A kind of tial alloy powder and its preparation method and application

An alloy powder and alloy electrode technology, applied in the field of metal powder, can solve the problems of unsatisfactory physical and chemical indicators such as powder hollowness, sphericity and particle uniformity, high content of impurity elements in TiAl alloy powder, and uneven powder particle size distribution. Long spheroidization time, low oxygen content and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a method for preparing the above-mentioned TiAl alloy powders of the embodiment, comprising the steps of:

[0026] The TiAl alloy bar finishing obtain TiAl alloy electrode rod; TiAl alloy rods comprising the mass percentage of the elements: Al: 37% ~ 39%, Nb: 4.7% ~ 5.1%, Cr: 2.5% ~ 2.9%, Gd: 0 ~ 0.02%, C: more than 0 and not more than 150ppm, N: more than 0 and not more than 200ppm, H: more than 0 and not more than 100ppm, O: more than 0 and not more than 600ppm, the balance being Ti;

[0027] The TiAl alloy electrode rod loaded to the rotary shaft of the reaction chamber, the reaction chamber is evacuated to a vacuum state, and then to the vacuum reaction chamber charged with protective gas, to the TiAl alloy is used as the consumable electrode rod electrode by plasma rotating electrode method were TiAl alloy powders.

[0028] The TiAl alloy bar finishing obtain TiAl alloy electrode rod.

[0029] In the present invention, the TiAl alloy bar ...

Embodiment 1

[0040] The chemical composition of TIAL alloy bar is: Al: 37%, Nb: 4.8%, Cr: 2.5%, GD: 0.02%, C: 180PPM, N: 180PPM, H: 80PPM, o: 600PPM, margin TI;

[0041] The TiAl alloy rod of the above composition is formed into a TiAl alloy electrode rod having a diameter of 70 mm and a length of 700 mm, and the surface roughness is 0.4 μm; the TiAl alloy electrode rod is loaded to the rotating shaft of the reaction chamber, and the reaction Chamber to vacuum (1 × 10 -3 ~ 1 × 10 -2 PA), then charge Ar in a reaction chamber of the vacuum, a TiAl alloy powder was prepared by a plasma rotary electrode method, and the plasma arc current was 1700A, and the electrode rotation was 20000R / min.

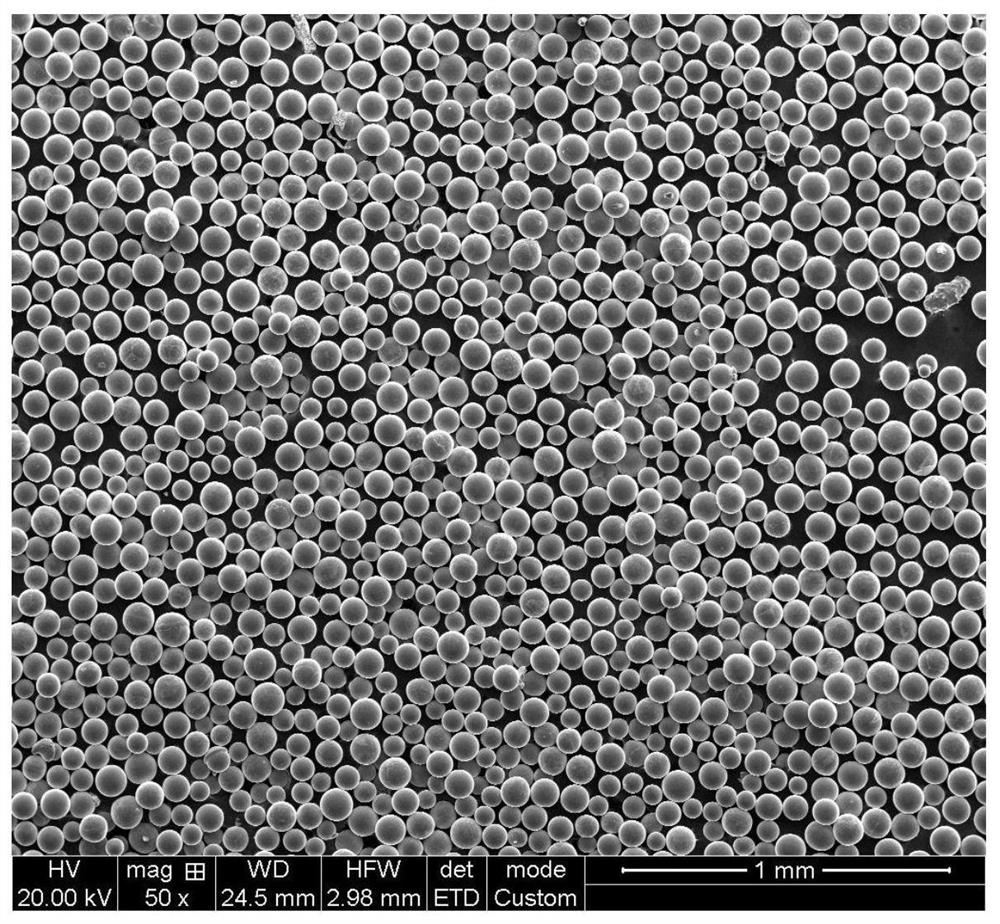

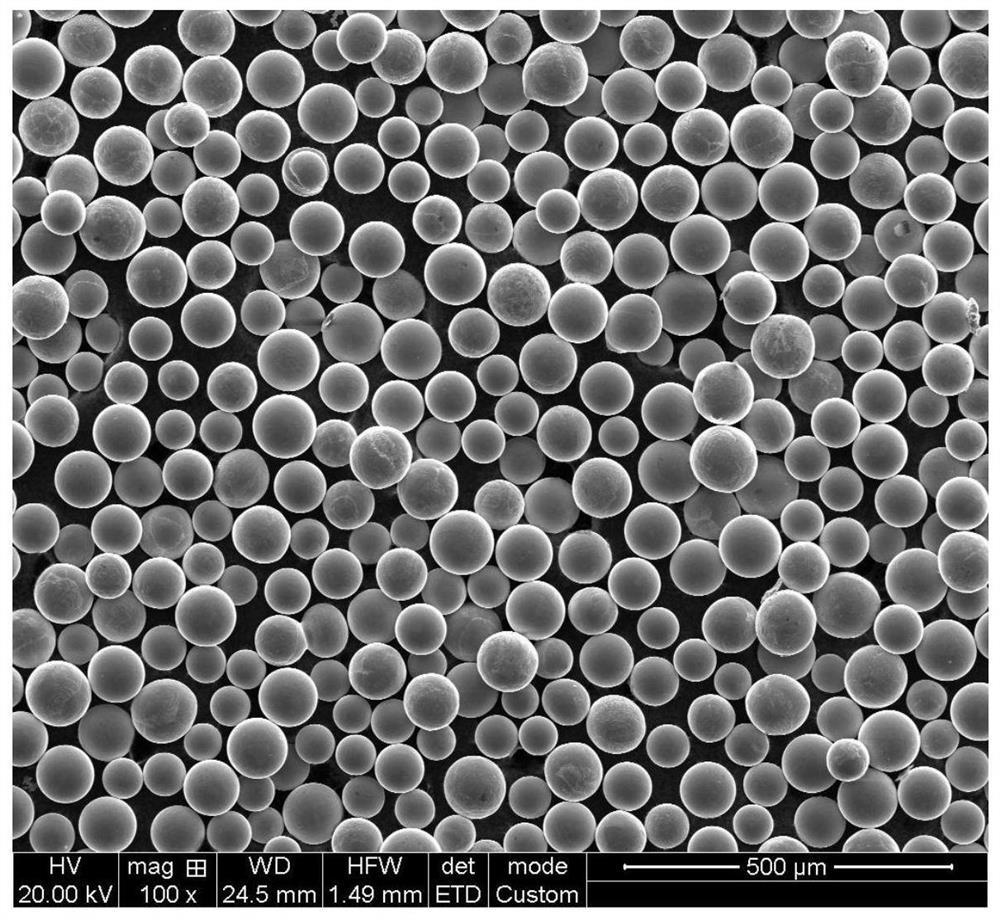

[0042] The TIAL alloy powder chemical composition was: Al: 34%, Nb: 4.5%, CR: 2.4%, CD: 0.015%, C: 180PPM, N: 700PPM, H: 90PPM, o: 700PPM, and margin TI. The TiAl alloy powder particles are spherical morphology, and the particle size of the powder is 70 to 90 μm, the fluidity is 15 s / 50g, and the tiol all...

Embodiment 2

[0044] The chemical composition of TIAL alloy bar is: Al: 39%, Nb: 5.1%, Cr: 2.9%, GD: 0.015%, C: 200PPM, N: 100PPM, H: 80PPM, o: 500PPM, margin TI;

[0045] The TiAl alloy rod of the above composition is formed into a TiAl alloy electrode rod having a diameter of 60 mm and a length of 750 mm, and the surface roughness is 0.5 μm; the TiAl alloy electrode rod is loaded to the rotating shaft of the reaction chamber, and the reaction Chamber to vacuum (1 × 10 -3 ~ 1 × 10 -2 PA), then filled with AR in the reaction chamber of the vacuum state, a TiAl alloy powder was prepared by a plasma rotary electrode method, and the plasma arc current was 1800A, and the electrode rotation speed was 20000R / min.

[0046] The TIAL alloy powder chemical composition was: Al: 35%, Nb: 4.9%, Cr: 2.7%, GD: 0.01%, C: 90PPM, N: 600 ppm, H: 90PPM, N: 600PPM, and balance TI. The TIAL alloy powder particles are spherical morphology, the powder particle size is 70 ~ 80 μm, the fluidity is 17s / 50g, and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com