Anti-oxidation high-temperature soft-solder solid wire and manufacturing method thereof

A soft solder and anti-oxidation technology, applied in the field of solder manufacturing, can solve the problems of insufficient mechanical strength performance of high lead tin wire, low interface adhesion work, easy wetting, etc., so as to improve mechanical properties and anti-oxidation. The effect of stability, long service life, easy winding and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

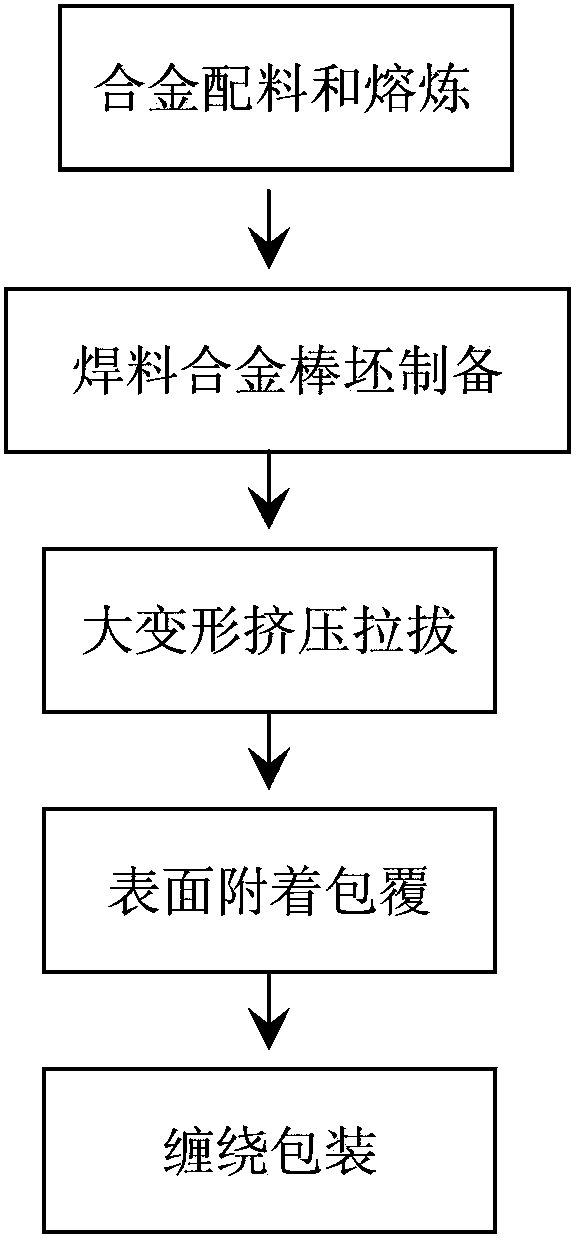

[0025] Such as figure 1 Shown is the process flow chart for the preparation of the anti-oxidation high-temperature solder solid wire of the present invention. The preparation method of the anti-oxidation high-temperature solder solid wire of the present invention includes 5 steps: 1 is alloy batching and smelting; 2 is Preparation of solder alloy bar blank; 3 is large deformation extrusion drawing; 4 is surface adhesion coating; 5 is winding packaging.

[0026] The first step: Weigh the alloy raw materials according to the composition ratio. The alloy composition is 2-15wt% Sn, 0-5wt% Ag, 0.01wt%-1wt% added elements P, Ge, Ga and Bi, Sb, Zn In order to improve the oxidation resistance and strength of the solder, 0.01wt%-1wt% of P, Ge, Ga and one of Bi, Sb, Zn are added. One or more combination elements; the second step: the alloy raw materials are smelted under the protection of nitrogen or argon atmosphere, and the stirring is strengthened to prepare an alloy rod with uniform co...

Embodiment 1

[0028] The preparation of tin wire with round ends and dodecahydroxystearic acid coating layer includes the following steps:

[0029] (1) According to the weight ratio Pb:Sn:Sb=97:2:1, weigh the purity to be 99.99% pure Sn, pure Sb and pure Pb, totaling 50kg, and heat to 700℃ to melt in a vacuum melting furnace protected by argon. Insulation, stirring, standing, and deslagging;

[0030] (2) Pour the above melt quickly on The cylindrical mold is prepared to produce a cylindrical bar blank with a defect-free appearance of Φ84×180mm;

[0031] (3) Load the obtained bar stock into a 350-ton large deformation extruder, extrude and draw into a solid wire of Φ0.5mm;

[0032] (4) Put a sufficient amount of dodecanoic acid in the tin wire coating barrel, control the temperature of the coating barrel at 100°C, pass the tin wire into the coating barrel for surface coating, and control the wire output speed at 2.0m / min or so, and air-dry at the end of the wire;

[0033] (5) The obtained tin wire...

Embodiment 2

[0036] The preparation of tin wire with a square end surface and a benzotriazole coating layer includes the following steps:

[0037] (1) According to the weight ratio Pb:Sn:Bi=89:10:1, weigh the purity to be 99.99% pure Sn, pure Bi and pure Pb, totaling 50kg, and heat to 500℃ to melt in a nitrogen-protected melting furnace. Stir, stand still, remove slag;

[0038] (2) Pour the above melt quickly on The cylindrical mold is prepared to produce a cylindrical bar blank with a defect-free appearance of Φ84×180mm;

[0039] (3) Load the obtained bar stock into a 350-ton large-deformation extruder, extrude and draw into a solid wire of 0.3×0.6mm square size;

[0040] (4) Put a sufficient amount of benzotriazole in the tin wire coating barrel, control the temperature of the coating barrel at 150℃, pass the tin wire into the coating barrel for surface coating, and control the wire output speed at 1.0m / About min, and air-dry at the end of the wire;

[0041] (5) The obtained tin wire is moved ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com