Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

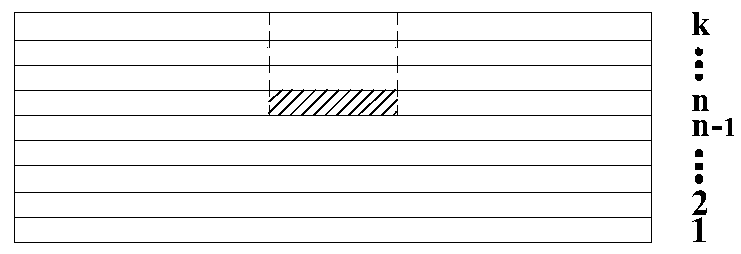

31results about How to "Avoid the introduction of impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

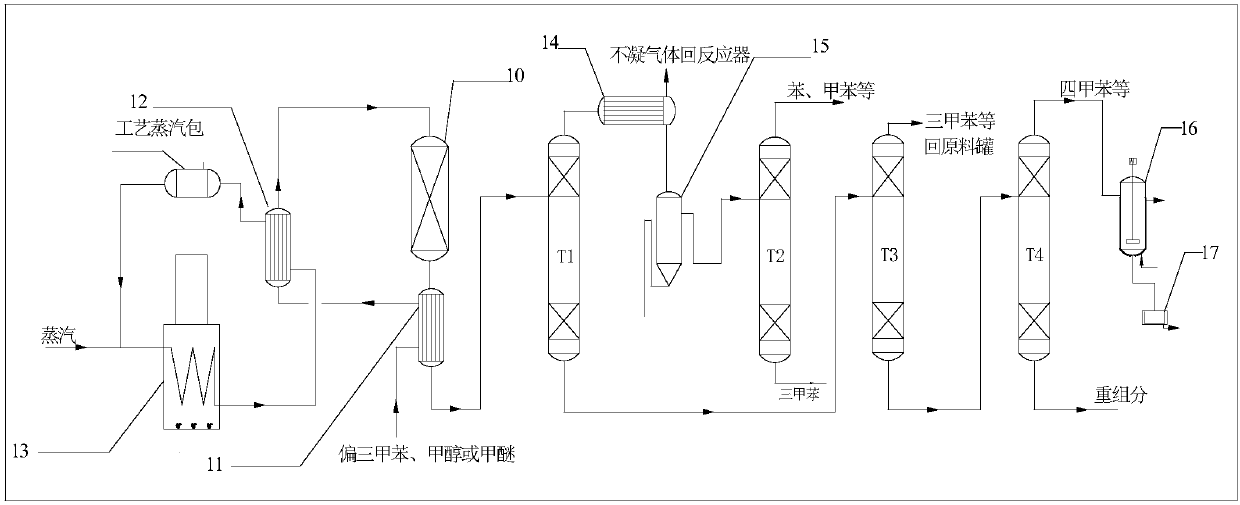

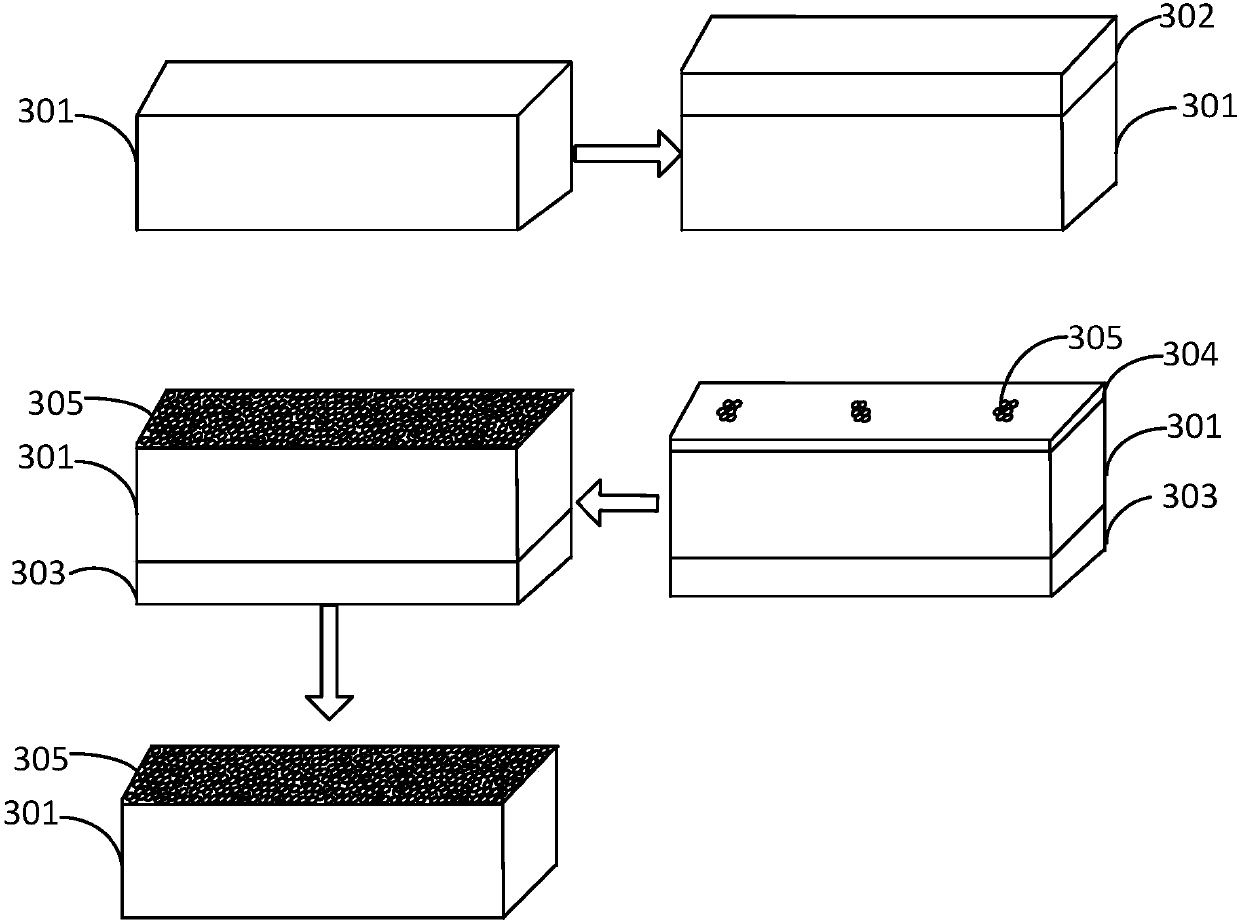

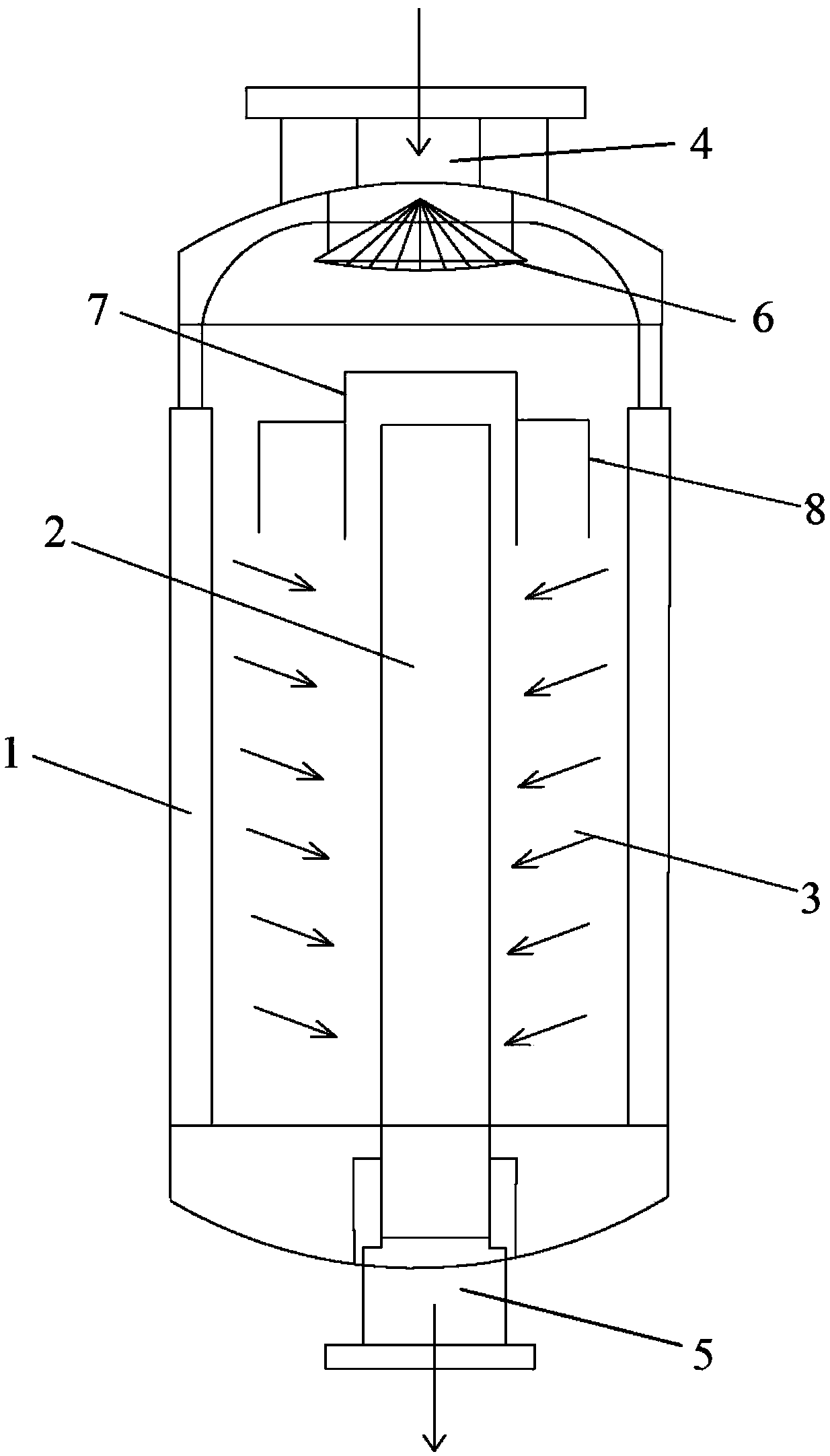

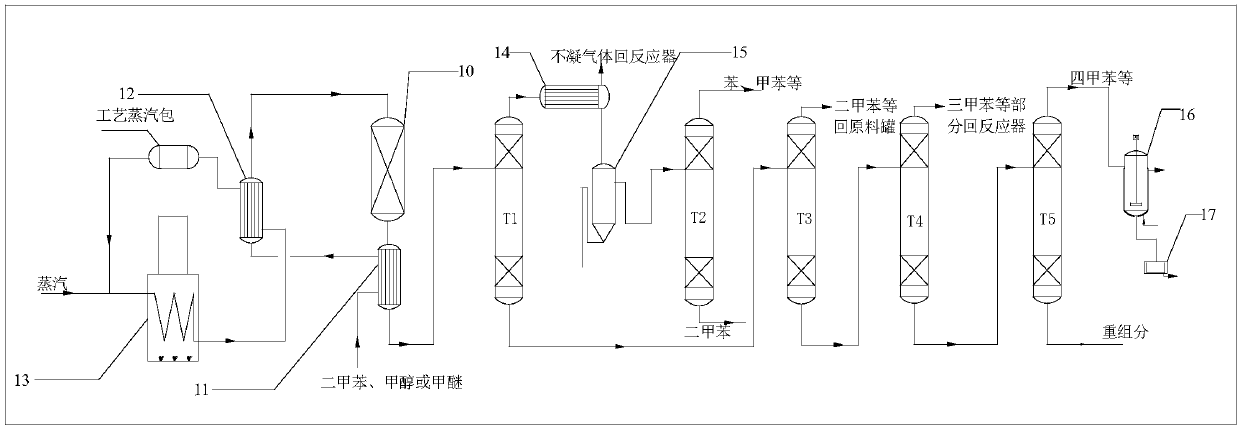

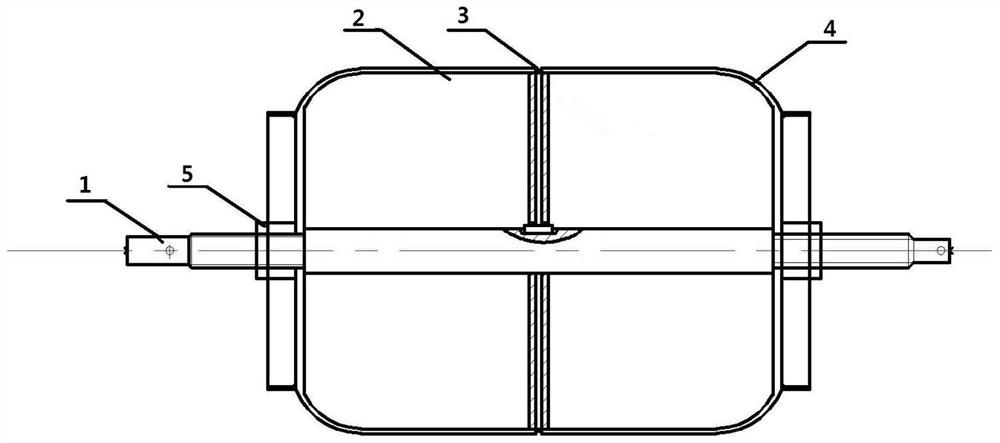

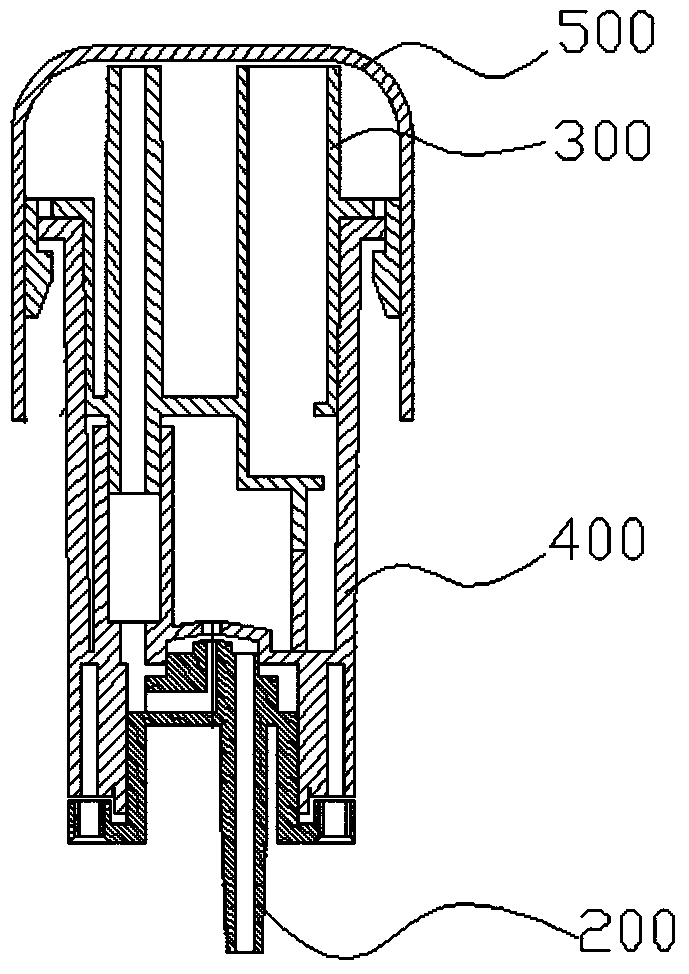

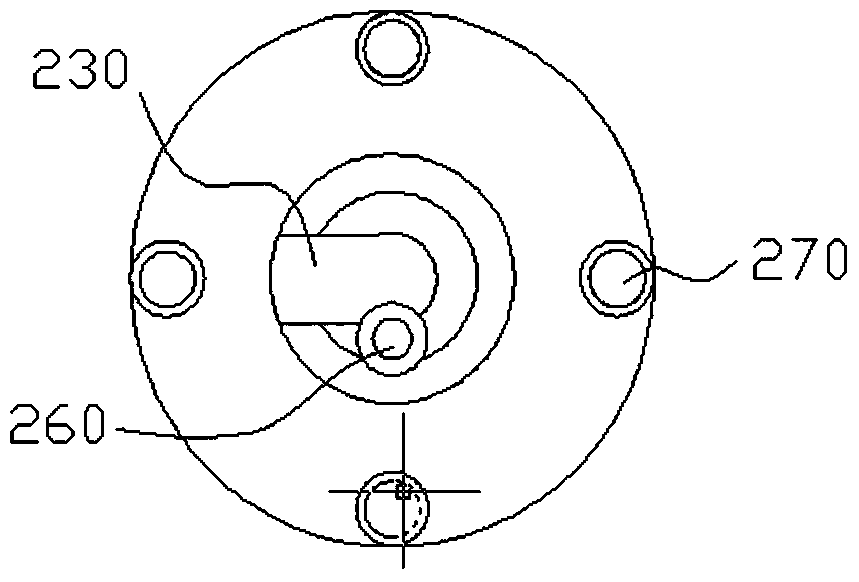

Method for production of durene by pseudocumene alkylation and reactor thereof

InactiveCN109966997ARelieve pressureIncrease contact areaMolecular sieve catalystCatalystsAlkyl transferFiltration

The invention discloses a method for production of durene by pseudocumene alkylation. The method includes: raw material gasification mixing, alkylation reaction, gas-oil-water separation, refining, freezing crystallization filtration and squeezing, wherein a radial fixed bed reactor is employed for alkylation reaction of pseudocumene. The invention also provides the radial fixed bed reactor used by the above method. The method for production of durene by pseudocumene alkylation has the advantages of: high catalyst activity and long service life, high product selectivity, high production safety, few alkylation by-product, stable finished product quality, low consumption of raw and auxiliary materials, long equipment service life, and is suitable for large-scale industrial production.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

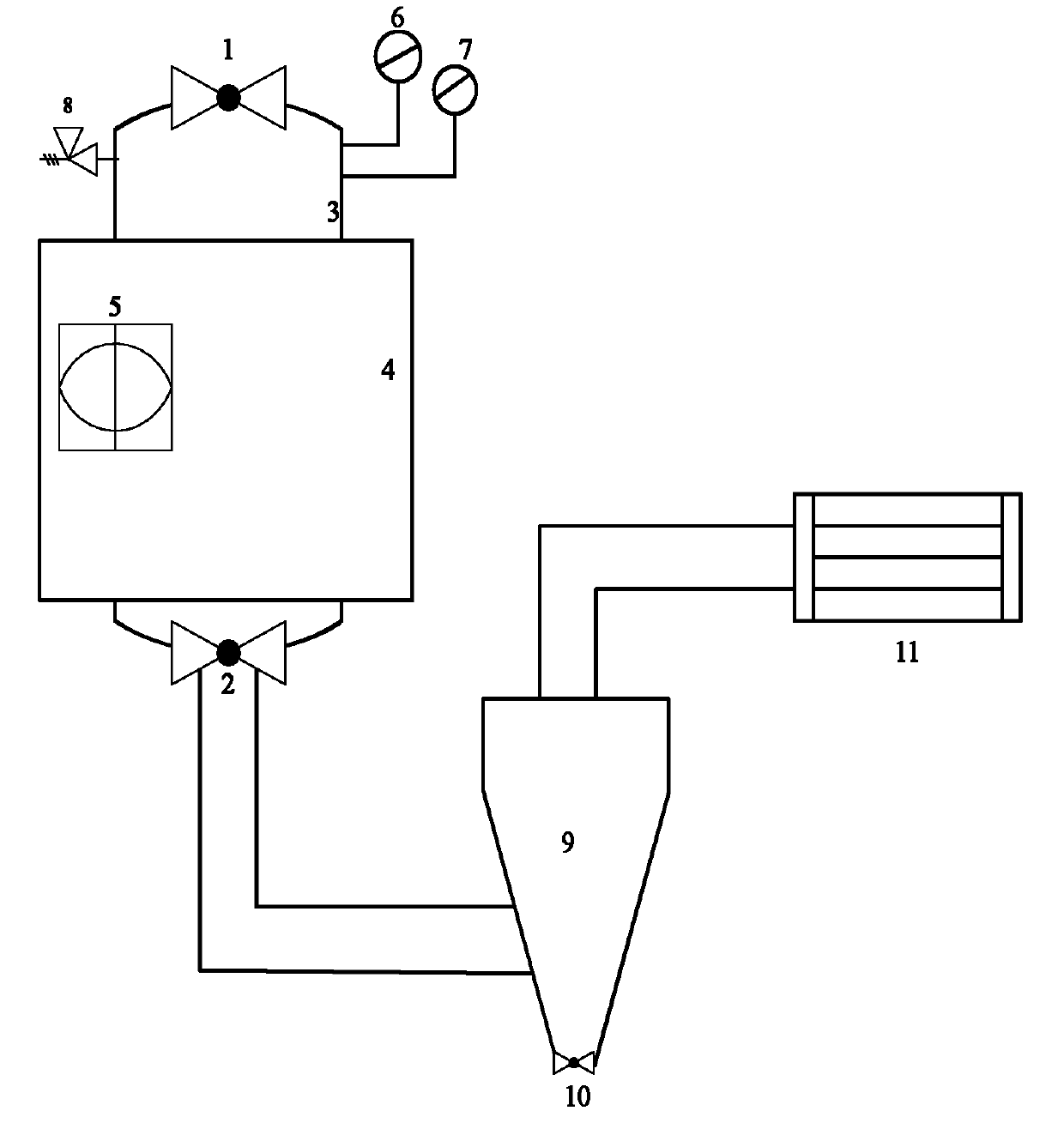

Microwave steam explosion device

InactiveCN102166508AAvoid the introduction of impuritiesMeet preprocessingPressurized chemical processEnergy based chemical/physical/physico-chemical processesAutomatic controlHigh energy

The invention relates to a microwave steam explosion device which comprises a feed-inlet ball valve, a steam explosion tank, a buffer vessel, and a gas condensation and recovery system, wherein the steam explosion tank is sleeved with a microwave oven cavity, the steam explosion tank is provided with a pressure gauge, a thermometer and a safety valve, and the steam is fed into the gas condensation and recovery system. The microwave oven cavity adopts an integral control system and a staggered and resonant arrangement design on industrial double-magnetrons, continuous output microwaves are obtained by using a high frequency close-loop feedback and magnetron anode current control mode, and through contactless infrared temperature control and contactless optical pressure monitoring, the real-time display of a pressure-temperature-time-power curve and a temperature-pressure-time curve can be realized on an ultra-large touch LCD (liquid crystal display) screen. The device provided by the invention has the advantages that the stream indirect heating is replaced with the microwave direct heating, so that 4 / 5 of the heating time is shortened, therefore, the problem of high energy consumption existing the existing steam explosion technology can be solved, and the requirements of solid materials such as foods and traditional Chinese medicines, and the like for water quality are satisfied; and in addition, because of adopting automatic control, the device is easy to operate, and has good economic and application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing copper-tungsten alloy doped graphene

InactiveCN108893637ASolve the uneven distribution of two phasesAddresses the presence of large copper enrichment zonesTransportation and packagingMetal-working apparatusCopper platingDoped graphene

The invention discloses a method for preparing copper-tungsten alloy doped graphene. The method comprises the following steps: uniformly and quantitatively depositing a layer of copper on the surfaceof tungsten powder, and modifying the surface state of copper-plated tungsten powder and graphene respectively with PVA and PVP; sufficiently stirring in a liquid medium to sufficiently mix the copper-plated tungsten powder and graphene, and performing cold-press molding and hog-press sintering to obtain the graphene doped copper-tungsten alloy. The method can be used for improving the wetting performance of the sintering process, and the chemical, electrical, thermal and other performance of the alloy prepared by the method are greatly improved in comparison with those of alloy prepared by atraditional method, the vacuum ablation performance is promoted when the alloy is applied to an electrical contact, the service life of the contact is prolonged, and the ablation can be more uniform.

Owner:XI AN JIAOTONG UNIV

Aging method of distilled spirit

InactiveCN104164348AImprove responseAccelerated agingAlcoholic beverage preparationFlavorTemperature control

The invention discloses an aging method of a distilled spirit. The method comprises the following steps: wine liquid storage, wine steam introduction and temperature control and storage. According to the method disclosed by the invention, the wine storage temperature can be controlled by introducing wine steam, physical reaction and chemical reaction of a wine can be accelerated, the aging of the wine can be promoted, the storage time can be greatly reduced, and the foreign flavor, mud flavor, distilled grain flavor and bitter taste of wine liquid also can be removed so as to ensure that a wine body is soft and pure and is harmonious in taste.

Owner:GUIZHOU MAOTAI TOWN GUOWEI WINE GRP

Method for detecting kiln coating suspension performance of fireproof brick for cement kiln

InactiveCN102879265AReduce volatilityExperiment operation is simpleMaterial strength using tensile/compressive forcesProcess engineeringCement kiln

The invention discloses a method-static shearing method for detecting the kiln coating suspension performance of a fireproof brick for a cement kiln, and a principle, equipment, a sample, steps and result calculation thereof. The static shearing method is low in experimental expense, strong in operability and quantizable, especially the shearing position is proper, the data is stable and good in repeatability in the shearing range, the influence caused by errors is greatly reduced, the practical kiln coating suspension performance of the fireproof brick for the cement kiln can be really reflected, the conventional fireproof material detection equipment is made full use of, and the conventional performance detection method for the fireproof brick is further improved.

Owner:TONGDA REFRACTORY TECH CO LTD +1

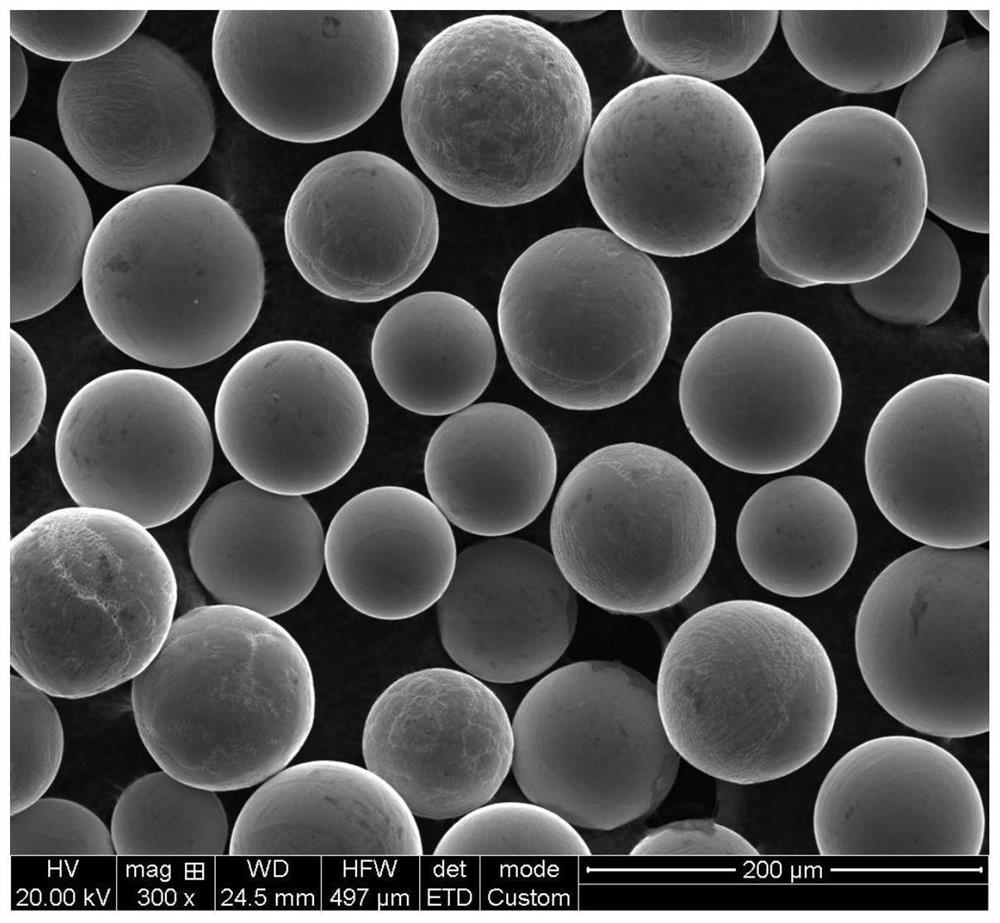

TiAl alloy powder and preparation method and application thereof

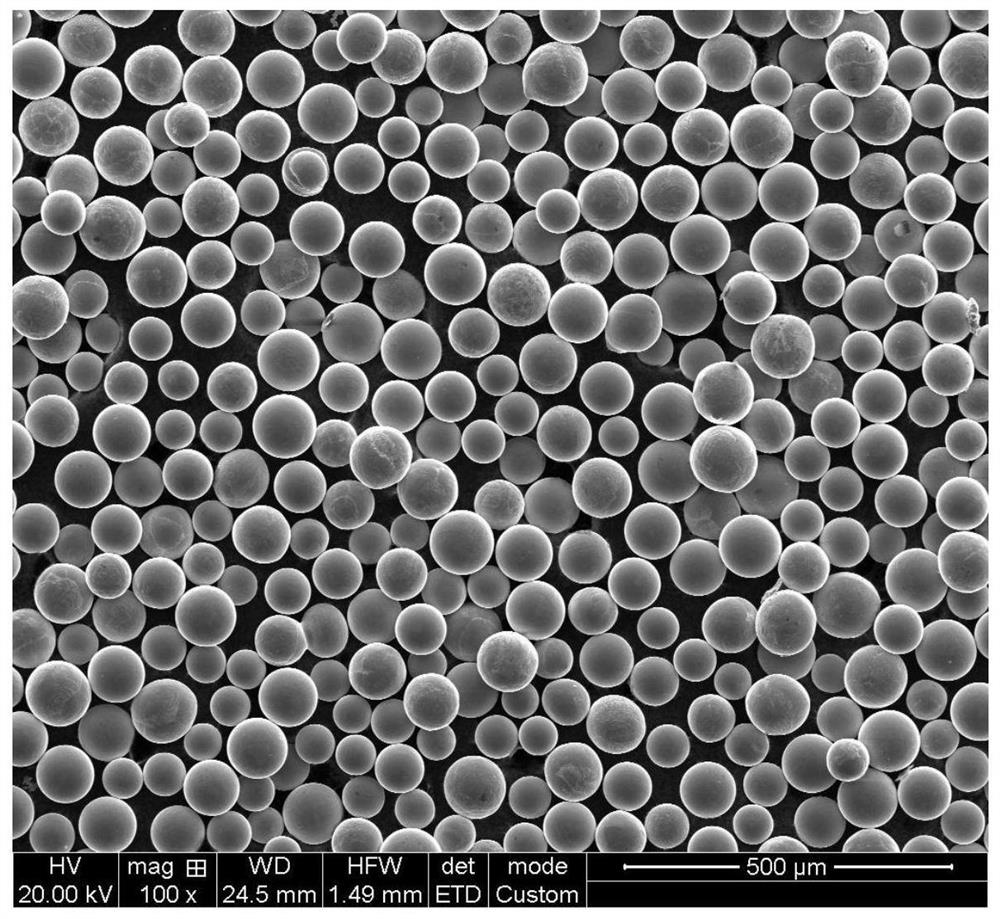

ActiveCN112575221AImprove purityNo pollution in the processAdditive manufacturing apparatusTransportation and packagingMetal powderTi element

The invention provides TiAl alloy powder and a preparation method and application thereof, and belongs to the technical field of metal powder. The TiAl alloy powder comprises, by mass percent, 34%-35%of Al, 4.5%-5.1% of Nb, 2.4%-2.7% of Cr, 0-0.02% of Gd, larger than 0 and not larger than 150 ppm of C, larger than 0 and not larger than 200 ppm of N, larger than 0 and not larger than 100 ppm of H,larger than 0 and not larger than 700 ppm of O and the balance Ti. The TiAl alloy powder is spherical, the particle size ranges from 40 micrometers to 106 micrometers, fluidity ranges from 10.0 s / 50g to 20.0 s / 50 g, and the hollow sphere rate is not larger than 0.5%.

Owner:CENT IRON & STEEL RES INST

Method for preparing single-layer graphene on surface of ultranano diamond

ActiveCN107902650ALarge Boundary DensityEffective diffusionSingle layer grapheneDiamondLattice mismatchSingle layer graphene

The invention is applicable to the technical field of semiconductor and provides a method for preparing single-layer graphene on the surface of ultranano diamond. The method comprises preprocessing anultranano diamond film to eliminate surface impurities and surface stress; forming a metal layer on the nucleation surface of the preprocessed ultranano diamond film, wherein the metal layer is composed of a nickel layer and a copper layer on the upper surface of the nickel layer or is a copper-nickel alloy layer; performing high-temperature annealing treatment on the ultranano diamond film withthe grown metal layer to self-organize the single-layer graphene. The method for preparing the single-layer graphene on the surface of the ultranano diamond saves a second transfer process by directlygrowing the single-layer graphene on the ultranano diamond film, thereby effectively avoiding introduced impurities and lattice imperfection during second transfer processes; meanwhile, the grown single-layer graphene is small in lattice mismatch and surface change.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Production method of durene

InactiveCN109970506AHigh purityRelieve pressureHydrocarbon purification/separationHydrocarbonsChemistryBy-product

The invention discloses a production method of durene. The method includes: gasification and mixing of xylene and an alkylating agent, alkylation reaction, refining, freezing crystallization filtration and squeezing. The production method of durene provided by the invention has the advantages of: high catalyst activity and long service life, high product selectivity, high production safety, few alkylation by-product, stable finished product quality, low consumption of raw and auxiliary materials, and long service life of equipment, and is suitable for large-scale industrial production.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

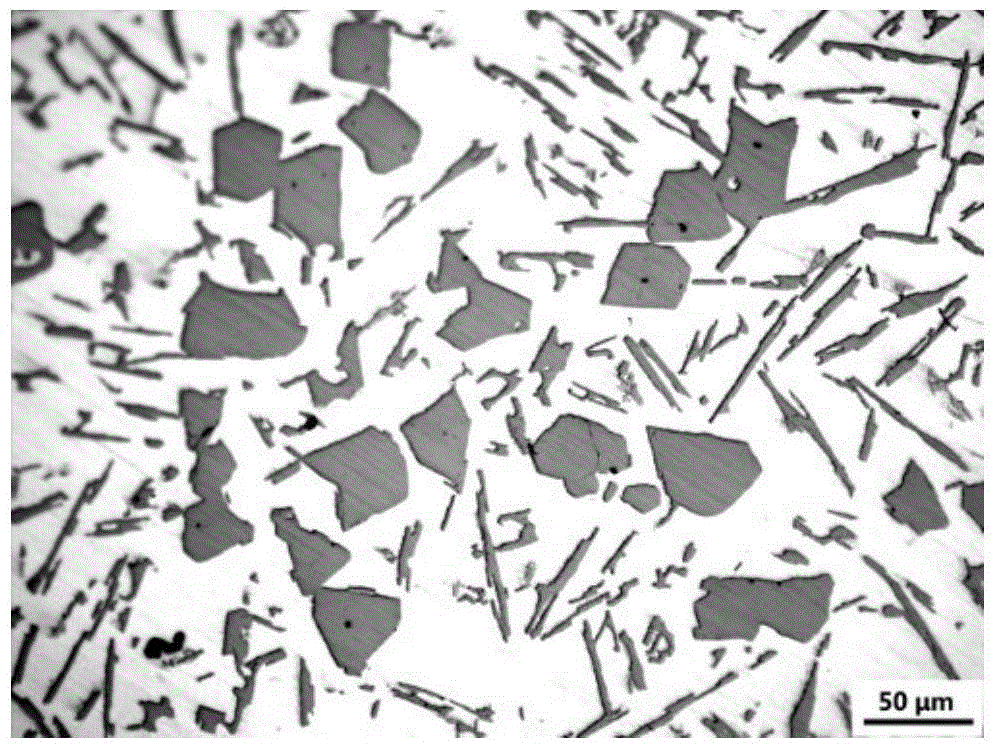

Dual deterioration method of hypereutectic Al-Si alloy

The invention discloses a dual deterioration method of a hypereutectic Al-Si alloy. An intermediate alloy of fine grain hypereutectic Al-Si alloy is added to achieve dual deterioration of primary crystal Si and eutectic Si, the intermediate alloy has the same components as a matrix alloy, impurities and elements are prevented from being introduced into the reaction, the process is simple and the operation is convenient; the size of the primary crystal Si in the hypereutectic Al-Si alloy is thinned from 44 microns to 14 microns after deterioration, the eutectic Si is deteriorated from a faller gill shaped into a highly branched fiber shape.

Owner:JIANGSU UNIV OF SCI & TECH

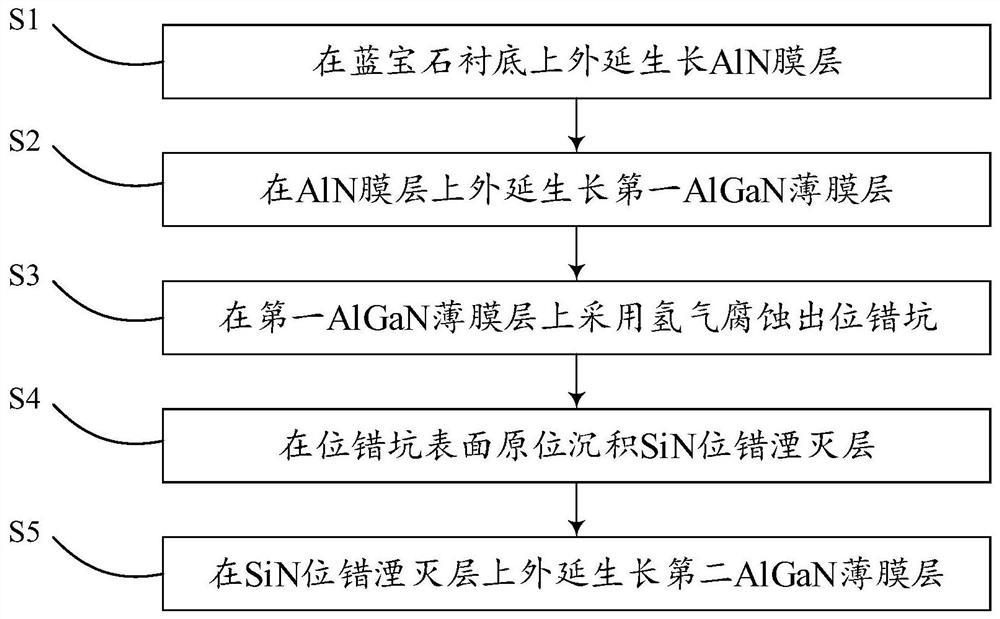

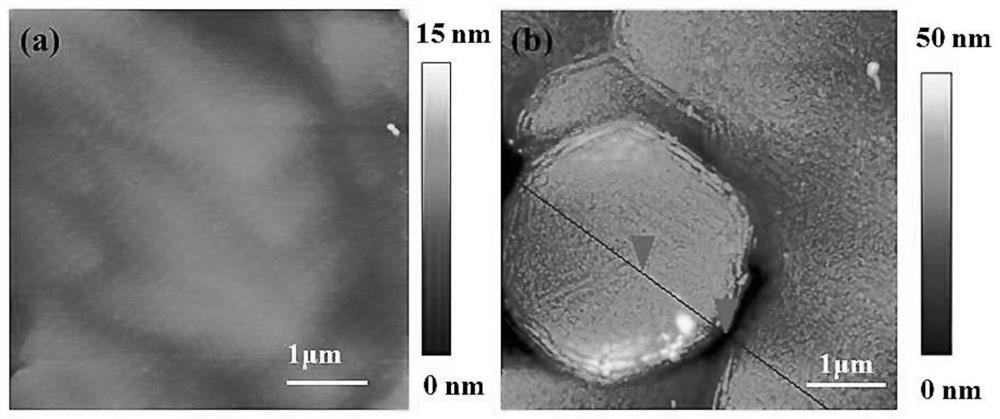

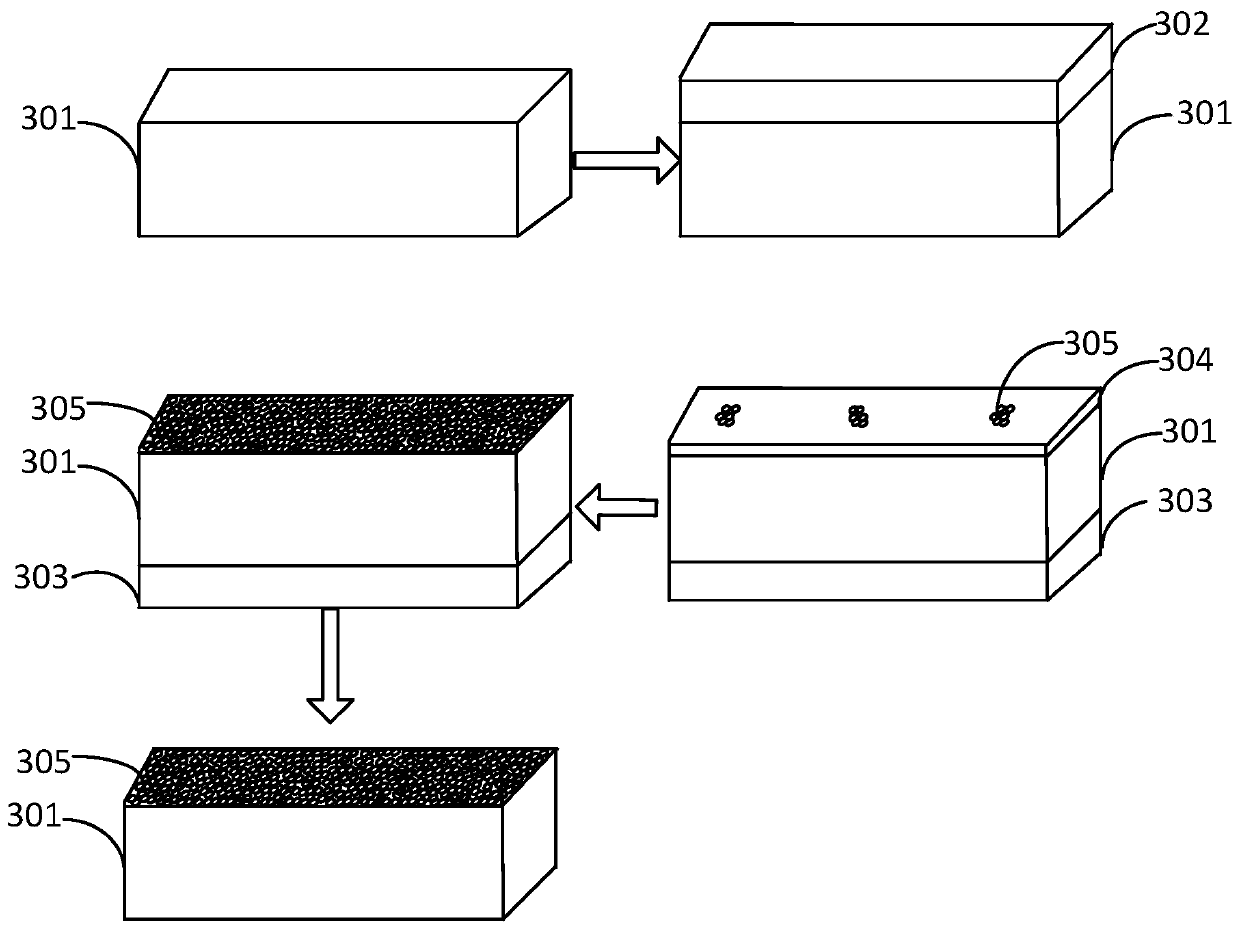

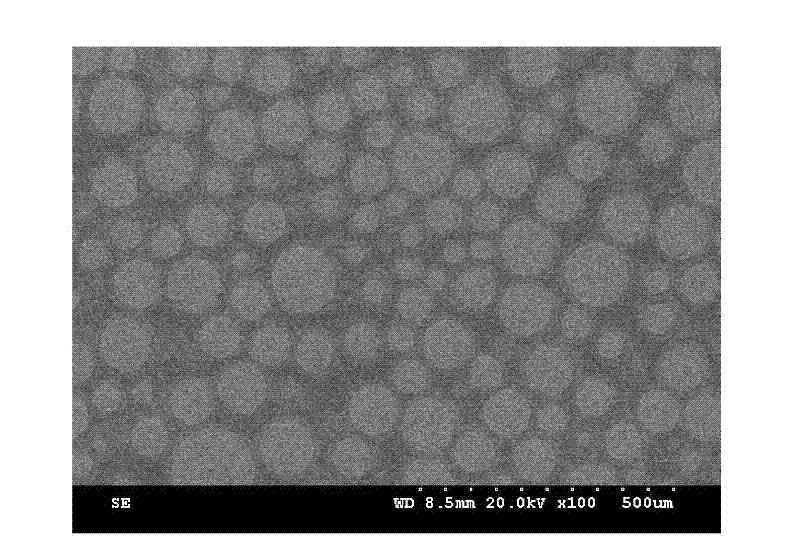

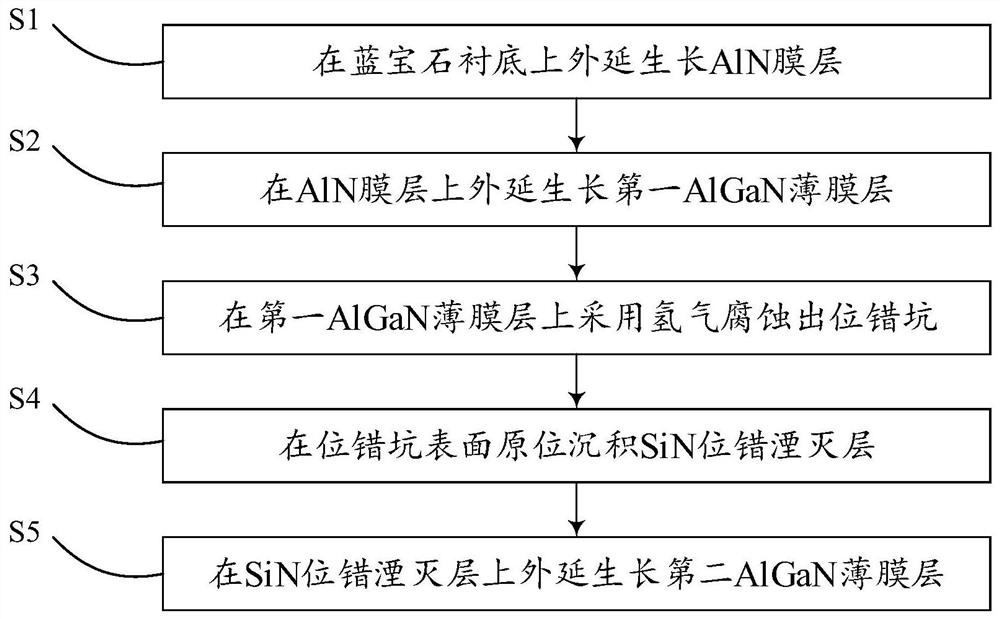

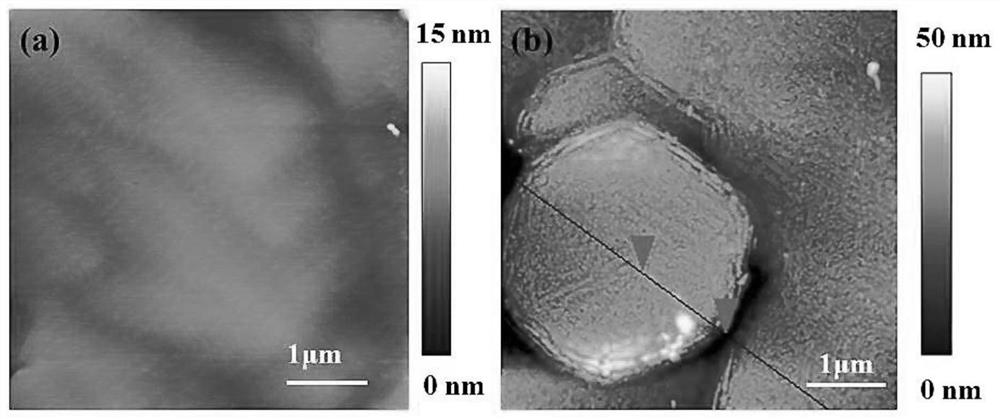

AlGaN film with in-situ SiN dislocation annihilation layer and epitaxial growth method of AlGaN film

ActiveCN112242459APromote growth and healingAvoid the introduction of impuritiesFinal product manufactureSemiconductor devicesCrystallographyGrown film

The invention discloses an AlGaN thin film with an in-situ SiN dislocation annihilation layer and an epitaxial growth method of the AlGaN thin film. The method comprises the steps that an AlN film layer is grown on a sapphire substrate in an epitaxial mode; a first AlGaN thin film layer is grown on the AlN film layer in an epitaxial mode; a dislocation pit is formed in the first AlGaN thin film layer through hydrogen corrosion; a SiN dislocation annihilation layer is deposited on the surface of the dislocation pit in situ; a second AlGaN thin film layer is epitaxially grown on the SiN dislocation annihilation layer. According to the method, the dislocation pits are etched in the first AlGaN thin film layer and then SiN in-situ filling is carried out; on one hand, the second AlGaN thin filmlayer and the subsequent film layer can be synchronously subjected to graphical processing in the growth process; the problems that an epitaxial wafer is taken out to be subjected to a complex etching process and impurities are introduced when the epitaxial wafer is taken out to be etched are solved; on the other hand, the SiN dislocation annihilation layer is of an island-shaped distribution structure corresponding to the same dislocation pit, and therefore the structure is more beneficial to growth and healing of the second AlGaN thin film layer.

Owner:SUZHOU UVCANTEK CO LTD

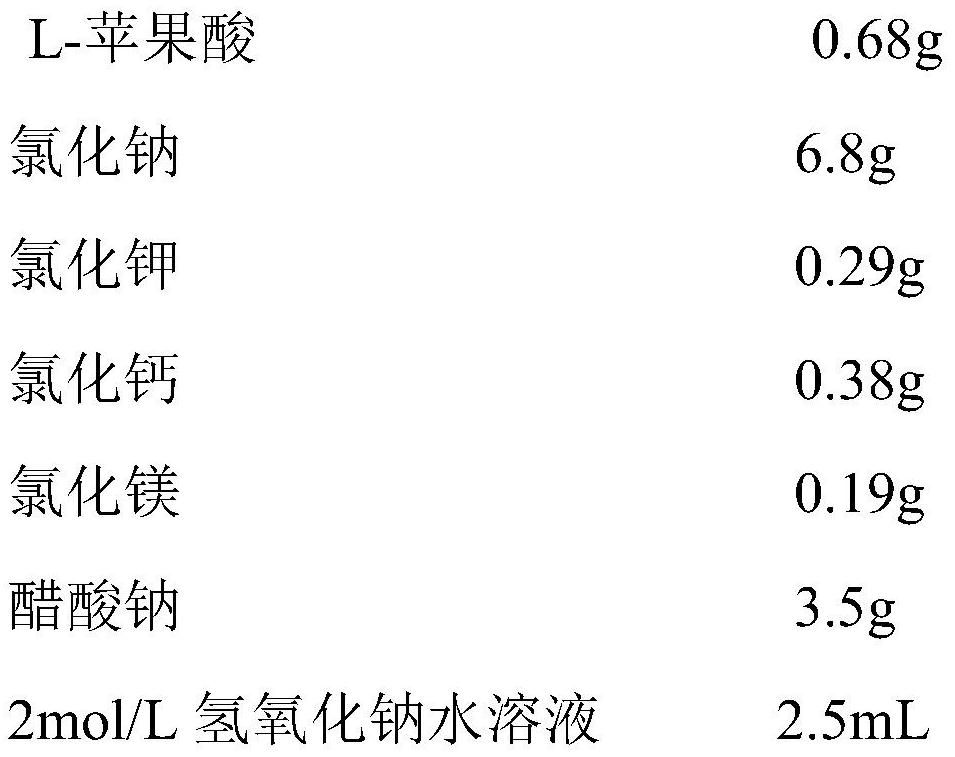

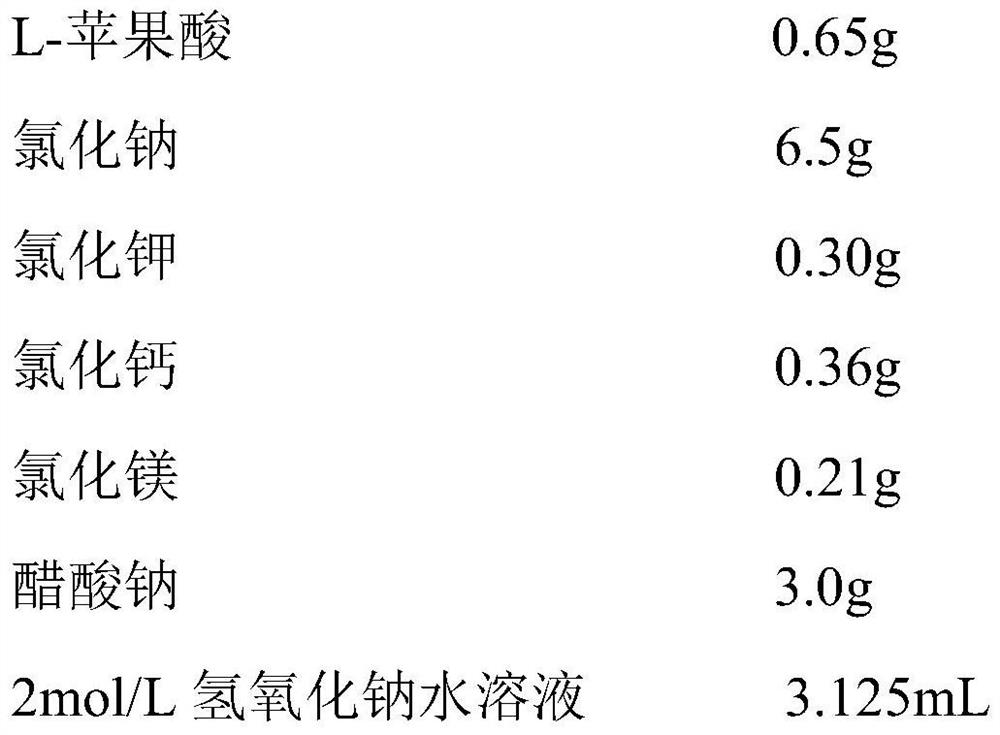

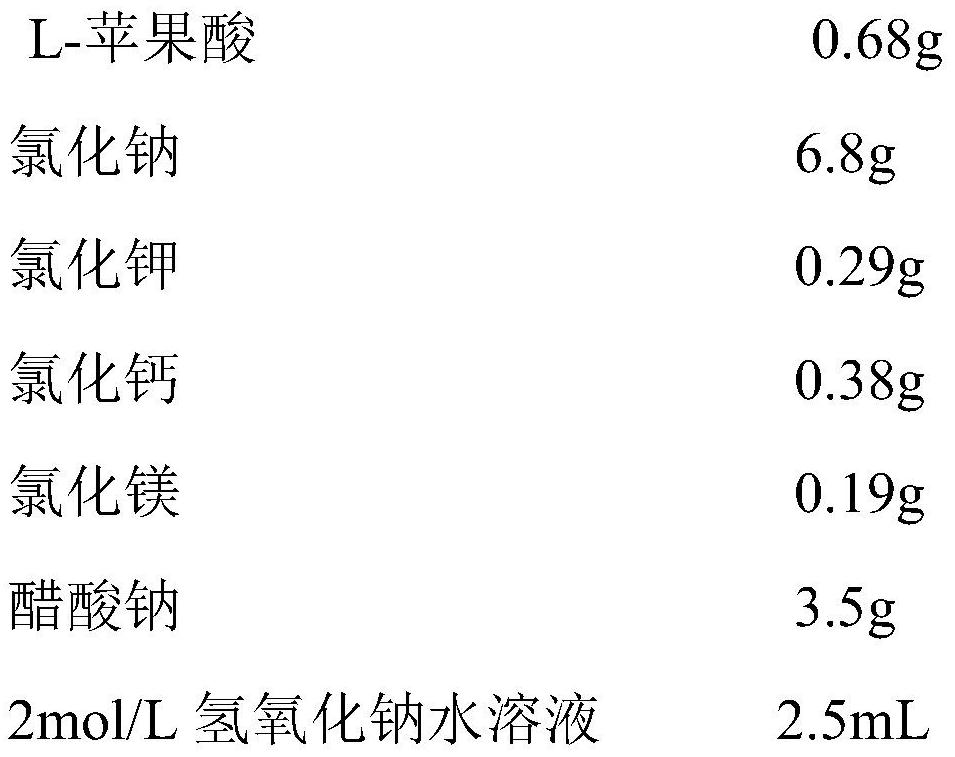

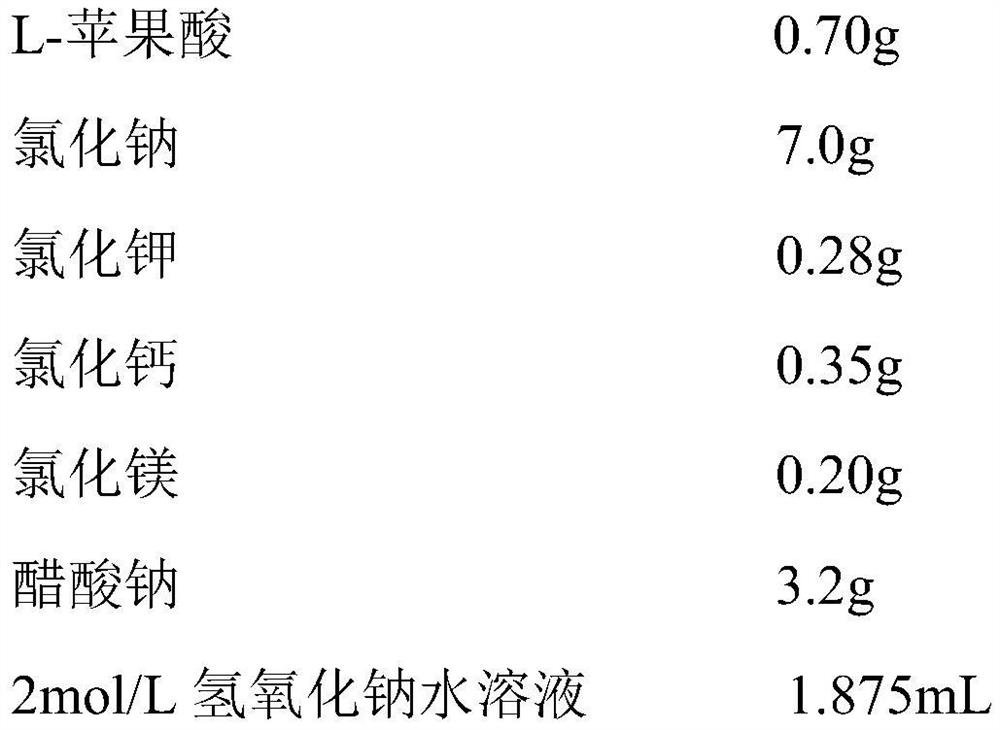

Compound electrolyte injection and preparation method thereof

ActiveCN113274350AImprove stabilityGood storage stabilityMetabolism disorderPharmaceutical product form changeSodium acetateDrugs preparations

The invention relates to the technical field of medicinal preparations, and specifically discloses a compound electrolyte injection and a preparation method thereof. The preparation method includes: successively adding L-malic acid, magnesium chloride, sodium chloride, potassium chloride, calcium chloride, sodium acetate and sodium hydroxide with a prescription dosage in order into 70-80% of the total preparation volume of water for injection, performing stirring and dissolving, performing heating to a boil, maintaining for 10-20 min; and replenishing the water for injection to the total preparation volume, performing filtering by using multistage polyethersulfone filter with successively reduced pore diameters, performing filling, and then performing sterilization to obtain the compound electrolyte injection. Through the one-step preparation method, the compound electrolyte injection (II) having significantly reduced impurity types and content can be obtained; the storage stability of the injection can be significantly enhanced; in a stability investigation test, the increasing of impurity content is not obvious; in addition, production technologies are greatly simplified, production efficiency is enhanced, and costs of production are reduced; and therefore, commercial production can be realized. The compound electrolyte injection and the preparation method thereof have wide application prospects.

Owner:SHIJIAZHUANG NO 4 PHARMA

Plastic screen cloth for chemical engineering powder screening

InactiveCN106589700AAvoid the problem of poor blending compatibilityGood flexibilityMolecular sievePetroleum resin

The invention discloses a plastic screen cloth for chemical engineering powder screening, and relates to the technical field of chemical equipment. The plastic screen cloth is prepared from, by weight, 20-25 parts of hard PVC regeneration particles, 10-15 parts of saturated polyester resin, 5-10 parts of C5 petroleum resin, 5-10 parts of lignocellulose, 3-6 parts of organic filler, 3-6 parts of bamboo powder, 2-4 parts of gum dammar, 2-4 parts of superfine polytetrafluoroethylene powder, 2-4 parts of ceramic micro powder, 1-2 parts of polymethyl methacrylate, 1-2 parts of molecular sieve raw powder, 0.5-1 part of nanometer zinc oxide, 0.5-1 part of lanonol and 0.05-0.1 part of lanthanum oxide. The screen cloth has the excellent corrosion resistance, wear resistance and vibration resistance and is applicable to screening of powder capable of achieving easy moisture absorption or corrosivity; the service life is long, and the replacement cost of the screen cloth is effectively lowered.

Owner:DONGZHI TIANFU CHEM

Graphene modified-carbon coated lithium iron phosphate material, preparation method thereof and solid-state lithium ion battery

PendingCN114497556AImprove controllabilityAvoid impurities and defectsMaterial nanotechnologyCell electrodesMuffle furnaceCarbon source

The invention relates to the field of lithium batteries, and discloses a graphene modified-carbon coated lithium iron phosphate material and a preparation method thereof, and a solid lithium ion battery, the preparation method comprises the following steps: dissolving a phosphate radical raw material, an iron salt and a lithium source in an alcoholic solution, then adding a template agent, a carbon source and an antioxidant, then adding graphene oxide, and carrying out ultrasonic dispersion, so as to obtain the graphene modified-carbon coated lithium iron phosphate material. Pouring into a reaction kettle, and carrying out hydrothermal synthesis to obtain a solid-phase material; and placing the solid-phase material in a vacuum oven for drying, and then placing the dried solid-phase material in a muffle furnace for high-temperature calcination to obtain the graphene modified-carbon coated lithium iron phosphate material. When the G / LFP / C material is applied to a solid-state battery, the transportation of electrons and lithium ions can be facilitated, and the interface impedance is reduced, so that the solid-state battery prepared from the G / LFP / C material can have excellent rate capability, electrochemical lithium storage performance and cycle performance.

Owner:GUANGDONG MIC POWER NEW ENERGY CO LTD

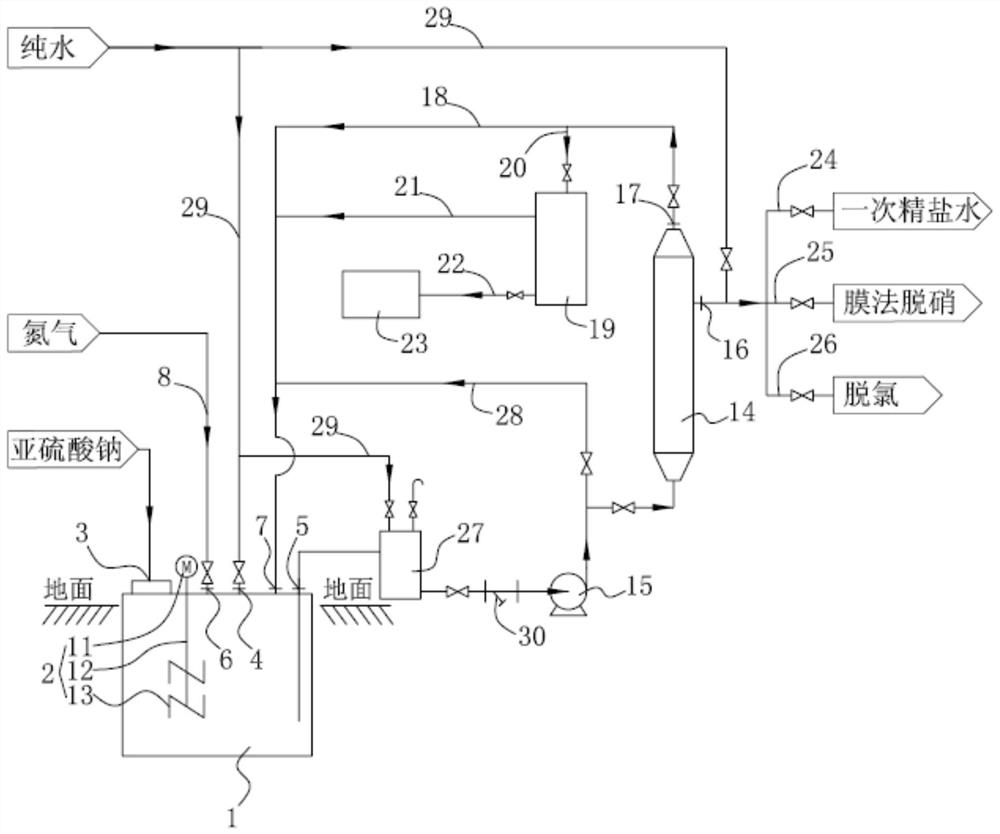

Chlor-alkali sodium sulfite solution preparation tank and preparation system

ActiveCN110882635BReduce oxidationIncrease in sizeTransportation and packagingInert gas productionSulfite saltPhysical chemistry

The invention discloses a sodium sulfite solution preparation tank for chlor-alkali and a preparation system, belonging to the technical field of preparation of sodium sulfite solution for chlor-alkali. In the present invention, after the protective gas connection port is set on the preparation tank body, the protective gas can be passed into the preparation tank body after being connected with the protective gas supply device, thereby reducing the oxidation of the sodium sulfite solution during the preparation process. Moreover, since the sodium sulfite solution in the configuration process will not be oxidized, the configured sodium sulfite solution can be directly stored in the configuration tank body without the need to separately set up a special storage tank structure, and it can be stored for a long time; therefore, since there is no storage tank structure, and can be stored for a long time, so the volume of the preparation tank body can be increased to reduce the frequency of preparation. At the same time, the main part of the entire preparation tank body can be installed below the ground to avoid manual transportation to high places and reduce labor intensity.

Owner:PANZHIHUA STEEL ENTERPRISES XINYU CHEM

A kind of preparation method of winding high-strength and high-purity carbon/carbon composite material rotor

ActiveCN111875401BIncrease infiltration densification rateShorten the diffusion pathCarbon compositesYarn

The invention discloses a method for preparing a revolving body of high-strength and high-purity carbon / carbon composite material by winding. The method comprises: 1. preparing a mandrel; 3. Perform chemical vapor deposition densification on dry yarn prefabricated parts to form deposition parts; 4. Repeat dry yarn winding process and chemical vapor deposition densification process to form carbon / carbon densification parts; 5. Carbon / carbon densification parts are treated at high temperature Obtain a high-temperature treatment part; 6. Prepare a pyrolytic carbon or silicon carbide coating on the surface of the high-temperature treatment part after demoulding to obtain a carbon / carbon composite material revolving body. The present invention adopts the method of graded winding molding-chemical vapor infiltration densification, which shortens the gas diffusion path of chemical vapor infiltration densification, thereby avoiding the phenomenon that the surface density of the deposit body increases faster than that of the interior, and improves the rotation of carbon / carbon composite materials. The bonding strength of the interface between the bulk layers improves the quality and purity of the product, and is used in photovoltaics, semiconductors and other fields.

Owner:XIAN CHAOMA SCI TECH

Method for preparing cobalt-coated tungsten carbide powder by freezing

ActiveCN110026551AUneven solutionSimple processTransportation and packagingMetal-working apparatusGranularityAlloy

The invention belongs to the field of hard alloy and material metallurgy, and particularly discloses a method for preparing cobalt-coated tungsten carbide powder by freezing. According to the method,metal cobalt salt and tungsten carbide powder are used as raw materials, and the preparation of the uniform cobalt-coated tungsten carbide powder is realized through the steps of dissolution, freezingcrystallization, three-step heat treatment and the like. The method comprises the following steps that the cobalt salt is dissolved in a hot liquid to obtain a cobalt-containing precursor solution, the tungsten carbide powder is added as a nucleating agent and gradually cooled in the stirring process, the cobalt salt is separated out and adhered and wraps outside the tungsten carbide powder to obtain uniformly-wrapped tungsten carbide, and the cobalt salt composite powder is dried, decomposed and reduced to obtain the uniformly-mixed cobalt-coated tungsten carbide powder at three different temperatures. The method realizes uniform tungsten carbide. The preparation method of the cobalt-coated powder has the advantages that the process flow is simple, the Co content of different brands canbe obtained, the granularity is easy to control, and the problem that a cobalt pool and the like in the current hard alloy production process are not uniform is effectively solved.

Owner:HUNAN GOLDEN EAGLE ENERGY TECH CO LTD

Method for preparing single-layer graphene on the surface of ultra-nanodiamond

ActiveCN107902650BLarge Boundary DensityEffective diffusionSingle layer grapheneDiamondLattice mismatchSingle layer graphene

The invention is applicable to the technical field of semiconductor and provides a method for preparing single-layer graphene on the surface of ultranano diamond. The method comprises preprocessing anultranano diamond film to eliminate surface impurities and surface stress; forming a metal layer on the nucleation surface of the preprocessed ultranano diamond film, wherein the metal layer is composed of a nickel layer and a copper layer on the upper surface of the nickel layer or is a copper-nickel alloy layer; performing high-temperature annealing treatment on the ultranano diamond film withthe grown metal layer to self-organize the single-layer graphene. The method for preparing the single-layer graphene on the surface of the ultranano diamond saves a second transfer process by directlygrowing the single-layer graphene on the ultranano diamond film, thereby effectively avoiding introduced impurities and lattice imperfection during second transfer processes; meanwhile, the grown single-layer graphene is small in lattice mismatch and surface change.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

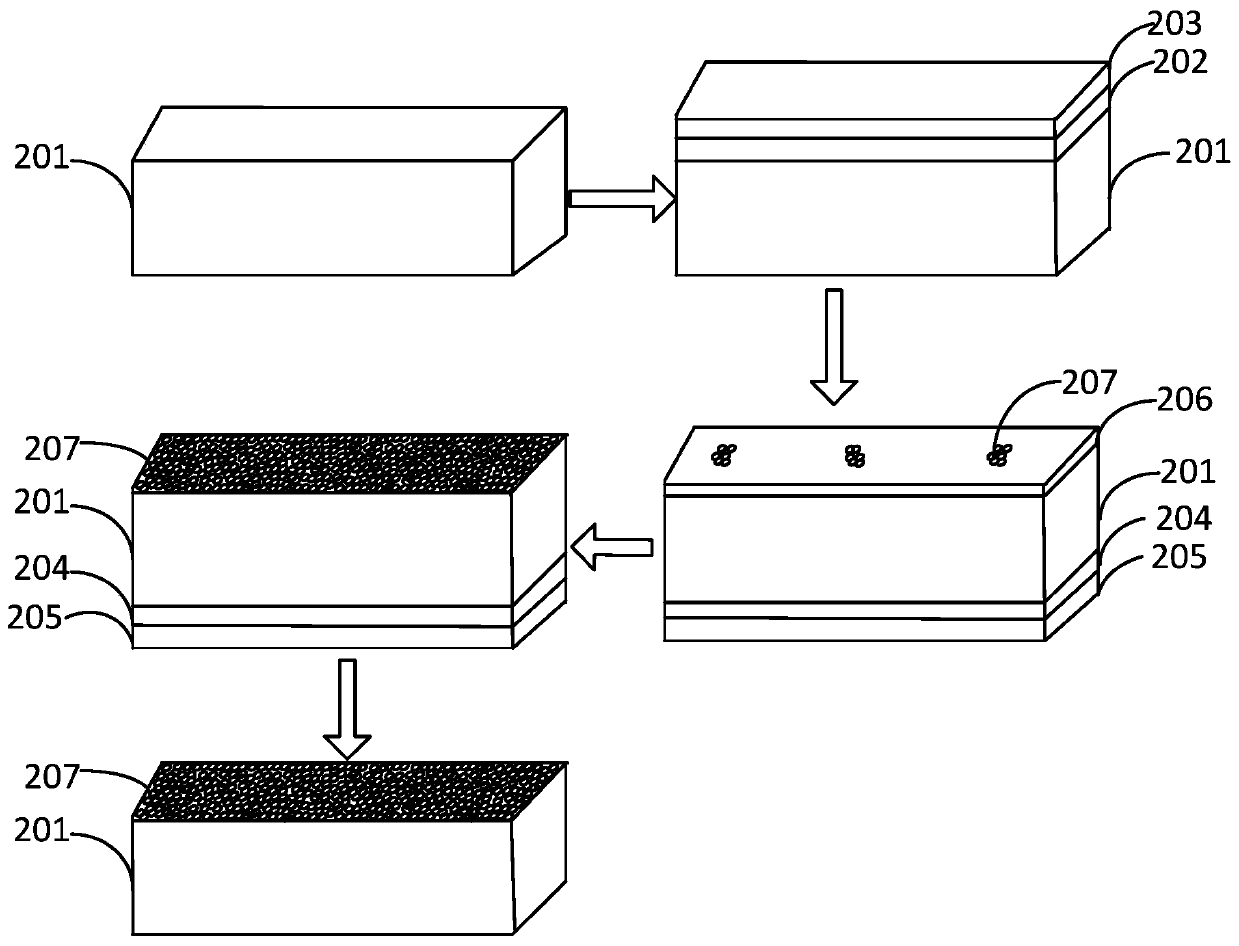

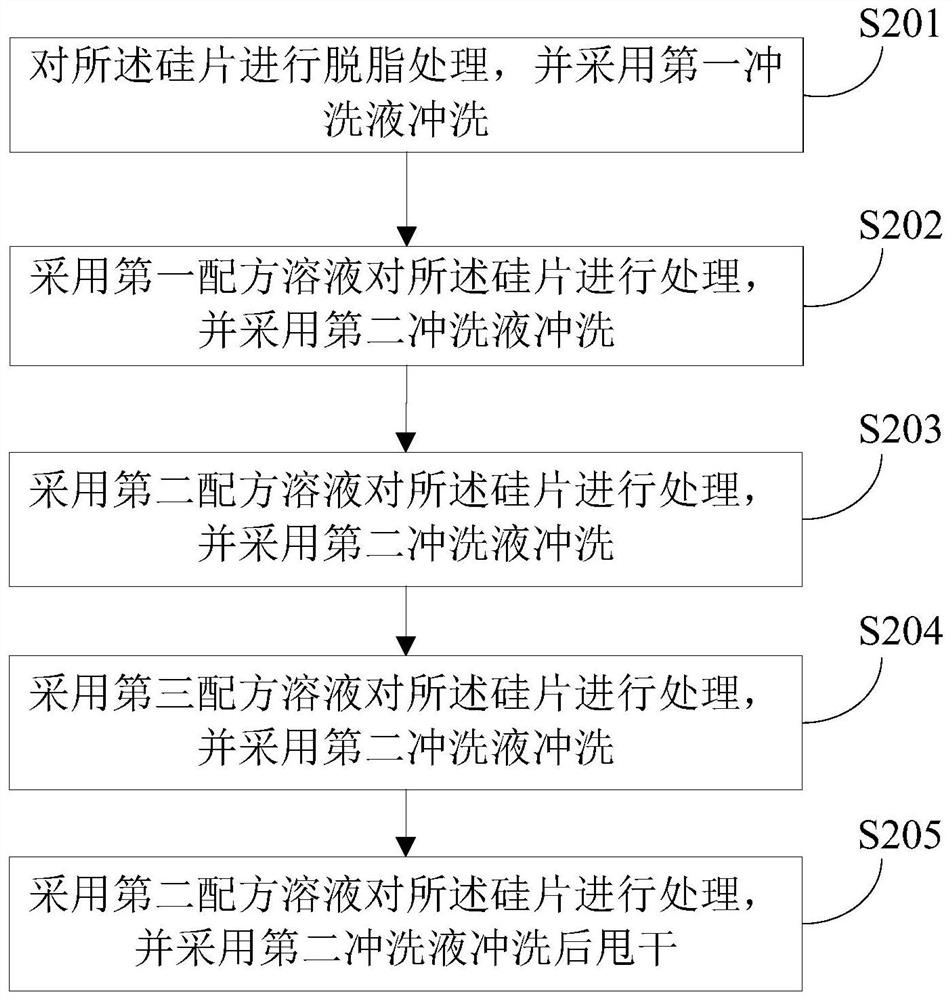

Processing method of silicon base substrate

ActiveCN110783183BLow flatnessImprove processing qualitySemiconductor/solid-state device manufacturingChemical treatmentSilicon chip

The invention proposes a method for processing a silicon-based substrate, comprising: obtaining a silicon wafer; chemically treating the silicon wafer to form a hydrogen passivation layer on the surface of the silicon wafer; performing a desorption process on the silicon wafer to remove hydrogen passivation layer. According to the silicon-based substrate processing method of the embodiment of the present invention, after the silicon wafer is chemically treated, a hydrogen passivation layer is formed on the surface of the silicon wafer, which can effectively protect the silicon wafer. Moreover, the desorption temperature of the hydrogen passivation layer is relatively low, thereby effectively reducing the problem of bending damage and introducing impurities caused by the high-temperature desorption of the passivation layer on the silicon wafer. Moreover, when selecting a silicon wafer, optimize the silicon Chip screening standards, thereby effectively reducing the flatness of silicon-based substrates, improving the processing quality of silicon-based substrates, and facilitating the processing of large area array devices.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Method for detecting kiln coating suspension performance of fireproof brick for cement kiln

InactiveCN102879265BChemical compositionApply evenlyMaterial strength using tensile/compressive forcesFire brickProcess engineering

The invention discloses a method-static shearing method for detecting the kiln coating suspension performance of a fireproof brick for a cement kiln, and a principle, equipment, a sample, steps and result calculation thereof. The static shearing method is low in experimental expense, strong in operability and quantizable, especially the shearing position is proper, the data is stable and good in repeatability in the shearing range, the influence caused by errors is greatly reduced, the practical kiln coating suspension performance of the fireproof brick for the cement kiln can be really reflected, the conventional fireproof material detection equipment is made full use of, and the conventional performance detection method for the fireproof brick is further improved.

Owner:TONGDA REFRACTORY TECH CO LTD +1

High-purity semi-insulating silicon carbide crystal growing apparatus and method therefor

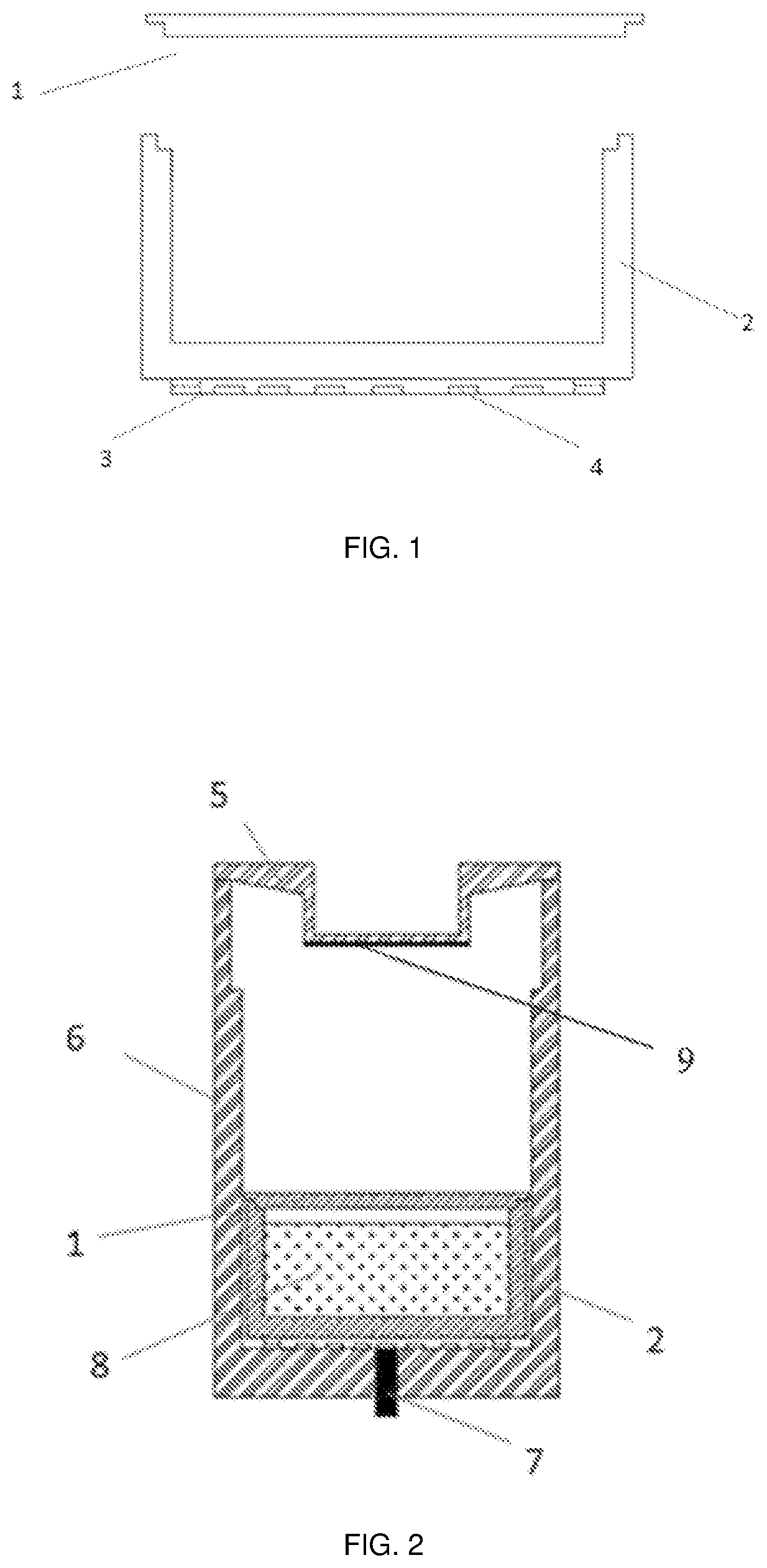

PendingUS20210332497A1Prevent introductionPrevent impurityPolycrystalline material growthFrom condensed vaporsCarbide siliconSemi insulating

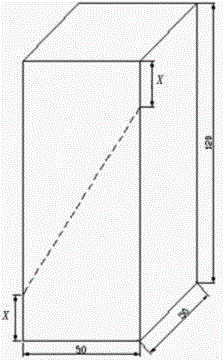

A high-purity semi-insulating silicon carbide crystal growing apparatus and a method therefor are provided, the apparatus comprising a growth crucible, a bottom part of the growth crucible having inserted a gas pipe, a top part of the growth crucible being provided with a growth crucible cover, a feedstock crucible having a bowl-shaped structure being disposed in the growth crucible, an upper part of the feedstock crucible being provided with a baffle, a bottom part of the feedstock crucible being provided with a ring-shaped supporting feedstock crucible bottom foot, the diameter of the feedstock crucible bottom foot being ⅛ the diameter of the feedstock crucible, and the feedstock crucible bottom foot having disposed thereon 8-36 evenly distributed gas holes.

Owner:FUJIAN BEIDIAN MATERIAL TECH CO LTD

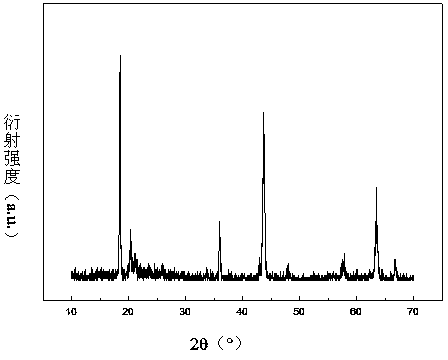

Preparation method of niobium-soluble lithium titanate solid-solution medium ceramic powder

ActiveCN103641159AAvoid the introduction of impuritiesGuaranteed high purity and homogeneityTitanium compoundsCitric acidGlycol synthesis

The invention discloses a preparation method of niobium-soluble lithium titanate solid-solution medium ceramic powder. The microwave medium ceramic powder adopts LiNO3, Ti(C4H9O)4 and Nb2O5 as raw materials. The method comprises the steps of weighing the LiNo3 and Ti(C4H9O)4 according to a molar ratio of (2+x): (1-4x) (wherein x is more than 0 and less than 0.2), adding the well-prepared citric acid solution, adding ethylene glycol, adjusting the pH value by utilizing ammonia water, uniformly stirring the obtained solution, standing the solution in a sealing manner so as to obtain gel, drying and grinding the gel, adding the Nb2O5 into the dry gel powder according to the molar ratio of Li: Nb: Ti of (2+x): 3x: (1-4x) (wherein x is more than 0 and less than 0.2), carrying out ball milling and mixing by adopting the absolute ethyl alcohol as the medium, and drying and calcining the obtained powder so as to obtain the ceramic powder. The method is simple in synthesis process, stable in process under the normal temperature and good in repeatability and has a wide application prospect.

Owner:广东奥胜新材料有限公司

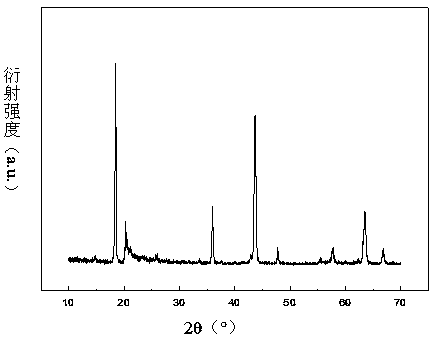

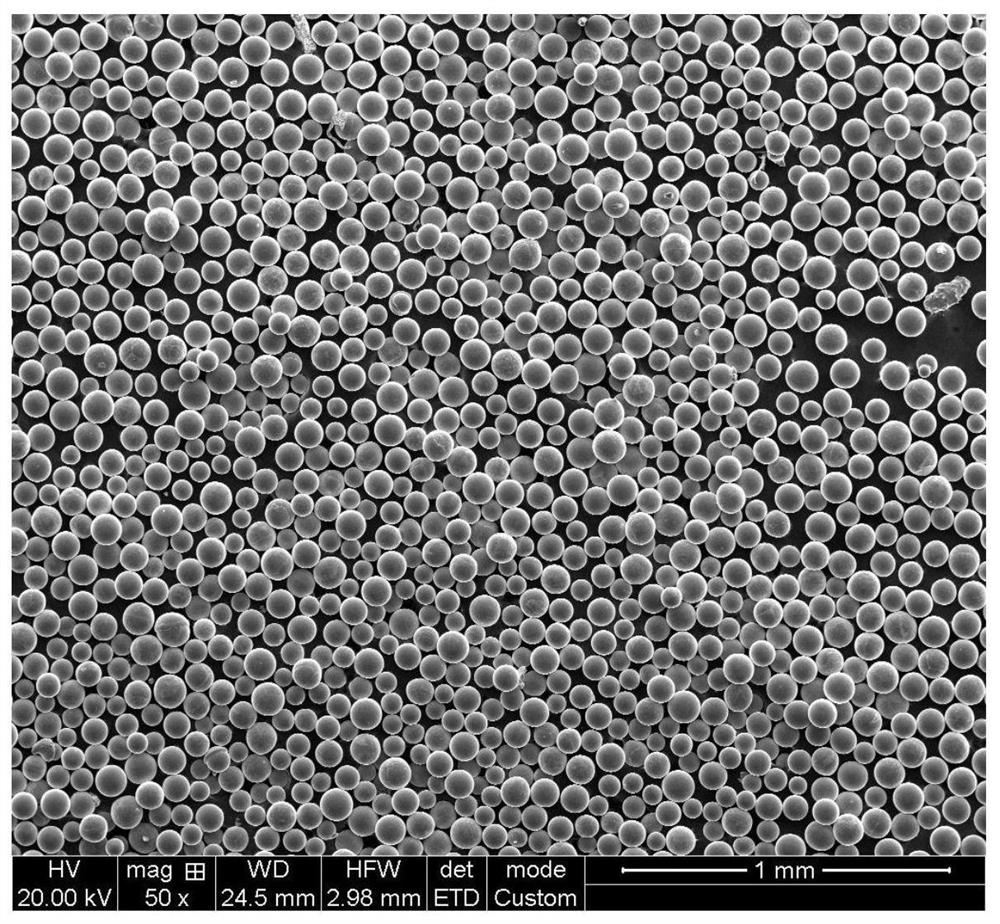

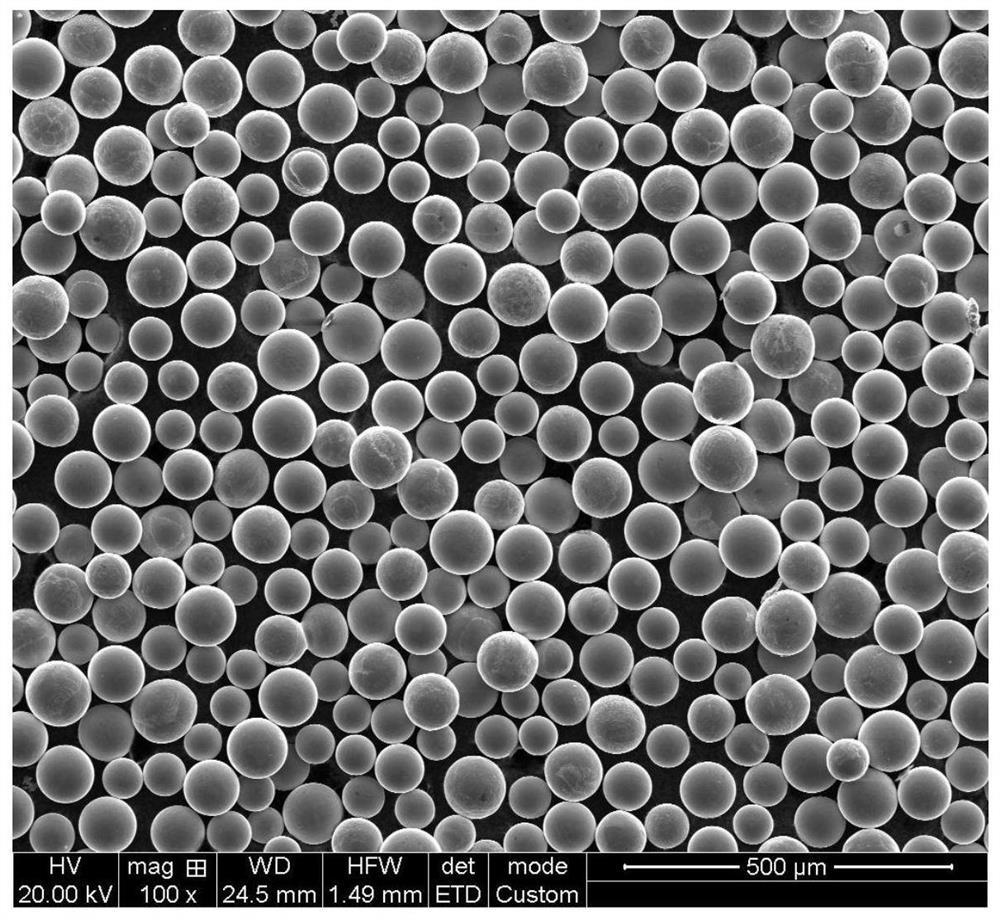

A kind of tial alloy powder and its preparation method and application

ActiveCN112575221BImprove purityNo pollution in the processAdditive manufacturing apparatusTransportation and packagingMetal powderTi element

The invention provides a TiAl alloy powder and its preparation method and application, belonging to the technical field of metal powder. The TiAl alloy powder includes the following elements by mass percentage: Al: 34%-35%, Nb: 4.5%-5.1%, Cr: 2.4%-2.7%, Gd: 0-0.02%, C: greater than 0 and not greater than 150ppm, N: more than 0 and not more than 200ppm, H: more than 0 and not more than 100ppm, O: more than 0 and not more than 700ppm, the balance being Ti; the TiAl alloy powder is spherical, with a particle size of 40μm-106μm, flowing The resistance is 10.0~20.0s / 50g, and the hollow ball rate is not more than 0.5%.

Owner:CENT IRON & STEEL RES INST

6N rotating target material and preparation method thereof

PendingCN112323027AEasy to prepareEasy to operateVacuum evaporation coatingSputtering coatingAlcoholCopper

The invention discloses a 6N rotary target material and a preparation method thereof. The preparation method comprises the following steps that the surface of a 6N copper raw material is polished andthen subjected to acid pickling for 10-20 min through a mixed solution, then the 6N copper raw material is washed with clear water and ethyl alcohol in sequence and dried, and a pretreated copper rawmaterial is obtained; the pretreated copper raw material is preheated for 1-3h at the temperature of 400-600 DEG C, smelted at the temperature of 1100-1200 DEG C, heated to 20-100 DEG C after completemelting to be subjected to overheating heat preservation for 10-20min, and then subjected to pouring and cooling to obtain a copper rod; and the copper rod is fixed by a die to be subjected to chambering for 4-6 times through a drilling machine, and the 6N rotating target material is obtained. The invention further discloses the 6N rotating target material prepared by the method. The preparationmethod is simple and easy to operate, the 6N rotating target material with low impurity content can be prepared, and the problems that in the prior art, mechanical stress and impurities are prone to being generated, grain gaps are large, and the production cost is high are effectively solved.

Owner:四川华芯腾科技有限责任公司

A kind of compound electrolyte injection and preparation method thereof

ActiveCN113274350BImprove stabilityGood storage stabilityMetabolism disorderPharmaceutical product form changeSodium acetatePharmaceutical formulation

The invention relates to the technical field of pharmaceutical preparations, and specifically discloses a compound electrolyte injection and a preparation method thereof. The preparation method is as follows: adding L-malic acid, magnesium chloride, sodium chloride, potassium chloride, calcium chloride, sodium acetate and sodium hydroxide in the prescribed quantity into the water for injection prepared with a total volume of 70-80% in sequence , stir and dissolve, heat to boil, keep for 10min-20min, add water for injection to the total amount of preparation, filter through multi-stage polyethersulfone filter elements with successively smaller pore diameters, fill, and sterilize to obtain compound electrolyte injection. The present invention prepares the compound electrolyte injection (II) with significantly reduced impurity types and contents through a one-step preparation method, which significantly improves the storage stability of the injection, and the impurity content does not increase significantly in the stability investigation test, and at the same time, The production process is greatly simplified, the production efficiency is improved, the production cost is reduced, the industrialized production is facilitated, and the invention has broad application prospects.

Owner:SHIJIAZHUANG NO 4 PHARMA

In-situ phosphorized catalyst for preparing cycloalkane from lignin as well as preparation method and application of catalyst

PendingCN114797914AAvoid emissionsAvoid the introduction of impuritiesHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystPhysical chemistry

The invention relates to a cycloalkane catalyst prepared from lignin through in-situ phosphorization and a preparation method and application of the cycloalkane catalyst, Cu-Mg-Al hydrotalcite serves as a precursor of the catalyst, a Cu / CuMgAlOx intermediate is obtained through calcination and reduction, and then the catalyst is prepared through in-situ phosphorization. The preparation method specifically comprises the following steps: respectively dropwise adding a mixed solution containing Cu < 2 + >, Mg < 2 + > and Al < 3 + > and a NaOH solution into a Na2CO3 solution, controlling the temperature and pH of the mixed solution, and precipitating; after dropwise adding is finished, aging, filtering, washing and drying the mixed solution in a stirring state to obtain a precursor; grinding the precursor into powder, and calcining to obtain a metal oxide; metal oxide is reduced and activated to obtain an intermediate, and mixed powder of red phosphorus and the intermediate is subjected to in-situ phosphorization in an inert atmosphere to obtain the catalyst. The catalyst has high catalytic activity on deep deoxidation of cycloalcohol intermediates in the lignin conversion process, and the yield and selectivity of cycloalkanes in the product are improved.

Owner:SOUTHEAST UNIV

Method for preparing TiAl alloy bars

The invention provides a method for preparing TiAl alloy bars, relating to a method for preparing alloy bars. The invention solves the problem of difficult hot extrusion in preparation of the TiAl alloy bars by the existing casting metallurgical method and the problems of easy introduction of impurities and low compactness of the TiAl alloy bars prepared by the powder metallurgical method. The method of the invention is as follows: 1) preparing Ti powder into porous Ti by cold compressing and sintering; 2) forming a hot-pressing piece by the porous Ti and alusil alloy; 3) preparing Ti-Al bimetal complexes by using a vacuum pressure infiltration method; 4) extruding to obtain Ti-Al bimetal composite bars; and 5) performing heat treatment to obtain the TiAl alloy bars. In the invention, theextrusion operation of the bars is carried out at lower temperature, the bar has the advantages that the extrusion is easy, no ball milling process is needed, the impurities are less, the tissues of the bars are uniform and fine, the compactness is 97-99%, and the tensile strength is 730-780 MPa, thereby be capable of being used in the fields of aviation, spaceflight and automobile.

Owner:HARBIN INST OF TECH

Preparation tank and preparation system for sodium sulfite solution used for chlor-alkali industry

ActiveCN110882635AReduce oxidationIncrease in sizeTransportation and packagingInert gas productionSulfite saltPhysical chemistry

The invention discloses a preparation tank and a preparation system for a sodium sulfite solution used for the chlor-alkali industry, and belongs to the technical field of preparing sodium sulfite solutions used for the chlor-alkali industry. The main body of the preparation tank is provided with a protective gas connection port, and protective gas can be fed into the main body of the preparationtank after the connection port is connected to a protective gas supply device, thereby reducing the oxidation situation during a sodium sulfite solution preparation process. In addition, since the sodium sulfite solution is not oxidized during the preparation process, the prepared sodium sulfite solution can be directly stored in the main body of the preparation tank, a special storage tank structure separately arranged is not needed and long-time storage can be achieved, and therefore, the frequency of preparation can be reduced by increasing the volume of the main body of the preparation tank. The main body part of the preparation tank can be installed underground to avoid the need of manual transportation to a high place and reduce the labor intensity.

Owner:PANZHIHUA STEEL ENTERPRISES XINYU CHEM

A kind of algan thin film with in-situ sin dislocation annihilation layer and its epitaxial growth method

ActiveCN112242459BPromote growth and healingAvoid the introduction of impuritiesFinal product manufactureSemiconductor devicesEtchingGrown film

The invention discloses an AlGaN film with an in-situ SiN dislocation annihilation layer and an epitaxial growth method thereof. The steps of the method include: epitaxially growing an AlN film on a sapphire substrate; epitaxially growing a first AlGaN thin film layer; using hydrogen gas to etch dislocation pits on the first AlGaN thin film layer; in-situ depositing a SiN dislocation annihilation layer on the surface of the dislocation pit; epitaxially growing a second dislocation annihilation layer on the SiN dislocation annihilation layer AlGaN thin film layer. In the present invention, by corroding dislocation pits on the first AlGaN thin film layer and then performing SiN in-situ filling, on the one hand, the second AlGaN thin film layer and subsequent film layers can be patterned synchronously during the growth process, It avoids the problem of taking out the epitaxial wafer for complex etching process and introducing impurities during taking out the etching; on the other hand, since the SiN dislocation annihilation layer is an island-like distribution structure corresponding to the dislocation pit, this structure is more conducive to Growth healing of the second AlGaN film layer.

Owner:SUZHOU UVCANTEK CO LTD

An atomization component and atomization device

ActiveCN105944859BSimple structureSimplified assembly stepsLiquid spraying apparatusMechanical engineeringSingle use

The invention discloses an atomization assembly applied to an opening of a container. The atomization assembly comprises a first air inlet pipeline, a liquid inlet pipeline, a mist outlet pipeline, a U-shaped air inlet pipeline and an atomization separation chamber, wherein the first air inlet pipeline is connected with one end of the U-shaped air inlet pipeline; the liquid inlet pipeline and the atomization separation chamber mutually communicate with the other end of the U-shaped air inlet pipeline; and the atomization separation chamber communicates with the mist outlet pipeline. The invention further discloses an atomization device. The atomization device comprises the sealable container and the atomization assembly. With the adoption of the U-shaped air inlet pipeline, the atomization assembly disclosed by the invention is compact in structure and capable of being arranged at the opening of the container. Therefore, on one hand, the structure is simplified, the occupied volume of the device is greatly reduced, and assembly steps are simplified; and on the other hand, the atomization assembly is disposable, thus the safety of liquid use is greatly improved.

Owner:龚日常

A method for preparing vertical cavities on ltcc substrates

InactiveCN103442521BHigh verticality on four sidesGood bottom flatnessPrinted circuit assemblingMultilayer circuit manufactureOptoelectronicsImpurity

The invention discloses a method for preparing a vertical cavity on an LTCC substrate, which can improve the quality of the vertical cavity and improve the performance of the vertical cavity. This method first selects the diaphragm A, film B, and diaphragm C; then cuts the film B into a film D; cuts and removes the part that is consistent with the length and width of the film D on the diaphragm C; then selects a certain number of diaphragms A is stacked one by one, and the film C and film D are put in during the stacking process; the laminated multi-layer film is pressed into a dense block; the block is cut with a cutting knife, and the block is cut after the cutting is completed. Excess dicing and film D are removed to form the desired vertical cavities. This method is to press the laminated multi-layer diaphragm into a dense block and then cut to form a vertical cavity. This method can greatly improve the quality of the vertical cavity and avoid the introduction of The problem of impurities and pollution is improved, the performance of the vertical cavity is improved, and it is suitable for popularization and application in the technical field of LTCC ceramic substrates.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com