Mono-disperse gallium oxide powder and method for preparing high-density ceramic targets from mono-disperse gallium oxide powder

A ceramic target, gallium oxide technology, applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve the problems of increased risk, long production cycle, increased economic cost, etc., and achieves convenient operation, The effect of high yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

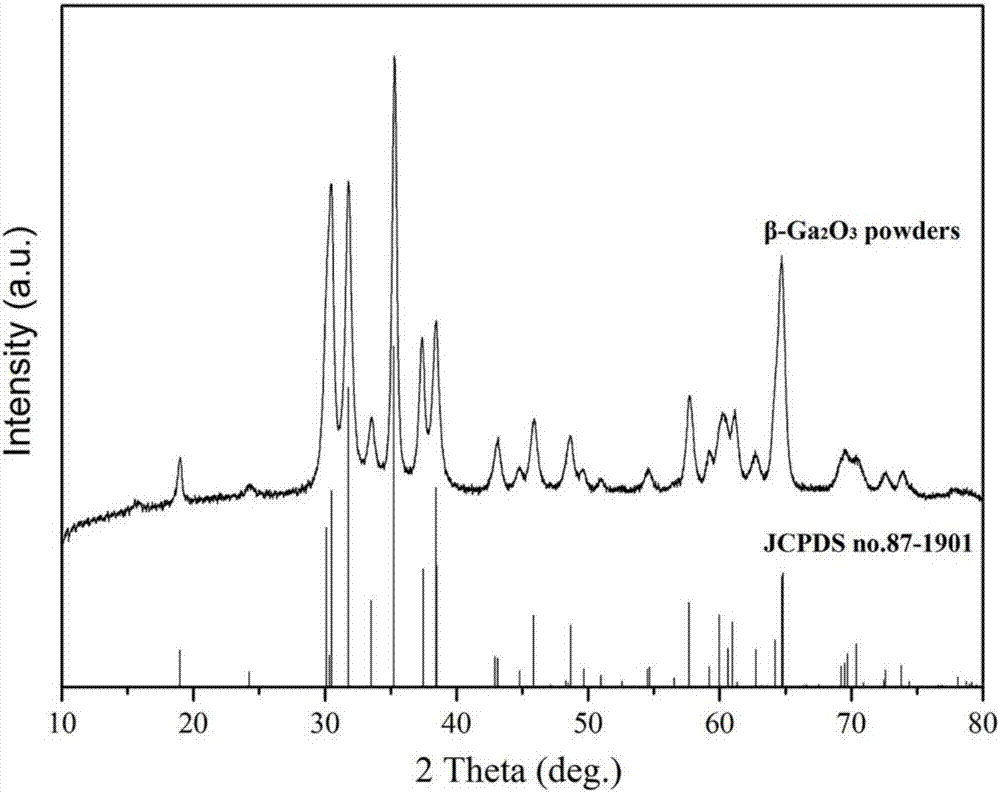

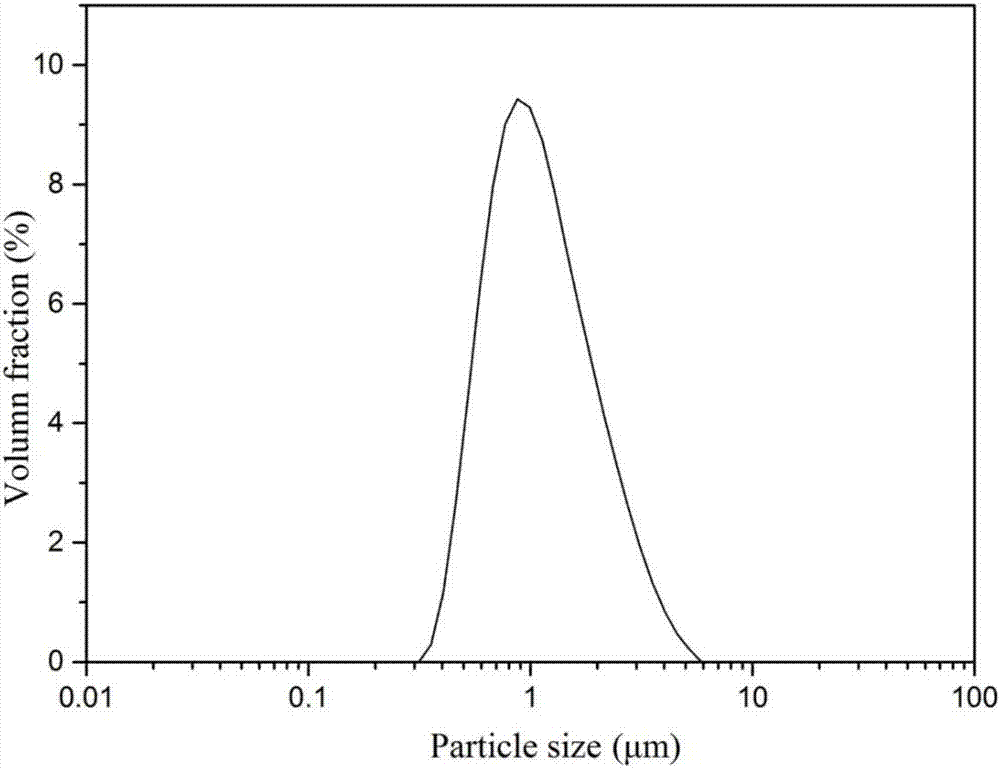

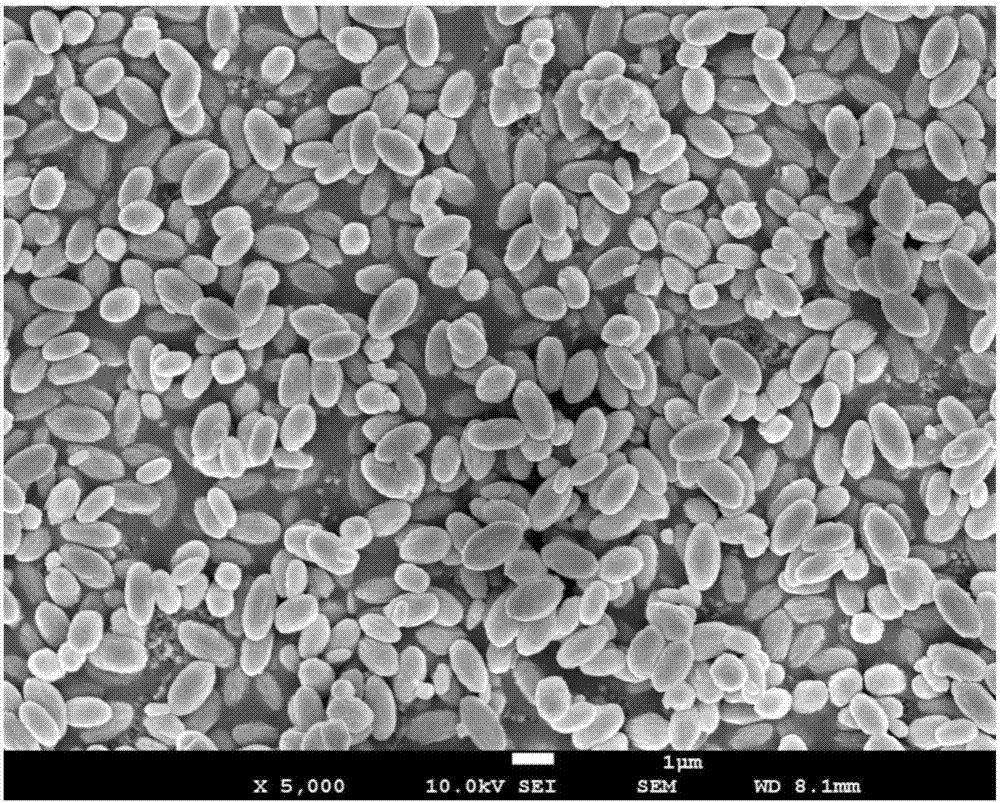

[0036] Gallium metal with a purity of 99.999% was used as a raw material, and 13.95 g (0.2 mol) of gallium metal was weighed. Use 65% concentrated nitric acid to dissolve gallium in a water bath at 50° C. After the gallium is completely dissolved, dilute the solution with deionized water to a 0.1 mol / L gallium nitrate solution. The above solution was placed in a water bath, and under mechanical stirring, a 10-fold diluted ammonia solution (25%) was added dropwise with a peristaltic pump, and the reaction temperature was controlled at 20°C. When the pH value of the reaction solution was 9, the dropwise addition of aqueous ammonia was stopped. Continue to stir the reaction solution and age it for more than 3 hours. During this process, ammonia water is added to keep the pH value stable at 9±0.2. The obtained precipitate was washed three times with deionized water, filtered and dried at 100° C. for 12 h. The obtained dry powder was calcined at 800° C. for 3 h to obtain gallium ...

Embodiment 2

[0038] Gallium metal with a purity of 99.999% was used as a raw material, and 13.95 g (0.2 mol) of gallium metal was weighed. Use 65% concentrated nitric acid to dissolve gallium in a water bath at 50° C. After the gallium is completely dissolved, dilute the solution with deionized water to a 0.2 mol / L gallium nitrate solution. The above solution was placed in a water bath, and under mechanical stirring, a 10-fold diluted ammonia solution (25%) was added dropwise with a peristaltic pump, and the reaction temperature was controlled at 30°C. When the pH value of the reaction solution was 8, the dropwise addition of aqueous ammonia was stopped. Continue to stir the reaction solution and age it for more than 3 hours. During this process, ammonia water is added to keep the pH value stable at 8±0.2. The obtained precipitate was washed three times with deionized water, filtered and dried at 100° C. for 12 h. The obtained dry powder was calcined at 900° C. for 1 h to obtain gallium ...

Embodiment 3

[0040] Gallium metal with a purity of 99.999% was used as a raw material, and 13.95 g (0.2 mol) of gallium metal was weighed. Use 65% concentrated nitric acid to dissolve gallium in a water bath at 50° C. After the gallium is completely dissolved, dilute the solution with deionized water to a 0.2 mol / L gallium nitrate solution. The above solution was placed in a water bath, and under mechanical stirring, a 10-fold diluted ammonia solution (25%) was added dropwise with a peristaltic pump, and the reaction temperature was controlled at 80°C. When the pH value of the reaction solution was 8, the dropwise addition of aqueous ammonia was stopped. Continue to stir the reaction solution and age it for more than 3 hours. During this process, ammonia water is added to keep the pH value stable at 8±0.2. The obtained precipitate was washed three times with deionized water, filtered and dried at 60° C. for 24 h. The obtained dry powder was calcined at 900° C. for 2 h to obtain gallium o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com