Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Avoid gel phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polyester staple fibers by using waste polyester raw material

InactiveCN102586933AImprove processing efficiencyAvoid gel phenomenonMonocomponent copolyesters artificial filamentGeotextileOxazoline

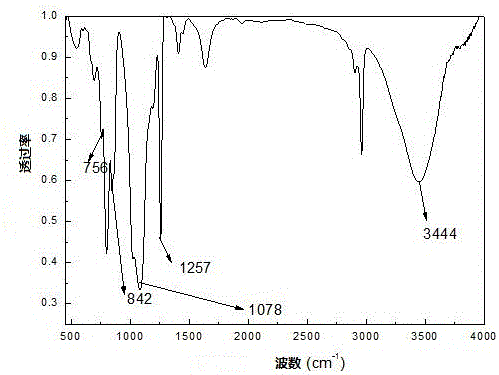

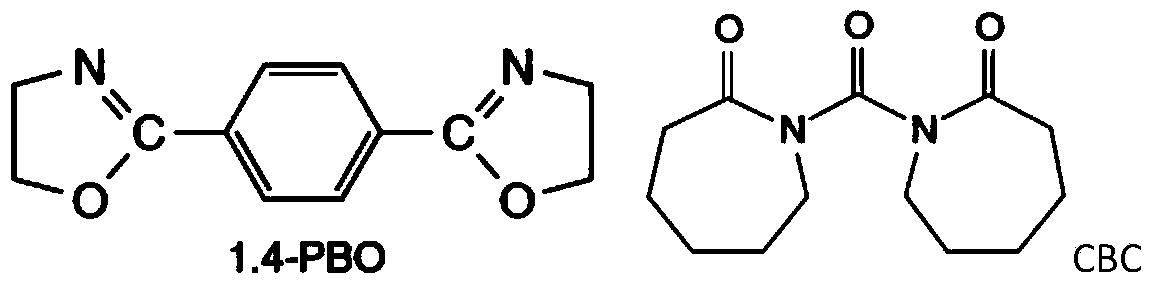

The invention discloses a method for preparing polyester staple fibers by using a waste polyester raw material. The method comprises the following steps of: cleaning and drying waste polyester, and performing compression aggregation and granulation; drying, conveying into a reaction type vented screw extruder, and adding phenyl bis-oxazoline and N, N'-carbonyl bis-caprolactam polyester chain extenders which are 0.5 to 3 mass percent of granules; conveying the polyester granules and the chain extenders to the reaction type vented screw extruder together, melting and mixing; and weighing a melt and conveying to a spinning unit to prepare the polyester staple fibers. The degradation of the waste polyester in the processing and using processes can be improved, the molecular weight of the waste polyester is improved, and the processing efficiency and fiber quality of the polyester fibers are improved. The prepared polyester fibers can be used for filling materials of clothing and furniture fabrics, geotextiles, roofing felt base cloth, nonwoven fabrics of insulating materials, shoe covers, wiping cloth and several disposable nonwoven products.

Owner:ZHEJIANG SCI-TECH UNIV

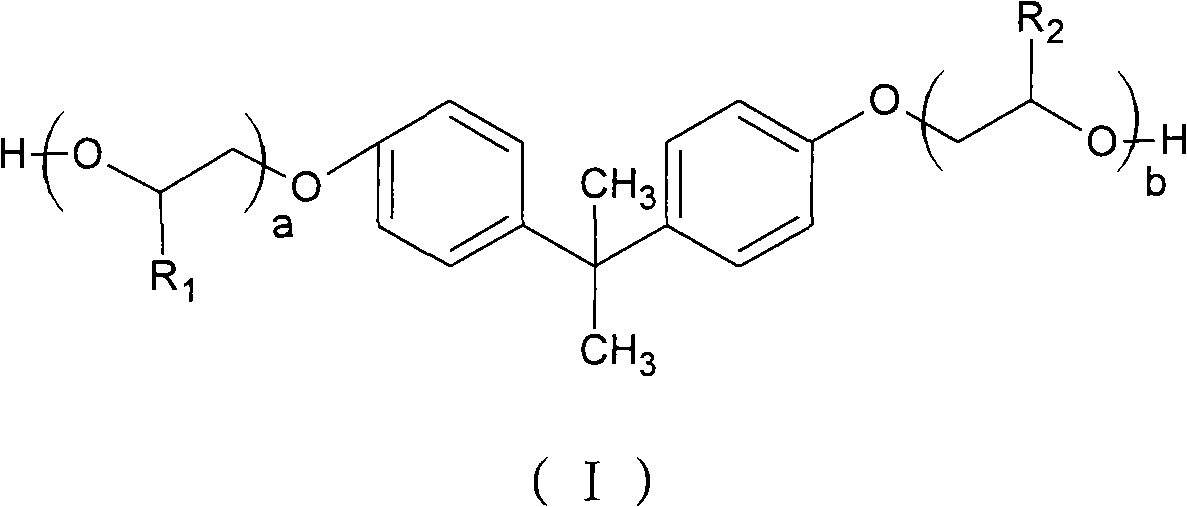

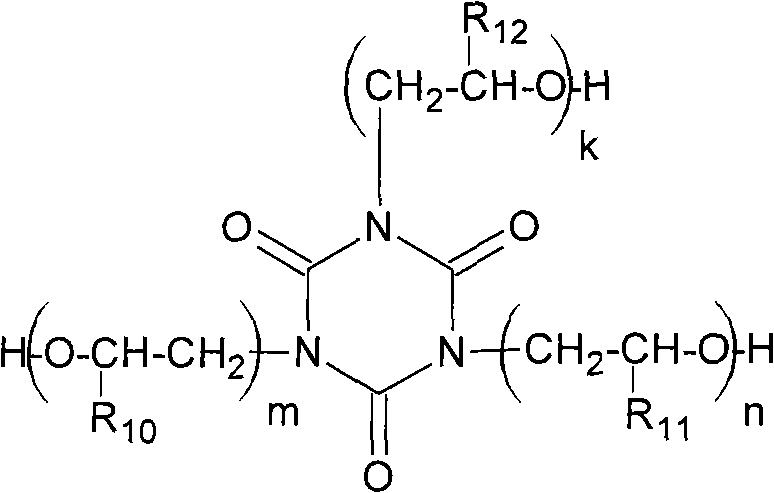

Polyurethane resin and preparation method and application thereof

ActiveCN104004159APrevents self-crosslinking reactionsAvoid gel phenomenonFibre treatmentPolyesterPolymer science

The invention provides polyurethane resin. The polyurethane resin is mainly prepared from, by weight, 150 parts to 200 parts of polyols, 10 parts to 45 parts of chain extender, 100 parts to 150 parts of isocyanate, 0.1 part to 10 parts of antioxidant, 0.1 part to 1 part of reaction terminator, 500 parts to 800 parts of solvent and reaction activity regulator. The polyols contain 40 percent to 70 percent of PTMG, 0 to 45 percent of polyester polyol, 0 to 15 percent of polycarbonate diol, 0 to 25 percent of polycaprolactone diol and 5 percent to 10 percent of modified polydimethylsiloxane diol. The invention further provides a preparation method and application of the polyurethane resin. Tiny and even cells can be formed when the prepared polyurethane resin is used for processing superfine fiber synthetic leather, and thus the produced superfine fiber product can have fine fold lines and plump fleshy feeling.

Owner:XUCHUAN CHEM SUZHOU

Bio-degradable polyester and method for preparing same

The invention relates to bio-degradable polyester and a method for preparing the same, and belongs to the technical field of bio-degradable copolyester products. The number-average molecular weight of the bio-degradable polyester material is 6,000 to 135,000g / mol, the molecular weight distribution is 1.2 to 6.5, and the crystallization temperature range is between 15 and 105 DEG C; the bio-degradable polyester overcomes defects existing in conventional products and can be used for producing film-forming materials, sheets and foam materials, the sticking characteristics are greatly changed in the machining process, and the appearance quality is higher; and after the heat resistance is improved, the novel polyester material can also be used in the machining process with a long cycle period, such as an injection machining process, and the bio-degradable aliphatic / aromatic polyester material provided by the invention possesses excellent mechanical properties.

Owner:KINGFA SCI & TECH CO LTD +1

A kind of biodegradable composition and preparation method thereof

InactiveCN102295825AImproved hydrolysis resistance and thermal oxygen resistanceFast biodegradationConjugated synthetic polymer artificial filamentsArtifical filament manufactureCopolyesterPolymer chemistry

The invention discloses a biodegradable composition and a preparation method thereof, which consist of a biodegradable homopolyester (A), a biodegradable copolyester (B) and a chain extender (C), the total weight of which is 100 parts by mass Calculated, containing (A+B) is 95.0~99.9 parts and containing C is 0.1~5.0 parts, wherein the ratio of A:B is in the range of 1:9~9:1. The present invention finds that the compounding of biodegradable homopolyester with faster biodegradation rate and biodegradable copolyester with better processability in different proportions can not only endow the composition with proper biodegradation rate, but also improve the composition The physical properties and processing performance can be properly adjusted according to the requirements of different processing and application fields; we also found that by introducing a chain extender with long chain characteristics into the biodegradable resin composition, the combination after chain extension can be avoided It can prevent unnecessary gel phenomenon during processing and improve the heat resistance and stability of the material.

Owner:KINGFA SCI & TECH CO LTD +2

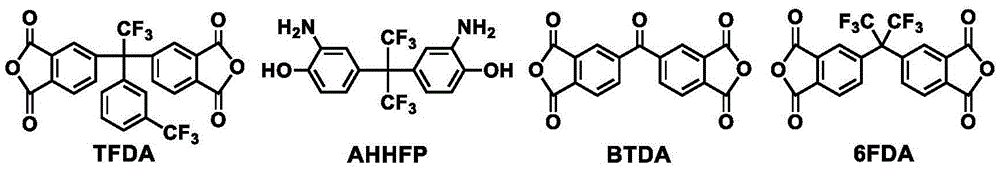

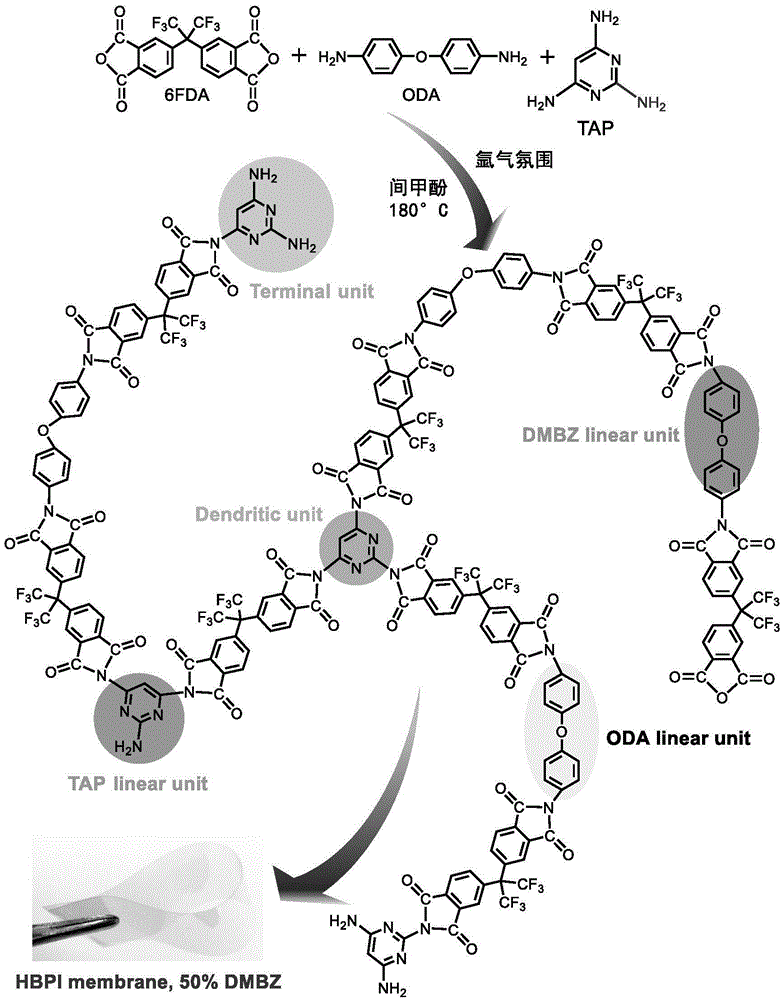

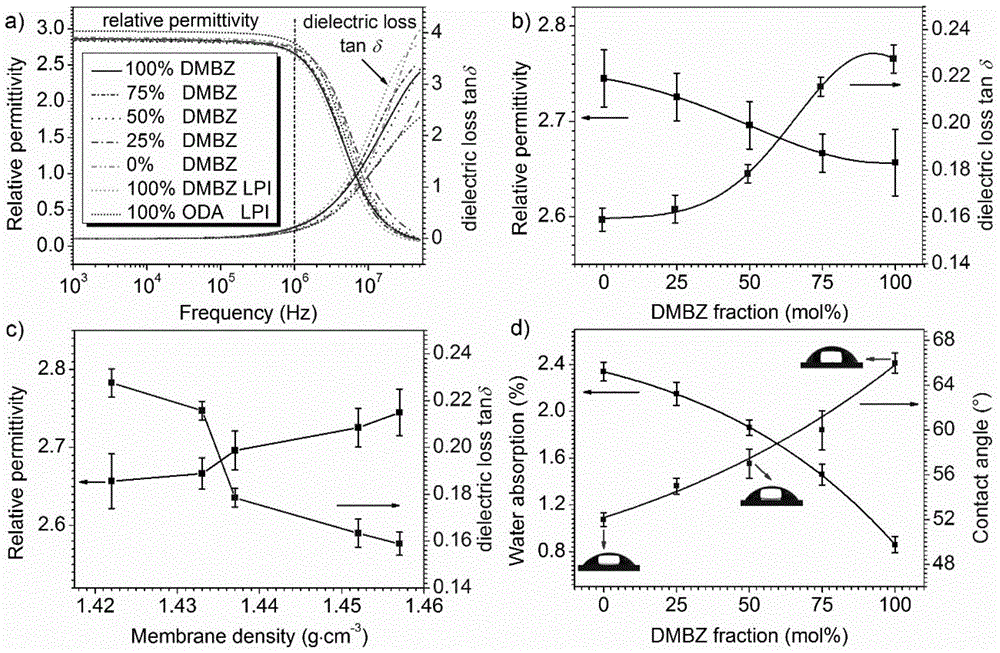

Preparation method for hyperbranched polymide film with low dielectric constant

The invention relates to a preparation method for a hyperbranched polymide film with the low dielectric constant. A series of the low-dielectric constant PI films with a hyperbranched structure are synthesized by taking 2,4,6-triaminopyrimidine (TAP) as a branching center through a one-step method. Through introduction of the hyperbranched structure, the dielectric constant of the PI film is significantly lowered, the inherent advantages of PI are better kept, and the good mechanical strength and thermo-oxidative stability are supplied to the film. The hyperbranched structure contains a large quantity of molecular chain end groups, dense packing of molecular chains is effectively inhibited, and therefore the hyperbranched PI film has the excellent dissolution characteristic to be more prone to be processed into a complex device. Compared with a Kapton standard film which is generally used at present, under the same testing conditions, the dielectric constant of the hyperbranched PI film prepared through the method is lowered by 20%-40%, the lowest dielectric constant even gets close to 2.0 and reaches the ultralow dielectric constant level, and the urgent demand for micro-electronic industry development in future can be met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Accurate double-liquid glue dropping device

InactiveCN101474609AQuality assuranceReduce collisionLiquid surface applicatorsCoatingsInlet valveEngineering

The invention discloses a dispensing device, comprising a framework, a container and a needle nozzle arranged from top to bottom in sequence. An elevating rod and a cam are installed in a cavity of the framework; a roller wheel at the top of the elevating rod contacts the cam tightly; the elevating rod stretches from the framework and is connected with the container; two hollow rods are arranged in the container; the two hollow rods are respectively sheathed with buffer springs and penetrate the bottom and a cover plate of the container; the two hollow rods are provided with connecting pipes at the bottom, pressure holes on the top covers and glue inlet holes on the sides; each hollow rod is internally provided with a piston and a glue inlet valve; the glue inlet valve is provided with a glue inlet opening and a glue channel; the glue channels of the two glue inlet valves are connected and the connecting pipe is connected with a mixing pipe communicated with the glue channel; the mixing pipe is provided with a mixed glue blade and is connected with the needle nozzle at the bottom end; the outside wall of the framework is fixed with a sensing surface of a displacement sensor; a probe of the displacement sensor is fixed on a support connected with the hollow rod. The dispensing device can carry out dispensing precisely; thereby can not only effectively avoid glue leakage and glue coagulation but also avoid damage of the needle nozzle.

Owner:ZHEJIANG UNIV

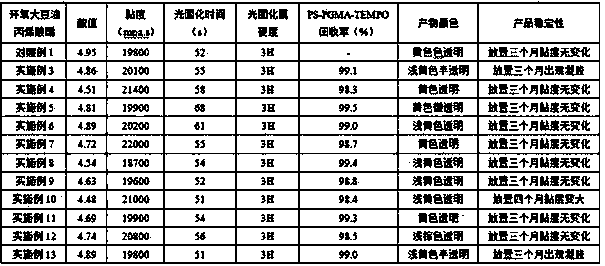

Preparation method and application of free nitroxide radical polymer brush polymerization inhibitor

ActiveCN104211863APerformance is not affectedAvoid self-polymerizationOrganic chemistryFatty acid esterificationEpoxyPolymer science

The invention relates to a preparation method of a free nitroxide radical polymer brush polymerization inhibitor, and application of the free nitroxide radical polymer brush polymerization inhibitor in synthesis of epoxy soybean oil acrylic ester. The preparation method comprises the following steps: firstly, grafting a polyglycidyl methacrylate polymer brush on the surfaces of cross-linked polystyrene microspheres by using an electron transfer regenerated catalyst atom transfer free radical polymerization technique, and secondly, bonding tetramethyl piperidine free nitroxide radical onto the polyglycidyl methacrylate polymer brush, thereby obtaining the free nitroxide radical polymer brush. The application comprises: taking the free nitroxide radical polymer brush as a main polymerization inhibitor and a small molecule polymerization inhibitor as a polymerization inhibitor aid, thereby forming a composite polymerization inhibition system for preparing epoxy soybean oil acrylic ester. The composite polymerization inhibition system not only has a high-efficiency polymerization inhibition function in the epoxy soybean oil acrylic ester preparation, but also is easy in recycling the main polymerization inhibitor, namely the free nitroxide radical polymer brush, so that the free nitroxide radical polymer brush can be recycled, and a product can be prevented from self-polymerization when being preserved when a small amount of the polymerization inhibitor is retained in the system.

Owner:廊坊市安次区调河头振达生物技术推广中心

High-nickel base cathode paste for lithium-ion battery and preparation method of high-nickel base cathode paste

InactiveCN105470461AAvoid gel phenomenonImprove follow-up performanceCell electrodesCarbon nanofiberLithium-ion battery

The invention relates to the technical field of materials for lithium-ion batteries, in particular to a high-nickel base cathode paste for a lithium-ion battery and a preparation method of the high-nickel base cathode paste. The cathode paste is prepared from the following raw materials in parts by weight: 80-98 parts of a high-nickel cathode material, 2-18 parts of a binder, 1-10 parts of a carbon nanofiber and 0-10 parts of a conductive agent; a chemical formula of the high-nickel cathode material is LiNi<x>M<1-x>O<2>, wherein x is smaller than or equal to 1 and greater than or equal to 0.5; M is CO, Mn, Al, Mg or Cr; the binder is a modified polyvinylidene fluoride binder; a solvent is N-methyl pyrrolidone; and a certain amount of the solvent is used to make the solid content of the cathode paste reach 40-70%. According to the preparation of the paste, the gel phenomenon of the paste in the preparation process is avoided; and the subsequent performance of the lithium-ion battery is improved.

Owner:WANXIANG 123 CO LTD +2

Method for grafting maleic anhydride with ethylene propylene terpolymer

The invention relates to a method for grafting maleic anhydride by ethylene propylene diene monomers. The method is characterized in that the ethylene propylene diene monomers are taken as raw materials, maleic anhydride is taken as a grafting monomer, a plasticizer, a reinforcing agent and a vulcanization retarder are added, the obtained mixture is evenly mixed and then put into an extruder to be fused and blended so as to granulate and obtain the graft of ethylene propylene diene monomers and maleic anhydride, i.e., EPDM-g-MAH; before the fusion and extrusion of the mixture, high-energy rayradiation is carried out to the mixture by a radiant point; and during granulation, the length-diameter ratio of the screw of the extruder is 15 to 33:1, the rotation speed of the extruder is 30 r / min to 180 r / min and the temperature of the die orifice of the extruder is 60 DEG C to 180 DEG C. The method does not cause the ethylene propylene diene monomers (EPDM) to gel, which is conducive to thecompatibility of the ethylene propylene diene monomer with a polar polymer (engineering plastics); the grafting rate of the grafting product is high and can reach up to 1.2 percent to 3.6 percent; and radiation grafting adopted does not pollute the environment, saves energy and reduces production cost by about 30 percent.

Owner:张万鹏

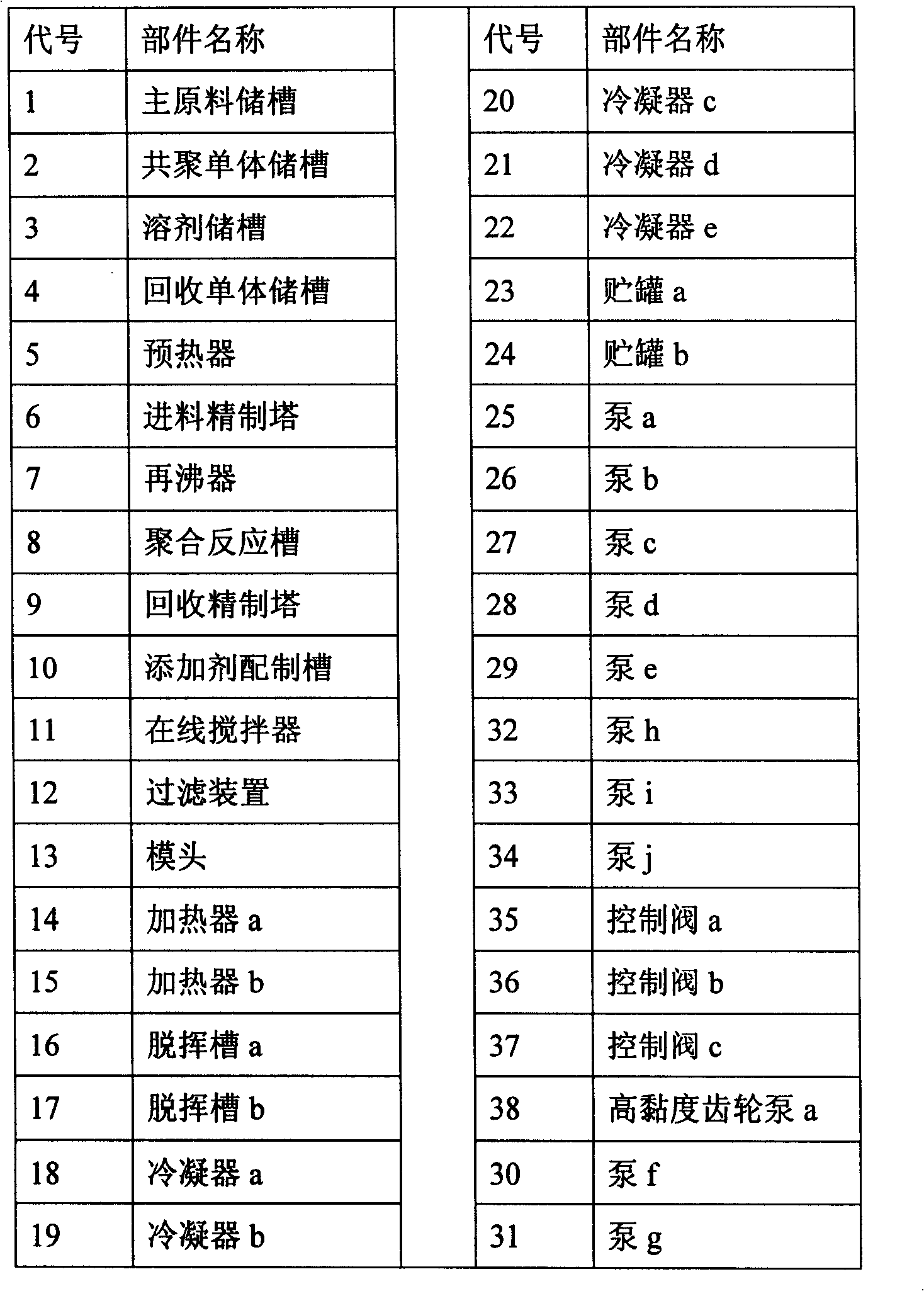

Optical-grade polymethylmethacrylate continuous solution polymerization process and equipment thereof

The invention relates to the preparation method of a polymer compound and a plant used therefor, in particular to a continuous solution polymerization process of optical-grade poly(methyl methacrylate) and the plant used therefor. The plant used for the continuous solution polymerization process of optical-grade poly(methyl methacrylate) comprises a refining and distillation device, a polymerization reaction device, a two-stage devolatilization device, and a wire-drawing and granulation device connected with each other in series, and specifically comprises a feed refining tower, a polymerization reaction groove, a recovering and refining tower, heaters a and b, and devolatilization tanks a and b. The continuous solution polymerization process can prepare optical-grade poly(methyl methacrylate) from monomers, a copolymer, a stabilizing agent, a molecular weight regulator, an initiator and a solvent according to the following four steps: (1) refining and distillation, (2) polymerization reaction, (3) flash devotilization and (4) wire drawing and granulation. The PMAA produced by the process has the advantages of high safety, no gel accumulation, improved physical properties and color of the produt, low energy consumption, environmental protection, clean production, good weathering resistance of the product, anhydrous polymerization, no black spots on the product, etc.

Owner:SHANGHAI JINGQI POLYMER MATERIAL

Regulation and control method for preparation process for bio-oil starch adhesive for wood

ActiveCN104910839AEliminate the effects ofGuaranteed accuracyGraft polymer adhesivesEmulsionHigh volume manufacturing

The invention relates to a regulation and control method for a preparation process for a bio-oil starch adhesive for wood, and belongs to the technical field of adhesives. The regulation and control method comprises the following steps: adding ammonium persulphate in an emulsion obtained by mixing starch and hydrochloric acid to obtain an acid-hydrolyzed and oxidized starch emulsion; adding polyvinyl alcohol, adjusting the pH value by sodium hydroxide solution, adding grafting monomer acrylamide, and then adding ammonium persulphate to obtain a composite modified starch emulsion; adding bio-oil to obtain an initial bio-oil starch adhesive; and repeatedly adjusting the pH value by the sodium hydroxide solution and the bio-oil to obtain the bio-oil starch adhesive. The method is simple and convenient, accurate, moderate in reaction, simple in parameters, high in process stability, capable of reducing the gel problems and reaction insufficiency phenomena of the starch adhesive, guaranteeing a reaction sufficiency degree and improving the performances of the bio-oil starch adhesive, and suitable for industrial mass production; the prepared adhesive is excellent in performance, and capable of meeting the application requirements thereof in the field of wood.

Owner:BEIJING FORESTRY UNIVERSITY

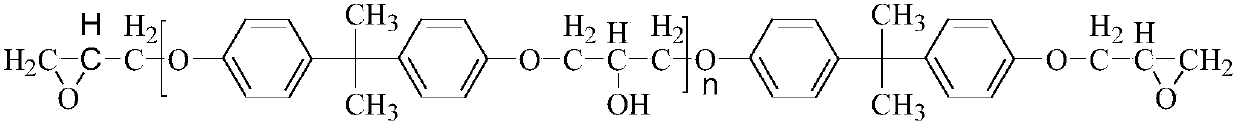

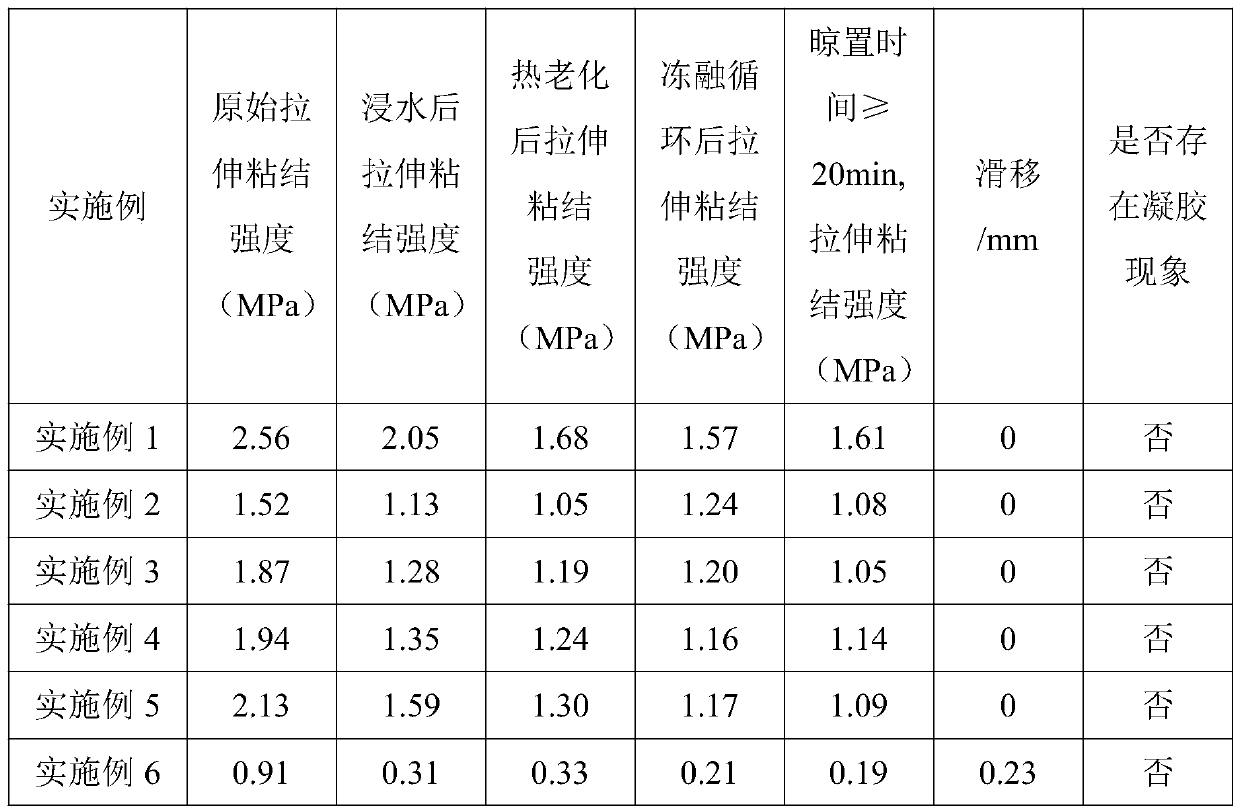

Waterborne epoxy resin modifier for emulsified asphalt and preparation method and application method thereof

ActiveCN109651569ASolving the phase segregation problemReduce reactivityBuilding insulationsEpoxySolvent

The invention discloses a waterborne epoxy resin modifier for emulsified asphalt and a preparation method and an application method thereof, and belongs to the technical field of road materials. The waterborne epoxy resin modifier for emulsified asphalt is prepared from the following ingredients: liquid epoxy resin, a solvent, an initiator, an acrylic monomer, a neutralizer and an amino protectant. The amino protectant is used for reducing activity of secondary amine of the liquid epoxy resin. The invention aims to provide a waterborne epoxy resin modifier for emulsified asphalt and a preparation method and an application method thereof to solve the problem that suitability between waterborne epoxy resin and emulsified asphalt is poor, demulsification is slow and high-temperature pull strength is low. Thereby, the product is more practical and has industrial utilization value.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD

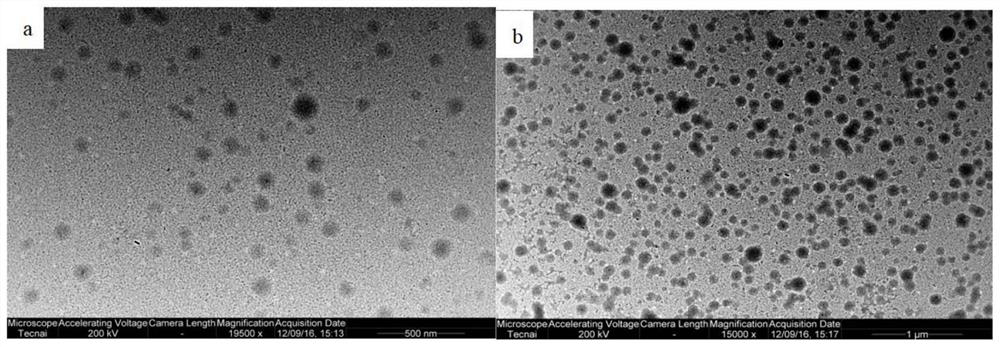

Preparation method and application of nano silicon dioxide modified soap-free fluorine-free cationic polyacrylate waterproof agent

PendingCN112898477AGood for particle size controlGood dispersionLiquid repellent fibresVegetal fibresPolymer scienceHydrolysis

The invention discloses a preparation method and application of a nano silicon dioxide modified soap-free fluorine-free cationic polyacrylate waterproof agent. In the preparation process of a fluorine-free long-chain polyacrylate waterproof agent, a reactive quaternary ammonium salt cationic emulsifier and a reactive nonionic emulsifier are utilized for synergistic emulsification and participate in a polymerization reaction; emulsifier molecules, long-chain acrylate, short-chain alkyl acrylate monomers and cross-linking monomers are copolymerized and bonded into waterproof emulsion macromolecular chains, and meanwhile, nano SiO2 particles are introduced into the macromolecular chains under the in-situ hydrolysis effect of an organic silicon reagent and the coupling effect of a silane coupling agent, therefore, the soap-free fluorine-free polyacrylate waterproof emulsion which is high in solid content, small in particle size and uniform and stable in distribution and can endow textiles with excellent waterproofness, durability and antibacterial property is developed.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Paste tile binder and preparation method thereof

The invention relates to the field of tile binders, and provides a paste tile binder. The paste tile binder at least comprises the following raw materials in parts by weight: 50-100 parts of an emulsion, 100-250 parts of a solvent, 1-6 parts of a coalescing agent, 0.5-4 parts of a defoaming agent, 1-10 parts of cellulose ether, 0.1-2 parts of butyl alcohol polyether, 300-400 parts of filler and 300-400 parts of quartz sand.

Owner:SHANGHAI NIUYUAN IND TRADE

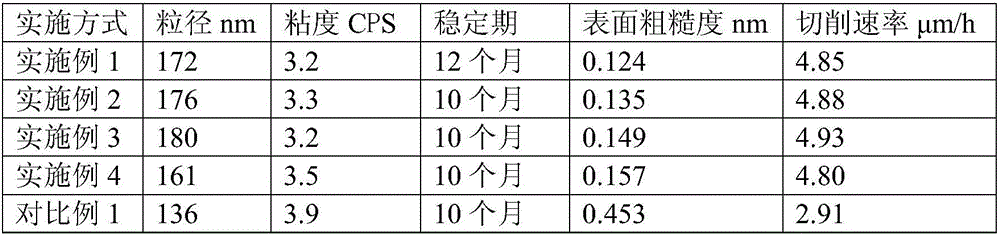

Preparation method of large-particle-size low-viscosity silica solution for polishing sapphire

InactiveCN106752968AEasy to control particle sizeImprove stabilityOther chemical processesPolishing compositions with abrasivesFiltrationFree cooling

The invention belongs to the technical field of hard material polishing, and concretely relates to a preparation method of a large-particle-size low-viscosity silica solution for polishing sapphire. The method comprises the following steps of (1) preparing a sodium hydroxide solution; (2) preparing activated silica powder; (3) preparing a dibenzofuran solution; (4) in water, adding glycerol, then slowly adding the activated silica powder and the dibenzofuran solution, and meanwhile, dropwise adding the sodium hydroxide solution; (5) after feeding the materials, continuously reacting, performing vacuum suction filtration after natural cooling, and obtaining the large-particle-size low-viscosity silica solution. The silica solution obtained through the invention has large grain size, the grinding effect of the silica solution on the sapphire can be remarkably improved, the polishing efficiency is improved, the silica solution is low in viscosity and difficult to agglomerate, the surface damage and the roughness of the sapphire are reduced, and the surface quality of the sapphire is ensured.

Owner:福建三邦硅材料有限公司

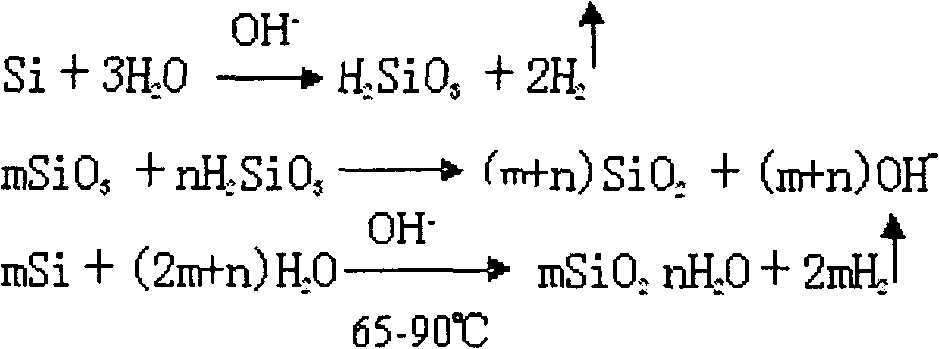

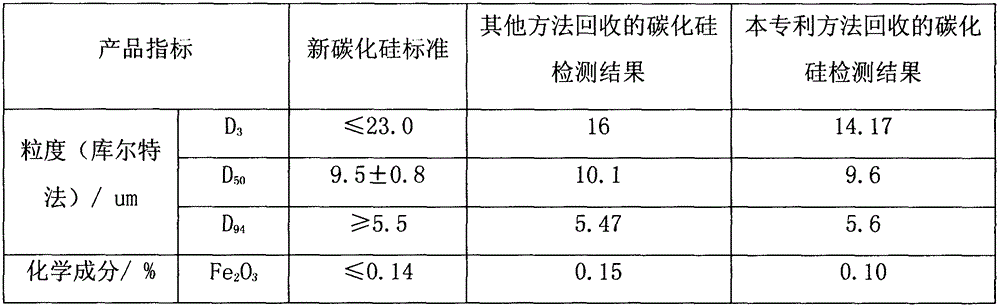

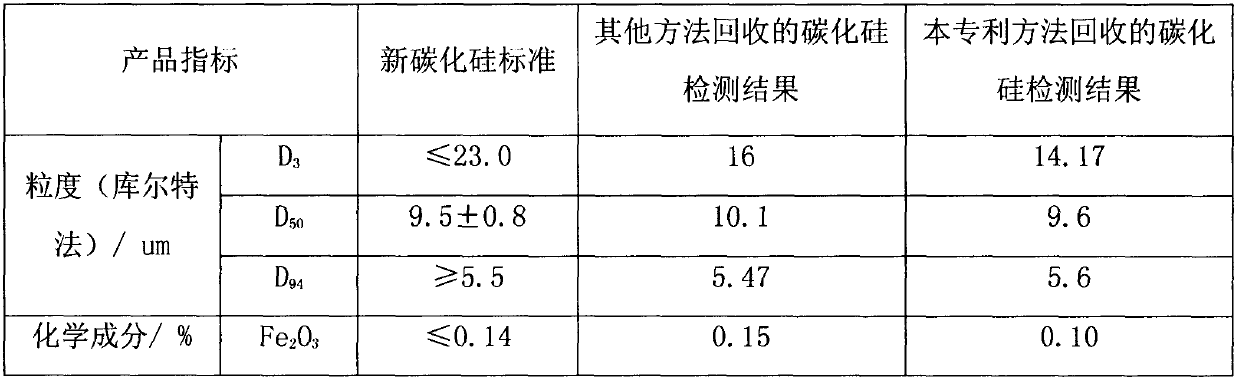

Method for recycling silicon cutting waste mortar

ActiveCN102746935AReduce dosageReduce cost investmentSilicon carbideSilicon compoundsDistillationPolyethylene glycol

Disclosed is a method for recycling silicon cutting waste mortar. The method comprises the steps of performing solid-liquid separation of the waste mortar; performing solid flow washing and vacuum filtration; drying the obtained filter cake, mixing with deionized water and performing activation reaction; adding water glass and sodium hydroxide successively and performing heating reaction, performing solid-liquid separation of the obtained product, performing ion exchange resin decolorization and distillation of the liquid phase to obtain silica sol, and performing solid phase washing and drying to obtain a silicon carbide raw material; and performing ultra precision filter of obtained liquid phase after solid-liquid separation of the waste mortar, adding a decoloring agent a filter aid to perform solid-liquid separation, reducing the conductivity, and heating and evaporating water to obtain finished polyethylene glycol cutting liquid. According to the technical scheme of the method, the flow line production is achieved, the silicon cutting waste mortar is recycled, the silica sol is prepared effectively, and the environmental pollution is reduced.

Owner:山东网金资源再利用发展有限公司

Hydroxyl resin for organic silicon-coated material and preparation method of hydroxyl resin

The invention provides hydroxyl resin for an organic silicon-coated material and a preparation method of the hydroxyl resin. The hydroxyl resin for the organic silicon-coated material is prepared from hydrochloric acid, ethanol, ethyl orthosilicate-40, hexamethyldisiloxane, water, an aqueous sodium carbonate solution and hydroxyl-terminated polysiloxane through the steps of mixing, reacting and solvent removing. The organic silicon-coated material prepared from the hydroxyl resin for the organic silicon-coated material not only has the advantages of being low in viscosity, high in strength, short in curing time and the like, but also has the properties of being resistant to high and low temperature and aging, flexible, insulative, dampproof, resistant to shake, corona, electric leakage and cold and hot changes and the like; the preparation method is simple, environmentally friendly and free of pollution and has important significance in promoting application and development of the organic silicon-coated material.

Owner:成都大蓉新材料有限责任公司

PIA (meta-phthalic acid)/nanometer titania modified alkyd resin and preparation method thereof

The invention discloses a PIA (meta-phthalic acid) / nanometer titania modified alkyd resin and a preparation method thereof. The PIA / nanometer titania modified alkyd resin comprises the following raw materials: acrylic acid, methylacrylic acid, methyl methacrylate, vinyltriethoxysilane, nanometer titania, epoxy resin, castor oil, trimethylolpropane, 2,2,4-trimethyl-1,3-pentanediol, tetrachlorophthalic anhydride, PIA waste, trimellitic anhydride, triethylamine, ethyl eneglycol monobutyl ether, propylene glycol mono-n-butyl ether, lauric acid, catalytic auxiliary, benzoyl peroxide, dimethylbenzene and water. The PIA / nanometer titania modified alkyd resin provided by the invention is good in water resistance, high in hardness and excellent in comprehensive performance; the PIA waste is used, so that the cost is saved.

Owner:ANHUI JINDUN PAINT

Environment-friendly refractory foam material and preparation method thereof

An environment-friendly refractory foam material and a preparation method thereof. The invention relates to a novel foam material capable of being used for energy-saving buildings and preparation thereof. The foam material includes: a sodium silicate component, a polyurethane component, and regular assistant materials and additives. The sodium silicate component (A) includes more than 60% of sodium silicate and also contains more than 0.5% of a catalyst and / or a co-catalyst so that in a normal-temperature foaming reaction, surface dry can be achieved within 10 min. The double components also contain more than 10% of a polyol or a polyol derivative. The polyurethane component (B) is a polyurethane prepolymer or is a combination of the polyurethane with a proper amount of polyisocyanate and / or an organic solvent and / or a plasticizer, wherein the polyurethane prepolymer is formed through a reaction of polyester polyol and / or polyether polyol and polyisocyanate, NCO content being 8-25% or8-13%. The weight ratio of component A to the component B is 1:1-1.5. The foam material is environment-friendly and refractory and has excellent heat insulation effect, is low in smoke density and toxicity, has good dimensional stability, has both rigidity and flexibility, and is low in manufacturing cost.

Owner:CHONGQING LIERDA SCI & TECH DEV

Method for preparing polyester staple fibers by using waste polyester raw material

InactiveCN102586933BHigh molecular weightImprove processing efficiencyMonocomponent copolyesters artificial filamentPolyesterFilling materials

The invention discloses a method for preparing polyester staple fibers by using a waste polyester raw material. The method comprises the following steps of: cleaning and drying waste polyester, and performing compression aggregation and granulation; drying, conveying into a reaction type vented screw extruder, and adding phenyl bis-oxazoline and N, N'-carbonyl bis-caprolactam polyester chain extenders which are 0.5 to 3 mass percent of granules; conveying the polyester granules and the chain extenders to the reaction type vented screw extruder together, melting and mixing; and weighing a melt and conveying to a spinning unit to prepare the polyester staple fibers. The degradation of the waste polyester in the processing and using processes can be improved, the molecular weight of the waste polyester is improved, and the processing efficiency and fiber quality of the polyester fibers are improved. The prepared polyester fibers can be used for filling materials of clothing and furniture fabrics, geotextiles, roofing felt base cloth, nonwoven fabrics of insulating materials, shoe covers, wiping cloth and several disposable nonwoven products.

Owner:ZHEJIANG SCI-TECH UNIV

Method for recycling silicon cutting waste mortar

ActiveCN102746935BGood dispersionImprove stabilitySilicon carbideSilicon compoundsDistillationPolyethylene glycol

Disclosed is a method for recycling silicon cutting waste mortar. The method comprises the steps of performing solid-liquid separation of the waste mortar; performing solid flow washing and vacuum filtration; drying the obtained filter cake, mixing with deionized water and performing activation reaction; adding water glass and sodium hydroxide successively and performing heating reaction, performing solid-liquid separation of the obtained product, performing ion exchange resin decolorization and distillation of the liquid phase to obtain silica sol, and performing solid phase washing and drying to obtain a silicon carbide raw material; and performing ultra precision filter of obtained liquid phase after solid-liquid separation of the waste mortar, adding a decoloring agent a filter aid to perform solid-liquid separation, reducing the conductivity, and heating and evaporating water to obtain finished polyethylene glycol cutting liquid. According to the technical scheme of the method, the flow line production is achieved, the silicon cutting waste mortar is recycled, the silica sol is prepared effectively, and the environmental pollution is reduced.

Owner:山东网金资源再利用发展有限公司

A kind of preparation method and application of nitroxide free radical polymer brush inhibitor

ActiveCN104211863BPerformance is not affectedAvoid self-polymerizationOrganic chemistryFatty acid esterificationGlycidyl methacrylatePolymer science

The invention relates to a preparation method of a nitroxide free radical polymer brush inhibitor and its application in the synthesis of epoxy soybean oil acrylate. The preparation method is to first adopt electron transfer regeneration catalyst atom transfer radical polymerization technology on the surface of cross-linked polystyrene microspheres, graft polyglycidyl methacrylate polymer brushes; Bonded thereon, a nitroxide radical polymer brush is obtained. Said application is to use nitroxide free radical polymer brush as the main polymerization inhibitor, and the small molecular polymerization inhibitor as auxiliary polymerization inhibitor to form a composite polymerization inhibition system to prepare epoxy soybean oil acrylate. The composite inhibitory system can not only have high-efficiency polymerization inhibitory effect in the preparation of epoxy soybean oil acrylate, but also is easy to recycle the main inhibitory agent nitroxide free radical polymer brush, so that it can be recycled, and a small amount of auxiliary inhibitory agent remains In the system, it can also prevent the self-aggregation of the product during storage.

Owner:廊坊市安次区调河头振达生物技术推广中心

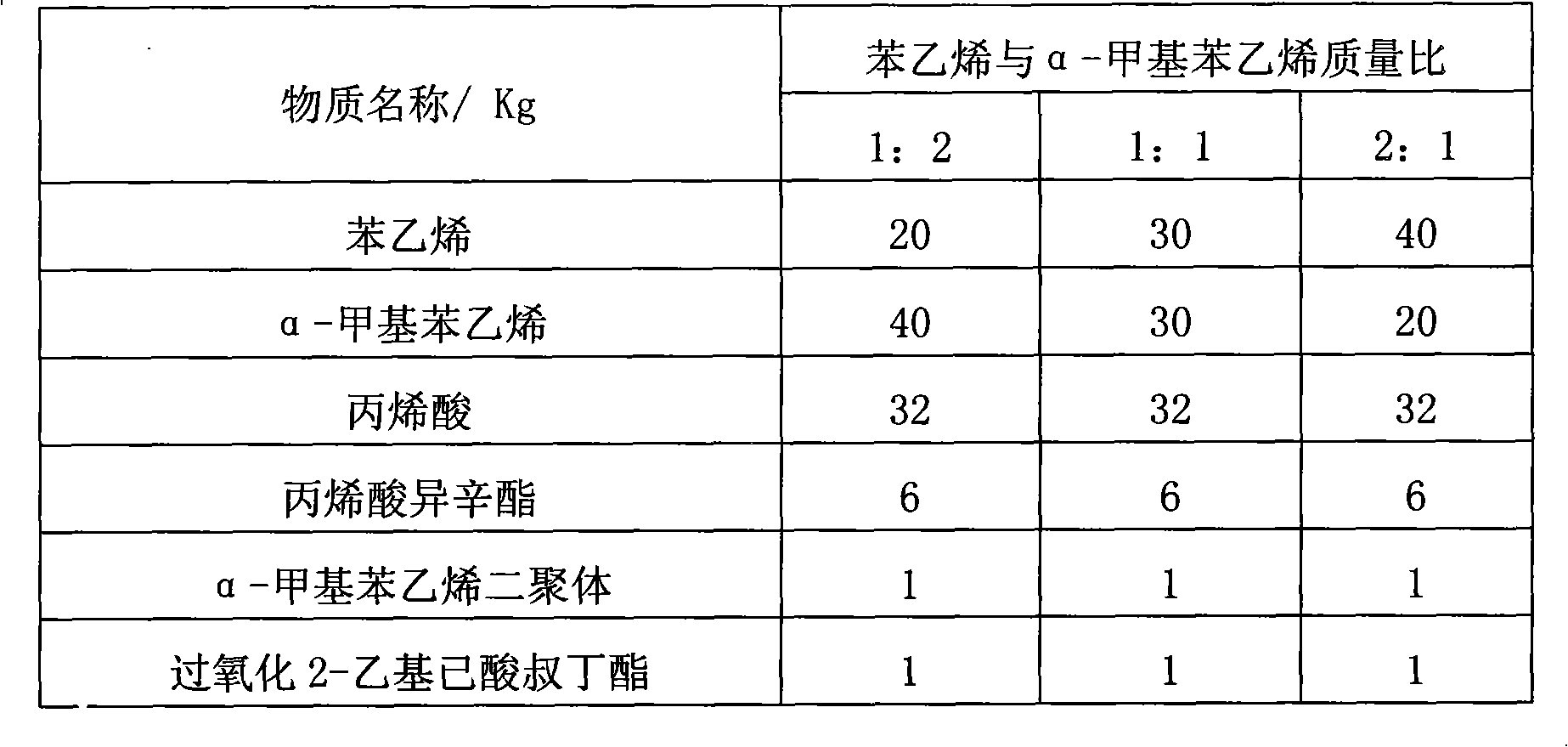

Supercritical polymerization preparation method and application of water-soluble solid styrene-acrylic resin

The invention discloses a preparation method and application of water-soluble solid styrene-acrylic resin. The preparation method comprises the following steps of: introducing supercritical fluid into a stirring reaction kettle as a reaction medium; adding a styrene monomer, an acrylic monomer, an initiator and a chain transfer agent to carry out radical polymerization reaction; and removing the volatile components and the supercritical fluid from a reaction product through exhausting and pressure reduction, thus the pure water-soluble solid styrene-acrylic resin is prepared, wherein the reaction temperature is equal to or higher than the critical temperature of a polymerization medium, the pressure is equal to or higher than the critical pressure of the polymerization medium, the critical temperature is 31.1 DEG C, and the critical pressure is 7.38MPa. The water-soluble solid styrene-acrylic resin prepared by the method avoids the condensation in the conventional preparation of the solid styrene-acrylic resin, obtains a polymer with narrower molecular weight distribution by adding the chain transfer agent alpha-methyl styrene dimmer and has good pigment wetting dispersity.

Owner:恒昌涂料(惠阳)有限公司 +1

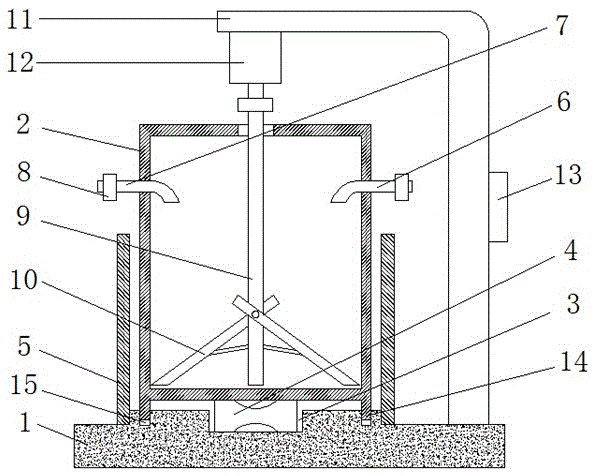

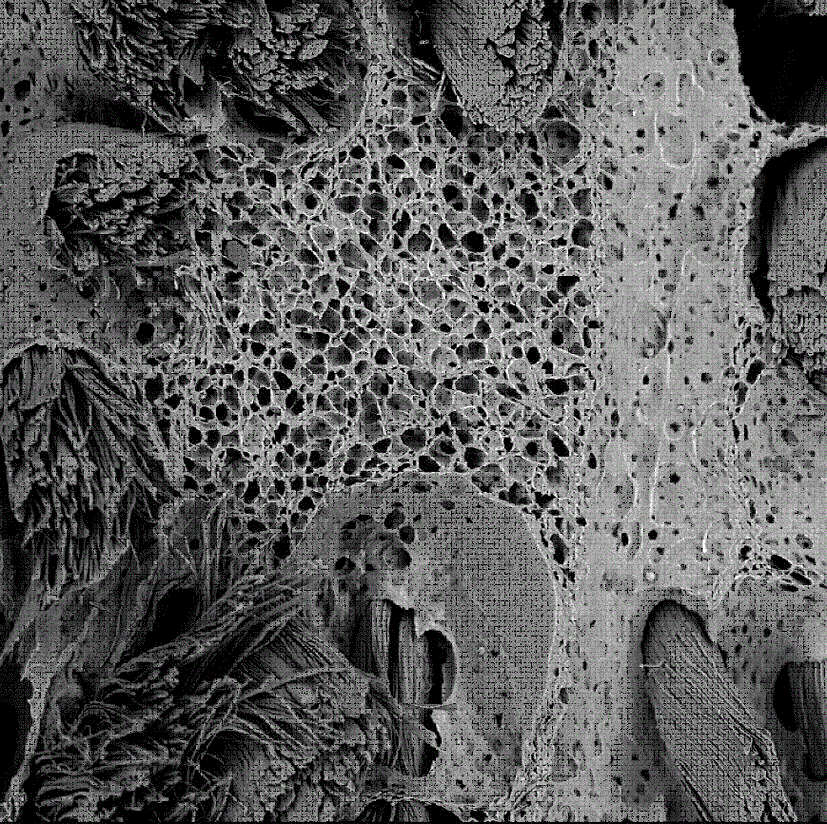

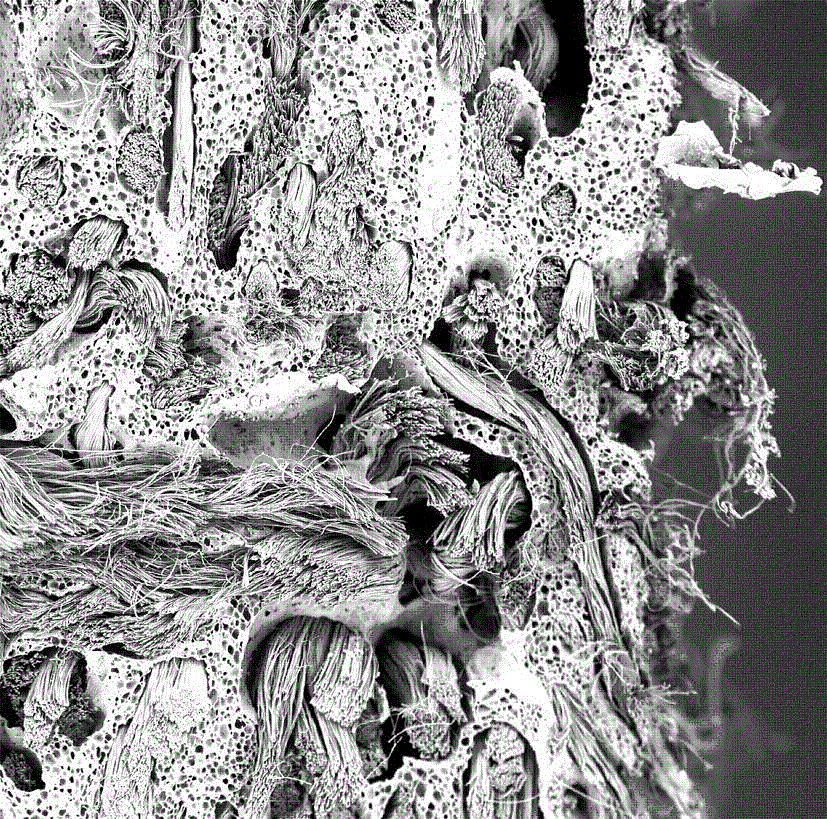

Adhesive mixing device

InactiveCN105457538AAvoid it happening againAvoid gel phenomenonShaking/oscillating/vibrating mixersTransportation and packagingElectric fieldMicrostructure

The invention discloses an adhesive mixing device. The adhesive mixing device comprises a base, wherein a casing is arranged above the base, a vibration motor is mounted in the middle of the bottom end of the casing, two opposite arc-shaped electric field plates are arranged outside the casing, a stirring shaft is arranged in the axis position of the casing, stirring blades are arranged on the stirring shaft, an L-shaped supporting arm is welded on the base on one side of the casing, a servo motor is fixed on the bottom surface of the top of the supporting arm, and a controller is arranged on the outer side surface of the supporting arm. When the stirring shaft of the adhesive mixing device drives the stirring blades to rotate for stirring, the vibration motor at the bottom of the casing vibrates the casing, a mixed adhesive on the inner wall of the casing falls off, the condition that gel is produced due to the fact that the mixed adhesive stays on the inner wall of the casing for a long time and the stirring blades cannot scrape the mixed adhesive is prevented, and electric fields produced by the two electric field plates on the outer side of the casing enable the mixed adhesive in the casing to have a delicate change in the aspect of the microstructure, so that the gel phenomenon is prevented.

Owner:无锡万能胶粘剂有限公司

Device for preventing acrylate adhesive from gelating

ActiveCN103008181AGuaranteed utilizationGuaranteed yieldLiquid surface applicatorsCoatingsAdhesiveColloid

The invention discloses a device for preventing an acrylate adhesive from gelating. The device comprises a high-voltage electric field treatment part positioned on an adhesive flowing plate. The high-voltage electric field treatment part is composed of a fixed plate, an electric field plate, a field distance adjustment part and guide rods. The electric field plate is arranged below the fixed plate. The field distance adjustment part is directly connected to the electric field plate through a hole disposed at the middle part of the fixed plate, and the distance between the electric field plate and an adhesive flow upper surface can be controlled by adjusting the field distance adjustment part. The guide rods control the directional stability of the electric field plate, which can directly act on the acrylate adhesive flowing on the adhesive flowing plate through a KV-KV high-voltage uniform electric field. By means of a physical treatment method, the microstructure of the acrylate adhesive body can have delicate change so as to prevent the occurrence of gelating. Thus, the device provides guarantee for the adhesive utilization rate and adhesive tape yield.

Owner:苏州市新广益电子股份有限公司

A kind of polyurethane resin and its preparation method and application

ActiveCN104004159BPrevents self-crosslinking reactionsAvoid gel phenomenonFibre treatmentPolyesterPolymer science

The invention provides a polyurethane resin. The raw materials for preparing the polyurethane resin mainly consist of the following components in parts by weight: polyol: 150-200 parts; chain extender: 10-45 parts; isocyanate: 100-150 parts; Oxygen agent: 0.1-10 parts; Reaction terminator: 0.1-1 part; Solvent: 500-800 parts; Reactivity modifier; The content of each component of the polyol: polytetrahydrofuran ether glycol: 40- 70%; Polyester polyol: 0-45%; Polycarbonate diol: 0-15%; Polycaprolactone diol: 0-25%; Modified dimethicone diol : 5-10%. The invention also provides the preparation method and application of the resin. The polyurethane resin prepared by the invention can form small and uniform cells when processing the superfine fiber synthetic leather, so that the produced superfiber can have finer creases and full fleshy feeling.

Owner:XUCHUAN CHEM SUZHOU

Preparation method of silicone rubber coloring master batch

InactiveCN104476693AImprove tear resistanceImprove wear resistanceMetal working apparatusDispersityRoom temperature

The invention discloses a preparation method of silicone rubber coloring master batch, including the following steps: (1) weighting the following raw materials respectively according to a formula: 60-80 parts of silicone rubber, 35-45 parts of reinforcing agent, 0.1-3 parts of structure controlling agent, 65-75 parts of coloring agent and 0.5-4 parts of age resister; (2) putting the weighted raw materials into an open mixing machine for mixing in a sequence of tapered weight parts, encapsulating a front roller first and then encapsulating a rear roller under the conditions that a roller spacing is 5-6mm, the temperature of the front roller is set to be 30-34 DEG C, the temperature of the rear roller is set to be 25-30 DEG C, and the mixing time is 12-18min; and (3) intensively mixing on an open mill, repeating overturn milling for 3-5 times, cooling to room temperature, cutting the materials into blocks and then packaging. The silicone rubber coloring master batch prepared according to the invention has the advantages of good dispersity, high cleanliness in the using process of downstream manufacturers and prolonged service life of products.

Owner:CHENGDU JINHUI TECH

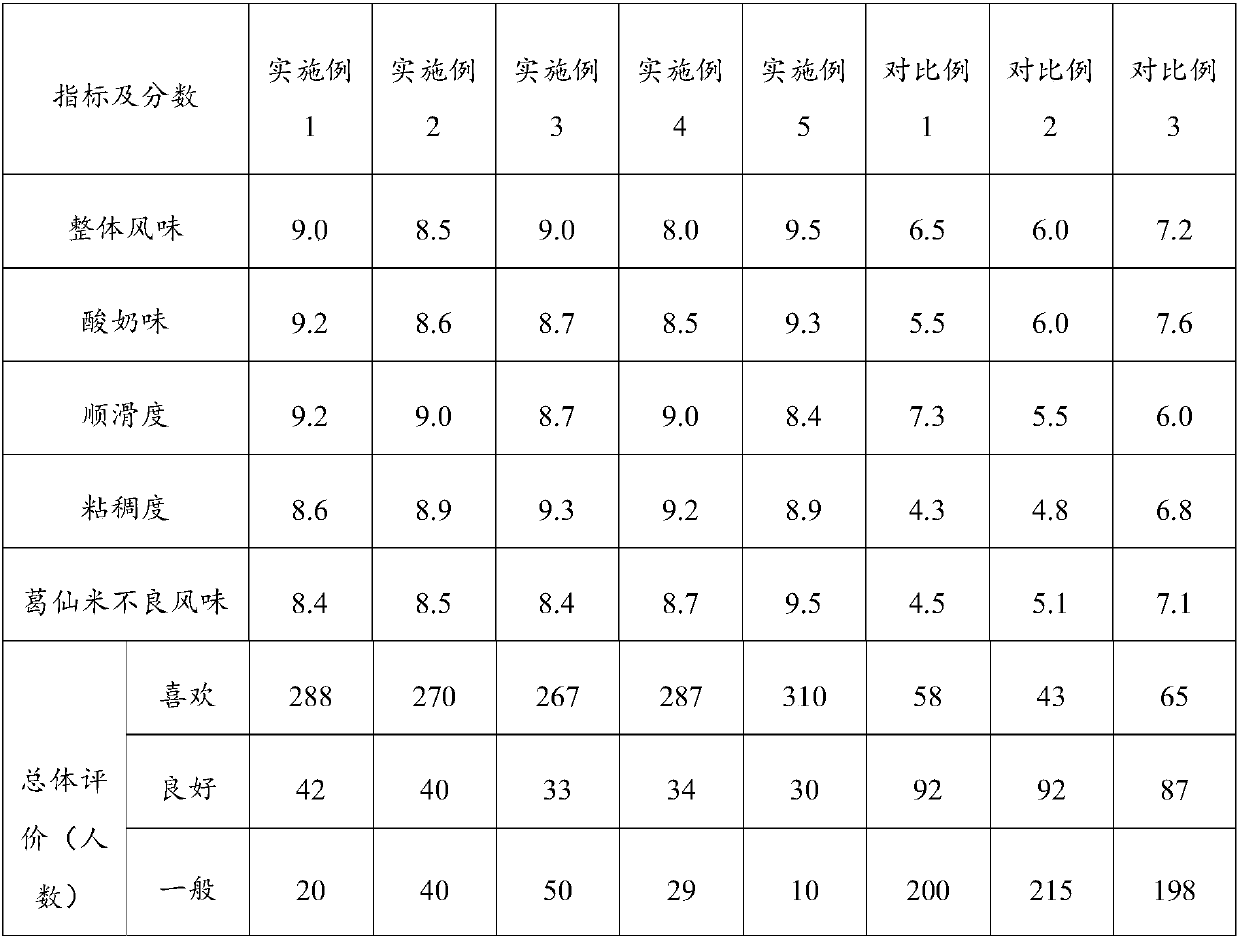

Additive-free normal-temperature yoghourt and preparation method thereof

The invention belongs to the technical field of milk food preparation, and particularly relates to an additive-free normal-temperature yoghourt and a preparation method thereof. Main raw materials ofthe normal-temperature yoghourt only comprise three main components of liquid milk, a sweetener and nostoc sphaeroides, and addition of additional stabilizers and acidity regulators is not needed. Theproduct provided by the invention can be stored at normal temperature for 5 months, and the yoghourt has thick, pure and delicious flavor and mellow and smooth taste. After the product is placed at normal temperature for 5 months, the product basically has no phenomena of water seepage, bad flavor, protein coagulation and precipitation phenomena, and has stable mouthfeel and longer shelf life. Finally, it proves that the product has a reasonable formula, good flavor and smooth mouthfeel. According to the preparation method disclosed by the invention, the nostoc sphaeroides powder is subjectedto hydration and independent fermentation treatment, so that polysaccharide substances of the nostoc sphaeroides powder are effectively dissolved out, and bad flavor brought by the nostoc sphaeroidespowder is also modified. According to the invention, viscosity and stability of the product are successfully improved in a green mode, and the normal-temperature yoghourt with clean ingredients is prepared.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Damp-proof using method of polymethacrylate pressure-sensitive adhesive

ActiveCN105440994AAvoid gel phenomenonPerformance is not affectedNon-macromolecular adhesive additivesEster polymer adhesivesAdhesivePoly methacrylate

The invention relates to a damp-proof using method of a polymethacrylate pressure-sensitive adhesive. The method comprises steps as follows: Step 1) evenly mixing a solvent type polymethacrylate pressure-sensitive adhesive and a solvent to prepare an adhesive diluent; Step 2) evenly mixing a solvent and a water removing agent with the mass accounting for 0.5%-5% of the dry weight of the solvent type polymethacrylate pressure-sensitive adhesive, and adding the mixture to the adhesive diluent; Step 3) evenly mixing a solvent and a water removing agent catalyst with the mass accounting for 5%-50% of the pure mass of the water removing agent, and adding the mixture to the adhesive diluent; Step 4) evenly mixing a catalyst of an isocyanate curing agent and a solvent, and adding the mixture to the adhesive diluent; Step 5) evenly mixing the isocyanate curing agent and a solvent, and adding the mixture to the adhesive diluent to obtain a polymethacrylate adhesive coating liquid; Step 6) coating the surface of a base material with the adhesive coating liquid, and performing desolvation, curing and post-curing in a drying oven to obtain the polymethacrylate adhesive product.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

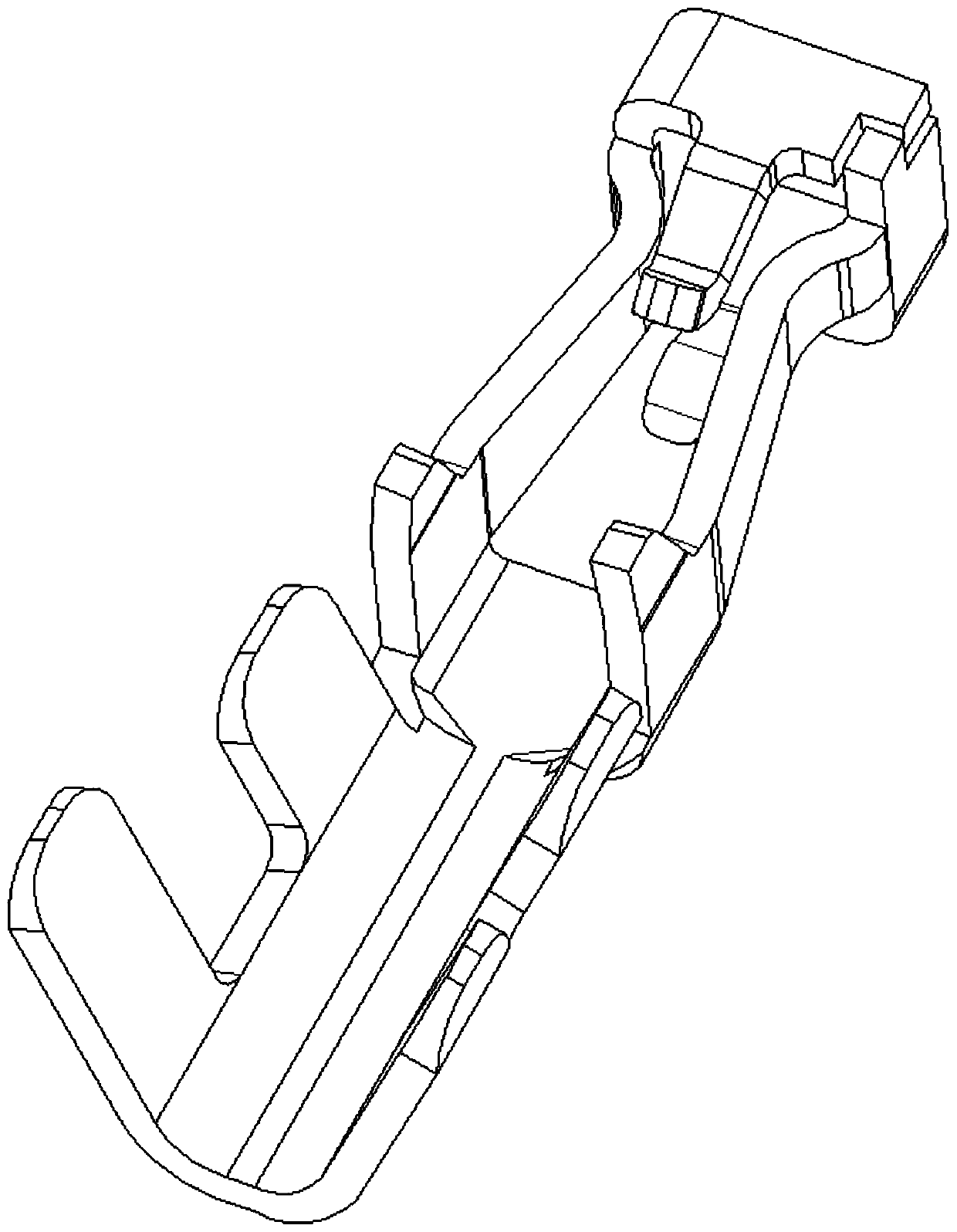

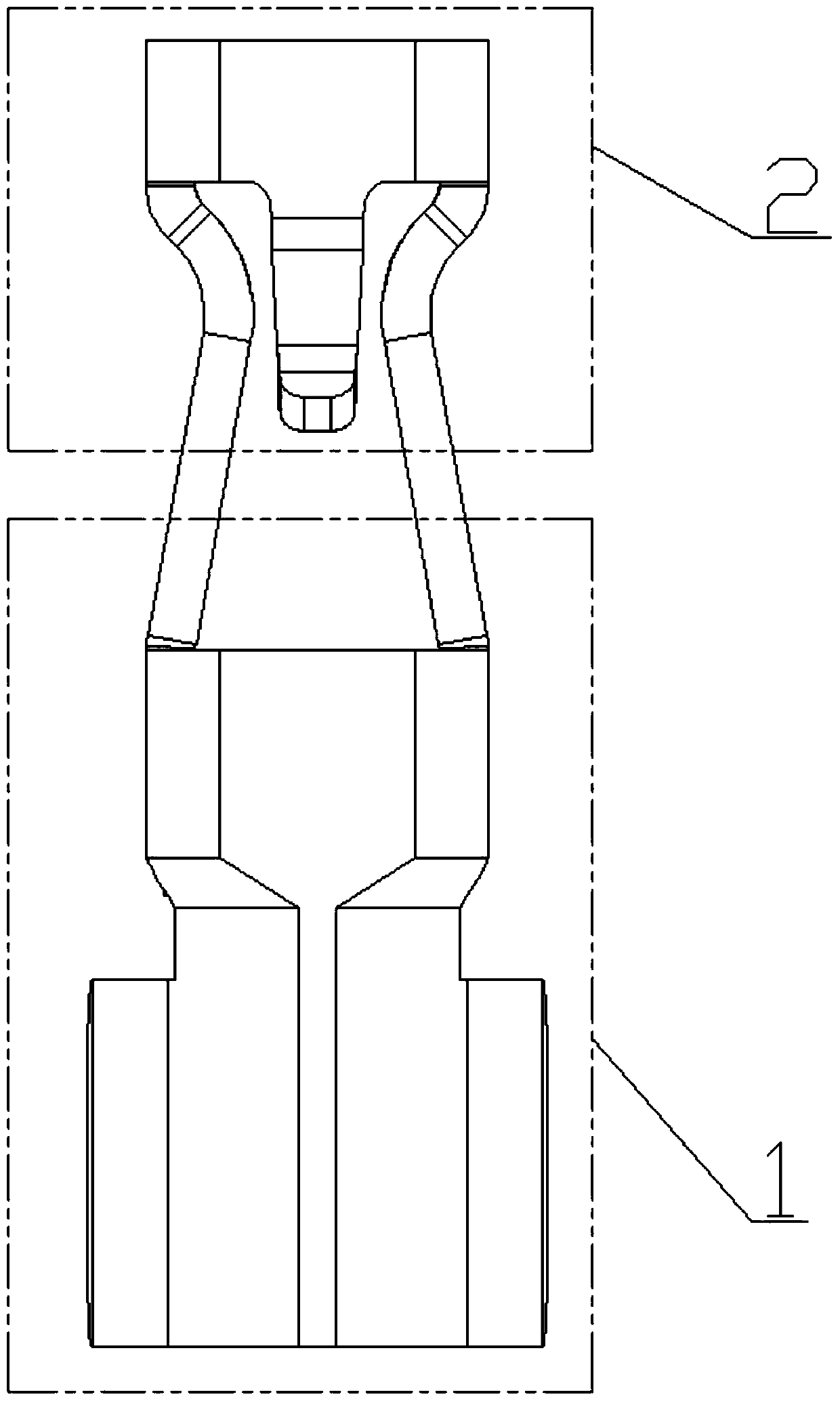

Electrical connector terminal

PendingCN110350338AAvoid enteringAvoid gel phenomenonCoupling contact membersElectricityInjection moulding

The invention relates to an electric connector terminal. A sheet-shaped metal body is punched and bent so as to form the electric connector terminal. The electric connector terminal is composed of a welding portion and a conductive insert core inserting portion. The cross section of the welding portion is U-shaped and is arranged along a direction away from the conductive insert core inserting portion; the welding portion comprises a first wire pressing area and a second wire pressing area which are connected in sequence; the left side and right side of the first wire pressing area are respectively provided with a left pressing wire elastic sheet and a right pressing wire elastic sheet; and the first wire pressing area comprises an adhesive stopping plate which is transversely placed in the cavity of the first wire pressing area. In this way, the adhesive stopping plate can effectively prevent liquid plastic from entering the conductive insert core inserting portion along the welding portion in an injection molding process, and therefore, adhesive solidification occurring on an elastic contact arm is avoided. In addition, the adhesive stopping plate can be used for limiting the insertion length of a conductive insert core, so that the convenience and consistency of construction are improved.

Owner:GOLDENCONN ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com