Dual deterioration method of hypereutectic Al-Si alloy

A hypereutectic, al-si technology, applied in the field of metal materials, can solve the problems of weakened metamorphism, environmental pollution, unstable effect, etc., and achieve the effect of convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Fine-grained hypereutectic Al-17% Si alloy master alloy thin strips were prepared by rapid solidification using the single-roll stripping method. During the preparation process, the single-roll speed was 40m / s, and when the instantaneous maximum temperature was 1300°C, the solidification speed was 10 6 k / s; the obtained thin ribbon can be prepared continuously, the surface is smooth, free of flying spurs and obvious macroscopic defects, and its macroscopic morphology and microstructure are as follows figure 1 and figure 2 Shown; Among them, the primary crystal Si is small in size, with an average size of about 1 μm, and the eutectic Si is in the form of highly branched fibers.

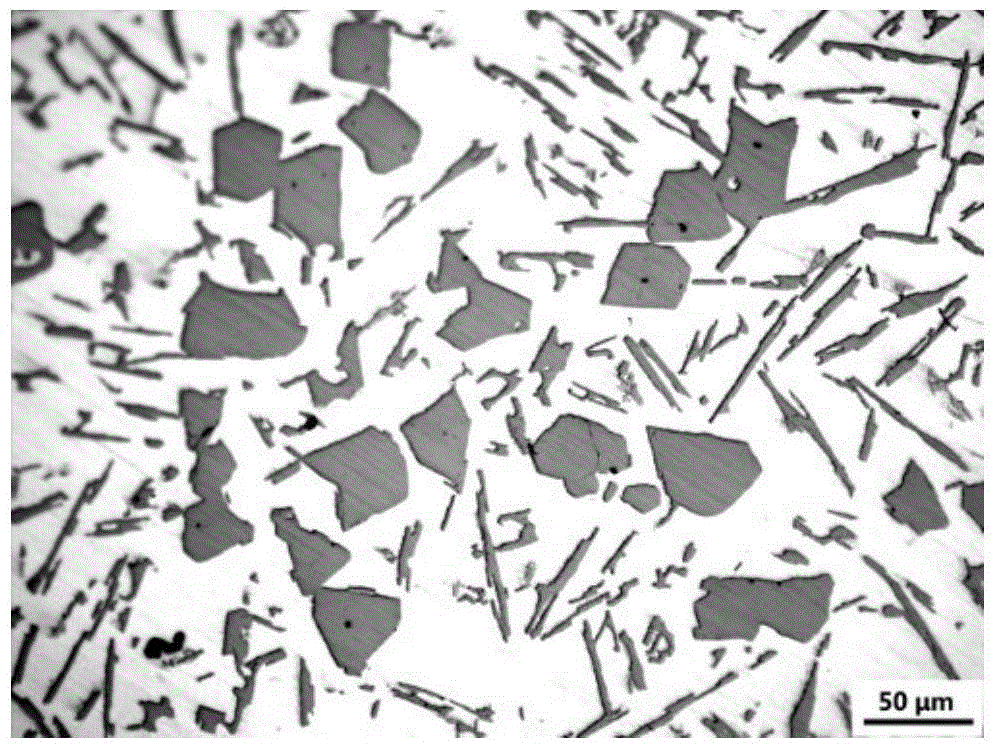

[0023] (2) Melt the substrate hypereutectic Al-17% Si alloy in a resistance furnace, heat up to 750°C, and keep it warm for 15 minutes to obtain molten hypereutectic Al-Si alloy metal liquid; unmodified hypereutectic Al-17% Si alloy original microstructure such as image 3 As shown, the p...

Embodiment 2

[0026] (1) Fine-grained hypereutectic Al-17% Si alloy master alloy thin strips were prepared by rapid solidification using the single-roll stripping method. During the preparation process, the single-roll speed was 40m / s, the instantaneous maximum temperature was 1300°C, and the solidification speed was 10 6 k / s; the obtained master alloy strip has a width of 2-3 mm and a thickness of 10 μm, and its macroscopic appearance and microstructure are as follows figure 1 and figure 2 Shown; Among them, the primary crystal Si is small in size, with an average size of about 1 μm, and the eutectic Si is in the form of highly branched fibers.

[0027] (2) Melt the substrate hypereutectic Al-17% Si alloy in a resistance furnace, heat up to 780°C, and keep it warm for 15 minutes to obtain molten hypereutectic Al-Si alloy metal liquid; unmodified hypereutectic Al-17% Si alloy original microstructure such as image 3 As shown, the primary Si is in the shape of a thick plate with an averag...

Embodiment 3

[0030] (1) Fine-grained hypereutectic Al-17% Si alloy master alloy thin strips were prepared by rapid solidification using the single-roll stripping method. During the preparation process, the single-roll speed was 40m / s, the instantaneous maximum temperature was 1300°C, and the solidification speed was 10 6 k / s; the obtained master alloy strip has a width of 2-3 mm and a thickness of 10 μm, and its macroscopic appearance and microstructure are as follows figure 1 and figure 2 Shown; Among them, the primary crystal Si is small in size, with an average size of about 1 μm, and the eutectic Si is in the form of highly branched fibers.

[0031] (2) Melt the substrate hypereutectic Al-17% Si alloy in a resistance furnace, heat up to 790°C, and keep it warm for 15 minutes to obtain molten hypereutectic Al-Si alloy metal liquid; unmodified hypereutectic Al-17% Si alloy original microstructure such as image 3 As shown, the primary Si is in the shape of a thick plate with an averag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com