Production method of durene

A technology of durene and xylene, applied in the field of durene production, which can solve the problems of uneven quality of coal tar, dependence on imports, and limited raw materials, and achieve stable product quality, low consumption of raw and auxiliary materials, and improved purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

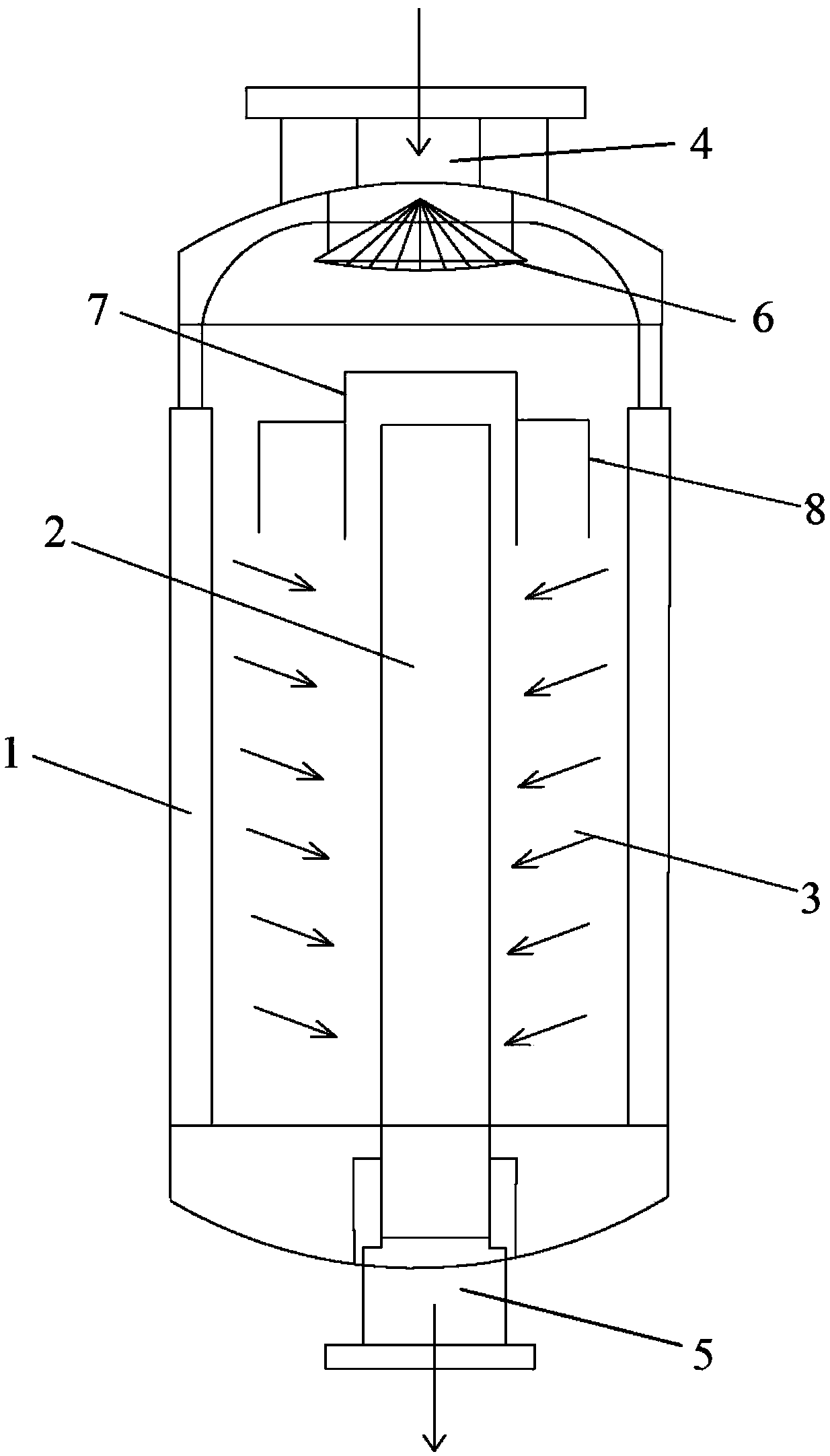

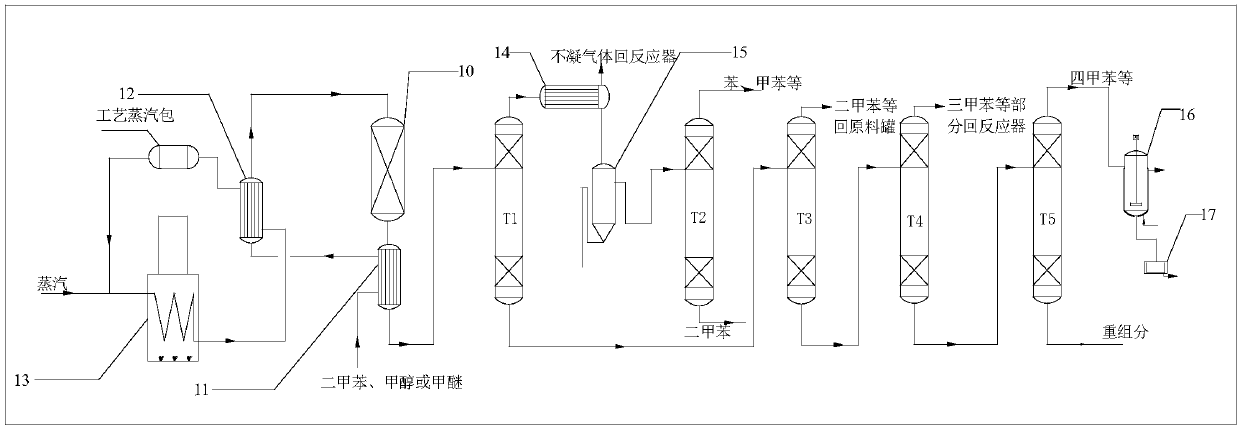

[0068] figure 2 The part on the left shows the technical process of raw material gasification: xylene and alkylating agent pass through the first heat exchanger 11 below the radial fixed bed reactor 10, and absorb the heat generated by the reaction in the radial fixed bed reactor 10. The heat is then sent to the second heat exchanger 12, and the steam from the heating furnace 13 is sent to the second heat exchanger 12 at the same time, so that the xylene and the alkylating agent are heat-exchanged with the steam to obtain gasified xylene and alkylating agents.

[0069] Such as figure 2 As shown, the raw material xylene (volume space velocity is 0.2h -1 ) and methanol are gasified by heat exchange with steam, and the gasified raw materials are sent into the radial fixed bed reactor through the inlet pipe at the top of the radial fixed bed reactor. 0.9m 3 ZSM-5 molecular sieve catalyst, alkylation reaction at 0.1Mpa, 320°C. The alkylation liquid obtained by the alkylation...

Embodiment 2

[0072] The raw material xylene (volume space velocity is 0.65h -1 ) and methanol are gasified by heat exchange with steam, and the gasified raw materials are sent into the radial fixed bed reactor through the inlet pipe at the top of the radial fixed bed reactor. 1.1m 3 ZSM-5 molecular sieve catalyst, alkylation reaction at 0.45MPa, 350°C. The alkylation liquid obtained by the alkylation reaction is discharged from the outlet pipe at the bottom of the radial fixed bed reactor, and is sent to the rectification tower T1 after being heat-exchanged in the first heat exchanger (the operating pressure at the top of the tower is 110KPa, the operating temperature at the top of the tower is 90°C, and the operating temperature at the bottom of the tower is 110°C); the material produced at the top of the rectifying tower T1 is sent to the cooler, and the material passing through the cooler is condensed by a pump The uncondensed gas obtained at the end is pumped out and sent back to the...

Embodiment 3

[0075] The raw material xylene (volume space velocity is 1.2h -1) and methanol are gasified by heat exchange with steam, and the gasified raw materials are sent into the radial fixed bed reactor through the inlet pipe at the top of the radial fixed bed reactor. 1.5m 3 HZSM-5 molecular sieve catalyst, carry out alkylation reaction at 0.8MPa, 380°C. The alkylation liquid obtained by the alkylation reaction is discharged from the outlet pipe at the bottom of the radial fixed bed reactor, and is sent to the rectification tower T1 after being heat-exchanged in the first heat exchanger (the operating pressure at the top of the tower is 115KPa, the operating temperature at the top of the tower is 95°C, and the operating temperature at the bottom of the tower is 115°C); the material produced at the top of the rectifying tower T1 is sent to the cooler, and the condensed material passing through the cooler is pumped The uncondensed gas obtained at the end is pumped out and sent back t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com