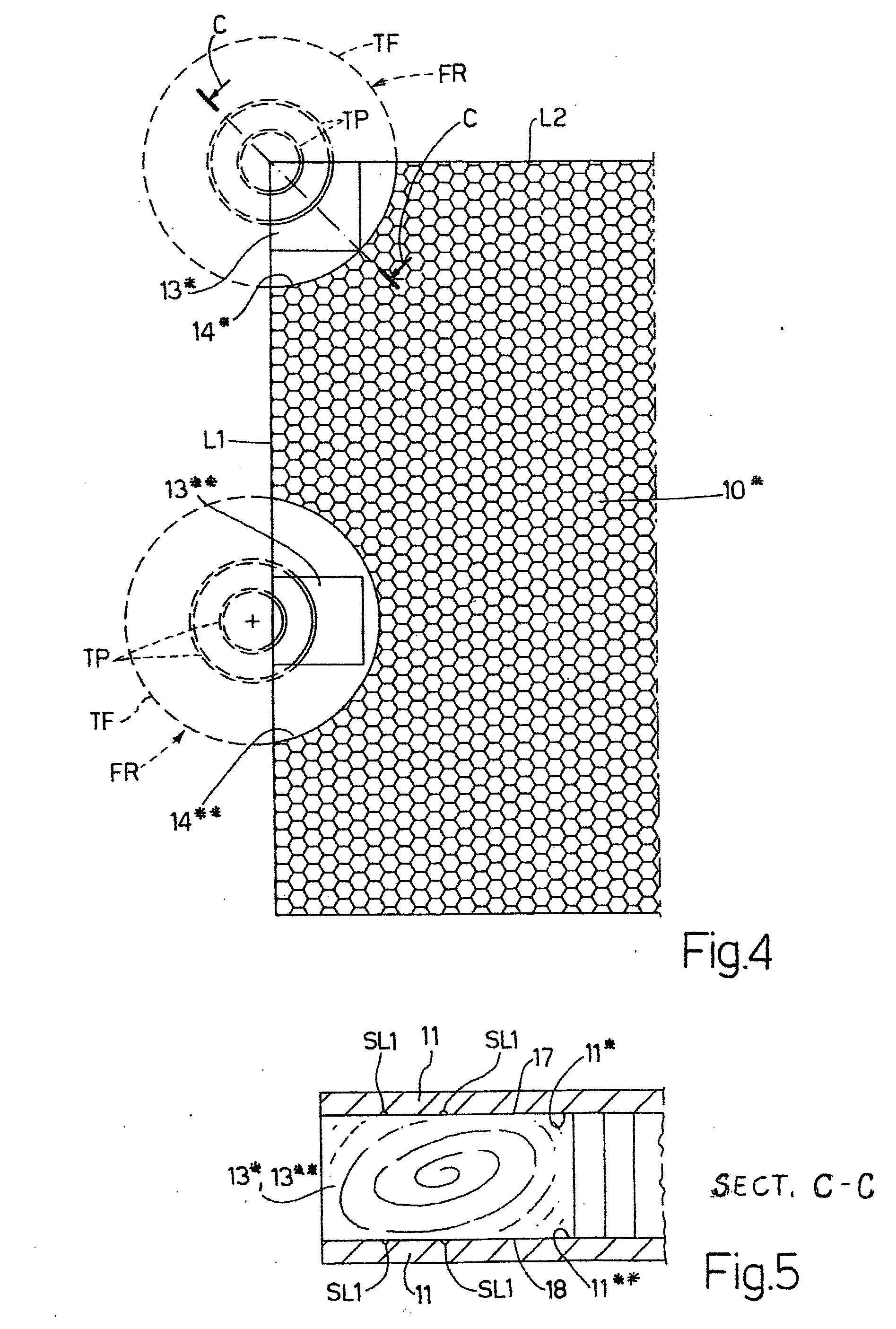

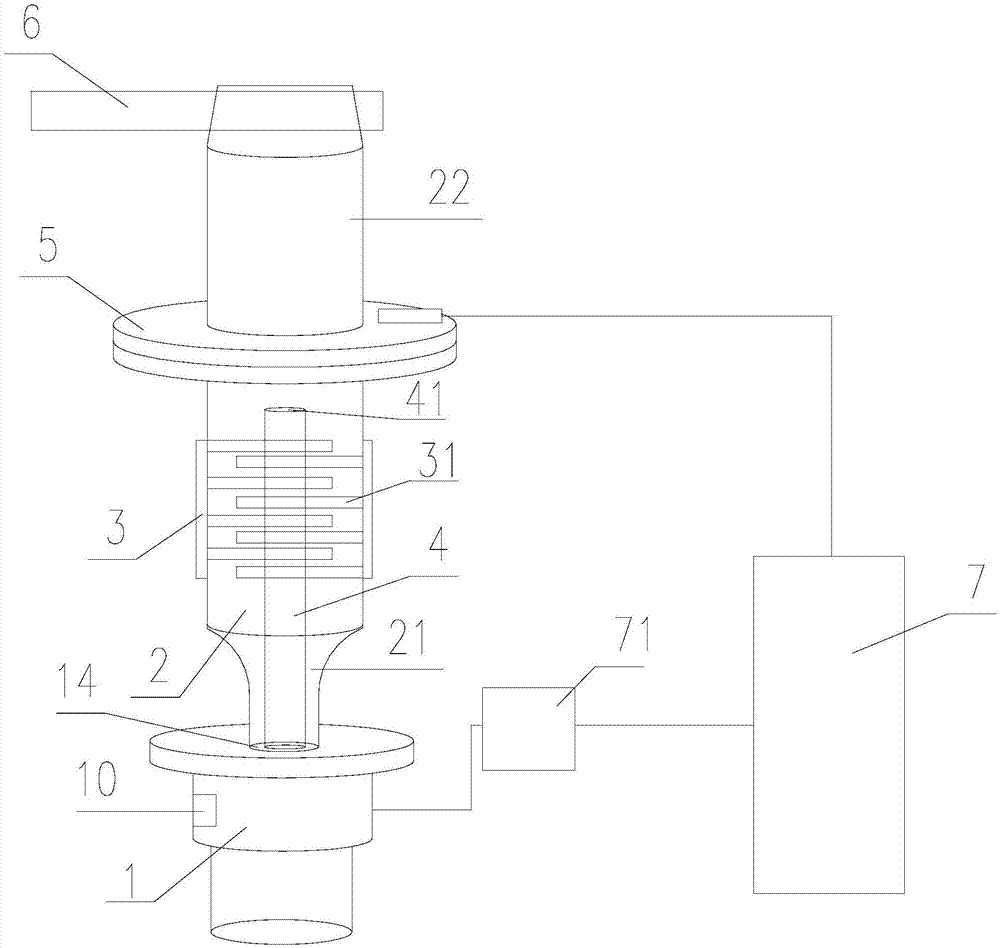

Panel and relative manufacturing system and method

InactiveUS20100227087A1Drawback can be obviatedEnvelopes/bags making machineryLamination ancillary operationsWood fibreManufacturing systems

A fully or partly edged panel (10; 200) of wood or wood fibre. The panel (10; 200) includes a sandwich blank (10*; 200*) having outer layers (11) of solid consistency, and at least one supple inner layer (12) with a lightweight, possibly “honeycomb” or supple foam material, structure. The panel (10; 200) is characterized by having at least one spacing block-shaped plug (13; 213) inserted between the two outer layers (11) of the sandwich blank (10*; 200*), and by the peripheral outer faces (15) of the sandwich blank (10*; 200*) being edged with an adhesive edging strip (16). Also described are methods and systems (100; 1000) for manufacturing the panel (10; 200).

Owner:NALDI VALTER

Medical PVC material adopted for steam sterilization, and preparation method thereof

The invention relates to a medical PVC material adopted for steam sterilization, and a preparation method thereof. The material comprises, by weight, 100 parts of PVC resin, 40-70 parts of a plasticizer DOP, 1.5-2.0 parts of a calcium / zinc heat stabilizer, 6-10 parts of an assistant heat stabilizer and 1.0-1.5 parts of a lubricant. The PVC resin is the polyvinyl chloride resin prepared through a suspension method, and has a polymerization degree of 1000-1300. The calcium / zinc heat stabilizer is a composite, wherein the composite comprises, by weight, 40-60% of calcium stearate, 20-30% of zincpalmitate, 15-30% of hydroxy magnesium / aluminum. The assistant heat stabilizer is epoxidised soyabean oil. The lubricant comprises, by weight, 55-60% of silicone oil and 40-45%of oxidized polyethylene wax. In the prior art, the PVC material is sterilized through the steam sterilization method, the high temperature (121 DEG C) and the long time treatment (30 minutes) during the steam sterilization process can cause degradation and yellowing of the PVC material, the precipitation of the plasticizer can cause clamminess generation of the instrument surface. With the present invention, the problems in the prior art are solved, the heat resistance of the medical PVC material is improved, and the probabilities of the yellowing and the precipitation of the plasticizer after steam sterilization are reduced.

Owner:常州恒方大高分子材料科技有限公司 +2

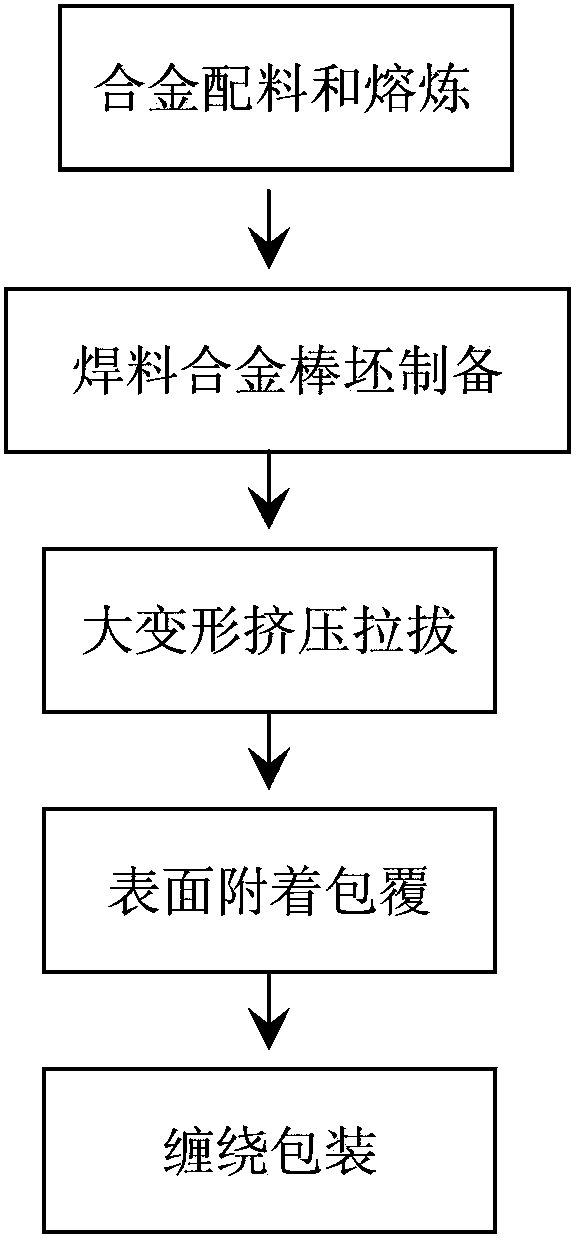

Anti-oxidation high-temperature soft-solder solid wire and manufacturing method thereof

InactiveCN104070303AImprove mechanical propertiesImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaManufacturing technologyConductor Coil

The invention relates to an anti-oxidation high-temperature soft-solder solid wire and a manufacturing method thereof and belongs to the technical field of solder production. The anti-oxidation solid wire comprises a high-temperature soft-solder solid wire and an anti-oxidation protective layer covering the solid wire. The high-temperature soft-solder solid wire comprises, by weight, Sn 2-15wt%, Ag 0-5wt%, one or multiple of P, Ge, Ga, Bi, Sb and Zn 0.01-1wt% and the balance Pb. Solder wires manufactured by the method effectively solve the problems such as black oxide of a surface layer of a lead-based solder, poor wetting during brazing without soldering flux and clamminess and damage to the surface of the solder wires in winding and use. The solder wires have the advantages of strong bonding strength, round welding spot, bright halation, good sealing performance, high reliability, long service life and the like in brazing and use.

Owner:BEIJING COMPO ADVANCED TECH

Alloy powder for laser cladding and preparation method thereof

The invention discloses alloy powder for laser cladding. The alloy powder comprises dissimilar metal powder and highly viscous liquid fluxing agents. The dissimilar metal powder comprises the following components, by mass percent, 0.01% to 0.05% of C, 0.3% to 0.8% of Si, 0.7% to 1.2% of Cr, 0.5% to 1% of Ni, 0.5% to 0.9% of Mo, 0.08% to 0.6% of Nb, 13% to 7% of A, 0.1% to 0.3% of Zr, 0.03% to 0.10% of V, and the balance Fe. The invention further discloses a preparation method of the alloy powder for laser cladding. The alloy powder for laser cladding is good in weldability and high in viscosity.

Owner:SHANDONG ENERGY HEAVY EQUIP GRP DAZU REMANUFACTURING CO LTD

All-steel radial truck tire air-tight layer and its preparation method

All-steel radial truck tire air-tight layer consists of (by weight percentage) montmorillonite / SBR nano composite material 160-200, silane coupling agent 0.4-0.6, 1.5-2.5 stearic acid, zinc oxide 2-4, B type microcrystalline wax 6-10, anti-aging agent 6PPD 1.5-2.5, anti-aging agent TMQ 1.5-2.5, octyl phenolic tackifying resin 6-10, accelerator NS 0.6-1, and sulfur 1-2. In the mixing process, silane coupling agent is added to perform interaction on silicon hydroxyl of a montmorillonite layer, to weaken network packing structure formed by the interaction between montmorillonite, improve binding force between montmorillonite and rubber, thereby improving the rubber tackiness, reducing the hardness, and improving material properties. Material tackiness can be further improved via adjusting the curing system, adding operation oil and tackifying resin, to improve theproperties of rubber compound.

Owner:AEOLUS TIRE

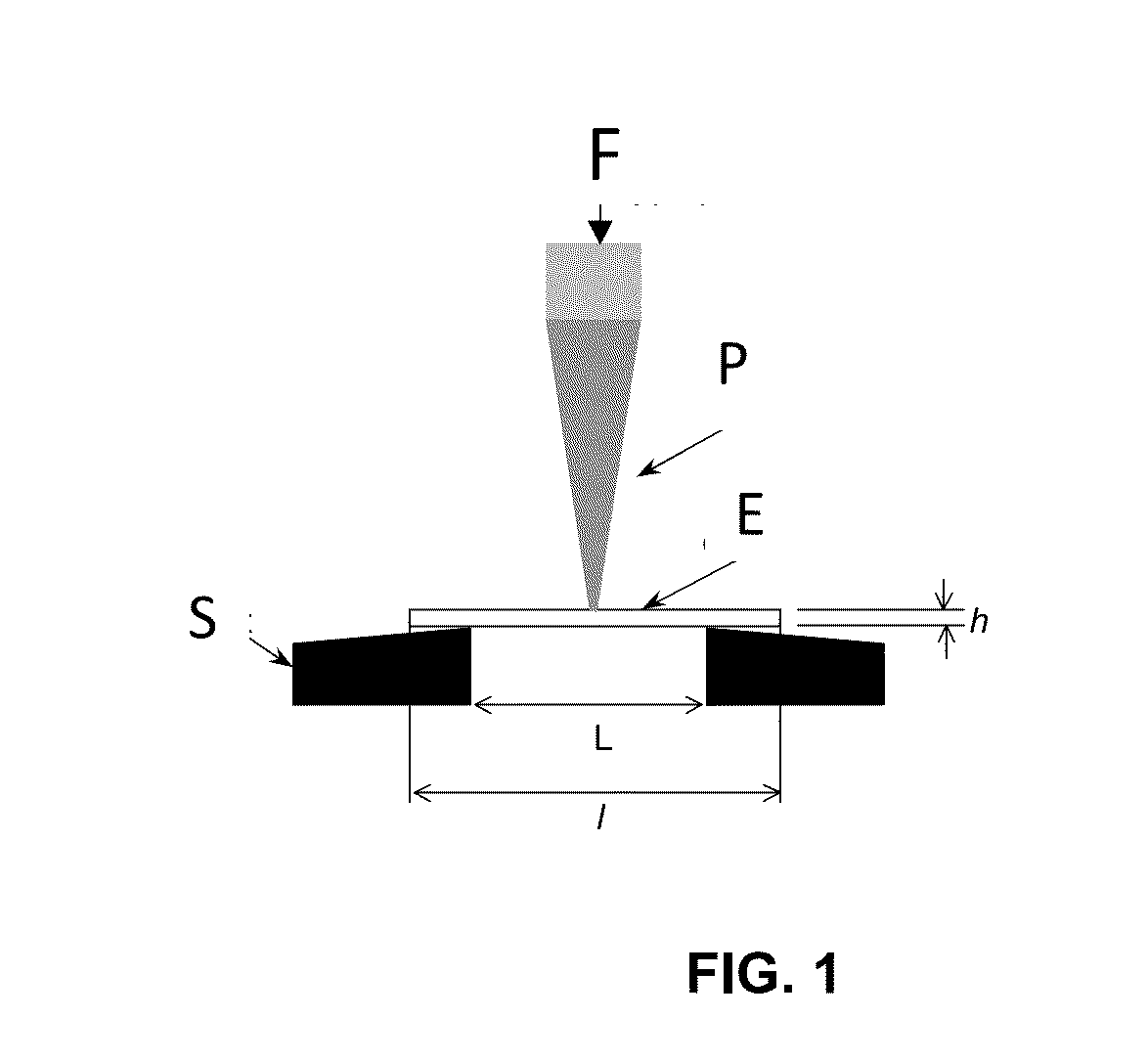

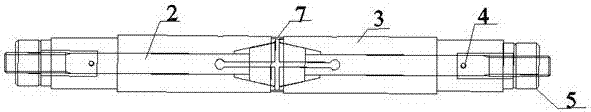

Tool and method for testing adhesive property of frameless self-adhesive enameled wire

PendingCN107505262AAdhesion truly reflectsAdhesion reflectsUsing mechanical meansMaterial analysisMechanical engineeringSelf adhesive

The invention discloses a tool and a method for testing the adhesive property of a frameless self-adhesive enameled wire, relating to the technical field of enameled wire coils. The tool comprises a base, two frock clamps and a frameless self-adhesive enameled wire coil, wherein the two frock clamps are symmetrically arranged on the base, one end of the frameless self-adhesive enameled wire coil is connected with one frock clamp, and the other end of the frameless self-adhesive enameled wire coil is connected with the other frock clamp. According to the tool and the method, the diameters of the clamps are changed by utilizing an expansion principle, the assembled clamps are used for fixing the two ends of the frameless self-adhesive enameled wire, and the phenomenon that the frameless self-adhesive enameled wire coil, particularly the frameless ultramicro self-adhesive wire coil, deforms due to uneven external force can be effectively avoided. According to the method, the nominal diameter of the enameled wire is indefinite, universality is achieved, and the adhesive force of the enameled wire can be tested rapidly, accurately and efficiently.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

Non-stick coating and preparation method and application thereof

ActiveCN109452872AHigh strength supportHigh hardnessCooking-vessel materialsCoatingsSurface layerHardness

The invention relates to the field of cooker coatings, and discloses a non-stick coating and a preparation method and application thereof. The coating comprises a polyetheretherketone (PEEK) bottom layer attached to a metal substrate and a non-stick surface layer formed on the polyetheretherketone bottom layer, the material of the non-stick surface layer is selected from at least one of fluorine-containing resin and ceramic. The non-stick coating is composed of a PEEK bottom layer and a non-stick surface layer coating, and can effectively solve the problems that a cooker coating is easy to scratch and has poor coating adhesion and corrosion resistance. The PEEK bottom layer can provide high-strength supporting force, hardness and binding force for the non-stick surface layer, and the surface layer formed by at least one of fluorine-containing resin and ceramic can provide strong non-stick performance.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

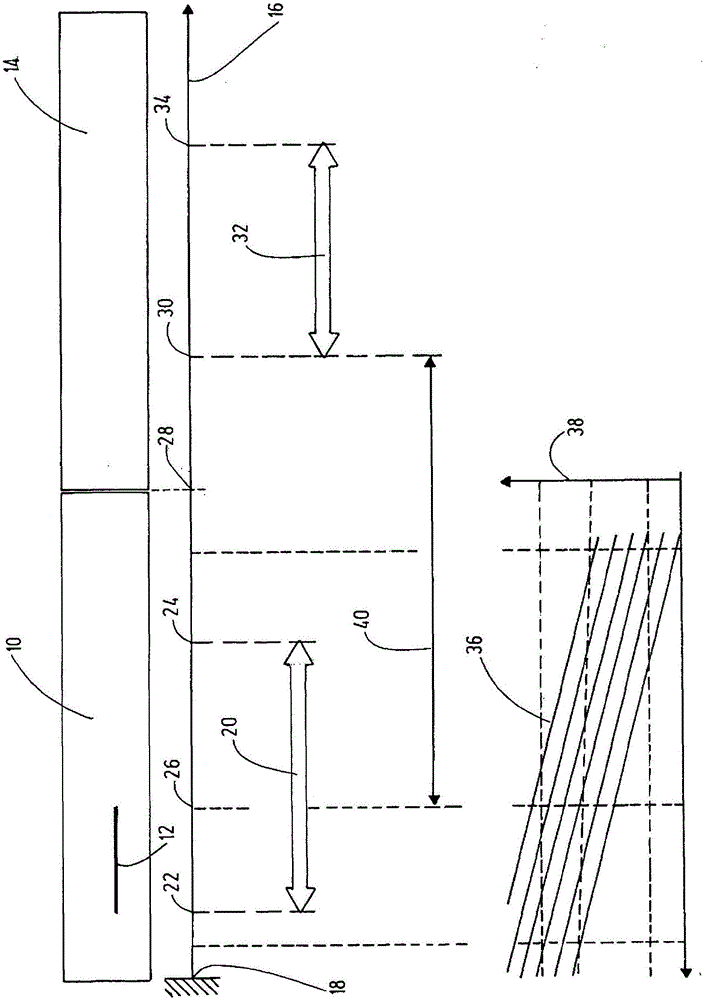

Method for applying a viscous material

The invention relates to a method for applying an at least two-component, curable and viscous material in the form of a material strand (12) or a series of material points to a workpiece, an application process (20) starting at an application start time (22) and ending at an application end time (24), and the workpiece with the material applied thereon being destined for further processing (32) which starts at a processing start time (30) and ends at a processing end time (34). According to the invention, the mixing ratio (38) of the components is varied by a control device depending on predetermined and / or measured parameters (22, 24, 30, 34) during the application process (20) in such a way that the material applied to the workpiece can be processed at any point of the material strand (12) or at any material point at the processing starting time (30).

Owner:ATLAS COPCO IAS GMBH

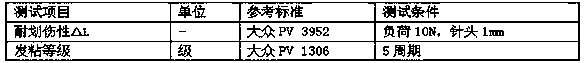

Polypropylene composite material as well as preparation method and application thereof

InactiveCN108034144AImprove scratch resistanceExcellent resistance to precipitation and stickinessPolypropylene compositesLubrication

The invention discloses a polypropylene composite material as well as a preparation method and application thereof. The polypropylene composite material is prepared from ingredients of 35 parts to 97parts of polypropylene resin, 2 parts to 15 parts of polyformaldehyde and 1 part to 5 parts of compatilizer. The polyformaldehyde with self lubrication characteristic is added in the polypropylene composite material disclosed by the invention, so that a surface fraction coefficient of the material is effectively reduced, and a scratch resistance effect is improved; furthermore, excellent separating-out resistance and clamminess resistance characteristics are ensured at the same time; the prepared polypropylene composite material has excellent scratch resistance, separating-out resistance and clamminess resistance and can be widely applied to preparing automotive upholstery.

Owner:WUHAN JINFA TECH CO LTD +1

Special food packaging and fresh-keeping film for high speed machine, and making method thereof

ActiveCN106945366AGood self-adhesiveImprove tensile propertiesSynthetic resin layered productsPolyolefinFood packaging

The invention discloses a special food packaging and fresh-keeping film for a high speed machine, and a making method thereof. The film is formed by coextruding, by mass, 10-20% of an inner layer material, 50-70% of a middle layer material and 10-20% of an outer layer material. Raw materials of the inner layer material, the outer layer material and the middle layer material are respectively placed in three mixing reaction kettles, and are uniformly stirred, the stirred raw materials undergo heating extrusion through extrusion screws to form a melt state, and the molten upper layer material, the molten middle layer material and the molten lower layer material are respectively extruded into the inner chamber, the middle chamber and the outer chamber of a die head; and the upper ends of the molten materials in the die head are clamped and upward stretched by clamping and stretching devices on the upper end of the die head to stick the inner, middle and outer layer materials together in order to form the fresh-keeping film. The fresh-keeping film produced in the invention has good autoadhesion and high stretching performance, is a plasticizer-free polyolefin (PO) fresh-keeping film, is suitable for high-speed food packaging processing, and meets high stretchability, high strength and high toughness required by the high speed machine.

Owner:知为(上海)实业有限公司

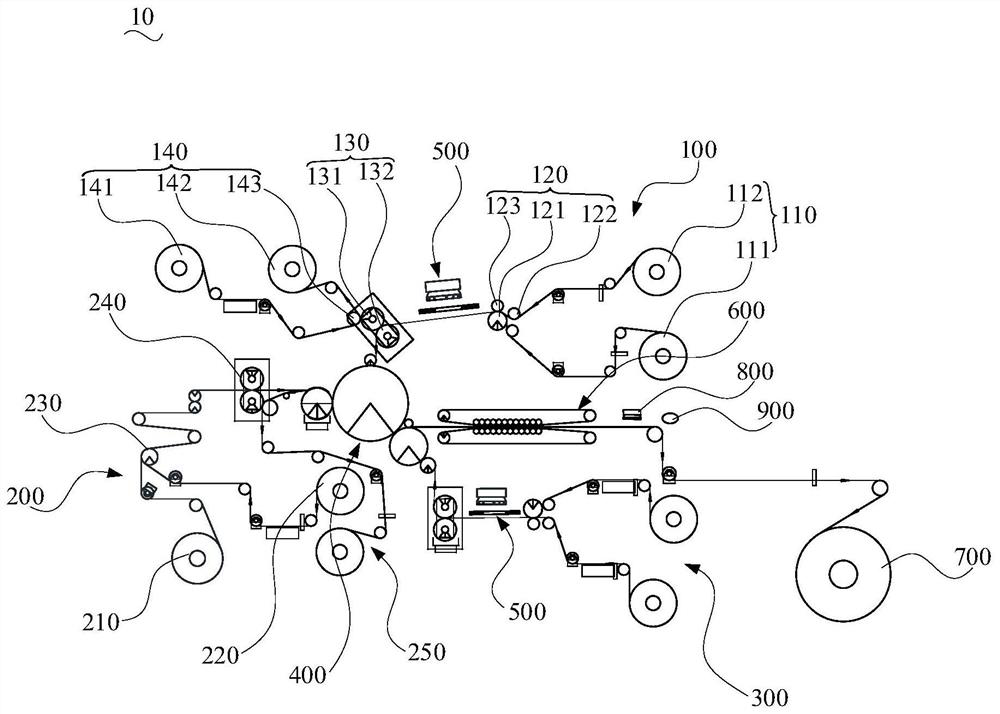

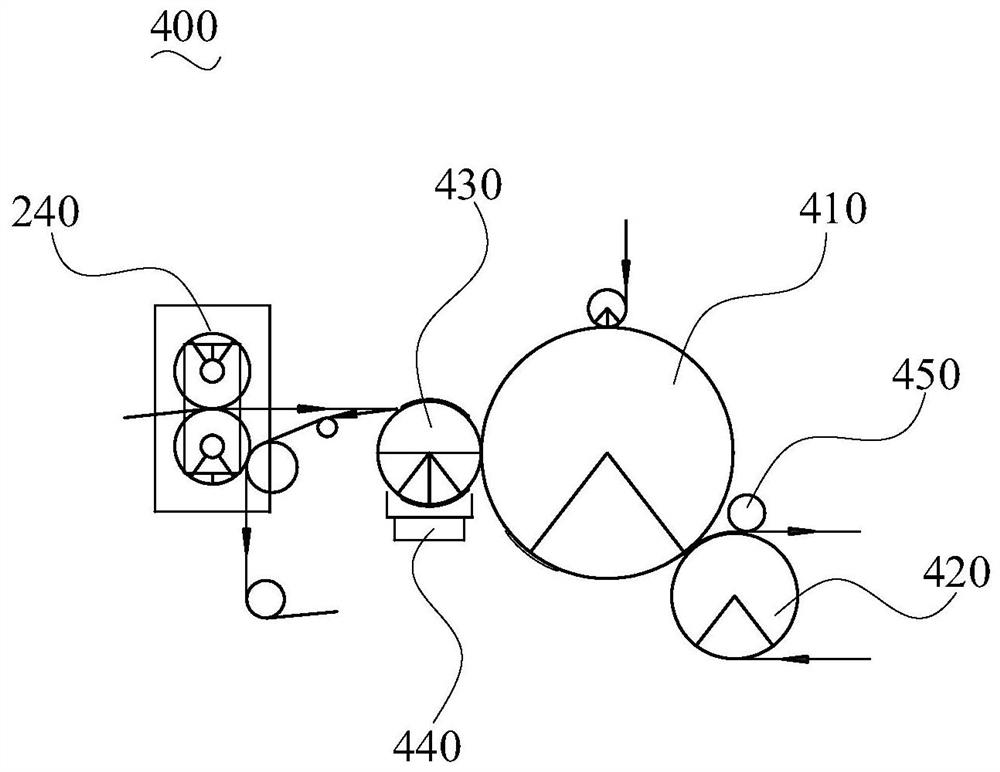

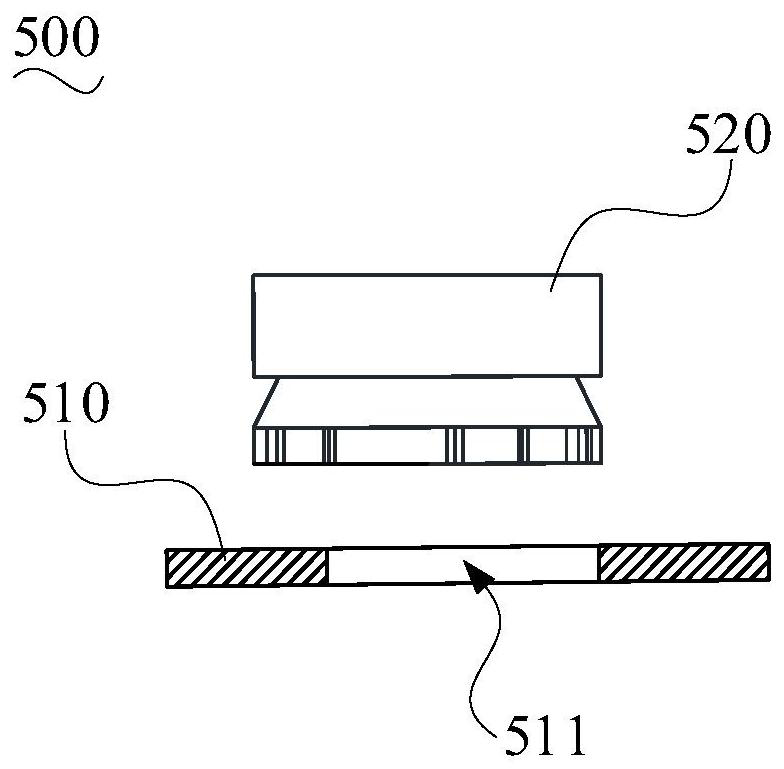

Five-in-one forming equipment

ActiveCN113793961AImprove molding efficiencyImprove alignment accuracyFuel cellsPtru catalystAdhesive

The invention relates to five-in-one forming equipment. The equipment comprises a first discharging device, a second discharging device, a third discharging device and a laminating device. Sheet-to-roll and roll-to-roll continuous lamination can be realized by utilizing the lamination device, so that the five-in-one forming equipment can be used for continuously forming a five-in-one material belt only by emptying at a fixed frequency through the first discharging device, the second discharging device and the third discharging device. In addition, the viscosity of a photosensitive adhesive in the functional areas of a first composite material belt and a third composite material belt can be weakened by a viscosity-removing device, so that a catalyst layer on the surface of a CCM sheet material is prevented from being damaged due to adhesion. Moreover, due to the continuous forming process, the CCM sheet material can be attached to an upper frame material belt and a lower frame material belt at the same time in the laminating device, and the situation that multiple materials are pretreated separately is avoided, so errors can be effectively reduced. Therefore, the five-in-one forming equipment can improve the forming efficiency of the five-in-one material belt and improve the alignment precision of the five-in-one material belt.

Owner:JIANGSU HYDROGEN GUIDE INTELLIGENT EQUIP CO LTD

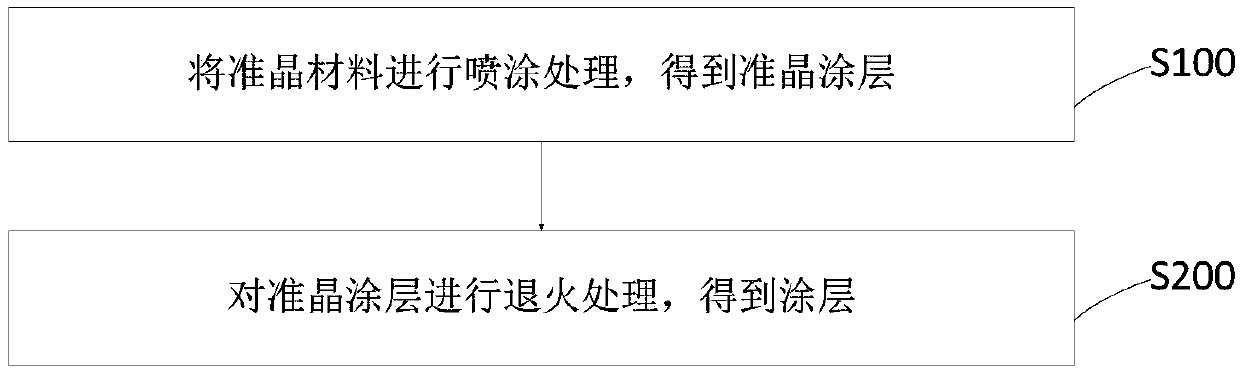

Coating and preparation method thereof, pot and cooking utensil

PendingCN110776759AGood non-stickExtended service lifeFireproof paintsCooking-vessel materialsHardnessCorrosion resistant

The invention provides a coating and a preparation method thereof, a pot and a cooking utensil, wherein the quasicrystal content in the coating is 20-90 wt% based on the total weight of the coating. According to the invention, the coating is good in non-stick performance, high in hardness, wear-resistant, scratch-resistant, corrosion-resistant, long in service life and high-temperature-resistant.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com