Preparation method and application of free nitroxide radical polymer brush polymerization inhibitor

A nitroxide free radical, polymer brush technology, applied in fatty acid esterification, organic chemistry, chemical recycling and other directions, can solve problems such as difficult recycling and reuse, prevent self-polymerization reaction, light color, avoid gel phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Disperse 5 g of PS-OH (containing 1.5 mmol of hydroxyl groups on the surface) in 35 ml of N,N-dimethylformamide (DMF), perform ultrasonic vibration to disperse the two evenly, and place in the Add the above mixture and 1.65mmol triethylamine into the 50ml three-neck flask with a constant pressure separatory funnel, and continuously feed N 2 protection, and then 8ml of DMF and 1.65mmol of 2-bromoisobutyryl bromide were mixed and slowly added through a constant pressure dropping funnel. Under ice-water bath, react for 2h, and continue to react for 24h at room temperature. Pour it into 150ml of absolute ethanol for centrifugation, and dry at 60°C to obtain PS-Br. The loading amount of the initiator is 0.25 mmol / g microspheres.

[0033] (2) After mixing copper bromide and 30ml solvent anisole, perform ultrasonic vibration to disperse the two evenly, then add it to a 50ml three-necked flask for stirring, and continuously feed N 2For protection, add the monomer GMA, add...

Embodiment 2

[0036] (1) Disperse 5g of PS-OH (with 1.5 mmol of hydroxyl groups on the surface) in 35ml of DMF, conduct ultrasonic vibration to disperse the two evenly, and add The above mixture and 3mmol triethylamine were continuously fed into N 2 protection, and then 8ml of DMF and 3mmol of 2-bromoisobutyryl bromide were mixed and slowly added through a constant pressure dropping funnel. Under ice-water bath, react for 1 h, and continue to react for 12 h at room temperature to end. Pour it into 150ml of absolute ethanol for centrifugation, and dry at 60°C to obtain PS-Br, with an initiator loading of 0.29 mmol / g microspheres.

[0037] (2) After mixing copper bromide and 30ml solvent anisole, perform ultrasonic vibration to disperse the two evenly, then add it to a 50ml three-necked flask for stirring, and continuously feed N 2 For protection, add the monomer GMA, add the ligand pentamethyldiethylenetriamine after 15 minutes, add 1.5g of PS-Br prepared in step (1) after 15 minutes, cont...

Embodiment 3

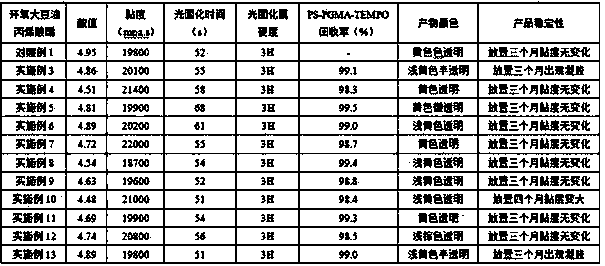

[0043] Add 120g of epoxidized soybean oil and PS-PGMA-TEMPO loaded with 0.15% TEMPO into a 500ml three-neck flask, heat the oil bath to 110°C under mechanical stirring, and then feed 28g of acrylic acid steadily at a feeding rate of 10.67ml / h with a peristaltic pump And a mixture of 1.5% triphenylphosphine, the feeding time is 2.5h. After the feed was completed, the reaction was continued at a constant temperature of 120° C. for 6 h. During the reaction process, the acid value of the system was measured, and the acid value was less than or equal to 5 mgKOH / g when the heating was stopped. The reaction product was naturally cooled to room temperature to obtain light yellow transparent viscous oily epoxy soybean oil acrylate. Filter to recover PS-PGMA-TEMPO. The performance test results of epoxy soybean oil acrylate are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com