Method of Mixing and Extruding Viscous Materials and Gearbox for Dispensing the Same

a technology of viscous materials and gearboxes, which is applied in the direction of dynamo-electric machines, opening closed containers, and containers, etc., can solve the problems of difficult to achieve high torque at low speed, low torque at high speed, and difficult to achieve high speed at low speed, and achieve high torque at high speed. , the effect of complex drive and changing gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

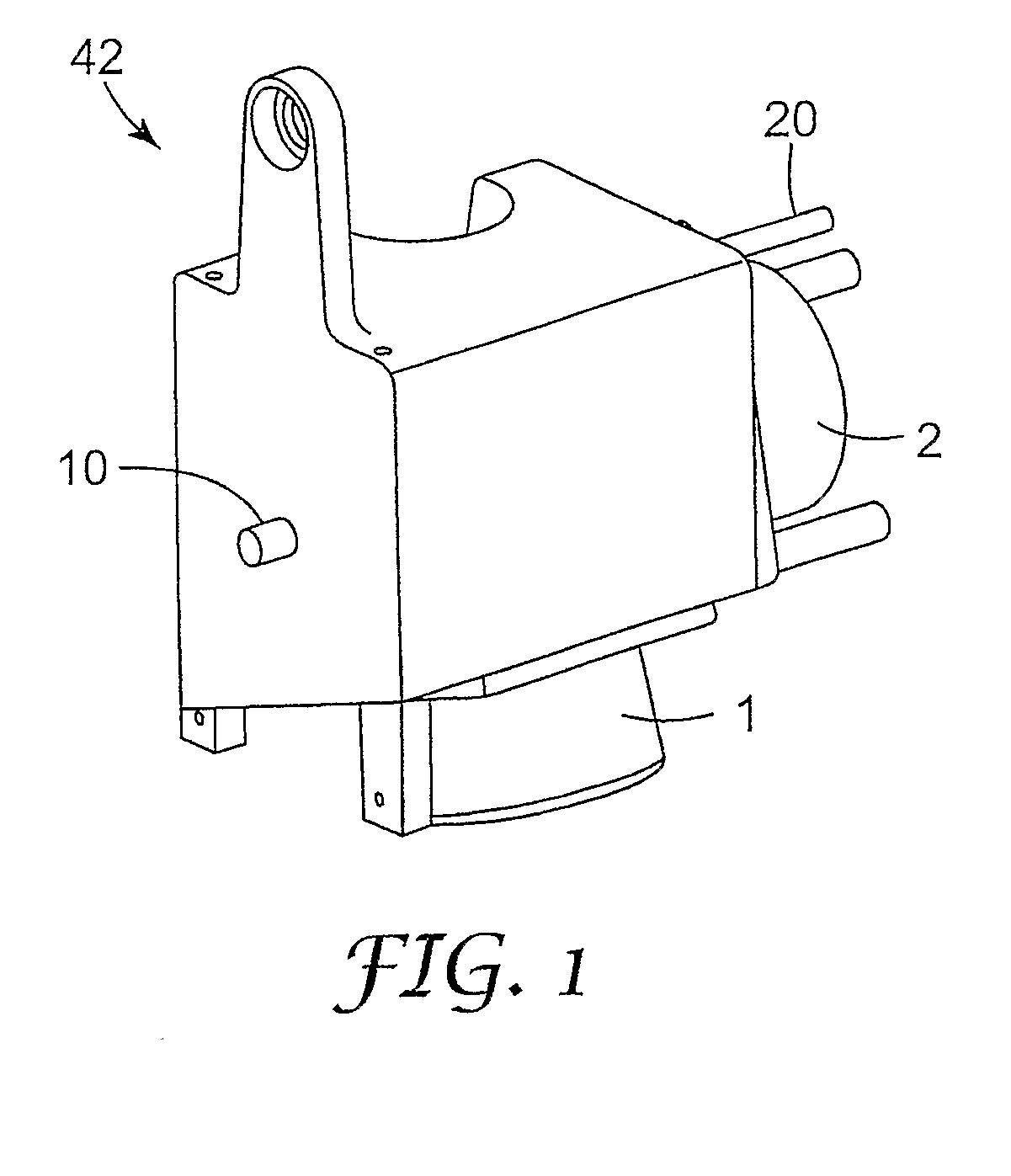

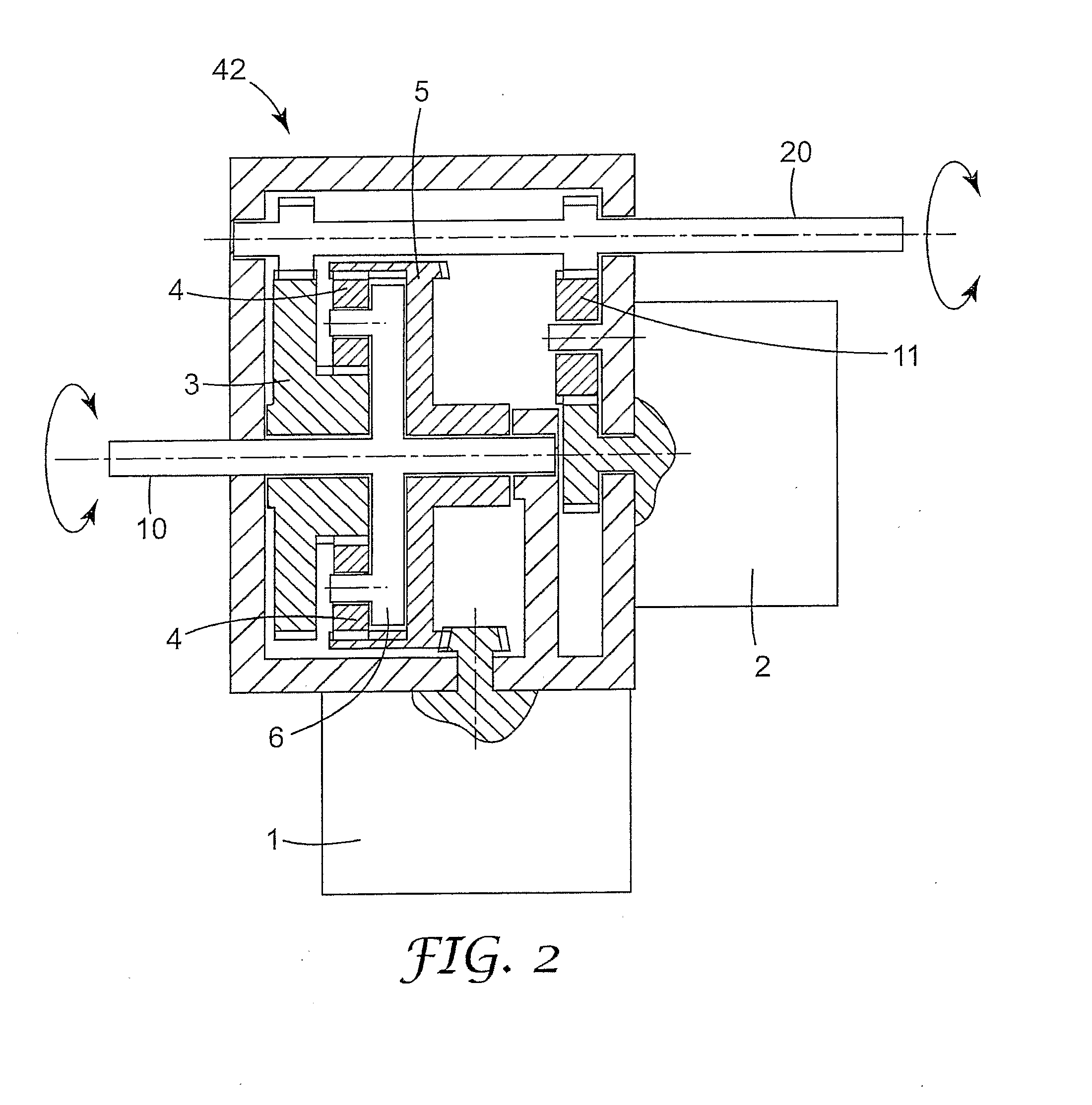

[0100]FIGS. 2 and 4 show a drive unit where the superimposing gear drive is a planetary gear drive. In this case, the above mentioned first, second and third gears correspond to a sun or inner gear 3, a annular or outer gear 5 and a planetary gear 4, respectively.

[0101]As shown in FIG. 2, in this first embodiment, the gearbox 42 further comprises a second output drive shaft 20 that is connected to the second motor 2 via a gear 11. The second output drive shaft 20 is further in connection to the inner gear 3. Thus, the inner gear 3 is driven by the second motor 2, providing by a suitable second transmission ratio high torque at the first output drive shaft 10. The first output drive shaft 10 is connectable directly or via a moving means (not shown), to at least one plunger (not shown) for advancing a piston (not shown) in a cartridge 35 (FIG. 5), or for driving the plunger in reverse direction toward a back position. The high torque is necessary at the plunger to supply sufficient fo...

second embodiment

[0106]FIG. 3 shows a drive unit where the superimposing gear drive is a bevel gear drive. In this case, the above-mentioned first, second and third gears are depicted by numerals 3′, 5′ and 4′, respectively.

[0107]In this second embodiment, the first motor 1 again drives the second gear 5′ whereas the second motor 2 drives the carrier 6. The first gear 3′ is connected to the first output drive shaft 10 and has a similar size and design like the second gear 5′ due to the bevel gear design.

[0108]According to the above and other embodiments of the invention, there is no changing of gears needed to accomplish a large speed ratio or range, i.e. the ratio or range between the high speed and the low speed, at an output drive shaft 10, which is preferable for a dispensing plunger providing either a fast positioning velocity or a high torque for dispensing. This results in less noise, highly reliable mechanics and minimal processing time.

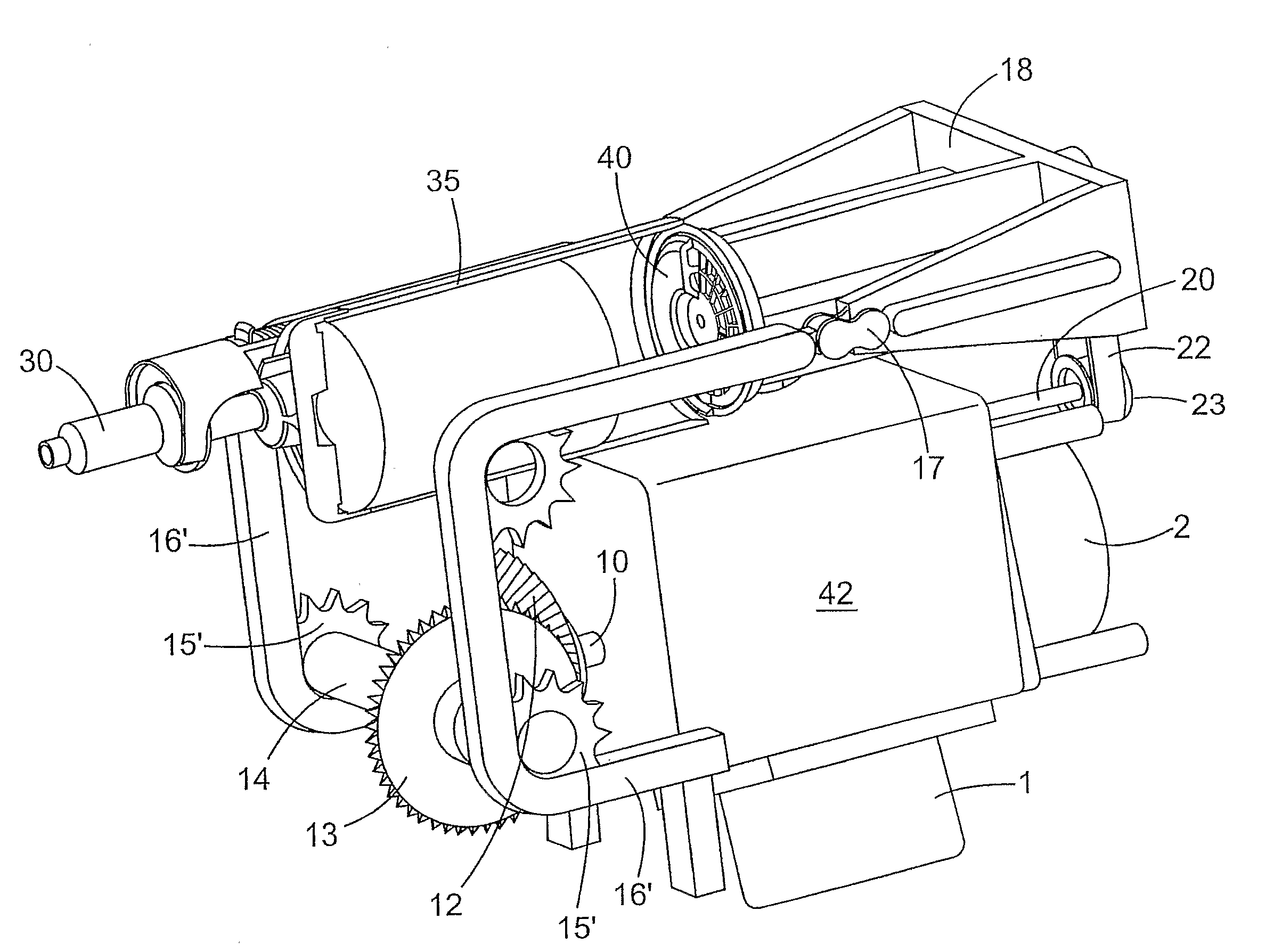

[0109]FIG. 4 shows a perspective view into a gearbox of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com