Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "Easy to remove the film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood plastic composite material building mould board, its preparation method and use

InactiveCN1948665AGood flexibilityGood compatibilityDomestic articlesForming/stuttering elementsWear resistantMechanical property

This invention discloses a kind of wood-plastic composite materials for construction template and its preparation methods and purposes. It belongs to building materials area. Against poor toughness, small strength and high cost defects of existing technologies, the main materials of this invention are PVC resin and / or plastic (new materials or waste materials) and wood fiber powder, the second materials are calcium power PE resins, short glass fiber, then adds the assistant, through mixing, heating, agitating, extrusion to matrix and cooling to shape, cutting steps to made into templates. It can increase the strength of plate by increasing various forms of reinforced structure in the process of preparation. It can be used for construct template of concrete processing. This invention can be recycled for several times, environmental protected, save resources and of low cost; the template are wear resistant and defend worms, non-absorbent, and hard to deform, with good mechanical properties, low coefficient of thermal conductivity, anti-acid and alkali.

Owner:四川自强科技有限公司

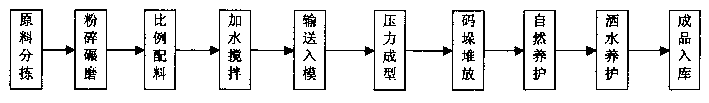

Baking-free slag brick and method of making same

InactiveCN1448360ALow raw material costSolve processing problemsSolid waste managementCeramic shaping apparatusBrickSlag

The baking-free slag brick is produced with building slag, inferior stone, cement with water-reducing agent in 1-2 % added, flash and lime. The production process includes the steps of: crushing andgrinding material, mixing, pressure molding at the pressure of 170-200 kg / sq cm to form adobe, and curing of the adobe at temperature over 0 deg.c for over 15 days. The utilization of building slag can reduce pollution and lower cost.

Owner:张庆军 +1

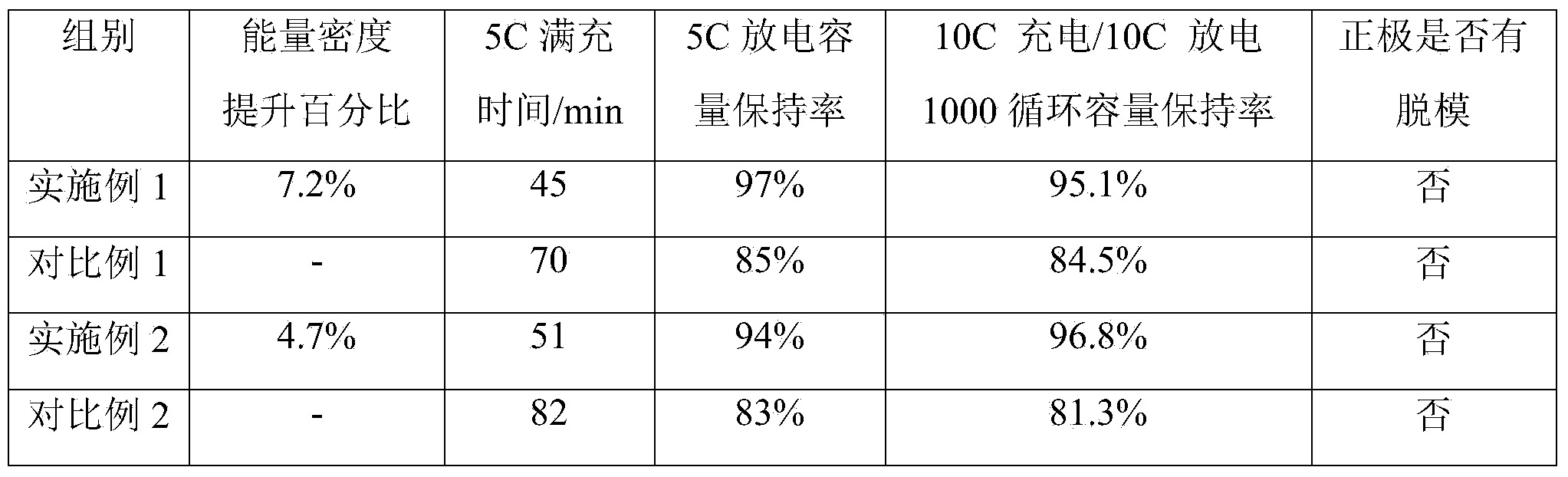

Lithium ion battery

InactiveCN104362346AGuaranteed not to release the filmIncrease energy densityCell electrodesSecondary cellsFiberCarbon fibers

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery. The lithium ion battery comprises a positive plate, a negative plate, an isolating membrane spaced between the positive plate and the negative plate and electrolyte, wherein the positive plate comprises a positive current collector and a positive active material layer arranged on the surface of the positive current collector; the positive active material layer comprises components in percentage by mass as follows: 98.1%-99.8% of positive active materials, 0.1%-1% of a positive conductive agent and 0.1%-1% of a positive adhesive; and a negative conductive agent comprises at least one of carbon fiber, carbon nano tubes, carbon nanorods and graphene or a mixture of carbon black with at least one of carbon fiber, carbon nano tubes, carbon nanorods and graphene. Compared with the prior art, the energy density of the battery and the high-power charge and discharge characteristics of the battery are improved under the premise that a diaphragm isn't separated.

Owner:DONGGUAN AMPEREX TECH

Water soluble anti-rust agent

InactiveCN101712817AShort film forming timeImprove quick-drying performanceAnti-corrosive paintsHazardous substanceSebacic acid

The invention relates to a water soluble anti-rust agent on the surface of ferrous metal, which comprises the following components: 2 to 10 weight percent of barium petroleum sulfonate and / or barium dinonyl decyl sulfonate, 1 to 6 weight percent of sodium molybdate and / or amine molybdate, 0 to 10 weight percent of sebacic acid, 2 to 10 weight percent of polyacrylic ester, 3 to 20 weight percent of triethanolamine oleic soap and / or 2 to 6 weight percent of polyoxyethylenesorbitan monooleate, 0 to 15 weight percent of sodium alkylsulfonate, 0 to 8 weight percent of glycerin and the balance of water or machine oil. Compared with the conventional water soluble anti-rust agent, the water soluble anti-rust agent of the invention has the advantages of short film forming time, firm film forming adsorption and good anti-rust effect; the actual anti-rust period can reach 3 to 6 months; the formed film is thin and only 3 to 5 microns; common workpieces do not need film removal and can be directly assembled and coated; the film removal is convenient, and the film is only soaked and rinsed in mild water over 50DEG C and then can be removed quickly; and the anti-rust agent has no component containing toxic and harmful substances, does not contain phosphorus, has the advantages of good environmental protection and no pollution to the environment, and is the environment-friendly water soluble anti-rust agent.

Owner:无锡市弘育化工有限公司

Preparation method for magnetic carrier in processing technique of sewage biological fluidized bed

InactiveCN101597105AHigh recovery ratePromote growthInorganic material magnetismSustainable biological treatmentCrusherCoking wastewater

The invention discloses a preparation method for a magnetic carrier in a processing technique of a sewage biological fluidized bed, which comprises the following steps: (1) magnetic powder is added into a reaction kettle; in the stirring speed of 40 to 100 r / min, inorganic acid and organic acid are sequentially added and heated till the temperature is risen to 65 to 80 DEG C and the reaction lasts for 1.5 to 2 hours; (2) reactant is transferred to a dying cabinet, dried for 0.5 to 1 hours in the temperature of 80 to 100 DEG C, anhydrated, cooled and then crushed by a grinding crusher and sieved with a mesh screen with 100 meshes to obtain granular magnetic carriers. The preparation method has simple process route, low energy consumption, high efficiency and low cost. The magnetic carrier obtained by the preparation method is a shell structure; microorganisms easily grow biological membranes on the magnetic carrier; residual biological membranes can be removed by a magnetic drum separator, thus avoiding the huge loss of organisms. The biological fluidized bed using the magnetic carrier is suitable for fields such as standard reaching discharging treatment of town sewage, synchronous denitrification and dephosphorization of high nitrogen and phosphorus medical waste water, nitrification and denitrification of garbage percolate, coking wastewater and the like.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

Method for preparing collagen film

ActiveCN102504302AIncrease added valueReduce manufacturing costFlexible coversWrappersEmulsionPlasticizer

The invention relates to a method for preparing a collagen film, relating to a food packaging film. The method comprises the following steps of: immersing the raw materials, such as fish skin, fish scales, fish bones or fish muscles and the like, by using an alkaline solution, after rinsing the raw materials to be neutral by using clear water, immersing the raw materials by using a hydrochloric acid aqueous solution, rinsing the raw materials to be neutral by using clear water again, then extracting in hot water, and mixing after adding an edible plasticizer into the obtained collagen aqueoussolution so as to obtain a collagen film solution; after heating and dissolving an aqueous solution containing an edible hydrophobic substance and an edible emulsifier, carrying out homogenization and emulsification treatment by utilizing a tissue pounding machine, and preparing a hydrophobic substance emulsion; and, after mixing the modulated collagen film solution and the hydrophobic substance emulsion, carrying out homogenization and emulsification treatment, after defoaming, uniformly coating the mixture on organic silicon resin, after drying, cooling the organic silicon resin to room temperature, and stripping the film so as to obtain the collagen film.

Owner:JIMEI UNIV

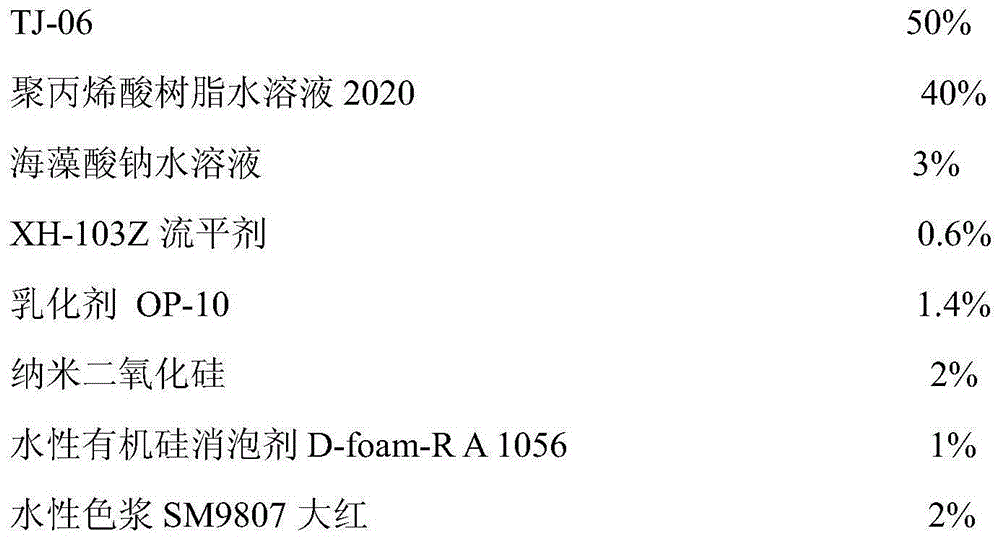

Washable touch screen temporary protection ink as well as preparation method and application thereof

InactiveCN105038401AImprove the disadvantages of insolubleImprove smoothnessInksOther printing apparatusWater basedEmulsion

The invention discloses washable touch screen temporary protection ink as well as a preparation method and application thereof. The washable touch screen temporary protection ink consists of the following raw materials by weight percent: 0 to 50 percent of polyacrylic acid resin solution, 5 to 90 percent of water-based paint resin, 5 to 50 percent of water-soluble macromolecule solution, 0 to 70 percent of polyacrylate emulsion, 1 to 10 percent of packing, 0.1 to 2 percent of pigment and 2 to 5 percent of functional additive, wherein the polyacrylic acid resin solution and the polyacrylate emulsion are not simultaneously equal to 0. When in preparation, a polyacrylic acid solution, the polyacrylate emulsion, a water-based leveling agent and packing are placed into a dispersion machine and uniformly mixed, and then the other components are placed into the dispersion machine to be uniformly mixed to obtain the washable touch screen temporary protection ink. The ink can protect touch screen cover plate glass or an ITO glass surface layer film against damage during a construction process at a high temperature of 200 DEG C; moreover, after the ink is used at 200 DEG C, the ink can fall off in block shapes in 30s to 2min after being soaked in water with the temperature of 50 DEG C.

Owner:SOUTH CHINA UNIV OF TECH

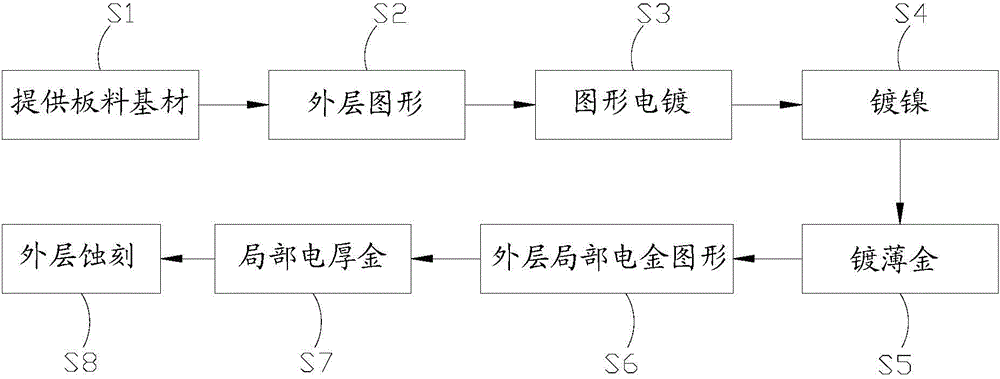

Printed circuit board and processing method thereof

InactiveCN104812171AEasy to remove filmShorten the processing cycleConductive pattern reinforcementCopper foilPattern processing

The invention is applied to the technical field of a printed circuit board, and provides a processing method of a printed circuit board and a printed circuit board formed by use of the processing method, for the purpose of solving the problems that since local electroplating thick gold processing is carried out after external-layer etching processing, a local electroplating thick gold position cannot be conductive and lead wires cannot be added to a part of the printed circuit board in the prior art. The processing method of the printed circuit board comprises the following step of providing a plate substrate, an external-layer pattern, pattern electroplating, nickel plating, thin gold plating, external-layer local electroplating gold pattern processing, the local electroplating thick gold processing and external-layer etching. According to the processing method, before the external-layer etching processing, the external-layer local electroplating gold pattern processing and the local electroplating thick gold processing are carried out, so that conductive lead wires are additionally arranged on an external-layer line pattern, the whole copper foil layer of the plate substrate can be conductive, the membrane removing operation is simple, the manufacturing efficiency is improved, and the processing period is shortened.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Removal method of PCB electroplating lead

ActiveCN107708321AResidue reductionAvoid the disadvantages of not being able to coverPrinted circuit manufactureSolder maskEngineering

A removal method of a PCB electroplating lead is used for removing an excess electroplating lead on a PCB and comprises a step (1) of providing a PCB on which a copper layer, a pad, a gold finger, animpedance line and an electroplating lead are arranged, wherein the electroplating lead and the pad are both provided with a solder mask protection layer on the outer sides; a step (2) of opening a window in the solder mask protection layer; a step (3) of selecting plating ink; a step (4) of performing pad surface treatment; a step (5) of removing a film; and a step (6) of etching to remove the lead. The beneficial effects of the invention are that the un-removed lead at one end of the pad in the subsequent procedure is made shorter and electrical parameters of the gold finger are more stableby providing the convex window; and the shortcoming of failing to cover the sidewall of the lead can be avoided and the film removal is facilitated by covering the lead with the selected plating ink;the residue of the lead can be reduced by using the etching method to remove the lead; and the removal method is highly practical and has a great significance in popularization.

Owner:东莞康源电子有限公司

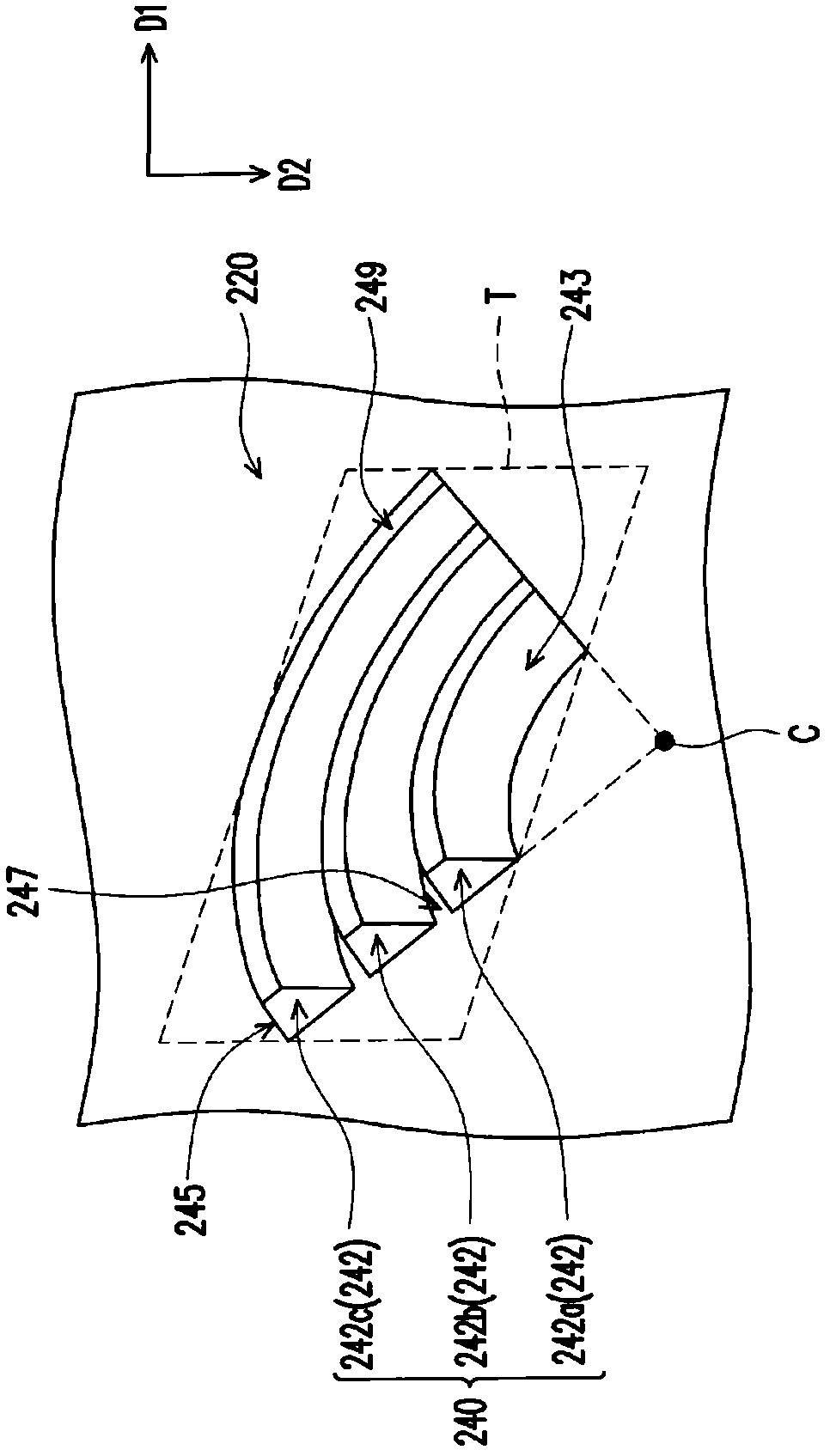

Light guide plate and light source module

ActiveCN102621622AEasy to remove the filmReduce usageMechanical apparatusElectric lightingLight guideComputer module

A light guide plate including a first surface, a second surface, at least one light incident surface, and a plurality of groove sets is provided. The light incident surface connects the first surface and the second surface. The groove sets are separately disposed on the second surface. Each of the groove sets includes a plurality of curved grooves. Each of the curved grooves has a curved inclined reflective surface and a curved back-to-light surface connected thereto. The curved inclined reflective surface is inclined with respect to the first surface. The curved grooves of each of the groove sets curve toward the same curving direction. The curved inclined reflective surface of one of two adjacent curved grooves is connected to the curved back-to-light surface of the other one of the two adjacent curved grooves through a connection surface. A light source module is also provided. By using the light guide plate, the light loss can be reduced. The light source module provided in the invention has higher light utilization rate.

Owner:CORETRONIC

Novel metallic film preparation technology on liquid phase substrate surface

InactiveCN1730716AEasy to operateUnique microstructureVacuum evaporation coatingSputtering coatingGrain structureVacuum evaporation

Disclosed is a novel metallic film preparation technology on liquid phase substrate surface, which comprises using liquid phase material whose saturated vapor tension is lower than the vacuum evaporation pressure as substrate, employing magnetron sputtering or thermal deposition method, evaporating the metal atoms with energy of argon ions in high speed movement or tungsten filament heated by electric current, then depositing the evaporated metal atoms onto liquid phase substrate surface, finally growing metallic film having polycrystalline grain structure through diffusion, core formation, rotation and agglomeration. The film has substantially no internal stress.

Owner:ZHEJIANG UNIV

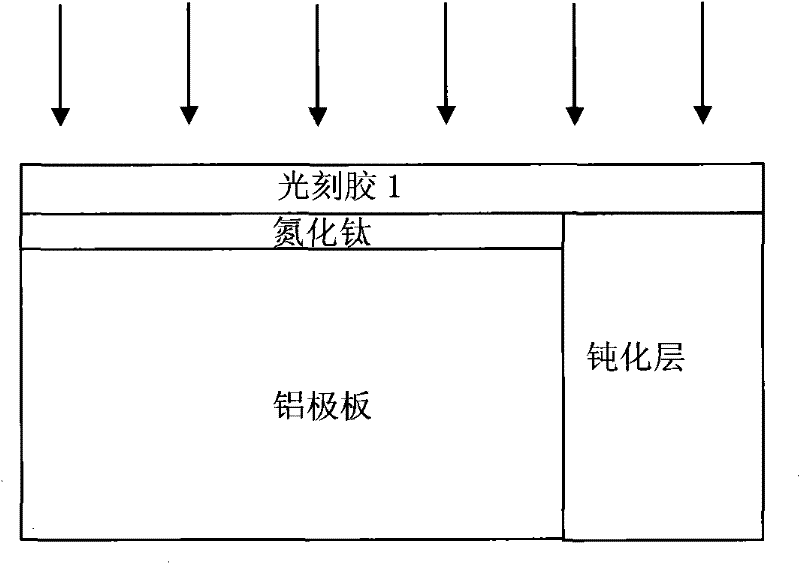

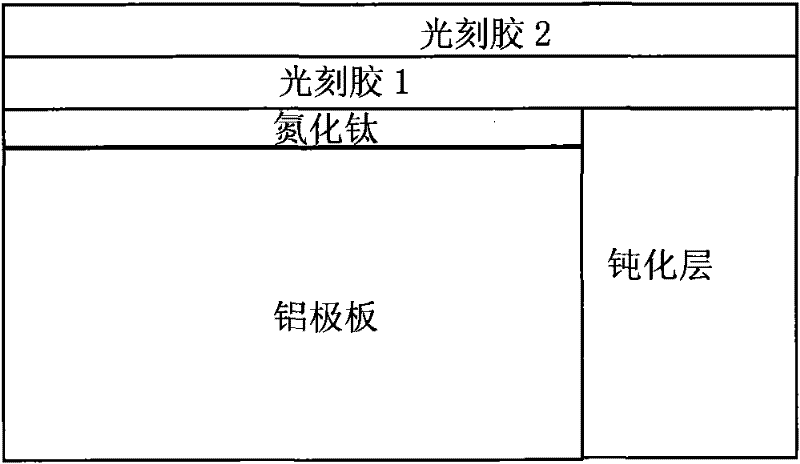

Method for plating silver on front side of silicon wafer

InactiveCN102130024AImplement selective coverageEasy to remove the filmSemiconductor/solid-state device manufacturingPhotosensitive material processingEvaporationSilicon chip

The invention discloses a method for plating silver on the front side of a silicon wafer, which comprises the following steps of: coating photoresist on the front side of the silicon wafer for the first time, and performing exposure on the full silicon wafer; coating the photoresist for the second time, and performing the exposure for the second time by using a photoetching mask; developing, so that the retained photoresist forms an inverted trapezoid graph; depositing the silver on the silicon wafer by an evaporation coating technology, wherein the thickness of the silver is less than that of the retained photoresist; laminating on the silicon wafer and stripping by a laminating and film stripping technology, so that the silver on the photoresist is stripped with a film; and removing the residual photoresist.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

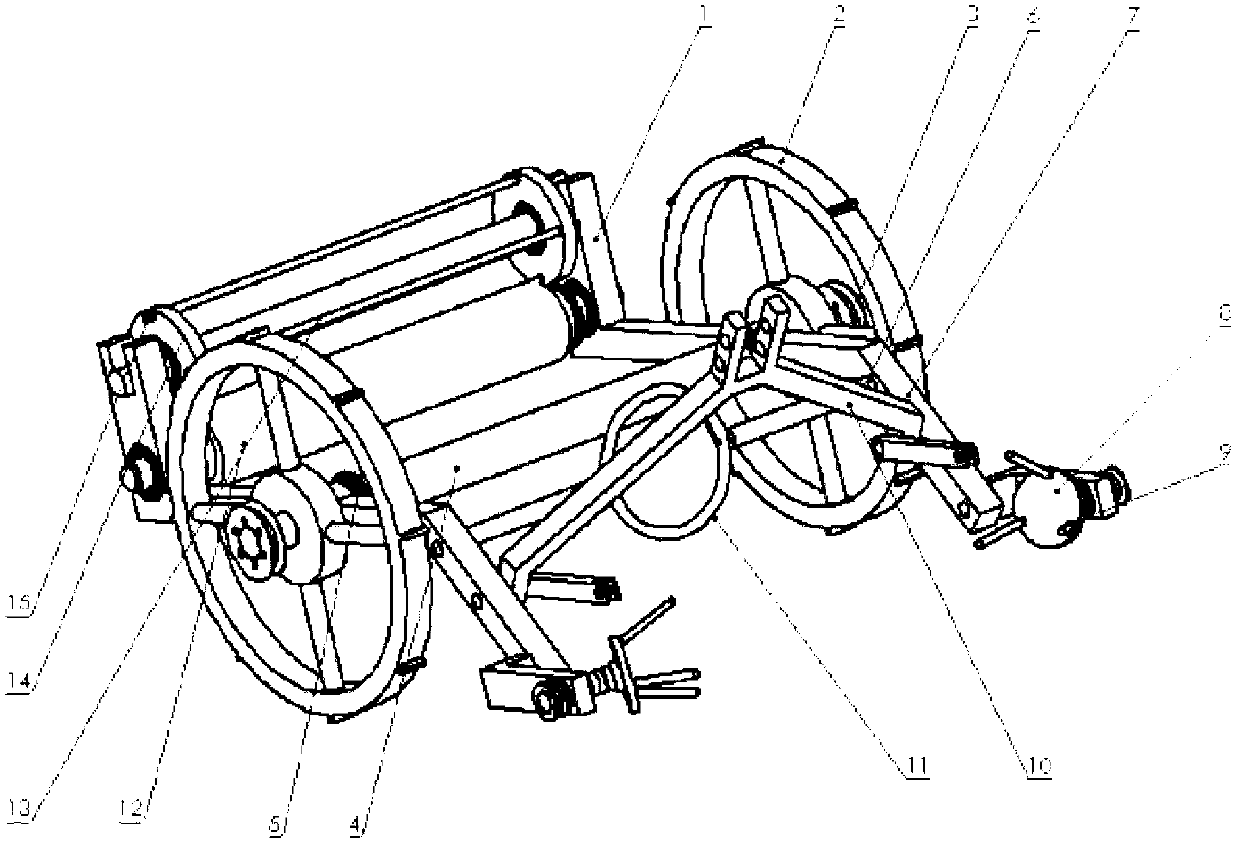

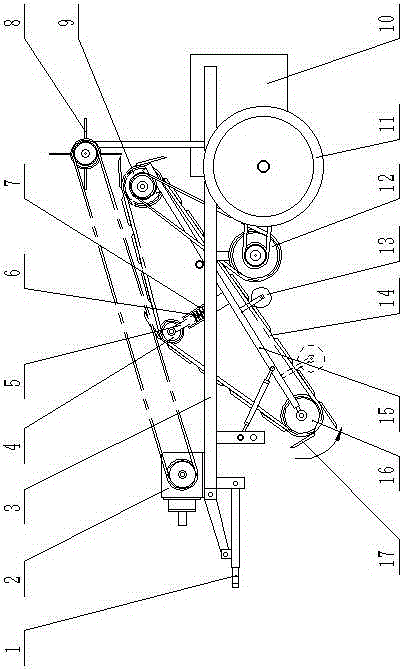

Picking tooth film-rolling type recycling machine for residual plastic films

InactiveCN103125159ARealize continuous recycling operationImprove tensile propertiesGatherer machinesTraction frameEngineering

The invention belongs to the field of agricultural machinery, in particular to a picking tooth film-rolling type recycling machine for residual plastic films suitable for picking crops of smaller stubbles. The recycling machine comprises a rack (1) and a traction frame (10), a land wheel shaft (4) is mounted in the middle of the rack (1), and a land wheel (2) is arranged on the land wheel shaft (4) and is disposed on an external side of the rack (1). A mulching film tightening ring (11) is connected at a middle-front position of the rack (1) through an annulus support rod (6). One end of a disc support frame (7) is connected with the front end of the rack (1), the other end of the disc support frame (7) extends forward to be connected with a film-picking disc (8), and a plurality of picking teeth (9) are uniformly distributed on film-rolling cylinders (14) at intervals. Friction wheels (12) are further arranged below the film-rolling cylinders (14). The picking tooth film-rolling type recycling machine for the residual plastic films is simple in structure, reliable in working and high in residual plastic film recovery rate.

Owner:CHINA AGRI UNIV

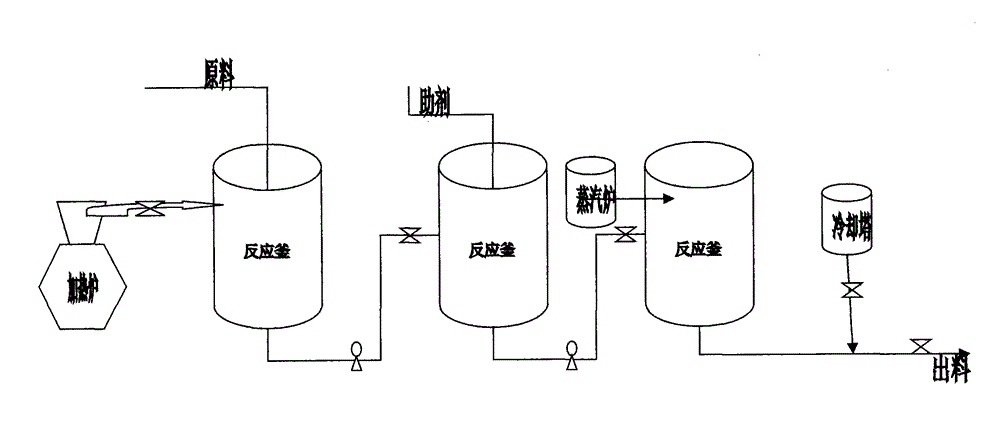

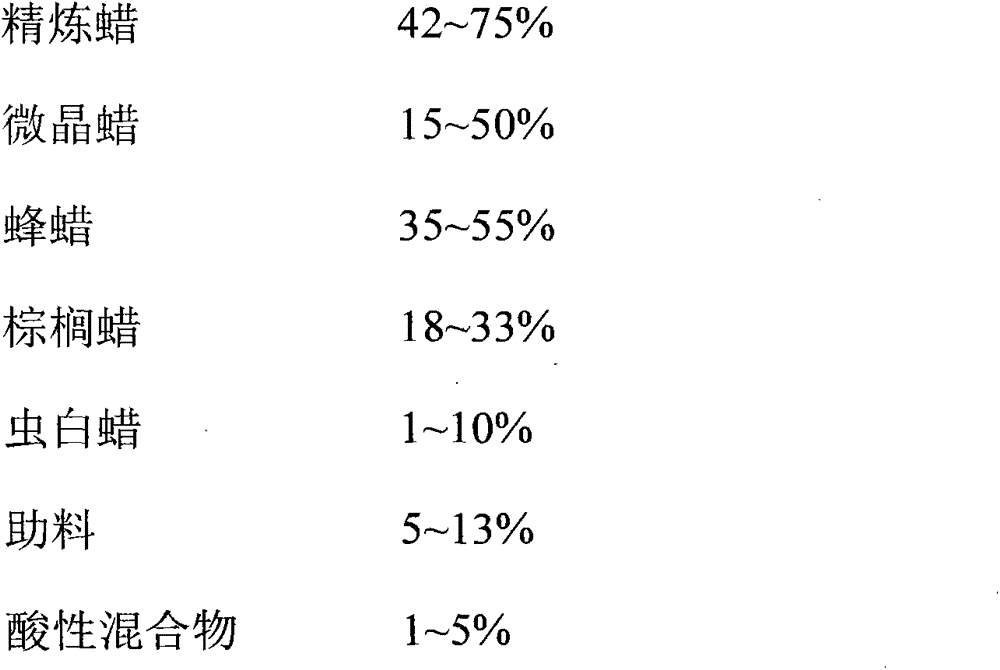

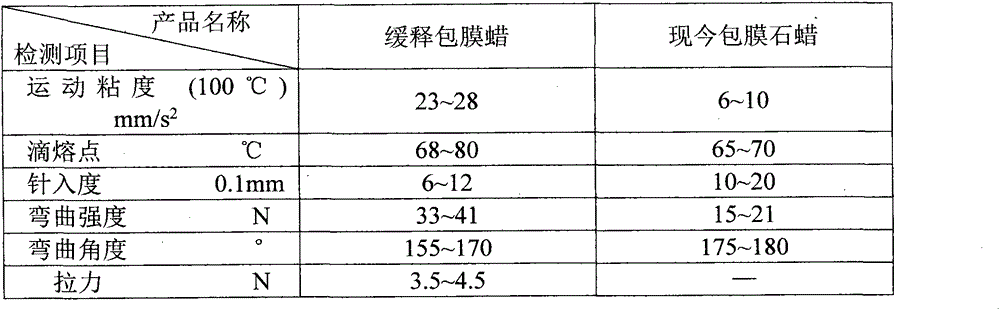

Slow release coated wax of efficient slow release composite fertilizer

InactiveCN104003784AAdjustable and controllable drop melting pointNo damage to technical indicatorsFertilizer mixturesMicrocrystalline waxUltimate tensile strength

The invention relates to a slow release coated wax of an efficient slow release composite fertilizer. The slow release coated wax of an efficient slow release composite fertilizer is glistened particles, and is prepared through a reaction of main raw materials comprising 42-75wt% of refined wax, 15-50wt% of microcrystalline wax, 35-55wt% of beeswax, 18-33wt% of palm wax and 1-10wt% of Chinese insect wax, and substances comprising an additive, an assistant, a biodegradation promotion substance, an acidic mixture and an organic material at 95-105DEG C for 20-40min. The slow release coated wax of an efficient slow release composite fertilizer has the advantages of simple preparation, wide raw material sources, good toughness and strength, good slow release effect in soil, neutralization of alkaline soil, and no pollution to the environment.

Owner:DALIAN NINGHUA MICROCRYSTALLINE WAX CHEM

Liquid demoulding coating for precise die casting of aluminum alloy

InactiveCN101758161AFully lubricatedEasy to remove the filmFoundry mouldsFoundry coresEmulsionDie casting

A liquid demoulding coating for precise die casting of aluminum alloy mainly comprises (by weight percentage) 70-85% of mineral oil selected from machine oil, hydraulic oil, diesel oil and gasoline, 25-35% of silicone oil (preferably, water-soluble silicone oil) and water and a proper amount of emulsion. The liquid coating not only has excellent lubrication effect on aluminum alloy casting chamber and facilitates demoulding, but also effectively cools the aluminum alloy casting chamber and improves product quality.

Owner:WUJIANG TIANLONG MACHINERY

Method for protecting chip in chip thinning process

ActiveCN101982870AImprove protectionLow costSemiconductor/solid-state device manufacturingAdhesiveThinning

The invention discloses a method for protecting chip in chip thinning process. A 3193 type or 319Y type hot stripping foil, a vacuum pad and a stripping heater are adopted, the 3193 type or 319Y type hot stripping foil is used for covering the front of silicon chip product, so as to carry out the chip thinning process, after chip thinning is qualified, and heating and stripping are carried out. The method of the invention is reasonable and simple, and chip front protection effect in the chip thinning process is good. The 3193 type or 319Y type hot stripping foil adopts hot foaming stripping adhesive, thus adhesive strength at normal temperature is extremely high, when temperature is increased to 135-145 DEG C, adhesive is foamed, stripping resistance is greatly reduced, so that stripping is easy, membrane can not be torn or remain on the surface of the silicon chip product, and meanwhile no adhesive residue is remained, operation is convenient, production material cost is saved, and product quality and working efficiency are greatly improved.

Owner:扬州晶新微电子有限公司

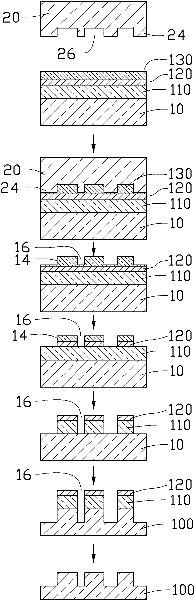

nanoimprint method

InactiveCN102279517AReduce adhesionIntegrity guaranteedNanoinformaticsPhotomechanical apparatusResistImage resolution

A nanoimprint method is provided. A substrate and a master stamp are first provided. The substrate has a first resist layer, a transition layer, and a second resist layer orderly formed thereon. The master stamp has a nanopattern defined therein. The second resist layer is a layer of hydrogen silsesquioxane. The nanopattern of the master stamp is then pressed into the second resist layer to form a nanopattern in the second resist layer at normal temperature which is in a range from about 20 centidegrees to about 50 centidegrees. Finally, the nanopattern of the second resist layer is transferred to the substrate.

Owner:TSINGHUA UNIV +1

Environmental-friendly long-acting sealing anti-rust oil composition and preparation method thereof

ActiveCN104450013AExcellent resistance to salt sprayExcellent water separation performanceLubricant compositionSolventChemistry

The invention discloses an environmental-friendly long-acting sealing anti-rust oil composition. The environmental-friendly long-acting sealing anti-rust oil composition is characterized in that the environmental-friendly long-acting sealing anti-rust oil composition is prepared from the following components in percentage by weight: 2-8 percent of petroleum calcium sulfonate, 0-8 percent of oxidized paraffin calcium soap, 1-2 percent of a film-forming agent, 3-10 percent of an anti-rust complexing agent, 15-30 percent of machinery oil and 58-77 percent of solvent oil. According to the anti-rust oil disclosed by the invention, the salt mist resistance, the moist resistance and the water separation property are excellent; metal barium and other heavy metals are not contained, so that the anti-rust oil is safe to use; the penetrating performance and the wettability are good; as the anti-pollution capacity is strong, and an oil film is formed by coating the anti-rust oil on the surface of a workpiece is thin, the anti-rust oil is small in oil consumption in the using process of a metal workpiece, the oil film is good in thixotropy and coating property, easy in film removal and wide in adaptation range of steel materials, and the anti-rust oil is suitable for long-time sealing and rust prevention of metal products made of steels in multiple textures and the like.

Owner:JIANGSU XINLU NEW MATERIALS CO LTD

Water-based UV coating having temporary protection effect as well as preparation method and application of coating

ActiveCN108485507AWith weak alkali resistanceHas a temporary protective effectPolyurea/polyurethane coatingsWater basedUV coating

The invention discloses a water-based UV coating having a temporary protection effect as well as a preparation method and application of the coating. The water-based UV coating comprises the followingcomponents in percentages by mass: 30-60% of water-based UV resin, 5-12% of a water-based UV monomer, 2-5% of a film forming auxiliary agent, 0.1-0.5% of a pH value adjusting agent, 0.1-1% of a water-based wetting agent, 0.1-0.5% of a water-based defoaming agent, 1-5% of a photoinitiator, 0.5-2% of an adhesion promoter, 0.5-5% of matting powder, and the balance of water, wherein the water-based UV resin is carboxyl-modified water-soluble polyurethane acrylate. The above water-based UV coating having the temporary protection effect disclosed by the invention has good adhesion and high hardness; and after the coating is sprayed on the surface of a metal substrate to form a temporary protection film, the formed film can effectively suppress an occurrence of badness such as scratches and burrs in the mechanical manufacturing processes such as drilling, punching and milling of metal workpieces, and is easy to take off at normal-temperature immersion and in an alkaline film taking off liquid, and the coating improves production efficiency.

Owner:HUNAN SOKAN NEW MATERIAL

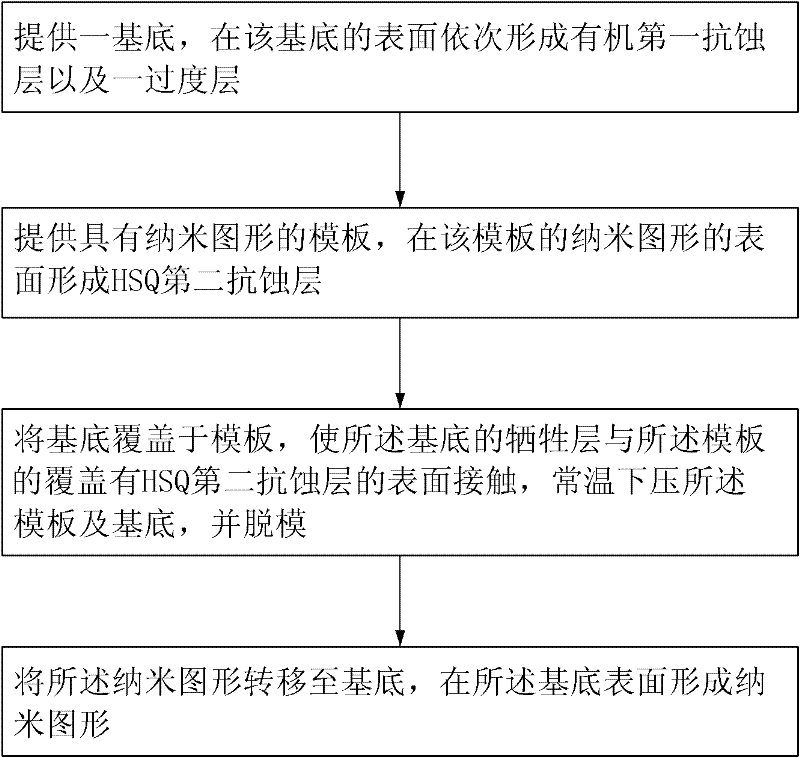

Photosensitive resin composition and application thereof

The invention discloses a photosensitive resin composition and application thereof. The resin composition comprises: in parts by weight, 40 to 70 parts of alkali-soluble resin, 20 to 50 parts of photopolymerization monomer, 0.5 to 10.0 parts of photoinitiator and 0.1 to 10.0 parts of additive, wherein the photopolymerization monomer comprises 0.5 to 15.0 parts by weight of a monomer containing a carbonate ester structure. The photosensitive resin composition is used as a dry film resist, has the characteristics of easy film stripping breakage, small film stripping fragments, high film stripping speed and the like, and has favorable line resolution and adhesive force, thereby effectively enhancing the production efficiency and product yield.

Owner:HANGZHOU FIRST ELECTRONIC MATERIAL CO LTD

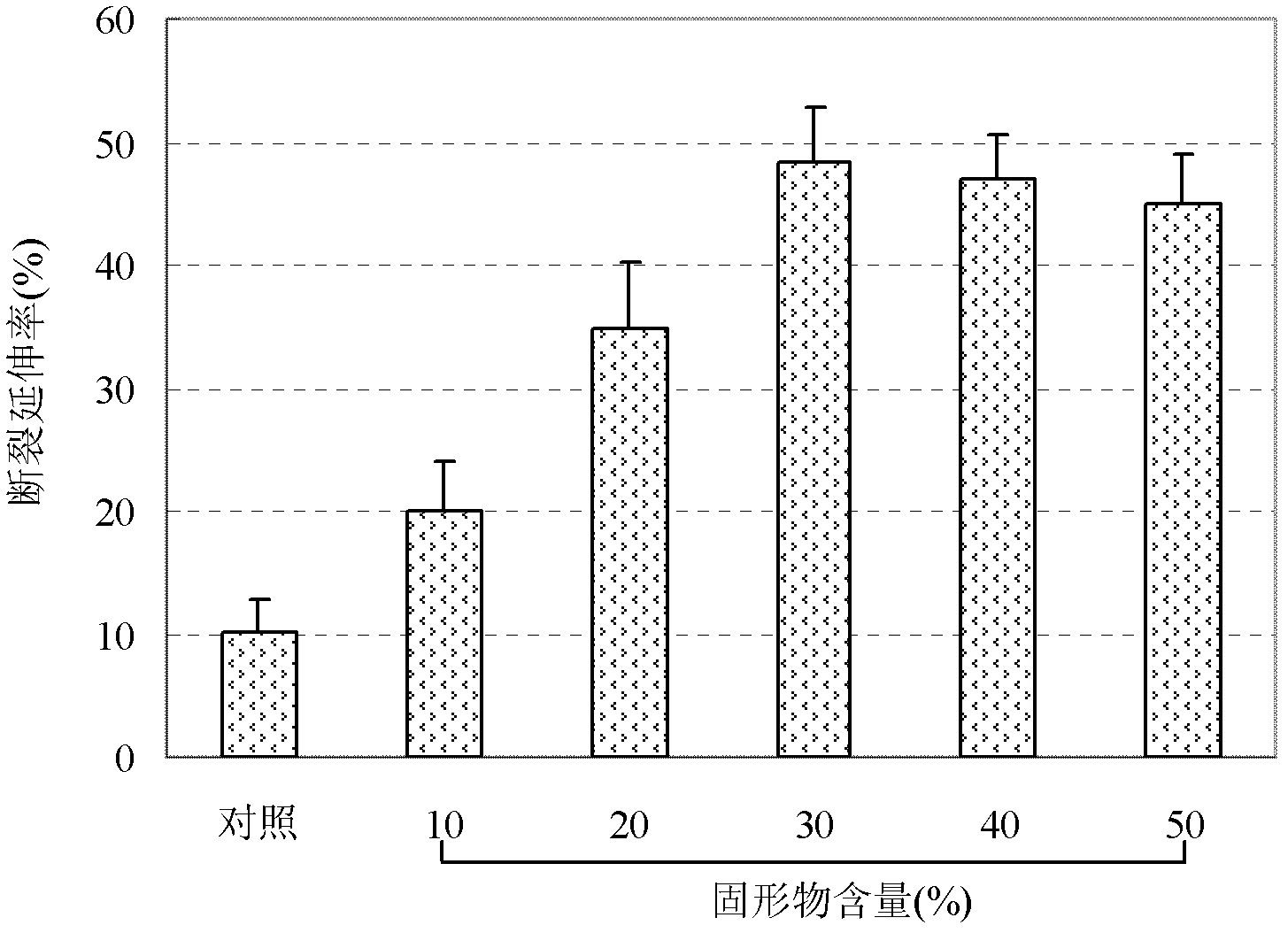

Preparation method of edible packaging film based on diatom polysaccharide

The invention discloses a preparation method of an edible packaging film based on diatom polysaccharide. The preparation method specifically comprises the following steps: degreasing diatom powder, concretely adding a chloroform methanol mixed solution into the diatom powder, carrying out degreasing, suction filtration, and drying to obtain degreased diatom powder; preparing the diatom polysaccharide, concretely uniformly mixing the degreased diatom powder with water, then adding 8-chlorotheophylline, and carrying out ultrahigh-pressure extraction and suction filtration, wherein the obtained filtrate is the water extracted crude polysaccharide; and preparing the edible packaging film, concretely taking the following components in parts by weight: the diatom polysaccharide, glycerol, gelatin, tea polyphenol and water, dissolving the components to prepare a film liquid, carrying out degassing, then uniformly pouring the degassed film liquid into a mold, and carrying out drying for forming a film, so as to obtain the edible packaging film. The preparation method disclosed by the invention has the beneficial effects that the preparation method is simple and feasible, the time consumption is low, the energy consumption is low, the utilization rate of the raw materials can be improved, and the degradable pollution-free packaging film with good performance can be formed. The surface of the packaging film is smooth and compact, the film is easy to uncover, and the packaging film is edible, is easy for industrial scale production and has good application value and market potential.

Owner:金华市铁骑士生物科技有限公司

Strawberry cultivation method

InactiveCN103355088AEnsure hygiene and safetyAvoid overgrowthPlant protective coveringsFragariaWeed infestation

The invention provides a strawberry cultivation method which comprises the following steps: after strawberries are planted for a month, covering a black mulching film, and leading strawberry seedlings out of the mulching film; constructing an arch-shaped canopy from the winter to the early spring period, and covering a top film. According to the strawberry cultivation method, the black mulching film can be used for preventing weed infestation and preventing fruits from being contacted with the ground and further being rotten, and has moisturizing and insulating effects; the top film is good in ventilation effect and can be used for preventing frosting, avoiding rain from beating the fruits and reducing the invasion of pathogens, and forms a double-layer protective system together with the mulching film; The strawberry cultivation method can be used for improving the yield and the quality, ensuring the security and sanitation of strawberries; 5-year test in Binyang county, Nanning city, Guangxi province proves that the yield can be increased by 30-50%.

Owner:韦中定

Fluorinated polyurethane porous membrane

ActiveCN106905690AImprove hydrophobicityExtended service lifeGrinding work supportsPorous membraneHydrophobe

The invention relates to a fluorinated polyurethane porous membrane. The structure of the porous membrane sequentially comprises a surface adsorption layer, a first foaming layer, a second foaming layer, a third isolating layer and a fourth foaming layer from top to bottom; the surface adsorption layer is a compact layer; both the first foaming layer and the second foaming layer are of drop-shaped porous structures; drop-shaped holes of the second foaming layer are larger than those of the first foaming layer; the thickness of the first foaming layer is 40 to 200 [mu]m; the thickness of the second foaming layer is 180 to 980 [mu]m; the thickness of the third isolating layer is 5 to 160 [mu]m; the thickness of the fourth foaming layer is 100 to 800 [mu]m. A glass grinding adsorption mat provided by the invention has a unique structure and stronger hydrophobic property, so that the progress of a polishing solution infiltrating into the porous membrane can be retarded, heat generated in the polishing process can be well dissipated out, and the service life of the grinding adsorption mat can reach 50 to 60 hours; compared with a glass grinding adsorption mat prepared from a known polyurethane resin composition, the glass grinding adsorption mat disclosed by the invention has the advantage that the polishing service life is prolonged by 10 to 20 hours.

Owner:ANHUI HECHEN NEW MATERIAL CO LTD

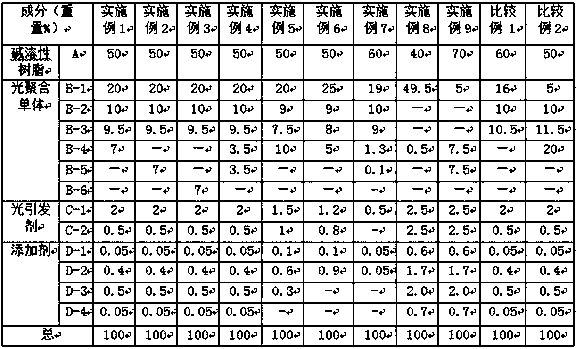

Water-soluble antirust liquid

The invention relates to water-soluble antirust liquid, which comprises the following components by weight: 2-5% of film-forming agent, 0.01-0.5% of film coalescing aid, 0.4-1.0% of antirust complex agent, 0.2-0.8% of preservative, 0.1-0.5% of defoamer, and 92-97.4% of mixed solvent. The water-soluble antirust liquid is a liquid state composition which can be used for many kinds of metal, especially for decorative protection on the metal shiny surface. The composition has the characteristics of high transparency, strong decorative protection and good antirust performance. The product is free from toxicity, extraneous odor and irritation. The liquid is good in film forming property and strong in binding force. The formed film is easily removed (by water), which does not influence the objective gloss of the original metal, so that the water-soluble antirust liquid is particularly suitable for long-term or short-term decorative protection of high-grade products.

Owner:GUANGDONG AOLIDAN IND

Water soluble rust inhibitor and preparation method thereof

The invention discloses a water soluble rust inhibitor, comprising the following components in parts by weight: 6-10 parts of macromolecule organic rust inhibitor, 3-10 parts of inorganic rust inhibitor, 8-15 parts of emulsifier, 2-6 parts of glycerinum, 5-10 parts of film-forming agent, 8-15 parts of petroleum sodium sulfonate and 40-60 parts of water. According to the water soluble rust inhibitor disclosed by the invention, a substance which can be dissolved into water at normal temperature and can form a film when meeting with black metal and organic and inorganic antirust components which have good anti-rust performance and can be combined with the film-forming agent are selected, so that an antirust protection film which is not dissolved into cold water is combined and formed by bridging action of the emulsifier, and the water soluble rust inhibitor is long in antirust time, thin and compact in formed film, convenient for film removal, and good in environmental protection property, can save a lot of cleaning materials and labor charges, and does not cause pollution to the environment.

Owner:刘晓萍

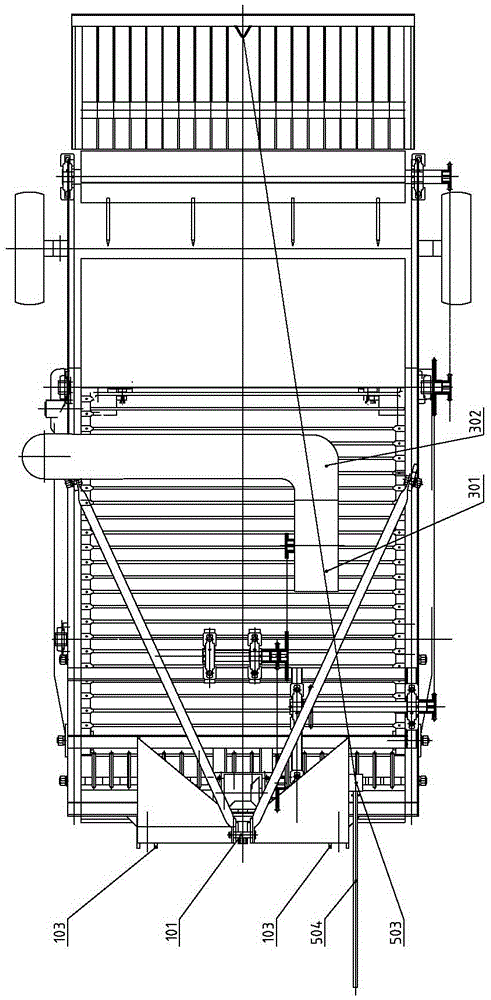

Clamp finger chain-type used plastic film collector

ActiveCN105191526ARecycle cleanMeet recycling requirementsGatherer machinesAgricultural engineeringSprocket

The invention relates to a clamp finger chain-type used plastic film collector which comprises a traction device, a rack, a film collection device, a film collection driving system, a film stripping device, a film stripping driving device, land wheels and a used plastic film tank, wherein the traction device is arranged at the front side of the rack; the film collection device is arranged at the middle of the rack; the film stripping device is arranged above the rear side of the film collection device; the used plastic film tank is arranged on the rear side of the film collection device; the film collection driving system and the film stripping driving system are respectively arranged on the rack; the film collection driving system is connected with the film stripping device; the land wheels are arranged at two sides of the rack; the film collection device consists of a film collection rack, a tensioning mechanism, a film clamping mechanism and a support chain roll; the tensioning mechanism consists of a support base, a spring, a bracket and a tensioner sprocket; the film clamping mechanism consists of a lower film collection sprocket, an upper film collection sprocket, a film collection chain and a clamp finger; the support chain roll is arranged at the lower sides of the film collection rack and the film collection chain. The clamp finger chain-type used plastic film collector has the advantages of simple structure, high operation speed and high used plastic film recovery rate, and can meet the used plastic film recovery requirement.

Owner:SHIHEZI UNIVERSITY

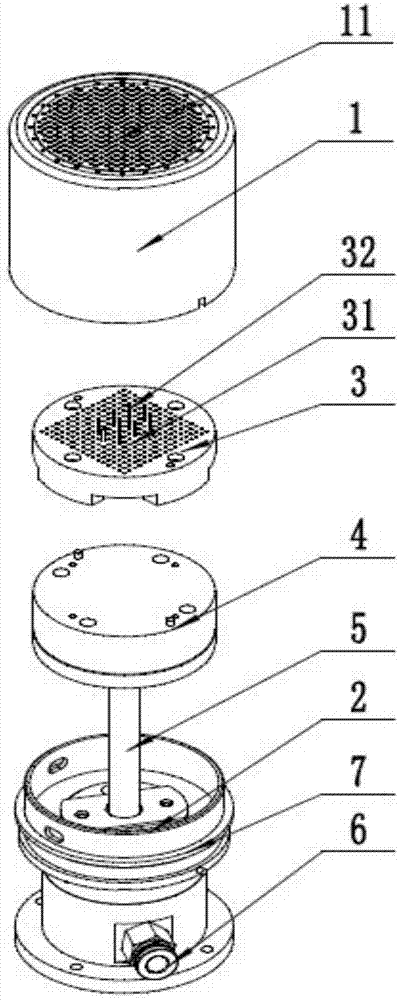

Ejector pin system

InactiveCN107093575AEasy to remove the filmFor quick replacementSemiconductor/solid-state device manufacturingEngineering

The invention discloses an ejector pin system, which comprises an ejector pin cap and a guide base, and is characterized in that the upper end face of the ejector pin cap is provided with first ejector pin holes, and the bottom of the ejector pin cap is connected with the guide base; the upper end of the guide base is further connected to an ejector pin fixing device, the ejector pin fixing device is located in the ejector pin cap, the upper surface of the ejector pin fixing device is provided with second ejector pin holes which are used for fixing ejector pins; the ejector pin fixing device comprises an ejector pin base and a magnetic attraction base, the magnetic attraction base is located at the bottom of the ejector pin base, fixation of the ejector pins adopts of a mode of magnetic attraction, and replacement is performed quickly, simply and conveniently; and both the first ejector pin holes and the second ejector pin hole adopt array distribution, any number of ejector pins can be installed at any positions, thereby being applicable to various sizes of chips, and being easy to demould the chips.

Owner:大连佳峰自动化股份有限公司

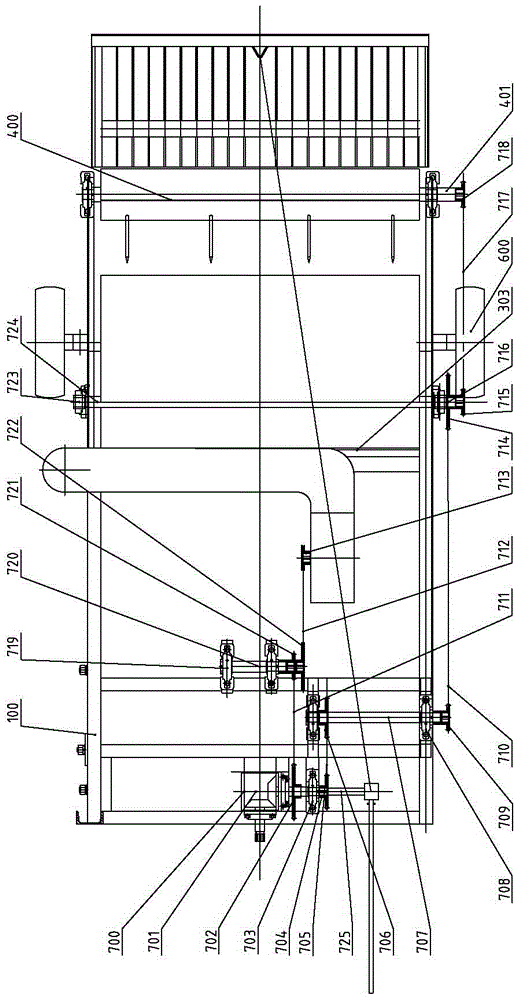

All-directional pneumatic film-and-weed-separation plastic-film-residue recycling machine

ActiveCN105850248AShallow working surfaceMissing rate is highSpadesPloughsSoil scienceAgricultural engineering

The invention discloses an all-directional pneumatic film-and-weed-separation plastic-film-residue recycling machine, relates to agriculture-field plastic-film-residue recycling, and in particular to a plastic-film-residue recycling machine which is capable of removing plastic film residues and weeds on the ground surface and the underground, achieving all-directional plastic-film-residue removing, and separating the plastic film residues from the weeds with the pneumatic mode. The all-directional pneumatic film-and-weed-separation plastic-film-residue recycling machine comprises a machine frame, a soil-shaking conveying system, a wind power system, a film winding roller, a weed collecting basket, a depth limiting wheel and a transmission system. All plastic film residues in soil can be cleaned in an all-directional mode, separation of the plastic film residues and the weeds is achieved, collection of the plastic film residues is achieved, and the soil preparation effect and the weeding effect are achieved, and the efficiency of the whole machine is high. A sample machine is stable in discovering performance and superior in expression in the practical application; the all-directional pneumatic film-and-weed-separation plastic-film-residue recycling machine is driven by a tractor, and the adaptability is high.

Owner:宁夏回族自治区农业机械化技术推广站 +2

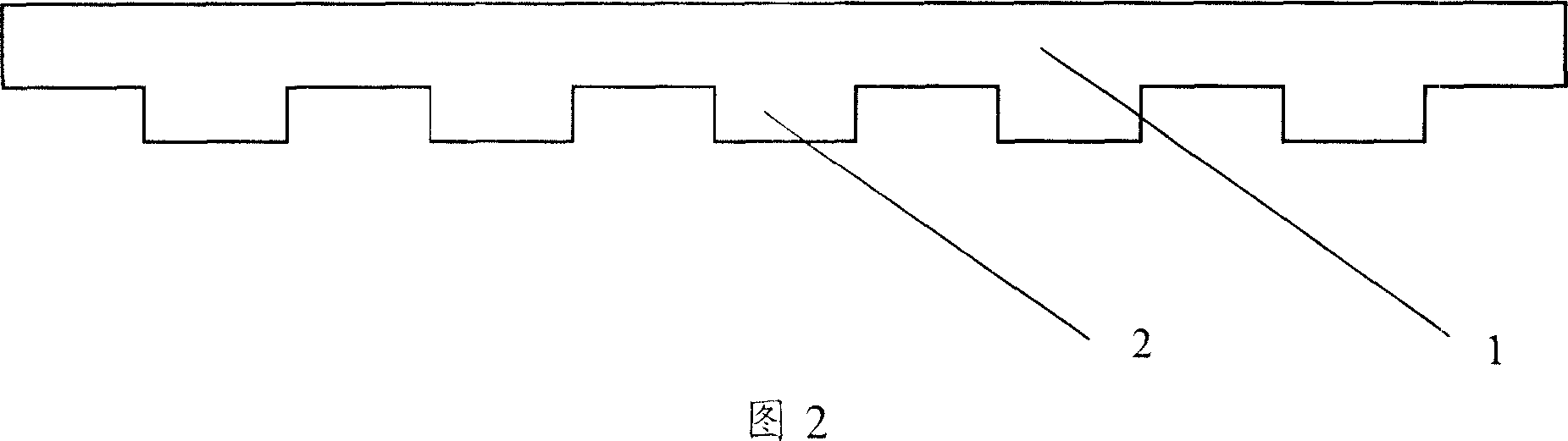

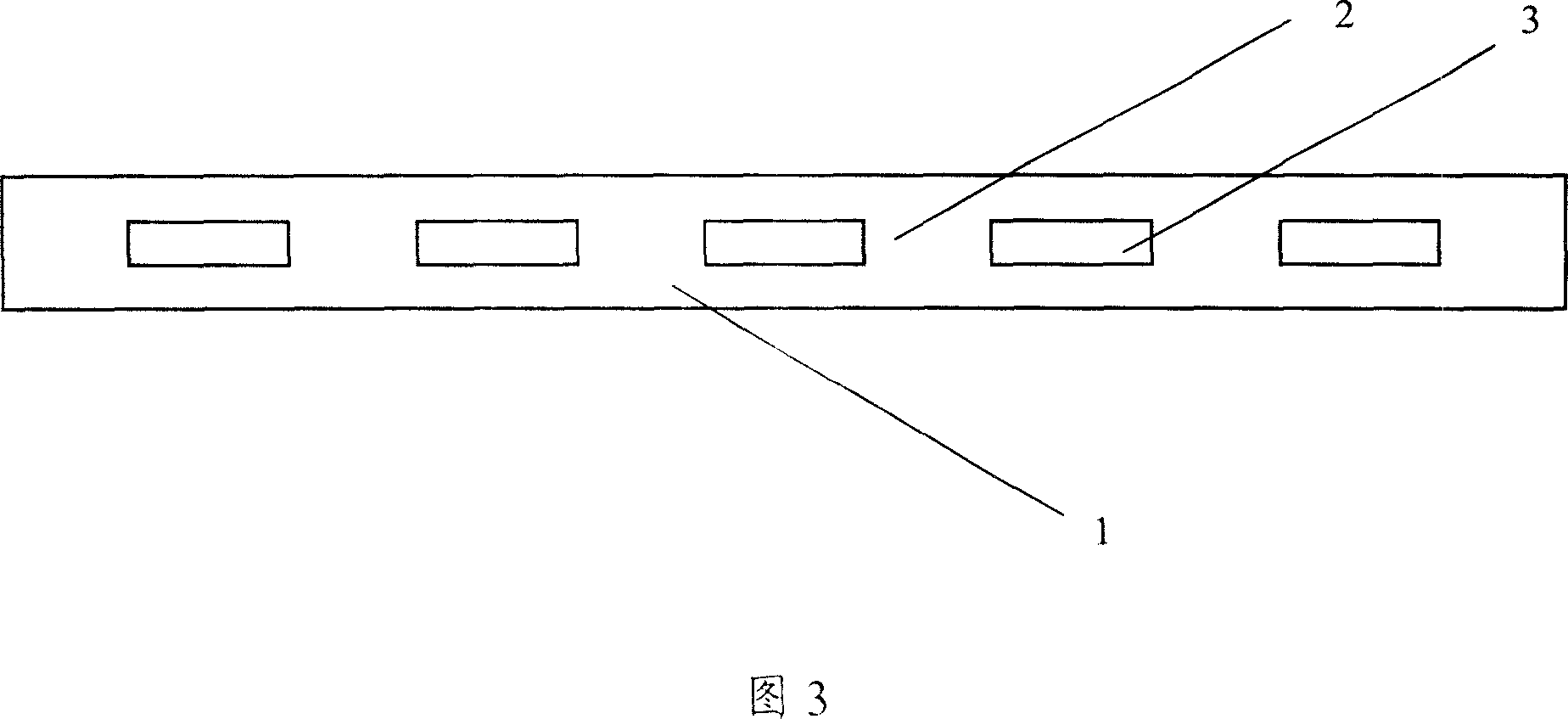

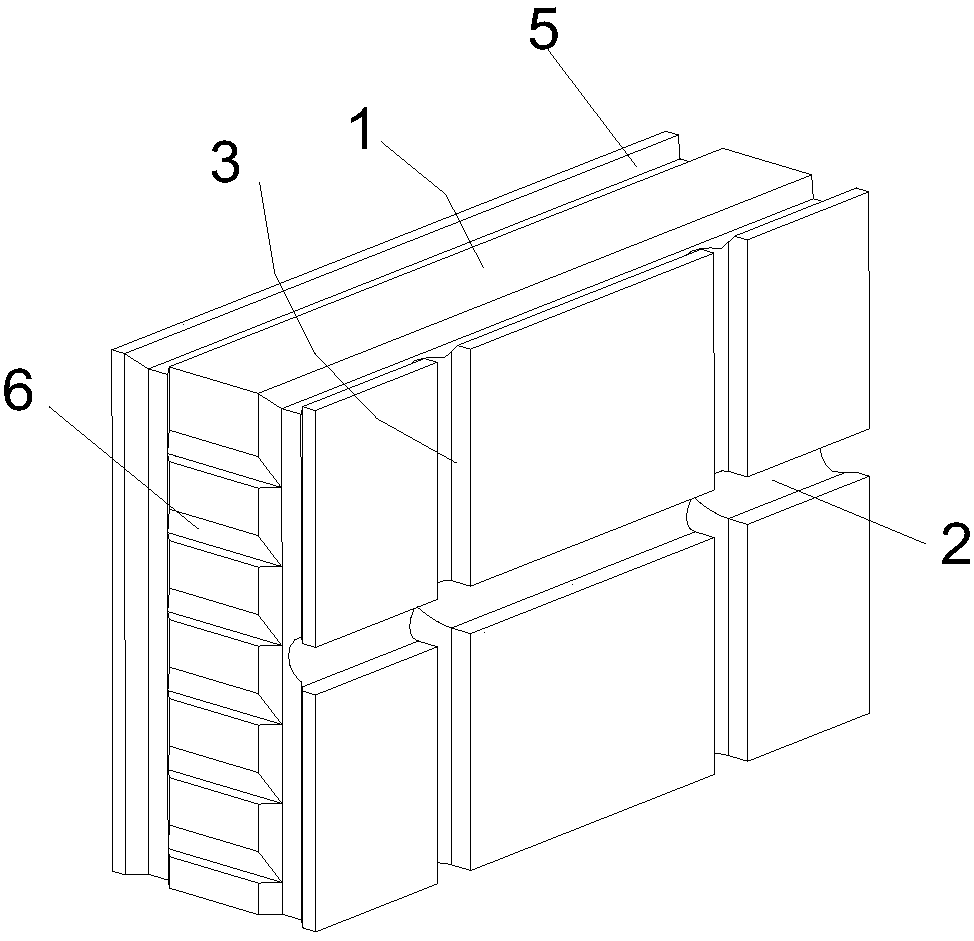

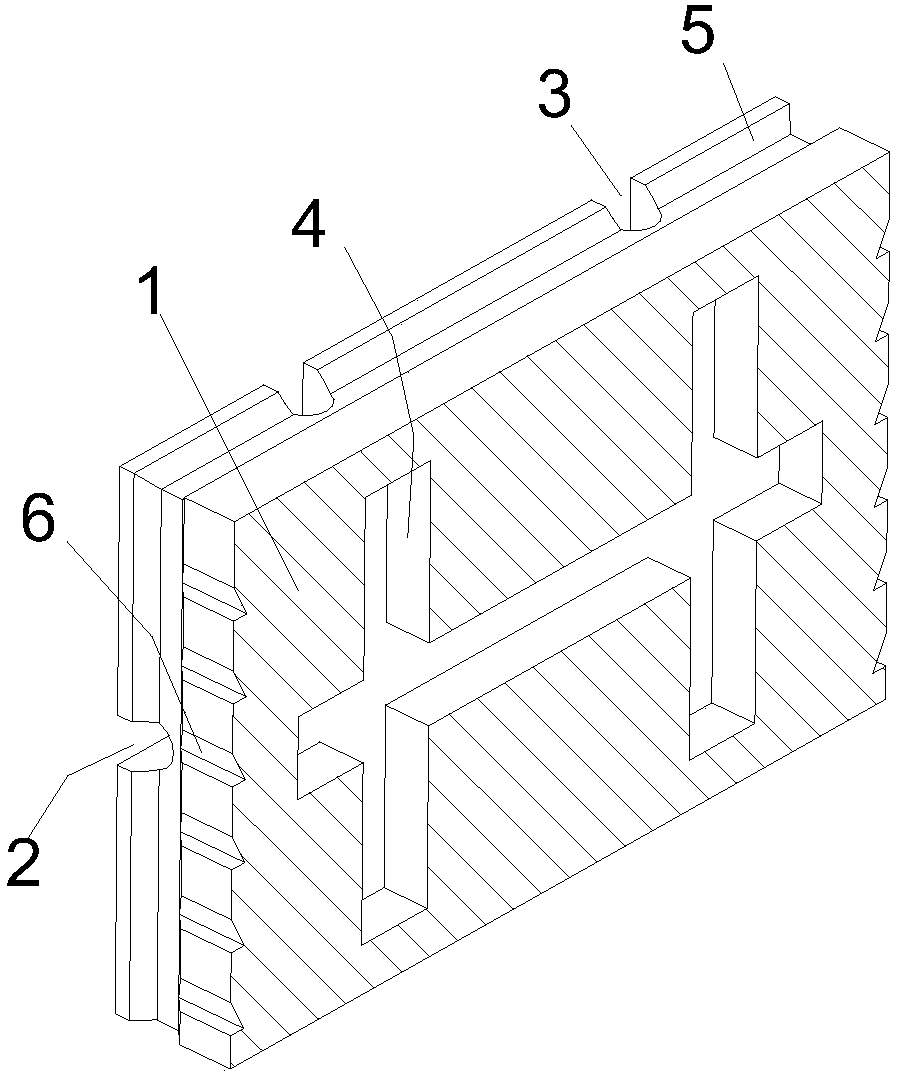

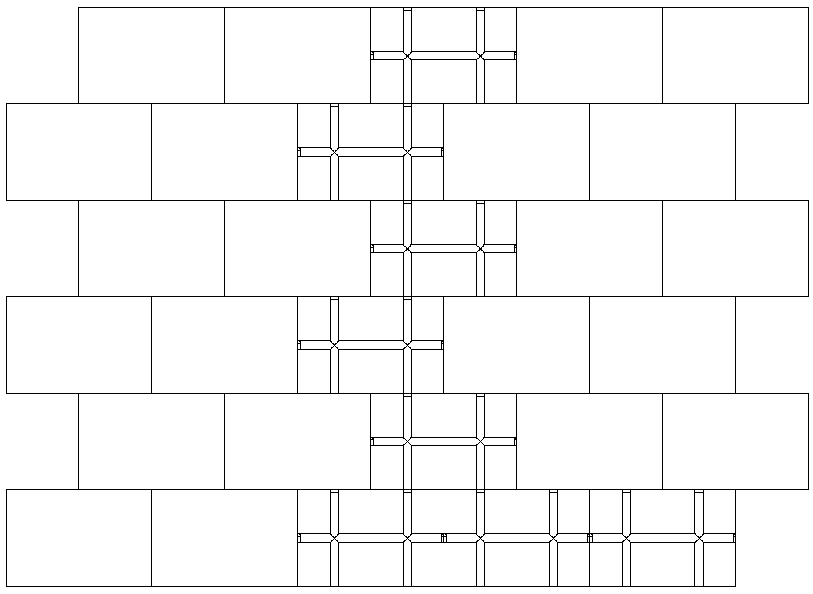

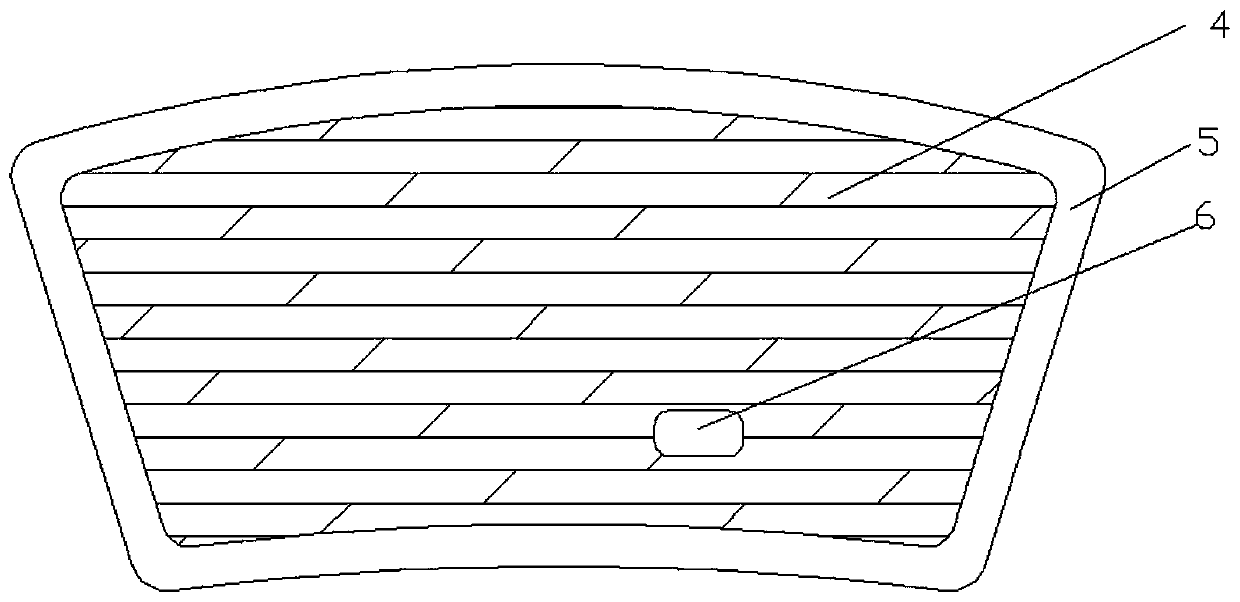

Slotting-free ceramsite building brick

The invention discloses a slotting-free ceramsite building brick, which comprises a cuboid-shaped body (1) made of ceramsite concrete, wherein a transverse wire groove (2) and two longitudinal wire grooves (3) are formed in the front side surface of the body (1); a cavity (4) positioned in the body (1) is formed in the back part of the transverse wire groove (2) and the longitudinal wire grooves (3); two grooves (5) are formed in the body (1); the grooves (5) sequentially penetrate through the left side surface, the top surface and the right side surface of the body (1); the two grooves (5) respectively approach to the front side surface and the back side surface of the body (1); plastering grooves (6) are respectively formed in the left side surface and the right side surface of the body(1). The slotting is not needed by a partition wall made by using the slotting-free ceramsite building brick during the wire distribution; the slotting-free ceramsite building brick has the advantagesthat the indoor soiling cannot be caused, the health of workers cannot be influenced, and the wall body structure infirmness cannot be caused.

Owner:ZHEJIANG DADONGWU GROUP CONSTR OF THE NEW MATERIAL

Manufacturing method of front windshield automobile coated glass

The invention relates to the technical field of automobile glass processing, in particular to a manufacturing method of the front windshield automobile coated glass. The manufacturing method providedby the invention comprises the following steps of dividing the automobile raw sheet glass into a coating area, a communication window area and an edge sealing area; coating the high-temperature silicone oil on the communication window area and the edge sealing area to obtain a high-temperature silicone oil layer; plating a low-emissivity film on the surface, coated with the high-temperature silicone oil, of the automobile raw sheet glass, and then cleaning away the low-emissivity film in the communication area and the edge sealing area to obtain the coated automobile raw sheet glass; and sequentially carrying out powder spraying, pairing, hot bending, sheet combining initial pressing and high-pressure heat treatment on the coated automobile raw sheet glass to obtain the front windshield automobile coated glass. According to the manufacturing method, the problems of corrosion and oxidation of the low-radiation film at the edge of the front windshield automobile coated glass are solved,and the smooth passing of the electromagnetic waves, such as GPS, ETC and RF, is guaranteed.

Owner:武汉长利新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com