Method for detecting kiln coating suspension performance of fireproof brick for cement kiln

A detection method, the technology of refractory bricks, which is applied in the detection field, can solve the problems of not reflecting the actual kiln skin performance of refractory bricks used in cement kilns well, the static method has many irrelevant influencing factors, and cannot carry out quantifiable detection, etc., to achieve perfection Performance testing method, low experimental cost, and stable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, the top 5mm of the moment refractory brick is used as the shear point, and the following steps are used to detect the magnesia-chrome refractory brick:

[0047] 1. Preparation of refractory brick samples:

[0048] (1) Cement raw material slurry preparation: Weigh a certain amount of cement raw material, pour it into a mortar and grind it until it passes through a 0.088mm standard sieve, then add the same amount of glycerol, mix and grind evenly, and then set aside;

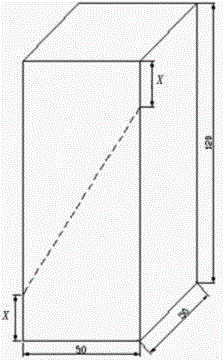

[0049](2) Cut out 3 cuboids with a length of 50 mm, a width of 50 mm and a height of 120 mm from the refractory brick to be tested. The error of each side is not more than 1 mm. ;

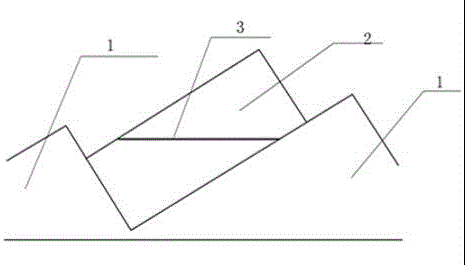

[0050] (3) if figure 1 , on a rectangular surface of the cut cuboid, take a point at the lower end of one of the long sides 5 mm, and another point at the upper end of the other long side at 5 mm, draw a line connecting the two points, and draw a line perpendicular to the rectangular surface Cut out 2 test...

Embodiment 1~18

[0064] Take magnesia-chrome bricks, dolomite bricks, and magnesia-alumina spinel bricks respectively. The specific implementation steps are the same as in Example 1. The test results of the refractory bricks hanging in the kiln are shown in the following table:

[0065] Table 1 Test results of skin force of each refractory brick hanging kiln

[0066] 。

[0067] It can be seen from Table 1 that the overall order of the skin force data of each refractory brick hanging kiln from large to small is: dolomite brick > magnesia chrome brick > spinel magnesia brick, and the results are consistent with the actual situation of cement rotary kiln lining bricks The data are relatively stable at the shear distance of each refractory brick at 15~30mm, and the error between the test value of each point and the average value is not more than 3.3%. The size of the results has little influence on the data, and it is not easy to cause errors. It can be used to characterize the actual hanging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com