Constant internal pressure air spring additional air chamber with continuously changing volume and working method

An air spring and continuous volume technology, which is applied in the field of vehicle air suspension system, can solve the problems of unstable internal pressure of air spring and reduction of suspension stiffness, achieve constant internal pressure, large stiffness variation range, and realize automatic and rapid effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

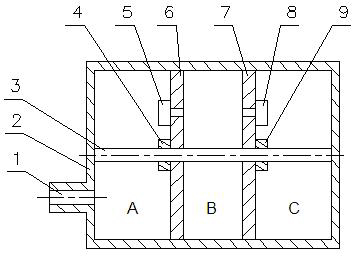

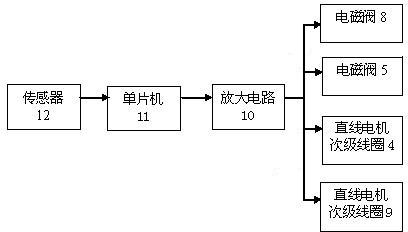

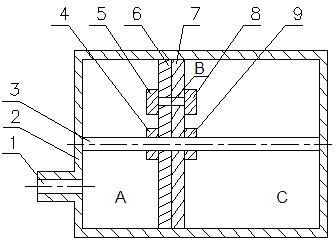

[0012] see figure 1 , the present invention has an air chamber cylinder 2, and one end of the air chamber cylinder 2 has an interface 1, and the interface 1 is connected to the air spring main air chamber, that is, the air spring main air chamber communicates with the air chamber cylinder 2 through the interface 1. Two partitions 6, 7, a double-secondary linear motor 3 and two solenoid valves 5, 8 are arranged in the cylinder body 2 of the air chamber. The first and second dividing plates 6,7 are arranged in the radial direction of the air chamber cylinder body 2, and there is a very small clearance fit between the first and second dividing plates 6,7 and the inner wall of the air chamber cylinder body 2, so that The first and second partitions 6 and 7 can move left and right in the air chamber cylinder 2 along the axial direction of the air chamber cylinder 2 . The first and second partitions 6 and 7 divide the gas chamber cylinder 2 into three chambers A, B and C, among wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com