Polypropylene composite material as well as preparation method and application thereof

A composite material, polypropylene technology, applied in the field of polypropylene composite material and its preparation, can solve the problems of molecular chromatography sticking, the risk of large precipitation sticking, reduce the surface friction coefficient, excellent anti-separation sticking performance, The effect of excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

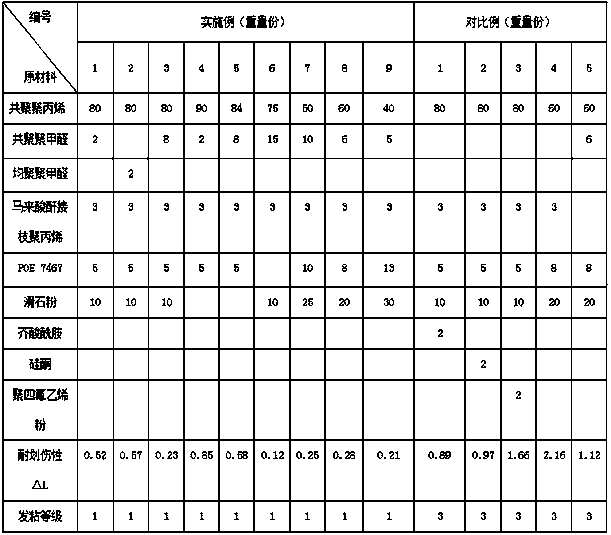

Embodiment 1-8 and comparative example 1-4

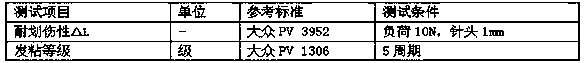

[0037] Weigh the components according to the parts by weight shown in Table 1, fully mix the raw materials of each component in a high-speed mixer according to the proportioning ratio for 5-30 minutes; transport the above-mentioned mixture to the twin-screw extruder, and set the temperature of each section of the screw barrel At 170-240°C, with a rotating speed of 300-500 revolutions per minute, the polypropylene composite material is obtained through melt blending, extrusion and granulation. The corresponding test samples were made according to the standard, and their properties were measured. The specific values are listed in Table 1.

[0038] Table 1 Composition and properties of polypropylene composites

[0039]

[0040] It can be seen from the test results of various examples and comparative examples that the present invention can effectively reduce the surface friction coefficient of the material by adding polyoxymethylene to the polypropylene composite material, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com