An atomization component and atomization device

A technology of atomizing device and atomizing air, which is applied in the direction of spraying device and liquid spraying device, etc., can solve the problems of unsatisfactory atomization and filtration effect, complex assembly, large space, etc., to increase process cost, simplify assembly steps, reduce volumetric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

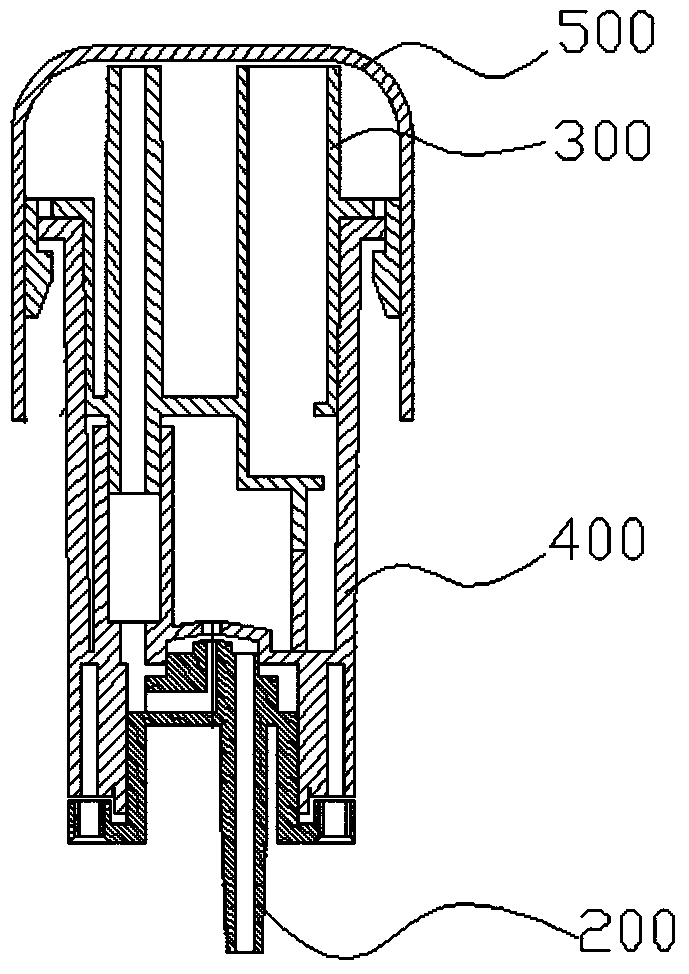

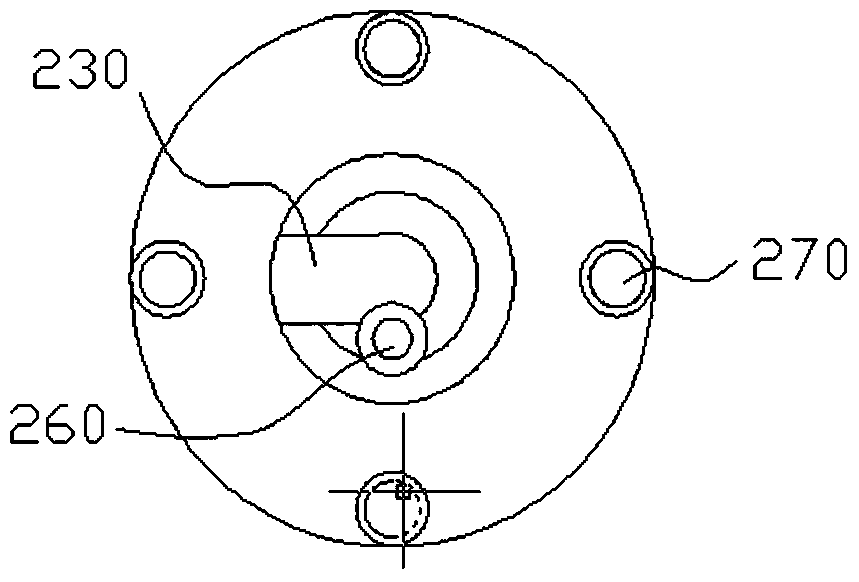

[0037] In the research and development process, in order to integrate the container and the atomization component, the atomization component can be placed at the opening of the container, and the side of the container is drilled to form a mist outlet pipe. Wherein the atomization component includes an air inlet pipe, a liquid inlet pipe, a mixing channel and a mixing chamber. The mixing chamber is respectively connected with the mixing channel, the air inlet pipe and the liquid inlet pipe. The mixing channel communicates with the inner space of the bottle body. The compressed gas enters the space above the liquid level inside the bottle after passing through the inlet pipe, mixing chamber and mixing channel. The gas is atomized together in the space above the liquid surface inside the bottle, and the atomized air enters the atmosphere through the mist outlet pipe.

[0038] Although this device can also set the atomizing component at the opening of the container, the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com