Preparation method of niobium-soluble lithium titanate solid-solution medium ceramic powder

A technology of dielectric ceramics and solid solutions, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of low sintering activity, low powder purity, coarse particles, etc., to achieve industrial production, process stability, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

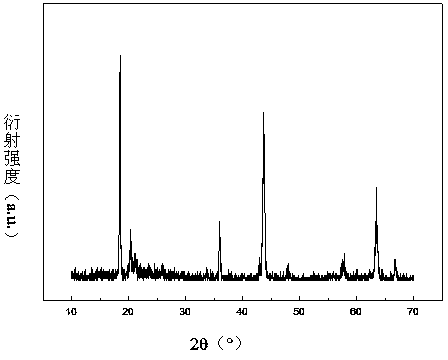

[0031] The present invention uses LiNO 3 , Nb 2 o 5 and Ti(C 4 h 9 O) 4 For the raw material. Raw material LiNO 3 , Ti(C 4 h 9 O) 4 and Nb 2 o 5 By the expression Li 2.06 Nb 0.18 Ti 0.76 o 3 The stoichiometric ratio of the preparation. First, the raw material LiNO 3 , Ti(C 4 h 9 O) 4 Weigh the raw materials respectively according to the Li:Ti molar ratio of 2.06:0.76; then weigh the LiNO 3 and Ti(C 4 h 9 O) 4 Add citric acid solution (mass concentration: 50%), the molar ratio of citric acid to metal ions is 3:1, and heat to about 40°C. After stirring for 30 minutes to dissolve, add ammonia water to adjust the pH value to adjust the pH of the solution The value is 5. Then add ethylene glycol to the solution, the molar ratio of ethylene glycol to citric acid is 3:1, and add sodium polyacrylate at the same time, the molar ratio of sodium polyacrylate to ethylene glycol is 0.5:1, and heat the solution to 90°C , and kept stirring for 6h, then a black we...

Embodiment 2

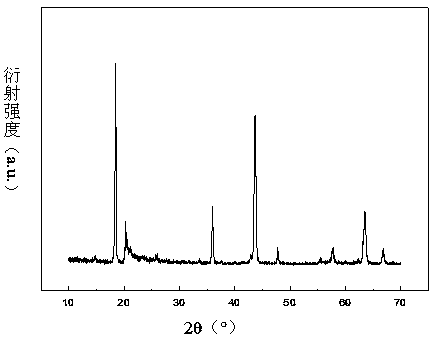

[0033] In this experiment, LiNO 3 , Nb 2 o 5 and Ti(C 4 h 9 O) 4 For the raw material. Raw material LiNO 3 , Ti(C 4 h 9 O) 4 and Nb 2 o 5 By the expression Li 2.08 Nb 0.24 Ti 0.68 o 3 The stoichiometric ratio of the preparation. First, the raw material LiNO 3 , Ti(C 4 h 9 O) 4 Weigh the raw materials respectively according to the Li:Ti molar ratio of 2.08:0.68; then weigh the LiNO 3 and Ti(C 4 h 9 O) 4 Add citric acid solution (mass concentration: 50%), the molar ratio of citric acid to metal ions is 3:1, and heat to about 40°C. After stirring for 30 minutes to dissolve, add ammonia water to adjust the pH value to adjust the pH of the solution The value is 5.5. Then add ethylene glycol to the solution (the molar ratio of ethylene glycol to citric acid is 3:1), and at the same time add sodium polyacrylate (the molar ratio of sodium polyacrylate to ethylene glycol is 1:1), and heat the solution to 90℃, and keep stirring for 8h, a black wet gel can be pre...

Embodiment 3

[0035] In this experiment, LiNO 3 , Nb 2 o 5 and Ti(C 4 h 9 O) 4 For the raw material. Raw material LiNO 3 , Ti(C 4 h 9 O) 4 and Nb 2 o 5 By the expression Li 2.01 Nb 0.03 Ti 0.96 o 3 The stoichiometric ratio of the preparation. First, the raw material LiNO 3 , Ti(C 4 h 9 O) 4 Weigh the raw materials respectively according to the Li:Ti molar ratio of 2.01:0.96; then weigh the LiNO 3 and Ti(C 4 h 9 O) 4 Add citric acid solution (mass concentration: 50%), the molar ratio of citric acid to metal ions is 4:1, and heat to about 40°C. After stirring for 30 minutes to dissolve, add ammonia water to adjust the pH value to adjust the pH of the solution. The value is 4.5. Then add ethylene glycol to the solution (the molar ratio of ethylene glycol to citric acid is 2:1), and at the same time add sodium polyacrylate (the molar ratio of sodium polyacrylate to ethylene glycol is 0.5:1), and heat the solution to 90°C, and kept stirring for 8h, then a black wet gel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com