Method for plating silver on front side of silicon wafer

A silicon wafer, silver plating technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem that the silver film cannot be etched to form a pattern, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Figure 9 For the method of silver plating on the front side of the silicon chip of the present invention, the application of the method of the present invention in CLIP Bonding (clip welding) packaging technology as an example will be specifically described below.

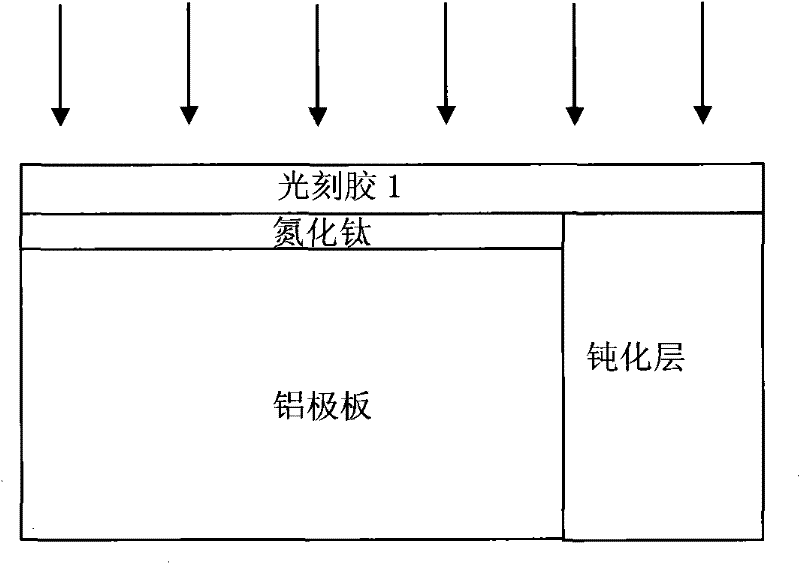

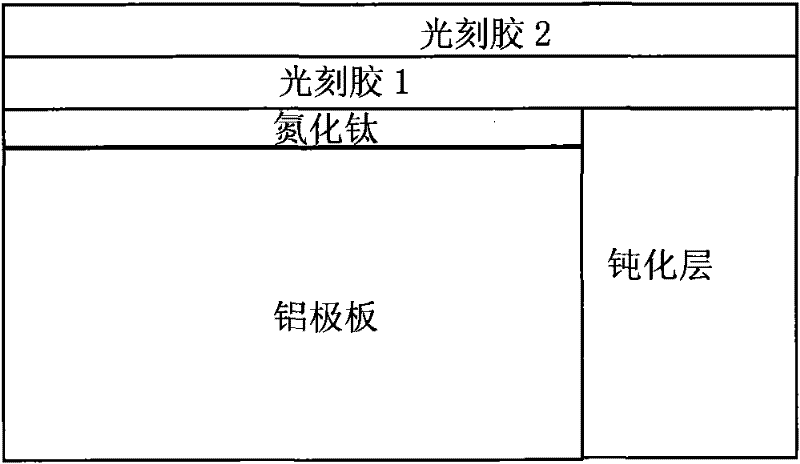

[0010] On the surface of the wafer where all processes have been completed, the photoresist is coated twice for exposure, twice and developed once to form an inverted trapezoidal photoresist pattern. Specifically, the photoresist coating is carried out first, and then the entire silicon wafer is exposed without using a photolithography mask (called blind exposure); then the photoresist is coated again, and then the photolithography mask is used for the second exposure. Secondary exposure; develop at last, make the remaining photoresist pattern be an inverted trapezoid (see Figure 1 to Figure 5 , Figure 5 The photoresists in include photoresist 1 and photoresist 2). The thickness of the photoresist coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com