Optimization method of process for repairing axial surface wear part by laser cladding

A technology of laser cladding and optimization methods, applied in design optimization/simulation, image data processing, special data processing applications, etc., can solve the problems of cash flow pressure, idle resource advantages, large workload, etc., to reduce experiments and errors Analysis, few coupling equations, and the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

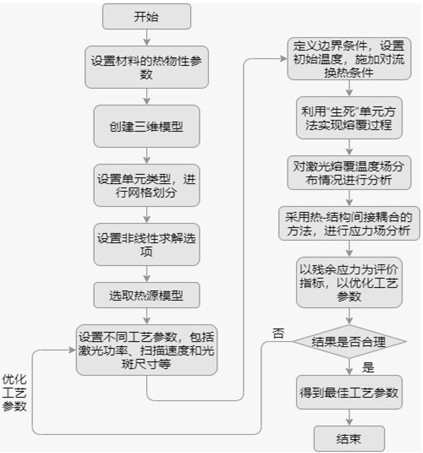

[0032] Embodiment: A method for optimizing the process of repairing worn parts on the shaft surface by laser cladding, which specifically includes the following steps:

[0033] (1) Determine the thermophysical parameters of axial wear parts and laser cladding powders with temperature changes, including thermal analysis physical parameters and stress analysis parameters. Thermophysical parameters include: density, thermal conductivity, specific heat capacity, heat transfer between air and workpiece Coefficient, elastic modulus, Poisson's ratio, yield strength, shear modulus, linear expansion coefficient, in addition to the total heat transfer coefficient of air, and all parameters are defined according to the change of temperature. ANSYS APDL software can consider the effect of material phase change by defining the enthalpy value of material with temperature change. The change in enthalpy in numerical simulation can be expressed as: , where ρ is the density, and c is the spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com