Non-stick coating and preparation method and application thereof

A non-stick coating, coating technology, applied in non-stick coating, preparation of non-stick coating, application of non-stick coating in cookware, can solve the problem of short service life, poor corrosion resistance and poor adhesion and other issues, to achieve high-strength support, strong corrosion resistance, and long-term service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

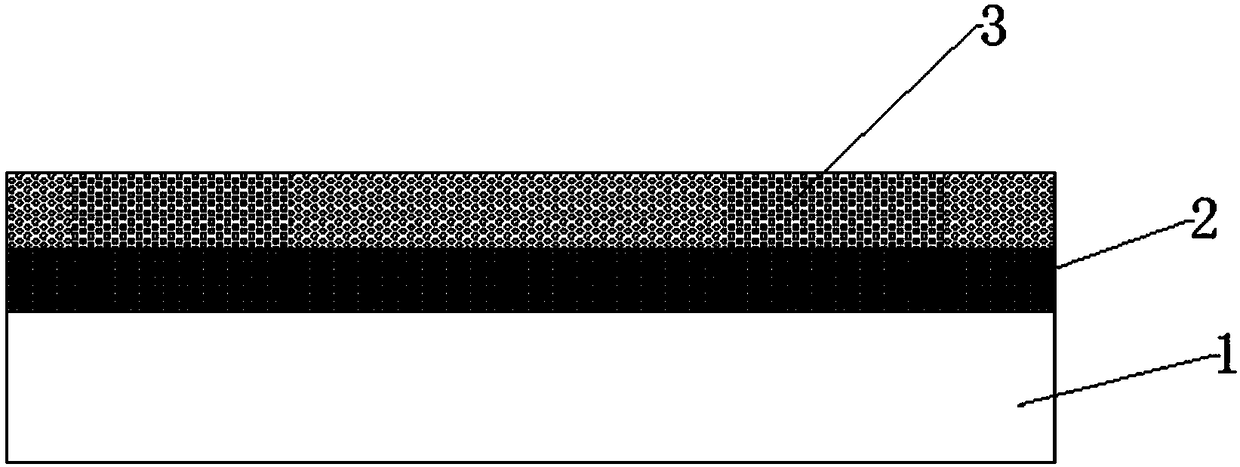

[0032] According to Embodiment 1, the coating of the present invention includes a polyetheretherketone underlayer attached to a metal substrate and a PTFE-containing coating formed on the polyetheretherketone underlayer as a non-stick surface layer.

specific Embodiment approach 2

[0033] According to Embodiment 2, the coating of the present invention includes a polyetheretherketone underlayer attached to a metal substrate and PFA as a non-stick surface layer formed on the polyetheretherketone underlayer.

specific Embodiment approach 3

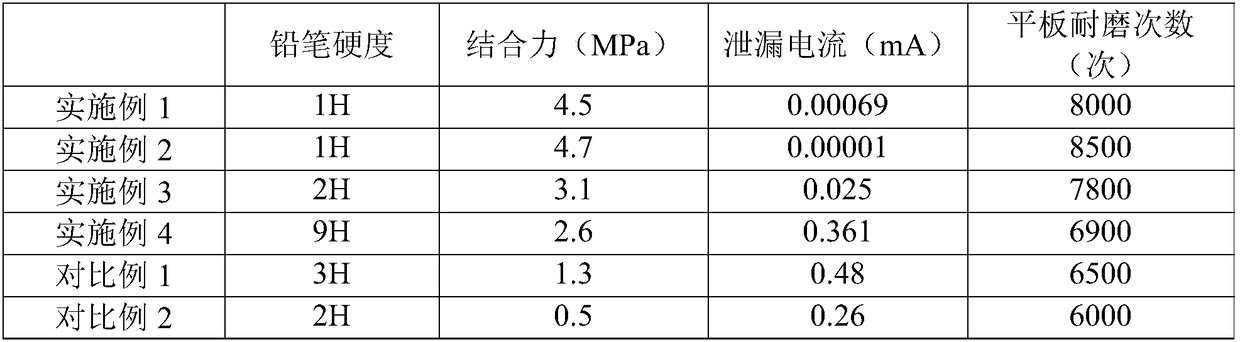

[0034] According to Embodiment 3, the coating of the present invention includes a polyether ether ketone bottom layer attached to a metal substrate, and a PTFE-containing coating and PFA as a non-stick surface layer formed sequentially on the polyether ether ketone bottom layer. The inventors of the present invention have found that the polyether ether ketone bottom layer has a synergistic effect with PTFE and PFA as the non-stick surface layer formed sequentially on the polyether ether ketone bottom layer, so that the present invention formed by using the specific embodiment 3 Scratch and corrosion resistance as well as surface hardness and coating adhesion can be optimized for non-stick coatings.

[0035] According to Embodiment 4, the coating of the present invention includes a polyether ether ketone bottom layer attached to a metal substrate and a ceramic coating formed on the polyetheretherketone bottom layer as a non-stick surface layer.

[0036] The material forming the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com