A method for preparing vertical cavities on ltcc substrates

A cavity and substrate technology, which is applied in the manufacture of multi-layer circuits, assembly of printed circuits with electrical components, etc., can solve problems such as paraffin carbonization or oxide residues, influence of circuit microwave performance, and high requirements for firing atmosphere, etc., to reach the bottom surface Good flatness, high verticality of four sides, ensuring overall performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The method for preparing a vertical cavity on an LTCC substrate comprises the following steps:

[0021] A. Select the raw porcelain tape prepared by dry casting method, which is recorded as diaphragm A; select a carrier film used to carry the green ceramic tape during casting, and record it as film B; select a piece of thickness consistent with film B The green ceramic belt, denoted as diaphragm C;

[0022] B. Cut the film B into the same figure as the length and width of the vertical cavity to be prepared, such as figure 1 As shown, the film after cutting is recorded as film D; cut and remove the part that is consistent with the length and width of film D on film C, as shown in figure 2 As shown, the position of the removed part in the diaphragm C is the same as that of the vertical cavity to be prepared in the diaphragm C;

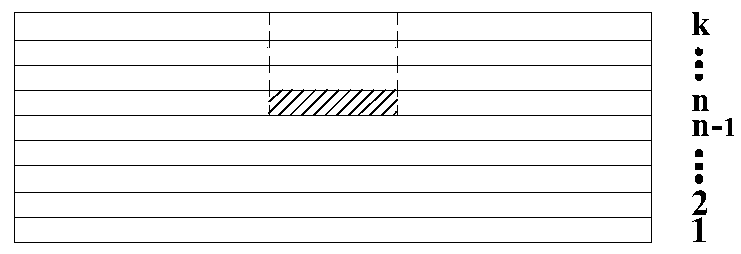

[0023] C. Select a certain number of diaphragms A to be laminated one by one. When stacking to the n-1th layer, select the diaphragm C obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com