Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

142results about How to "Avoid excessive corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for metallic phase sample of 1060 aluminium plate and MB3 magnesium alloy palate join

InactiveCN101034044AAvoid excessive corrosionEasy to analyzePreparing sample for investigationAcetic acidEtching

This invention relates to a preparation method of 1060 aluminium plate and MB3 magnesium alloy board joint's metallographic specimen; include sampling, ground, polish, etching steps. 1Etching solution mixture ratio of 1060 aluminium plate: HNO3 2ml, HCl 2ml, HF 1ml, H2O 50m;etching solution mixture ratio of joint region: oxalic acid 1g, HNO3 1ml, acetic acid ml, H2O 150ml;Etching solution mixture ratio of MB3 magnesium alloy board: HNO3ml, oxalic acid 1to 5g, H2O 100ml. Comparing with available homogeneity stuff, this invention overcomes the problem of over etching phenomena of joint region. Prepared metallographic specimen is lucidity, is prone to analyze soldered joint's microstructure feature.

Owner:王训宏

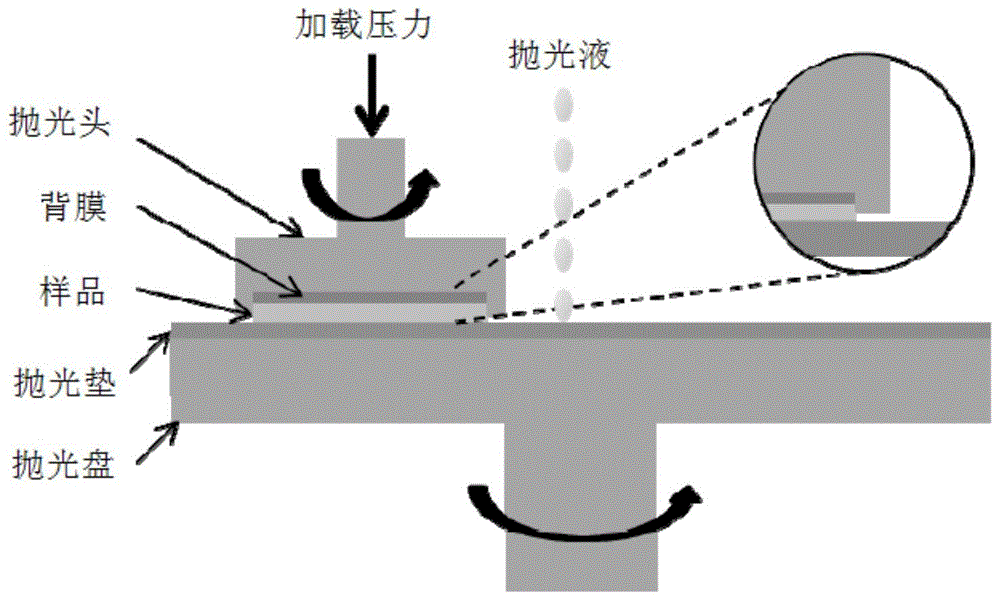

Polishing solution for chemically and mechanically polishing cobalt barrier layer structure and applications thereof

ActiveCN104830235AReduced removal rateAdjustable removal rateSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesCopperCobalt

The invention discloses a polishing solution for chemically and mechanically polishing a cobalt barrier layer structure and applications thereof. The polishing solution comprises the following components in percentage by weight: 0.01 to 20 wt% of grinding particles, 0.01 to 10 wt% of oxidant, 0.01 to 10 wt% of metal complexing agent, 0.005 to 5 wt% of metal corrosion inhibitor, 0.001 to 1 wt% of surfactant, and the balance being water. The polishing solution can form a layer of protective passivation film on the surface of cobalt and copper so as to prevent over-corrosion during the polishing process, can reduce the removal rates of cobalt and copper materials, and obtains the removal rate selectivity of an adjustable material.

Owner:TSINGHUA UNIV

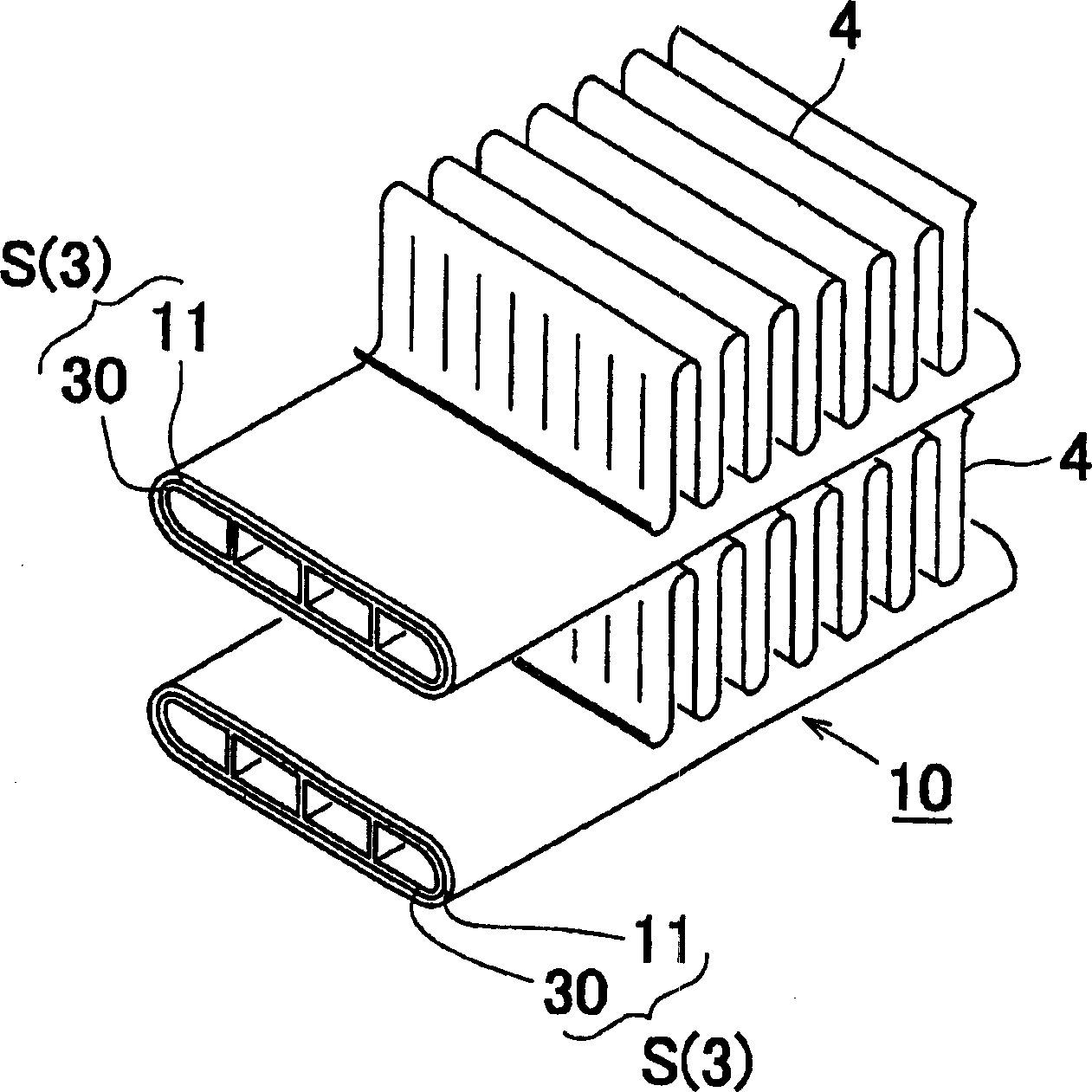

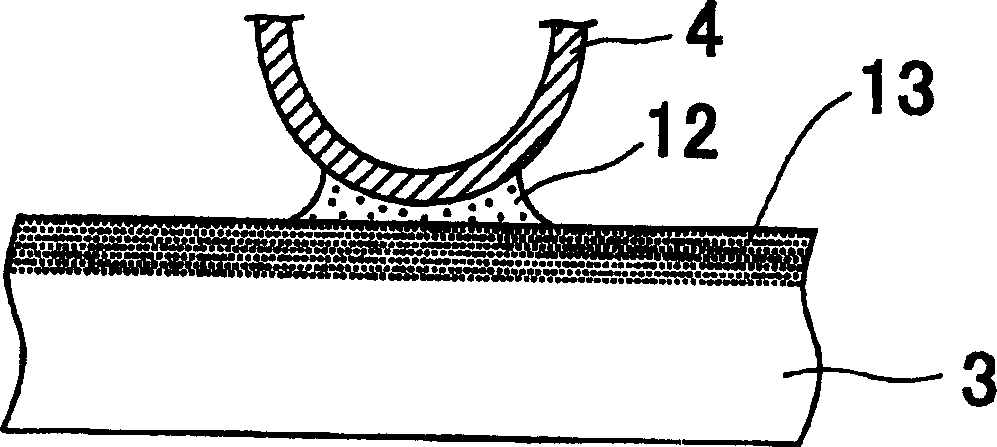

Aluminum alloy brazing material, brazing member, brazed article and brazinh method therefor using said material, brazing heat exchanging tube, heat exchanger and manufacturing method thereof using sai

InactiveCN1726114AAvoid excessive corrosionReduce the predetermined thicknessWelding/cutting media/materialsHeat exchange apparatusPlate heat exchangerImpurity

A heat exchanger 10 includes a brazing heat exchanging tube S and a fin 4. The heat exchanging tube S and the fin 4 are brazed with each other via the brazing layer 11 of the heat exchanging tube S. The brazing layer 11 is formed by spraying of a brazing material consisting of Si: 6 to 15 mass%, Zn :1 to 20 mass%, at least one of Cu: 0.3 to 0.6 mass% and Mn: 0.3 to 1. 5 mass, and the balance being aluminum and inevitable impurities.

Owner:SHOWA DENKO KK

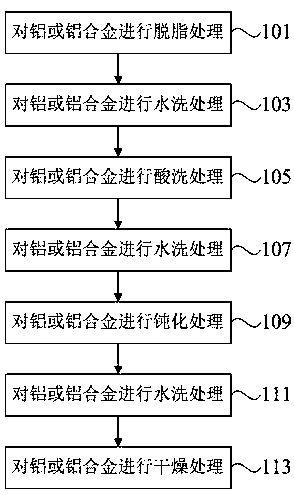

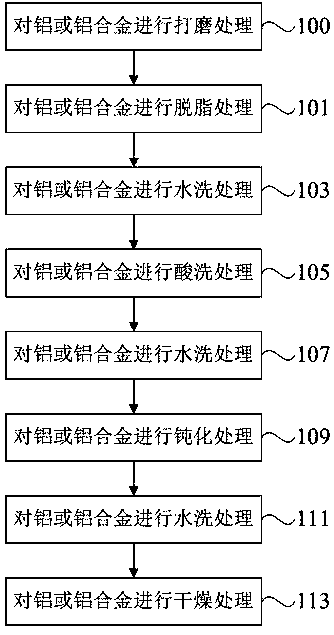

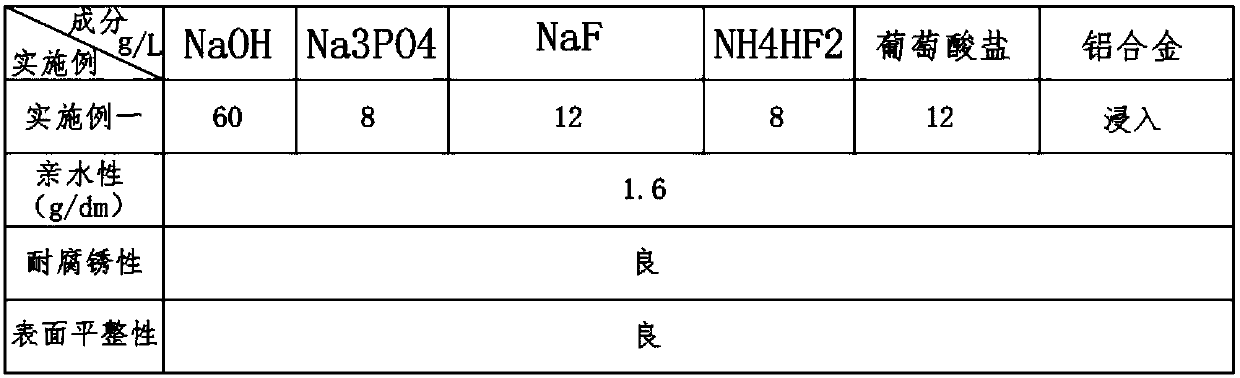

Environment-friendly aluminum and aluminum alloy surface treatment method

InactiveCN109402618AImprove yieldSimple processMetallic material coating processesHydrofluoric acidEnvironmental resistance

The invention relates to an environment-friendly aluminum and aluminum alloy surface treatment method, which comprises the following steps: degreasing treatment is carried out on the aluminum or aluminum alloy: soaking the aluminum or aluminum alloy in degreasing solution for a period of time. Washing treatment: washing the aluminum or aluminum alloy taken out from the degreasing solution with clear water. Pickling treatment: soaking the aluminum or aluminum alloy in pickling solution for a period of time, wherein the pH value of the pickling solution is 0.1-4, and the pickling solution comprises the following components: hydrogen peroxide, ammonium bifluoride, hydrofluoric acid and water. Washing treatment: washing the aluminum or aluminum alloy taken out of the pickling solution with clear water. Passivation treatment: soaking aluminum or aluminum alloy in the passivation solution for a period of time. Washing treatment: washing the aluminum or aluminum alloy taken out from the passivation solution with clear water. Drying treatment. The treatment method has the advantages of simple and convenient procedures; high treatment efficiency and low treatment cost, and greatly reduces the pollution to the environment.

Owner:惠州市四维化工有限公司

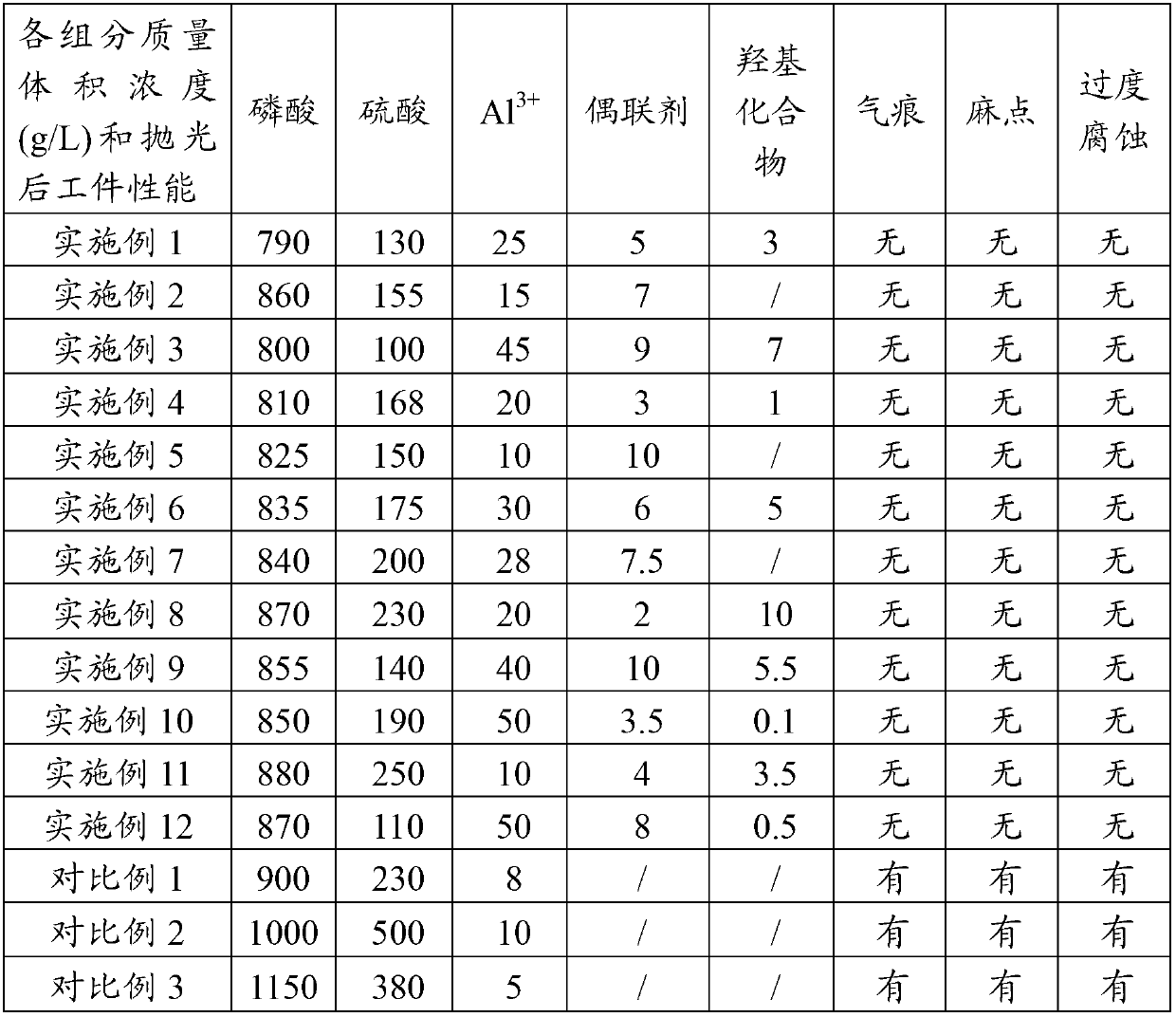

Chemical polishing agent

The invention discloses an aluminum alloy chemical polishing agent applicable to automatic production. The chemical polishing agent comprises aqueous solutions of the following substances: according to mass-volume concentration, 790g / L to 880g / L of phosphoric acids, 100g / L to 250g / L of sulfuric acids, 10g / L to 50g / L of aluminum ions and 2g / L to 10g / L of coupling agents. According to the chemical polishing agent, the proportion of the phosphoric acids and the sulfuric acids is adjusted, and aluminum ions are further added, so that the corrosion of the polishing agent is reduced. The viscosity of the polishing agent is added by the adding of the coupling agents, so that the flow speed of gas released in the polishing process is changed, and the gas cannot leave gas marks on workpieces after the polishing; besides, as the coupling agents can be attached onto the workpiece surface, a layer of protection film is formed between highly corrosive acids and alloy surfaces, so that excessive corrosion caused by the continuous reaction of workpieces after the workpieces leave polishing grooves (during the slow transfer of the automatic production) is avoided, and further, the production stability is guaranteed, and requirements of automatic production is met.

Owner:广州波耳化工科技有限公司

Polishing solution for electrochemical polishing of nickel-titanium alloy and application

InactiveCN107675244AGood corrosion inhibition effectImprove the leveling effectElectrochemistryTitanium alloy

The invention provides a polishing solution for electrochemical polishing of a nickel-titanium alloy, and belongs to the field of nickel-titanium alloy surface treatment. The polishing solution is composed of the following matter of, by volume, 22%-43% of concentrated sulfuric acid, 37%-50% of ethylene glycol, 5%-10% of an additive agent and the balance water. The invention further discloses a method for electrochemical polishing of the nickel-titanium alloy, the nickel-titanium alloy is treated as the anode, a stainless steel plate is treated as the cathode, the anode and the cathode are placed into the electrical polishing solution, and electrochemical polishing is conducted. The electrochemical polishing solution and the polishing method can be used for polishing a medical nickel-titanium alloy, the nickel-titanium alloy which is subjected to polishing treatment is good in corrosion resistance. The formula of the nickel-titanium alloy electrochemical polishing solution is not proneto volatilizing, stable and environmentally friendly, low in cost and good in operating environment.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

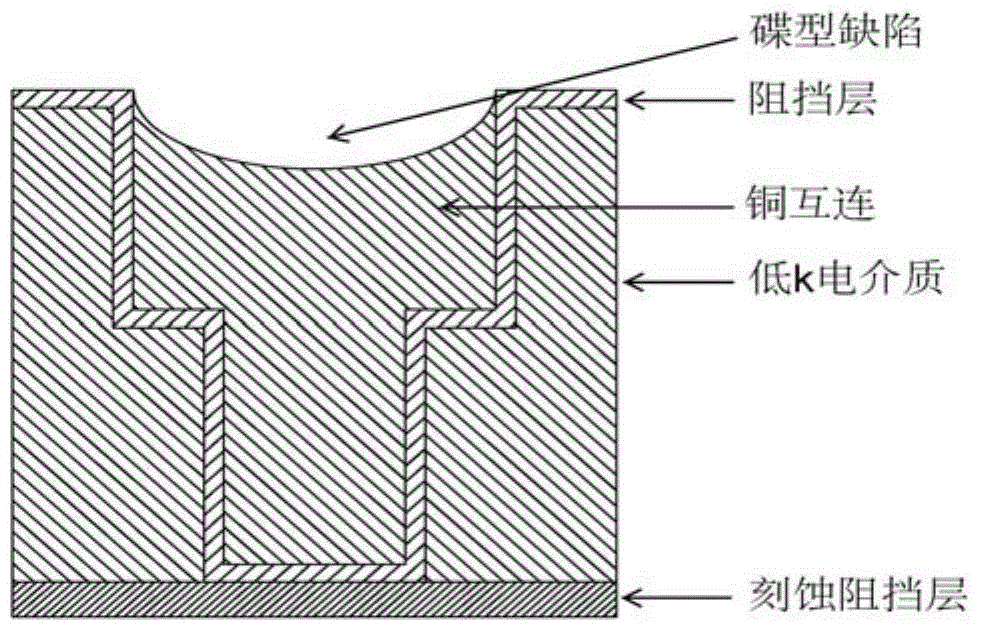

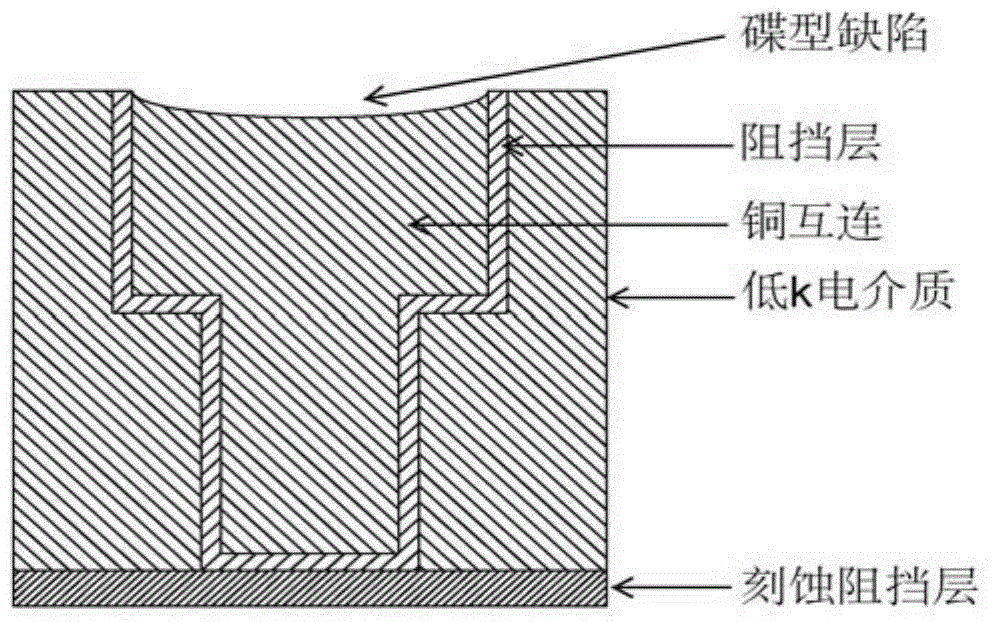

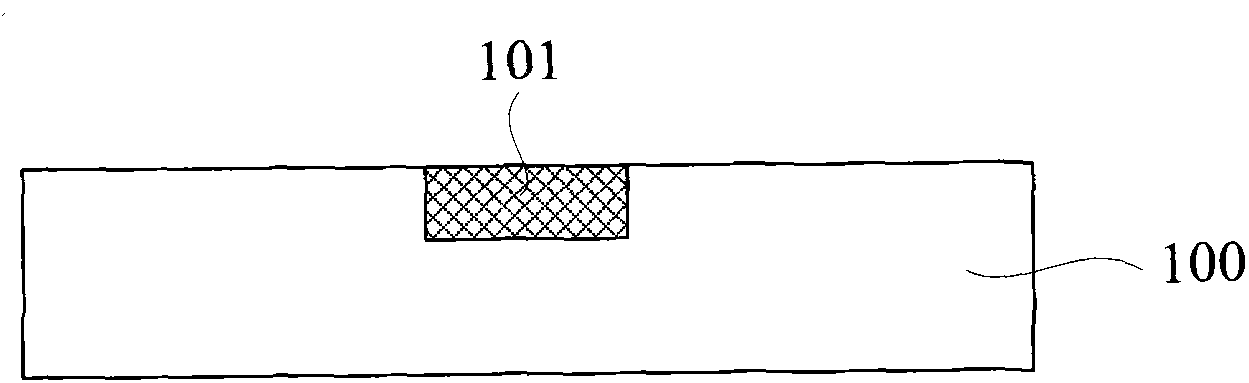

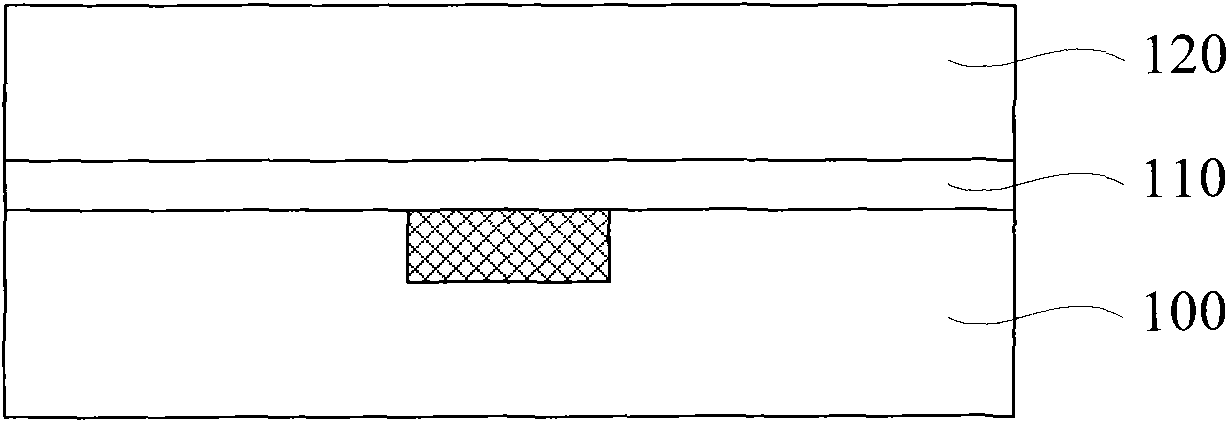

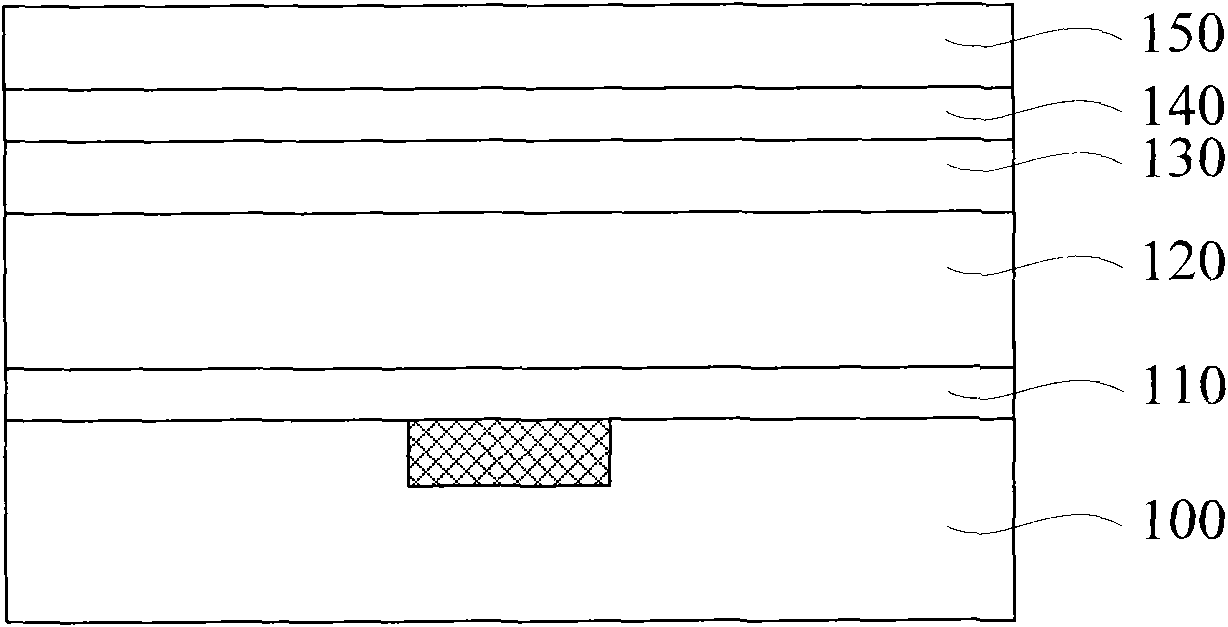

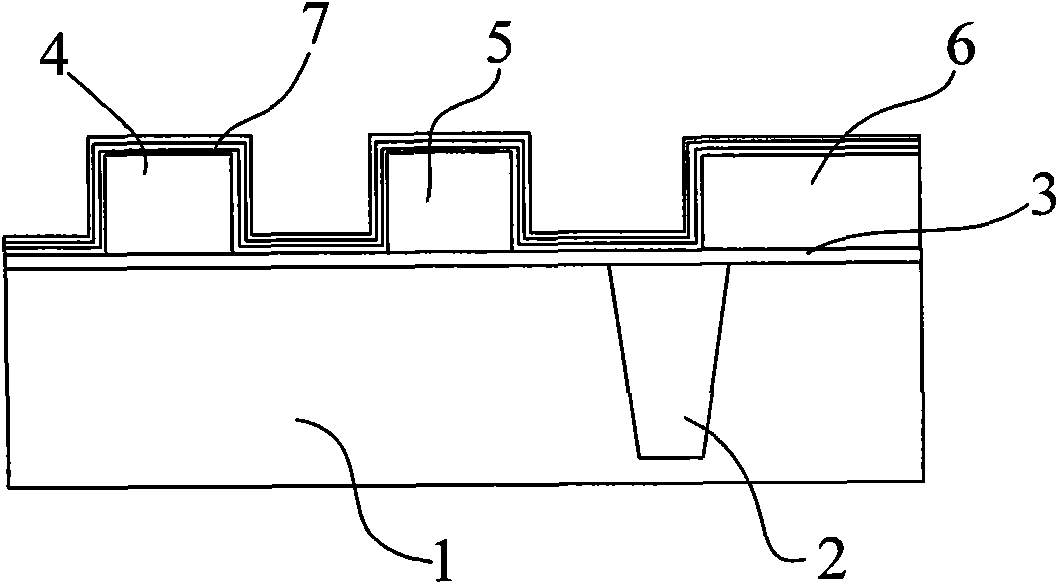

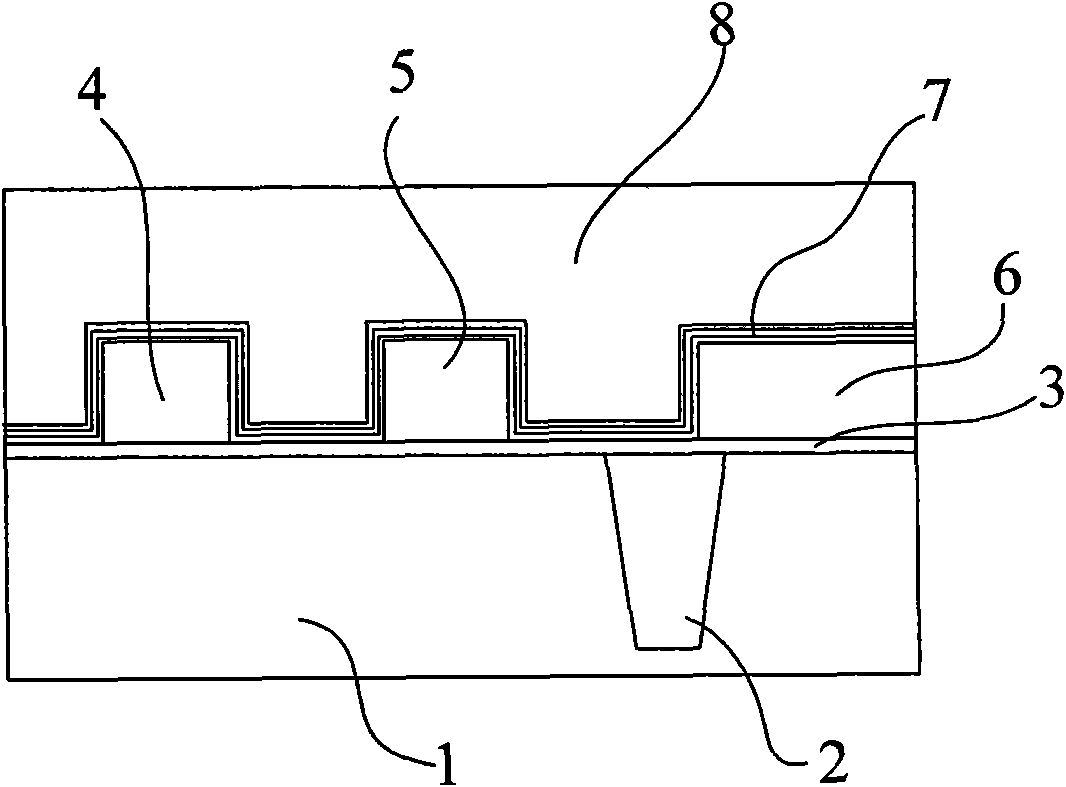

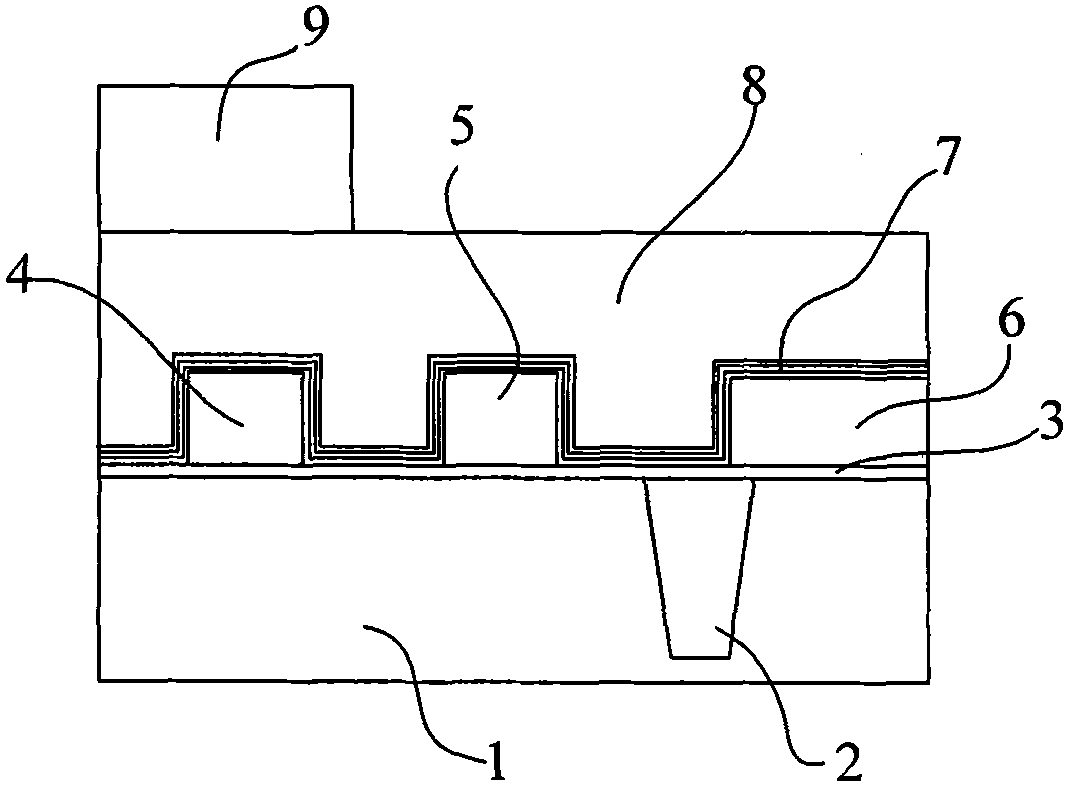

Preparation method of semiconductor device

InactiveCN102487039AAvoid excessive corrosionImprove adhesionSemiconductor/solid-state device manufacturingDielectric layerNitrogen doped

The invention discloses a preparation method of a semiconductor device. The preparation method comprises the following steps of: providing a semiconductor substrate on which a metal interconnecting wire is formed; forming a dielectric layer on the surface of the semiconductor substrate; forming a nitrogen doped silicon carbide layer, an oxide layer and a hard mask layer on the surface of the dielectric layer in sequence; carrying out dry etching on the hard mask layer, the oxide layer, the nitrogen doped silicon carbide layer and the dielectric layer so as to form an opening at the position corresponding to the metal interconnecting wire; carrying out wet cleaning on the semiconductor substrate. According to the preparation method, the nitrogen doped silicon carbide layer is used for replacing the traditional Octamethyl cyclotetrasiloxane layer so that the nitrogen doped silicon carbide layer is prevented from being corroded excessively, thereby improving the reliability of the semiconductor device.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

Magnesium alloy surface activating process

Surface activation of Mg alloy is carried out by: coarsening surface mechanically and uniformly, polishing, removing oil and dirt, and activating to effectively control wearing rate of surface to verify adhesion of Mg basement with electroplated coating. A wet rotary machine is used to grind surface with grinding liquid with pH = 6 - 9, which comprises: solid content and water with ratio of (1-5:1) vol. The solid contains pumacite 40 - 60%, Mg oxide 20 - 30% and Si oxide 20 -30%. The activation can increase adhesion between Mg alloy basement and electroplated or paint coating while avoid corrosion heavily.

Owner:嘉瑞国际控股有限公司

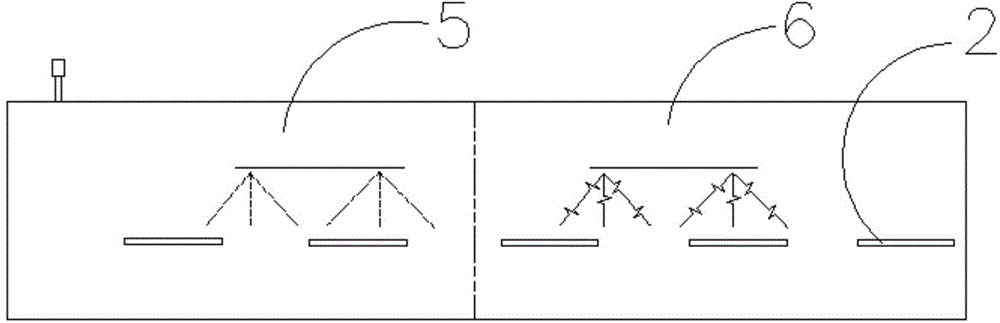

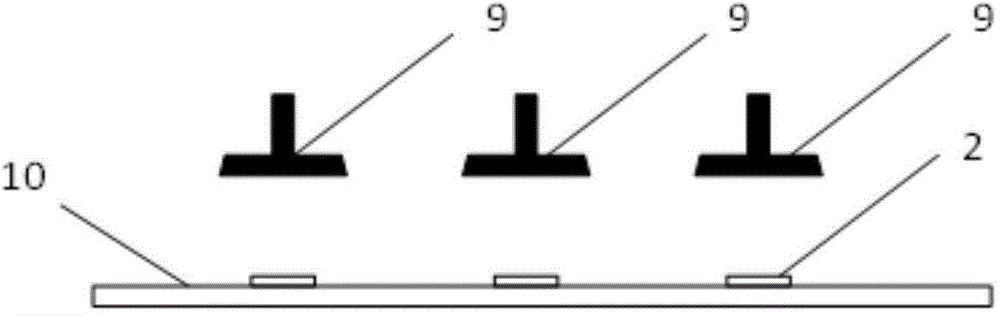

Etching and cleaning device and method for OSP substrate

ActiveCN104599950AAvoid influenceAchieve the effect of etching and cleaningSemiconductor/solid-state device manufacturingSolventChemical agent

The invention discloses an etching and cleaning method for OSP substrate. The etching and cleaning method for OSP substrate comprises the following steps: step 1, mixing the H2SO4 solvent, H2O2 solvent, additive AGS2116, additive AGS2115 and pure water, adding the chemical agent prepared according to the ratio into the cavity of the etching and cleaning device; step 2, guiding the OSP substrate to the etching and spraying chamber and the cleaning and spraying chamber through the track of the etching and cleaning device; step 3, etching the OSP substrate in the etching and spraying chamber, cleaning the OSP substrate in the cleaning and spraying chamber; step 4, checking the etching effect, confirming whether the OSP layer and the oxide layer are etched from the bonding pad. An etching and cleaning device for OSP substrate is also provided, the etching effect of the chemical agent is good, and the etching effect is more even. The H2SO4, H2O2 and other chemical agent are separated via the etching device and prepared according to the scene production status and practical situation of the OSP substrate, and the etching value is controlled, the operation is convenient and the efficiency is high.

Owner:NANTONG FUJITSU MICROELECTRONICS

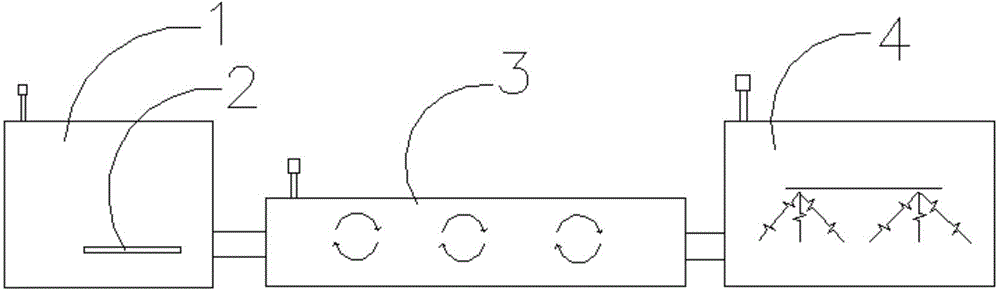

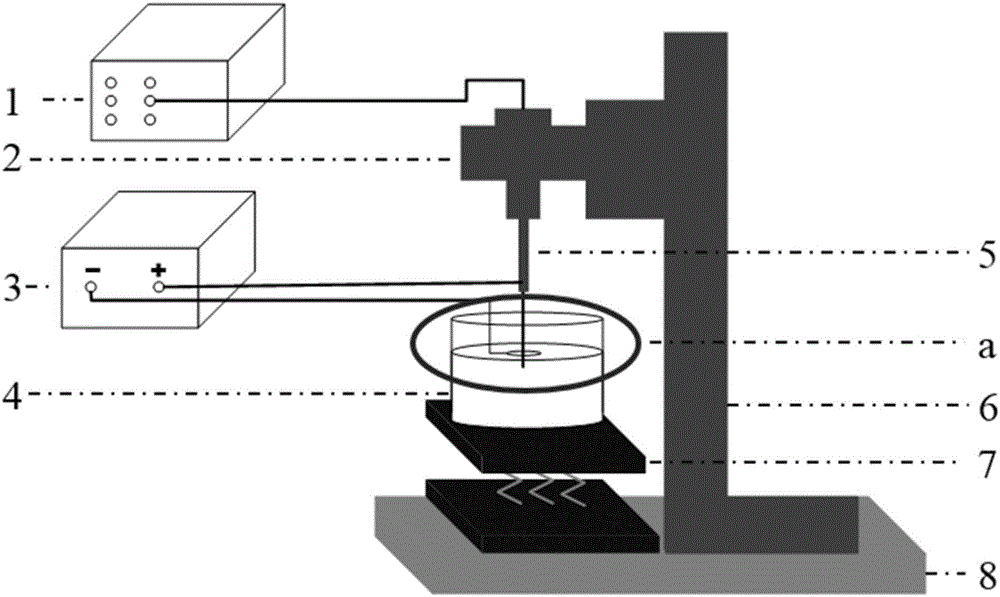

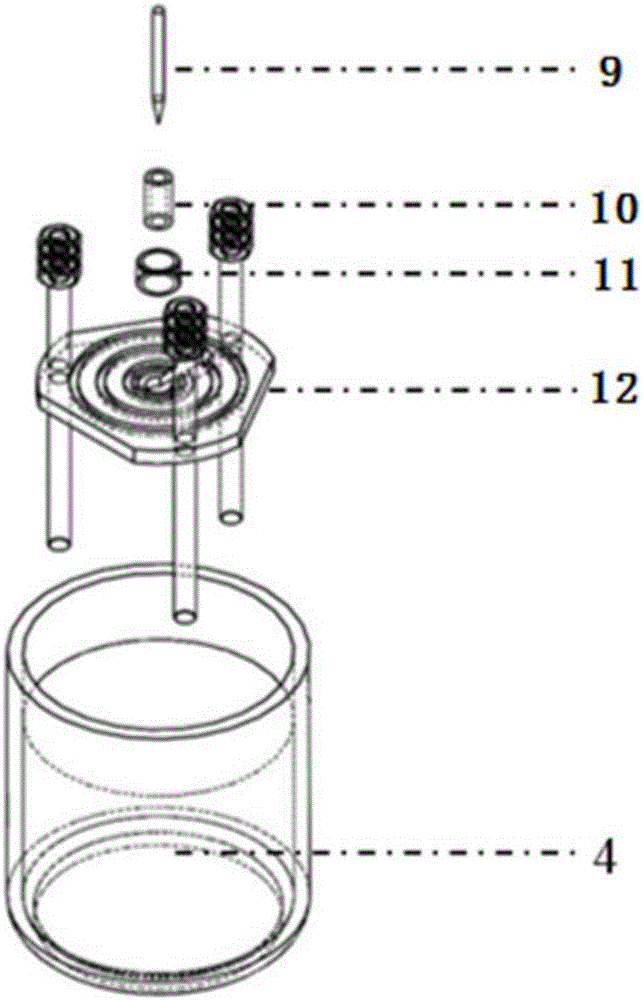

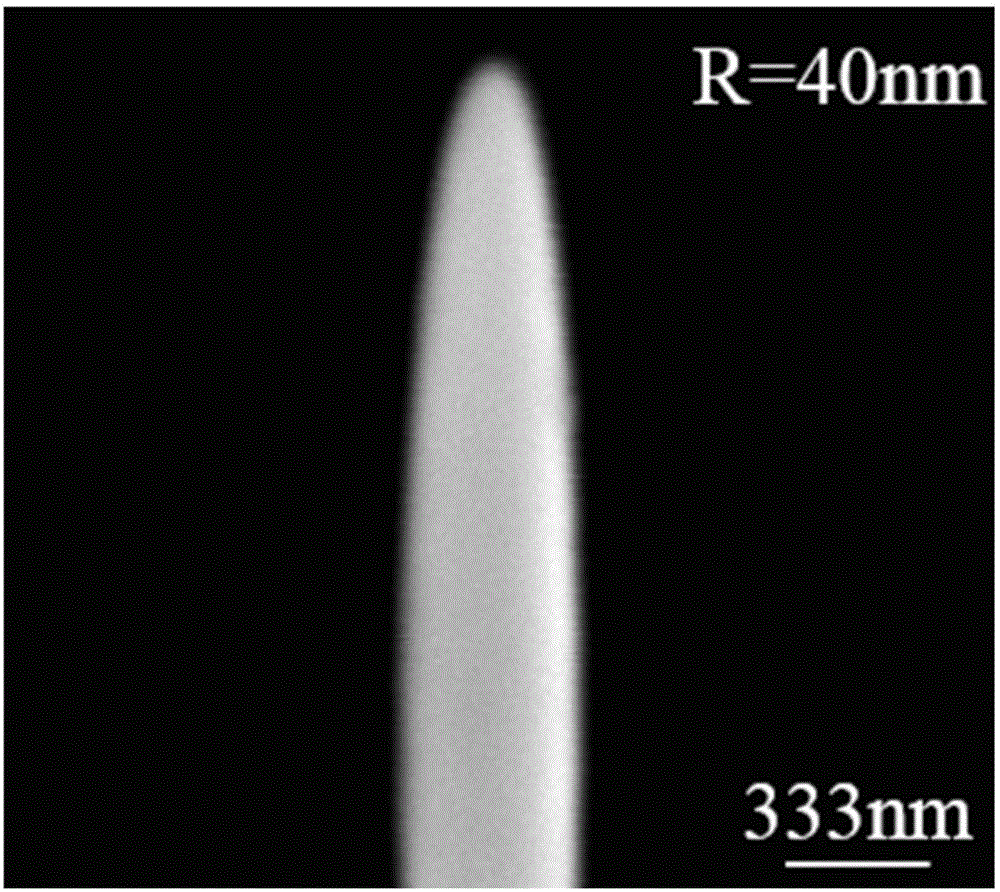

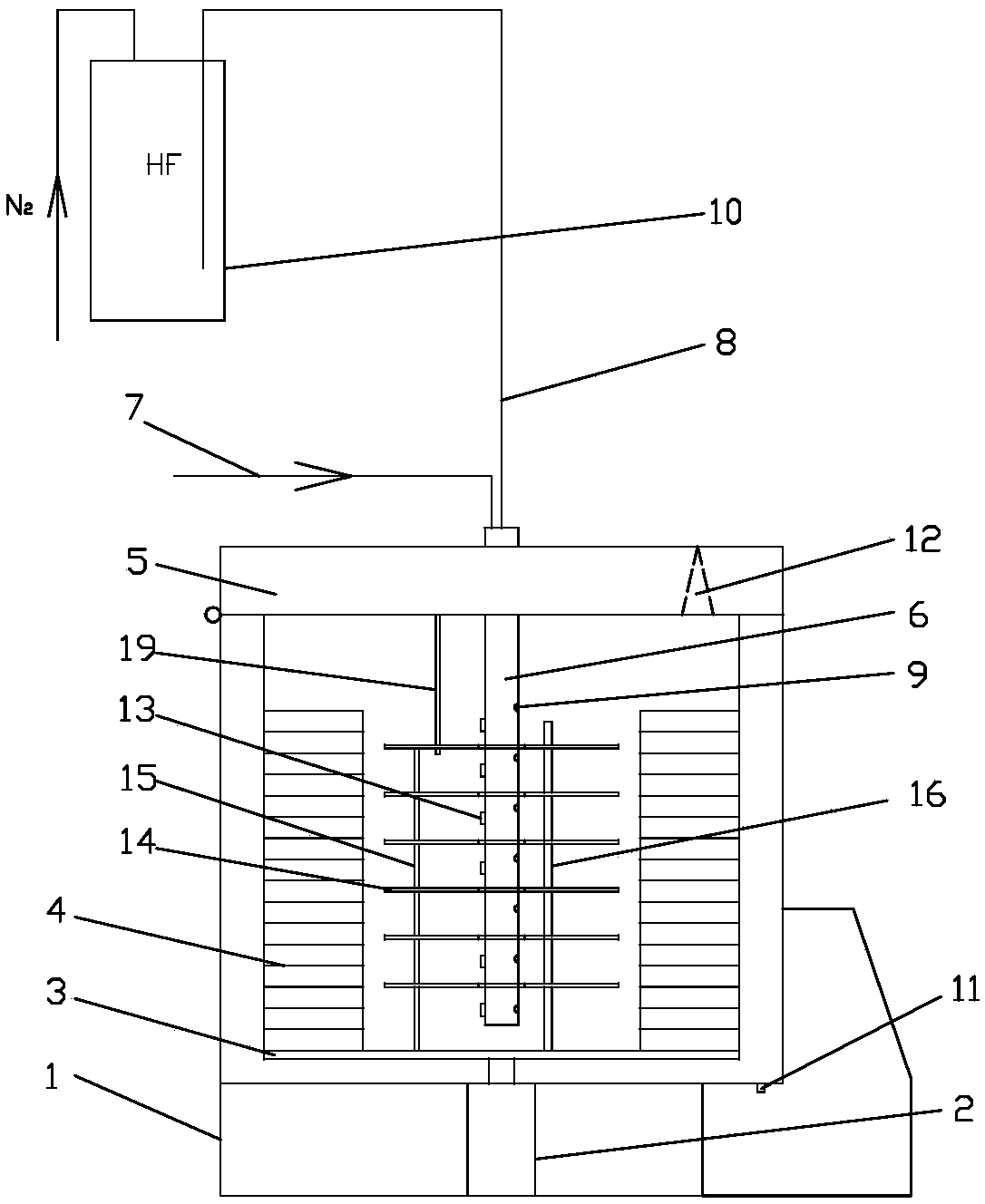

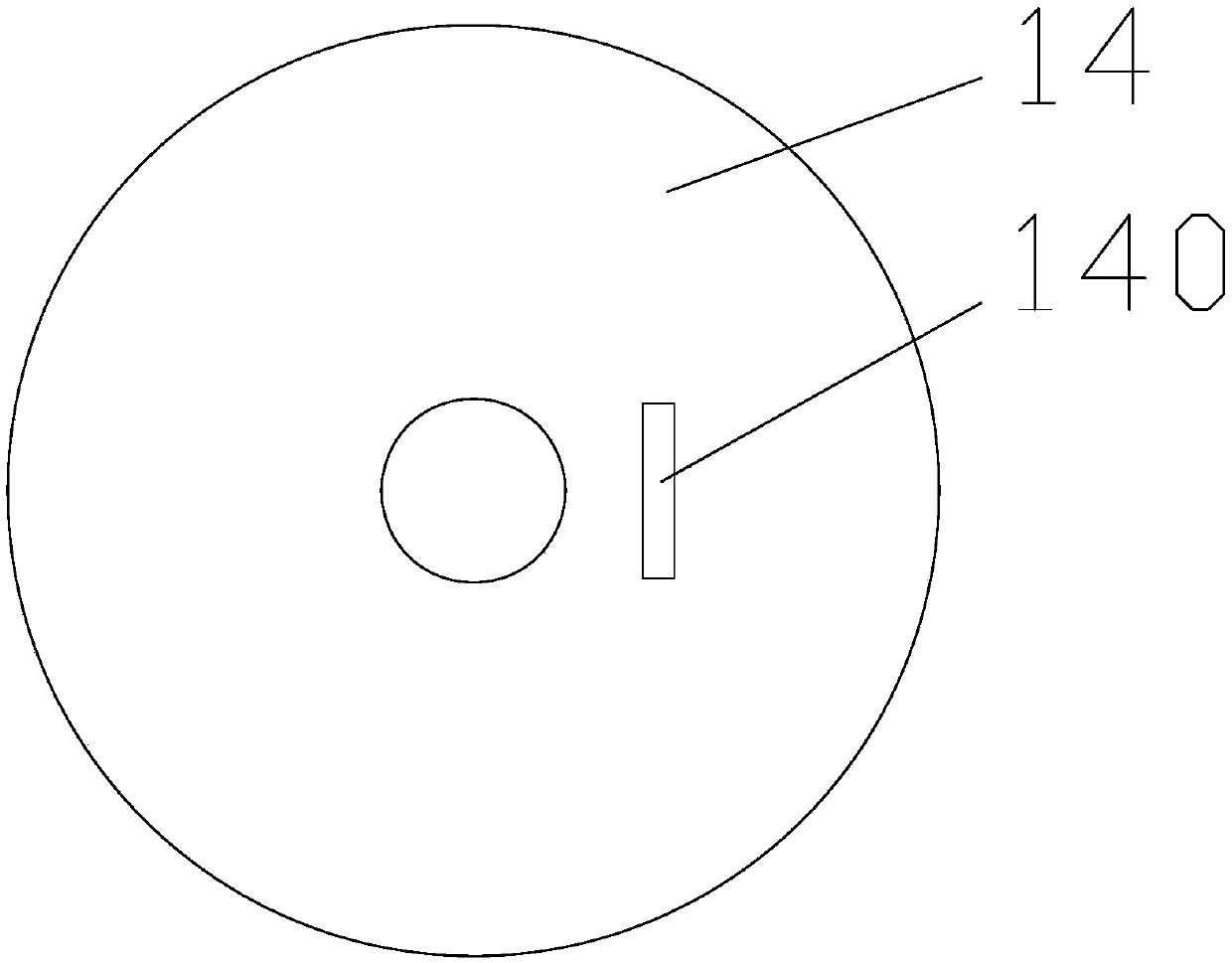

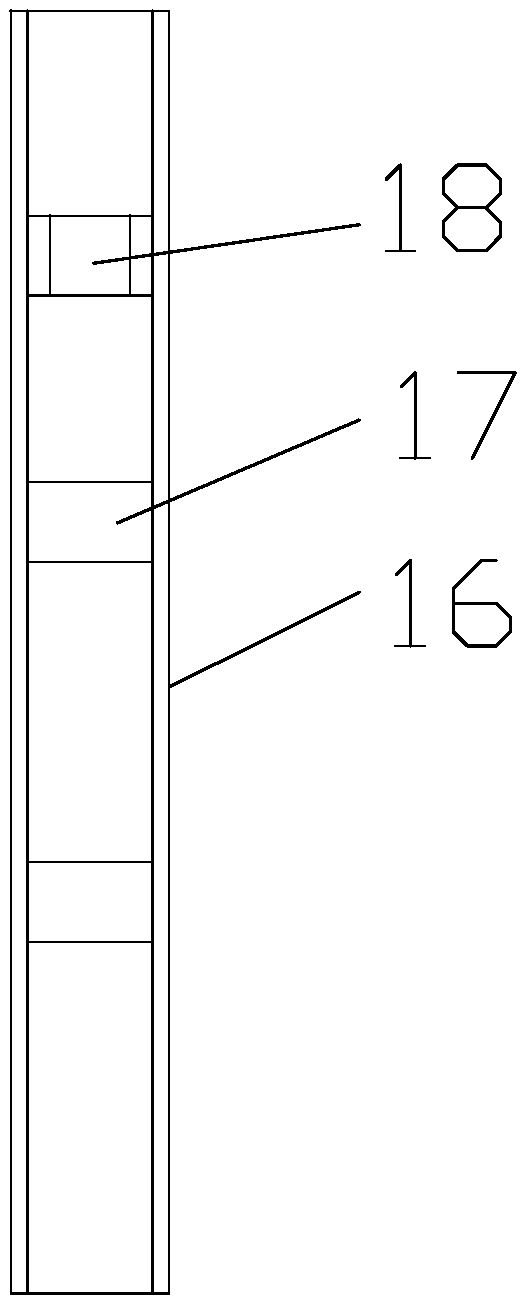

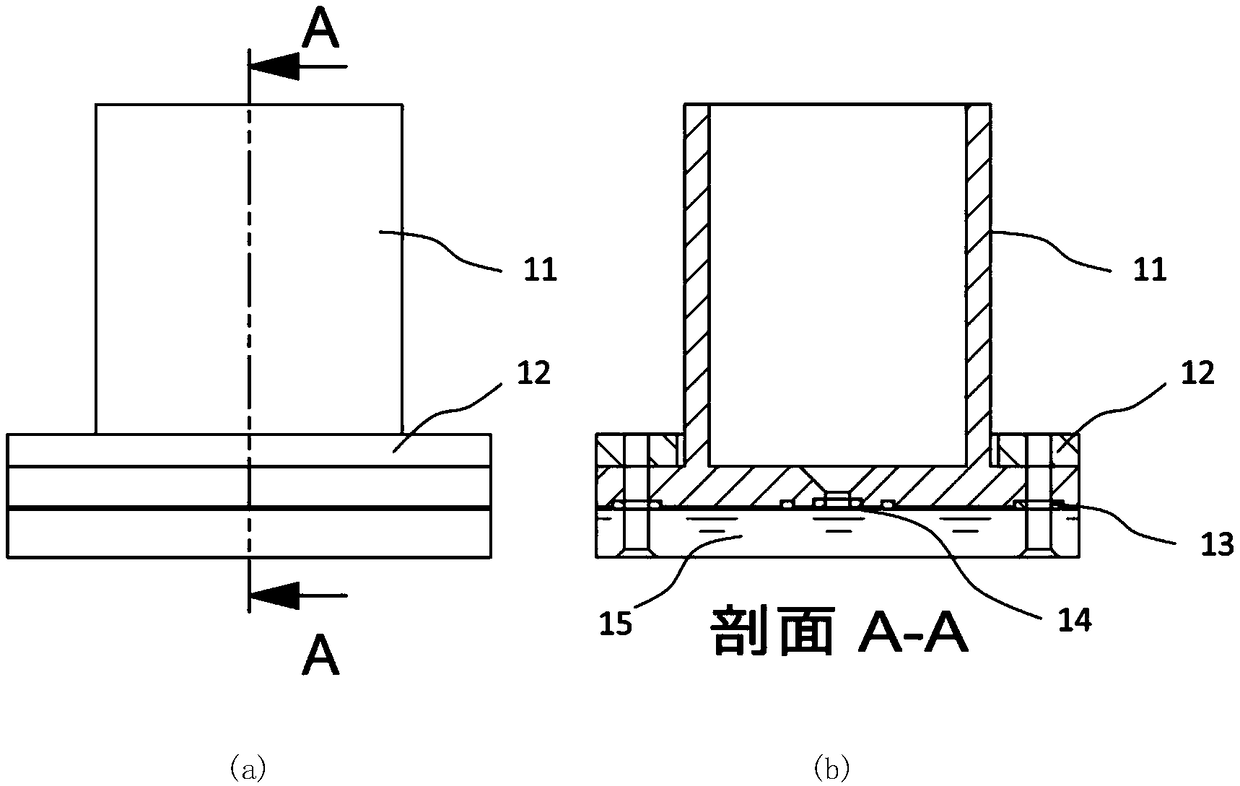

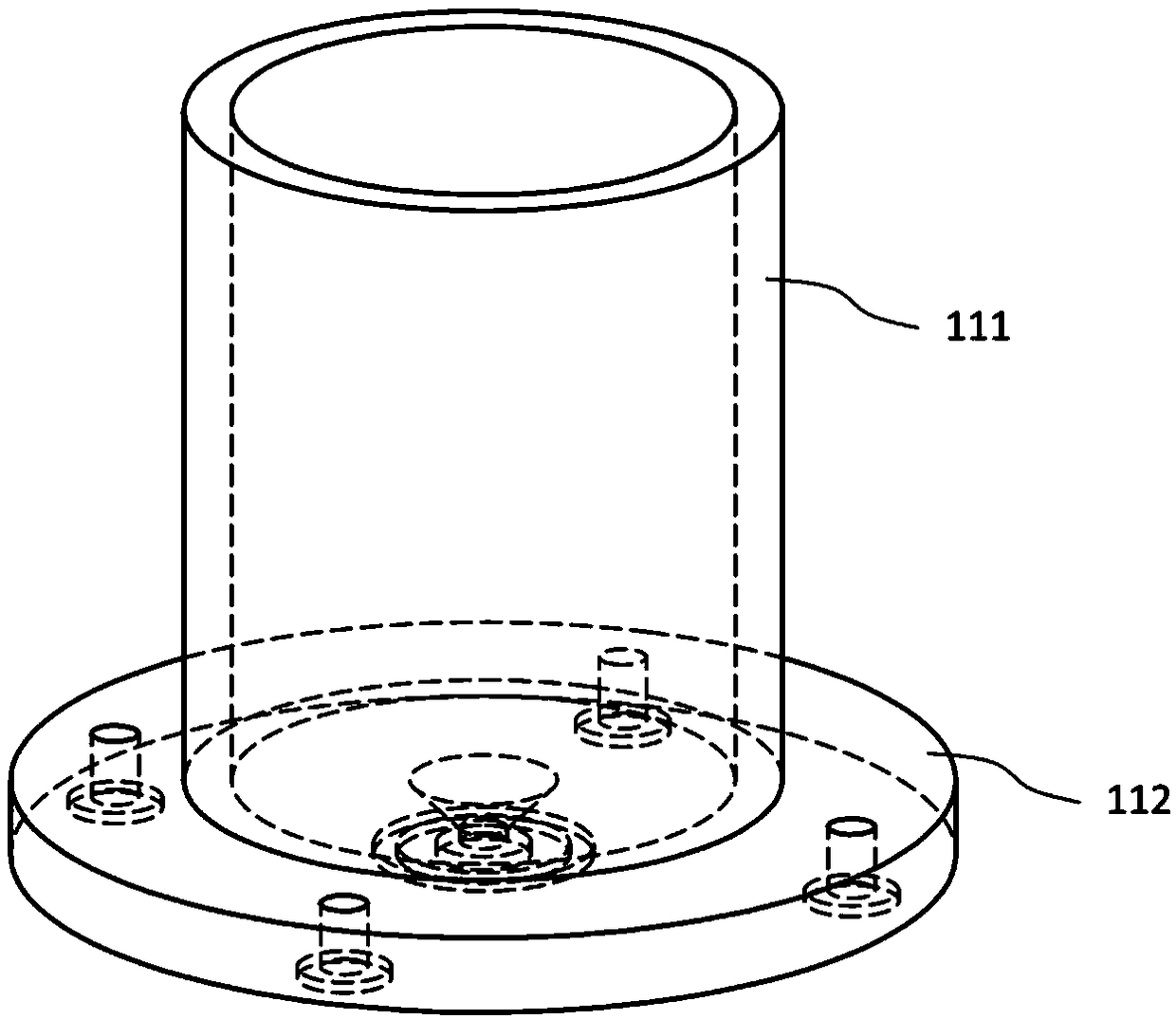

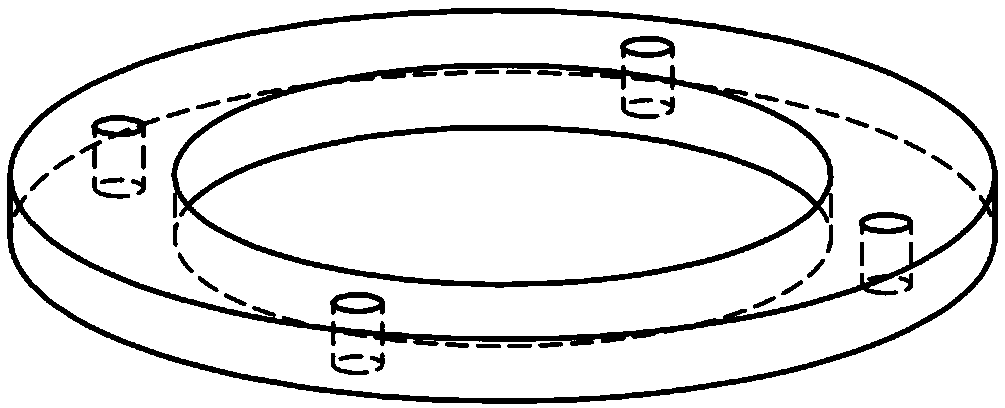

Preparation apparatus and method of ultra-low roughness tungsten probe

InactiveCN106501555AControl lengthEfficient separationScanning probe microscopyEngineeringElectrochemical corrosion

The invention discloses a preparation apparatus and method of an ultra-low roughness tungsten probe. The preparation apparatus of an ultra-low roughness tungsten probe includes a damping platform, wherein the damping platform is connected with an L type fixed support; the L type fixed support is connected with a motion control system for driving motion of a tungsten filament; the damping platform is also provided with a container filled with etchant solution; the container filled with etchant solution is arranged just below the tungsten filament; a copper ring counter electrode is arranged in the container filled with etchant solution; a counter electrode isolation system is also arranged in the container filled with etchant solution, and is used for isolating the copper ring counter electrode from the tungsten filament; and the copper ring counter electrode and the tungsten filament are respectively connected with the cathode and anode of a digital control DC source. Based on a dynamic electrochemical corrosion principle, the preparation apparatus and method of an ultra-low roughness tungsten probe. The preparation apparatus of an ultra-low roughness tungsten probe can prepare an ultra-low roughness tungsten probe on the premise of effectively controlling the contour and the ratio length / diameter ratio of the probe point.

Owner:XI AN JIAOTONG UNIV

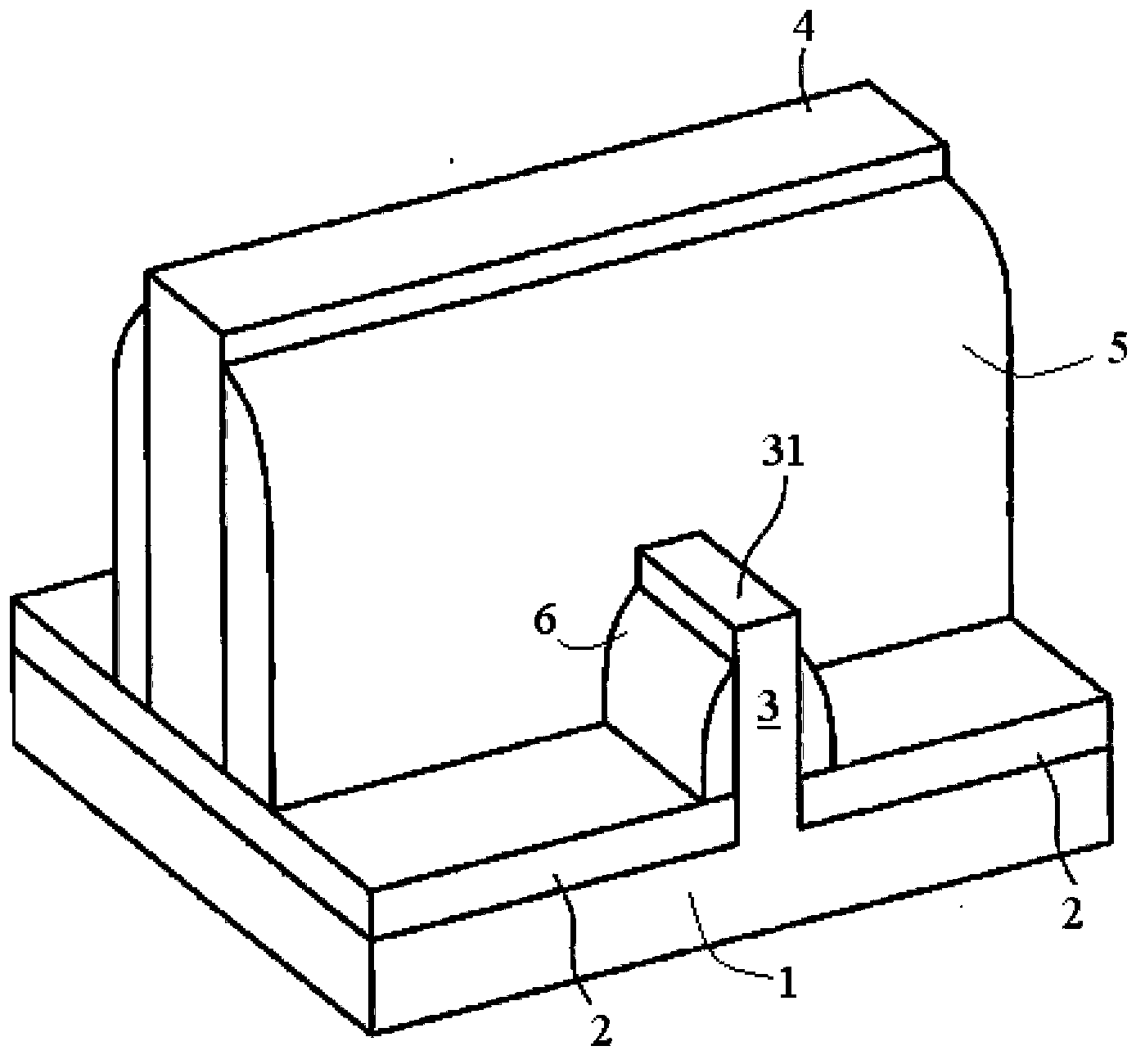

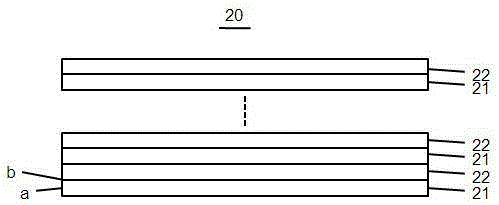

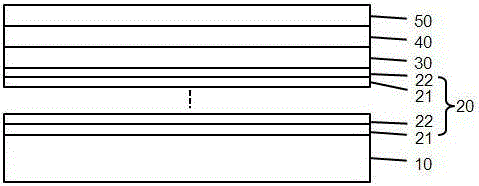

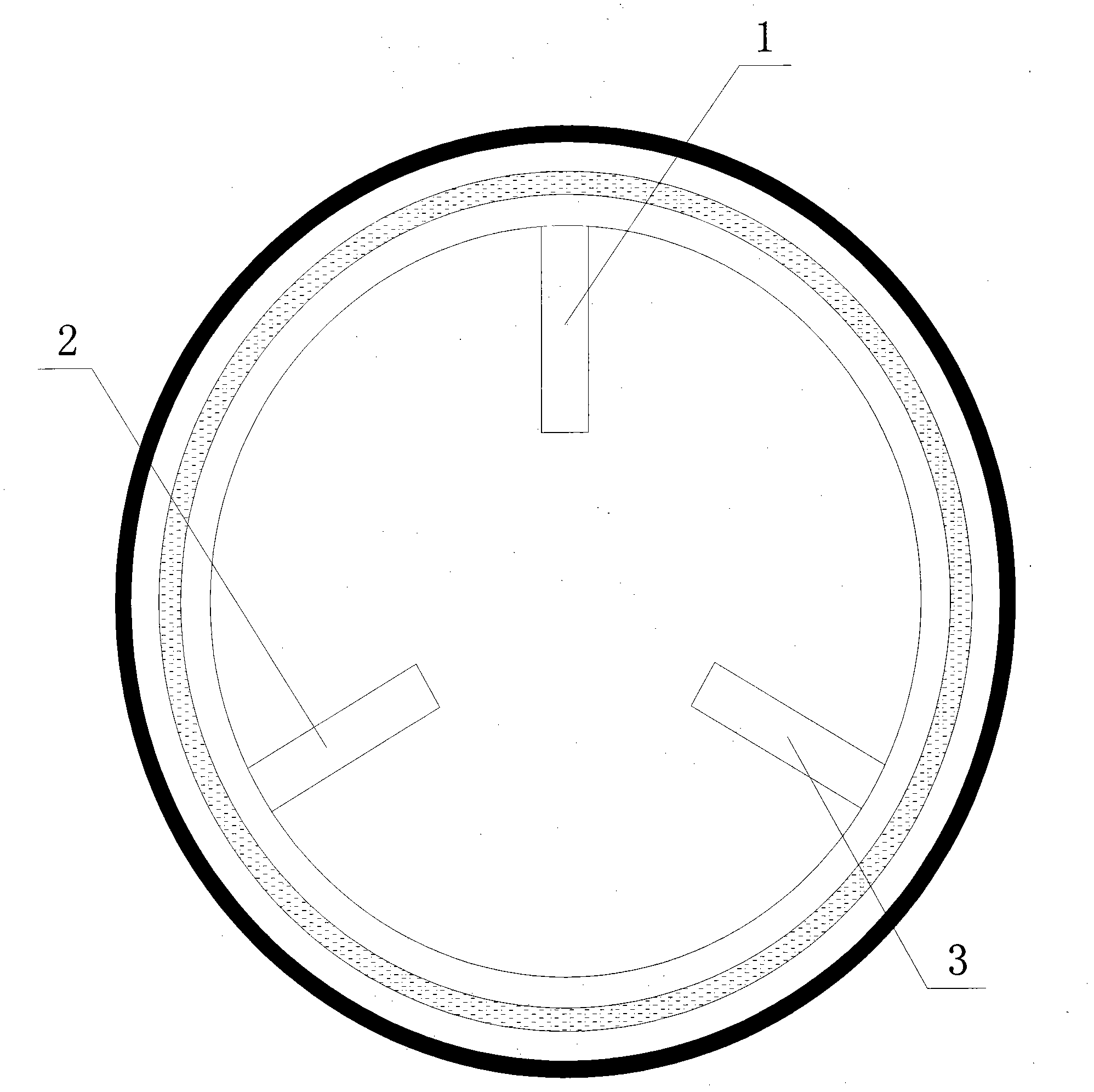

Cleaning device in front of chip potential barrier and cleaning process

ActiveCN107799446AAvoid excessive corrosionEasy accessFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMoisture

The invention provides a cleaning device in front of a chip potential barrier and a cleaning process, relates to the field of fabrication of integrated circuits, and specifically relates to a cleaningprocess in front of the chip potential barrier. Provided are a cleaning device in front of the chip potential barrier, which facilitates processing, effectively removes moisture, and improves the product quality, and a cleaning process. The cleaning device comprises a box body, the middle of the box body is provided with a support bench driven by a driver, the support bench is provided with a plurality of frames uniformly arranged in an annular manner, the frames are used for placing a plurality of wafers, the top of the box body is hinged to a box cover, the center of the box cover is provided with a spraying pipe, the spraying pipe, located at the upper portion of the box cover, communicates with a first pipeline and a second pipeline, and the spraying pipe, located at the lower portionof the box cover, is provided with a plurality of nozzles. According to the cleaning device and the cleaning process, the operation is reliable, and the product quality is guaranteed.

Owner:YANGZHOU YANGJIE ELECTRONIC TECH CO LTD

Suspension type waterborne grinding fluid preparation method

ActiveCN106281044AWon't scratchMany originsOther chemical processesPolishing compositions with abrasivesMontmorilloniteColloid

The invention provides a suspension type waterborne grinding fluid preparation method. The preparation method comprises the step one of preparing sub-nanometer montmorillonite suspension liquid; the step two of evenly mixing a dispersing agent, a chelating agent, a lubricating agent, an antirust agent and water according to a proportion to obtain a mixture; the step three of evenly mixing the suspension fluid and the mixture according a proportion to obtain suspension type waterborne grinding liquid. According to the preparation method, the sub-nanometer montmorillonite is utilized as a suspension agent, the colloid dispersion and the lamella adsorption property of particles of the montmorillonite are utilized, and the suspension dispersion montmorillonite colloid has a suspension and adsorption effect on abrasive micro powder when the abrasive micro powder is used. Due to the stability of the montmorillonite colloid, the grinding fluid also has a good suspension effect even if the grinding fluid is diluted by 20 times or more. Thus, the effects that the abrasive micro powder is good in suspension, low in viscosity and high in machining precision are achieved, the grinding fluid has the advantages of being low in cost, strong in dilution capacity and easy to clean, and the raw materials of the grinding fluid are easy to obtain.

Owner:XIAN BOER NEW MATERIAL CO LTD

Surface treatment process of 6063 aluminum alloy profile

The invention discloses a surface treatment process of a 6063 aluminum alloy profile, and relates to the related technical field of aluminum alloy profile production and processing. The process comprises the following steps of A, cutting; B, sand blasting, C, oil removing, D, washing, E, alkali washing, F, neutralizing, G, oxidizing, H, hole sealing, I, airing, and J, forming. Compared with a traditional acid etching process, the process has the advantages that pollution is less, aluminum material is more saved, the overall quality of the aluminum material is guaranteed, and the utilization rate of the aluminum material is higher; when the 6063 aluminum alloy is processed through a soaking pool, NaF is added into an alkali etching agent, so that the outer surface of the 6063 aluminum alloycan be effectively sealed, and the problem of uneven corrosion on the outer surface of the 6063 aluminum alloy is solved; and the gluconate is added into the alkali etching agent, through the gluconate, the leveled surface reduction efficiency of the 6063 aluminum alloy can be improved when the 6063 aluminum alloy is soaked and processed, so that the outer surface of the 6063 aluminum alloy is more leveled.

Owner:国际铝业(厦门)有限公司

Environment-friendly water-based metal cleaner

The invention discloses an environment-friendly water-based metal cleaner. The environment-friendly water-based metal cleaner comprises the following components: 4-10g / L of surfactant, 1-10g / L of alkali compound, 1-10g / L of nitrate, 1-10g / L of phosphate and 1-5g / L of amine salt. By adopting the cleaner, the oil removing effect on the surface of a workpiece is increased, simultaneously the corrosion to the workpiece is low and the cleaning residual solution hardly causes environmental pollution.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Composition for finishing polish of silicon wafer and preparation method of composition

InactiveCN104530987AEnhance the firmness of the packageAchieve near-limit polishingSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesDispersityCompound (substance)

The invention relates to a composition for finishing polish of a silicon wafer and a preparation method of the composition and relates to the field of chemical mechanical polishing. The composition comprises silicon dioxide sol, a hydroxyl nitrogen-containing alkaline compound, a hydroxyl carboxyl acidic compound, an alkaline compound, a high-molecular compound, a surfactant and deionized water, wherein the particle size of grinding particles in the silicon dioxide sol is 0.1nm to 10nm. According to the composition disclosed by the invention, polishing particles of which the particle size is reduced to a plurality of nanometers are adopted, the hydroxyl nitrogen-containing alkaline compound and the hydroxyl carboxyl acidic compound for stabilizing the polishing particles are also adopted, and the components have the function of effectively maintaining the stability and dispersity of particles, so that the precision and quality of the polished surface of the silicon wafer are improved.

Owner:SHENZHEN LEAGUER MATERIAL +2

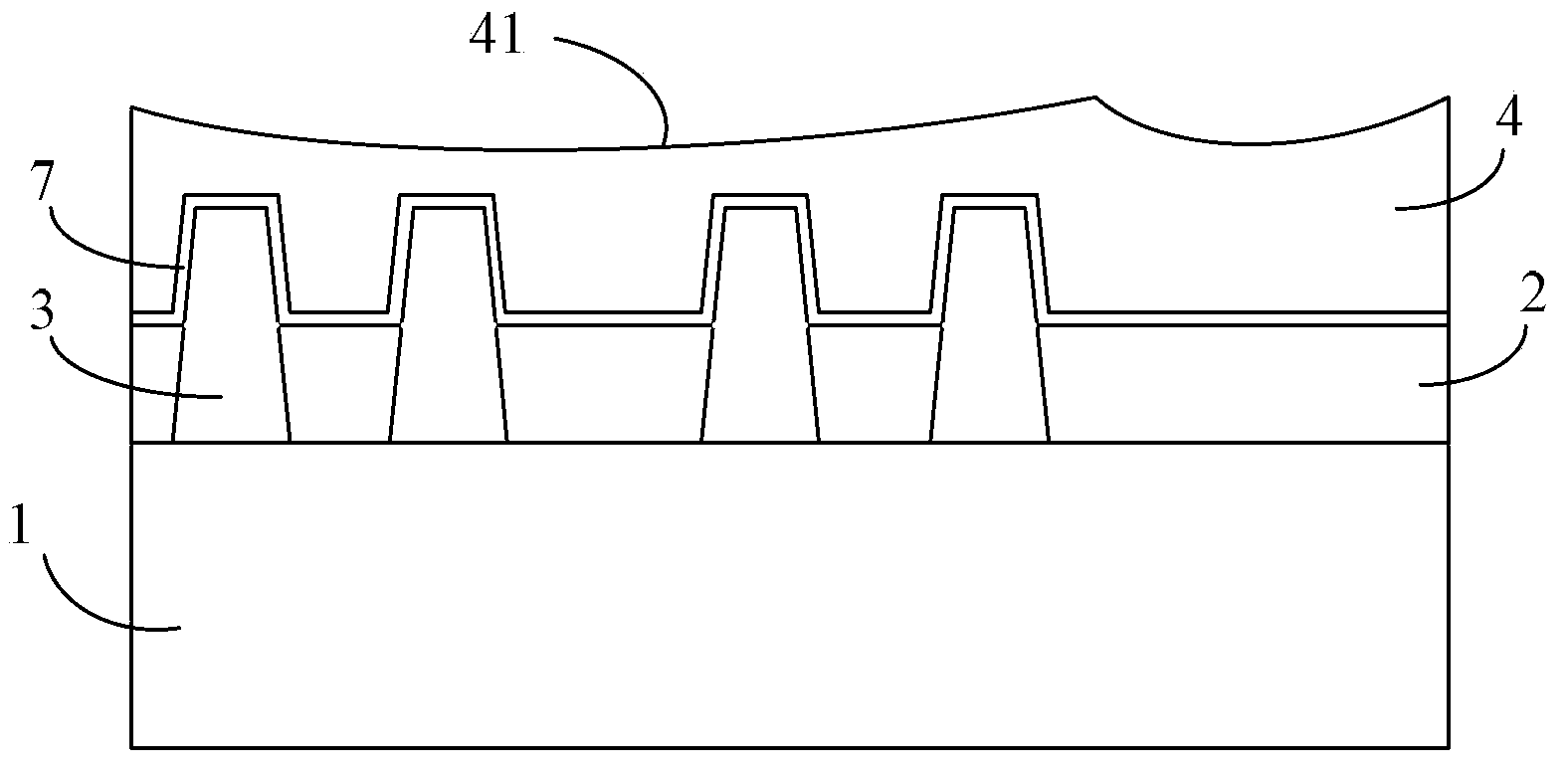

Method for forming semiconductor device and method for forming fin field effect transistor

ActiveCN104282564AHighly consistentImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceSemiconductor materials

The invention provides a method for forming a semiconductor device and a method for forming a fin field effect transistor. According to the method for forming the semiconductor device, the position on the surface of a semiconductor material layer at a device dense area of a semiconductor substrate is higher than the position of a semiconductor material layer at a device sparse area, hence, the semiconductor material layer at the device sparse area is covered with a mask layer, ions are injected to the partial thickness part of the semiconductor material layer at the dense area, so that an ion injection area is formed, and then the ion injection area is removed. After the ions are injected, the characteristic of a semiconductor material in the ion injection area is changed, the character of the ion injection area of the semiconductor material layer differs from the character of a nonionic injection area of the semiconductor material layer, the semiconductor material layer with the nonionic injection area is hardly affected in the subsequent removing process of the ion injection area, accordingly, the heights of the semiconductor material layers at the device sparse area and the device dense area are close to be the same ultimately, and therefore the performance of the semiconductor device is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

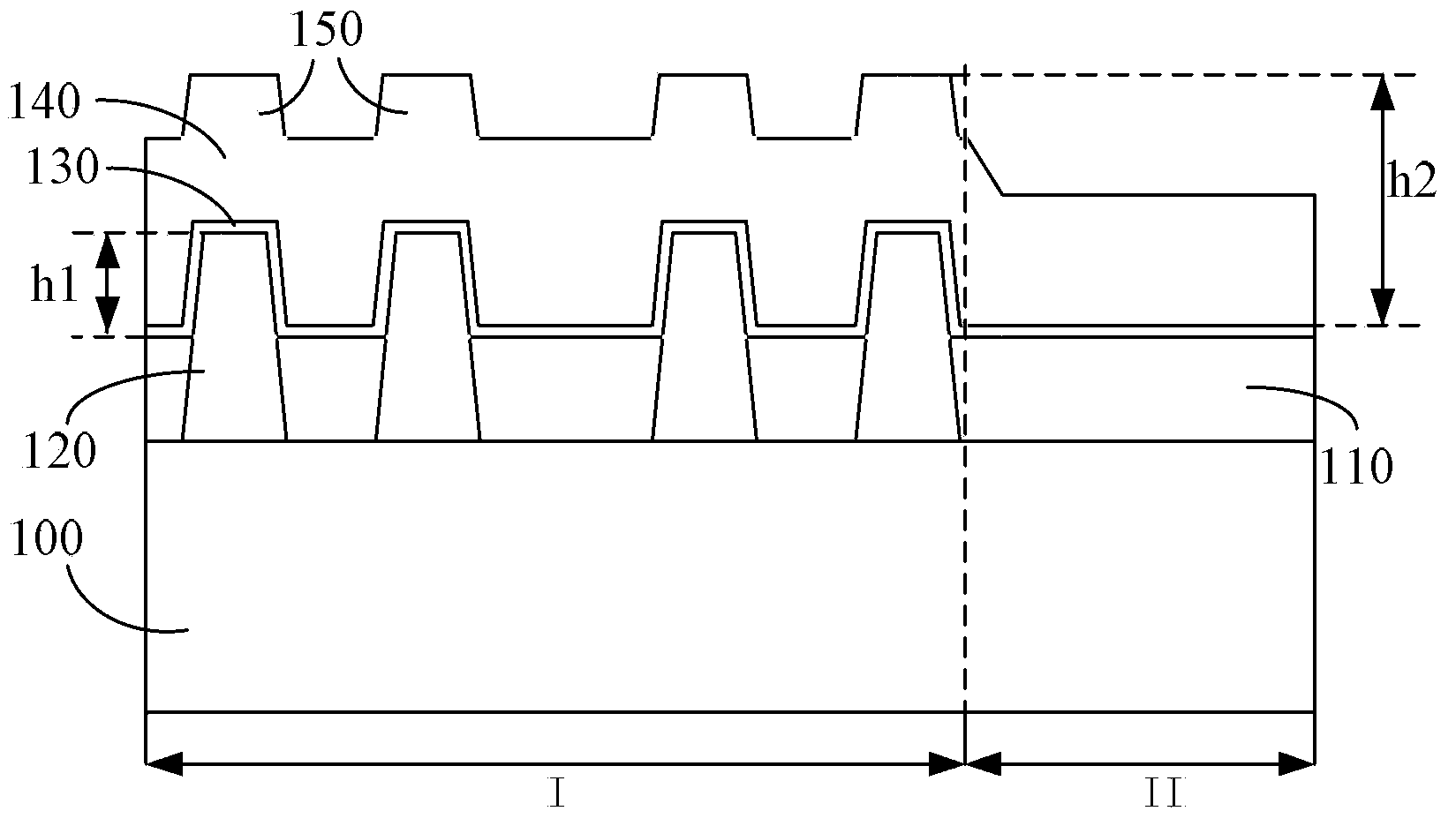

Method for manufacturing flash memory control grid

InactiveCN102024764AGuaranteed heightAvoid excessive corrosionSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon oxideSemiconductor

The invention discloses a method for manufacturing a flash memory control grid, which comprises the following steps of: dividing a semiconductor substrate into a core device area and a peripheral circuit area, and forming shallow trench isolation between the core device area and the peripheral circuit area on the semiconductor substrate; forming a tunnelling oxide layer on the surface of the semiconductor substrate; depositing and etching a first polysilicon layer, forming a floating grid and a selection grid in the core device area, and forming a peripheral circuit area control grid in the peripheral circuit area of the core device area; forming silicon oxide / silicon nitride / silicon oxide (ONO) layers on the surfaces of the first polysilicon layer and the tunnelling oxide layer; depositing a second polysilicon layer on the ONO layer; etching the second polysilicon layer above the peripheral circuit area to reach the surface of the ONO layer; and etching the rest second polysilicon layer above the peripheral circuit area again completely. Therefore, the height of the first polysilicon layer is retained to prevent ions from passing through the first polysilicon layer when subsequent ion implantation is performed, and thus, the physical properties of devices are retained.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Semiconductor element and preparation method thereof

ActiveCN105261681AImprove corrosion resistanceCorrosion resistanceSolid-state devicesSemiconductor/solid-state device manufacturingChemical solutionPhysical chemistry

The invention provides a semiconductor element, which comprises a superlattice structure buffer layer including an Al<x>N<1-x> layer and an Al<y>O<1-y> layer (both x and y are less than 1 and greater than 0). According to the superlattice structure buffer layer, the corrosion degree of a chemical solution can be reduced and the chip yield is improved in a side wall corrosion process of a chip manufacturing process. Meanwhile, the invention provides a preparation method to prepare the superlattice structure buffer layer. The effects of the semiconductor element are achieved.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

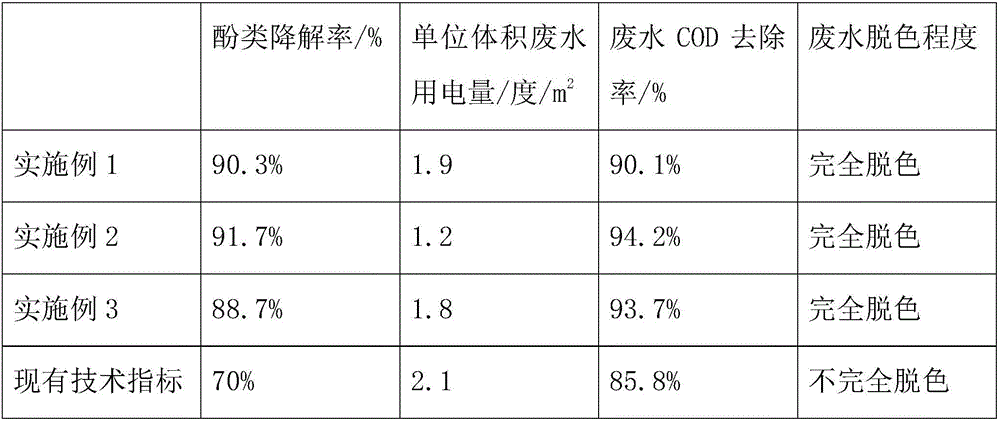

Phenol-containing wastewater treatment process

InactiveCN105858823AHighly corrosiveAvoid excessive corrosionWater contaminantsWater/sewage treatmentSolubilityCopper electrode

The invention discloses a phenol-containing wastewater treatment process. In step (1), the time for rinsing a titanium plate with hydrofluoric acid is 4 seconds; the hydrofluoric acid is highly corrosive to the titanium plate and can remove an oxide film on the surface of the titanium plate, so as to remove the oxide film within 4 seconds and prevent the excessive corrosion of the titanium plate; an organic solvent in step (1) is absolute ethyl alcohol; the solvent has excellent solubility, can remove oil on the surface of the titanium plate, and is low in price and extensive in source; in step (2), the titanium plate is vertically placed in a hydrothermal reaction kettle, so that copper oxide films can grow on and be attached to both sides of the titanium plate; in step (3), a cathode adopts a copper electrode, wherein the electrode has performances close to a platinum electrode, but is lower in prices; sodium sulfate is added to the phenol-containing wastewater before degradation in step (3) and can be used as an electrolyte, so that the degradation efficiency is improved.

Owner:ANHUI GUONENG YISHENG ENVIRONMENTAL PROTECTION SCI & TECH

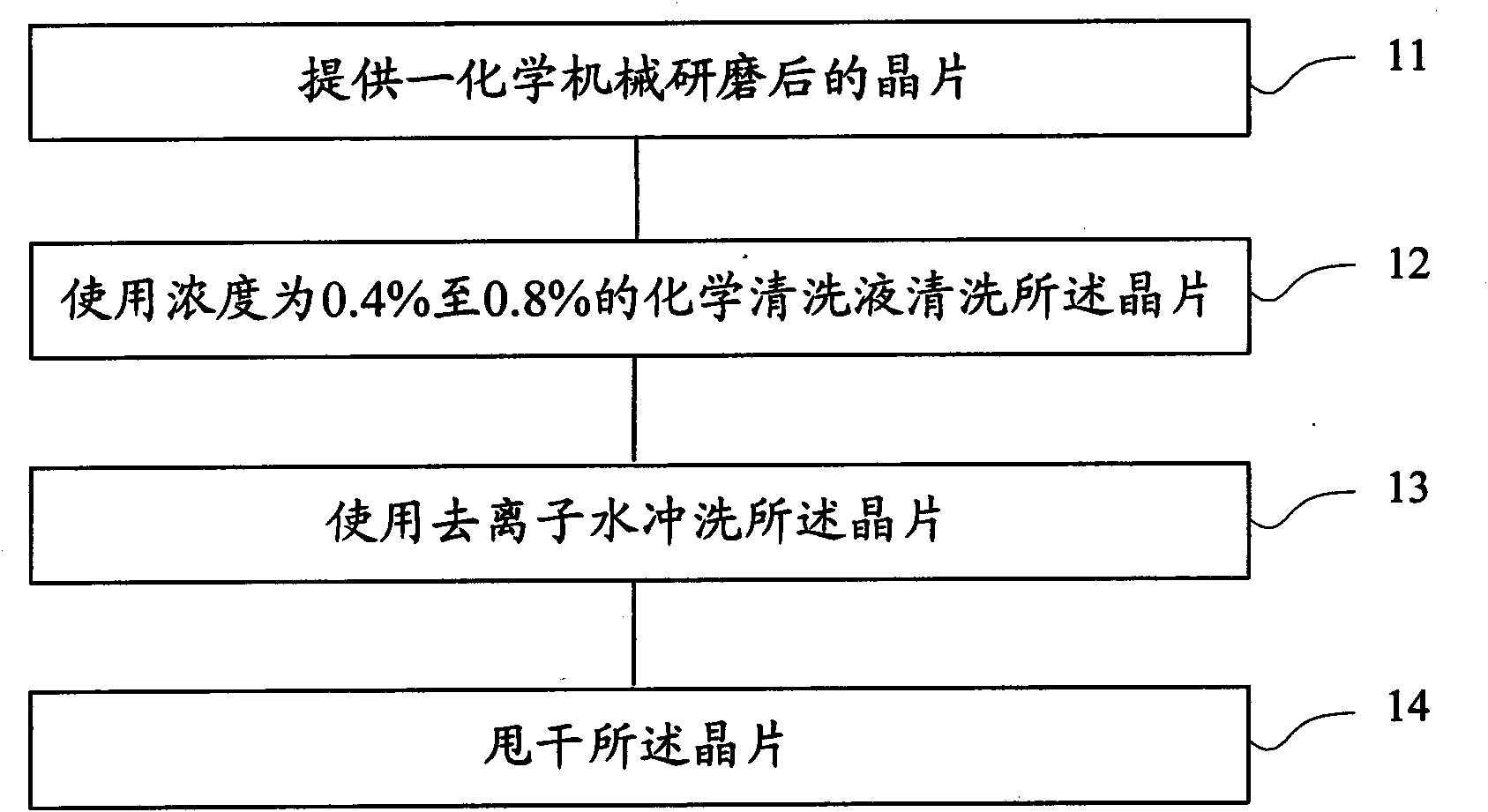

Method for cleaning wafer after chemical mechanical polishing

InactiveCN101905221AAvoid excessive corrosionAvoid Pit DefectsSemiconductor/solid-state device manufacturingCleaning using toolsCompound (substance)Engineering

The invention discloses a method for cleaning a wafer after chemical mechanical polishing, comprising the following steps: providing a wafer after chemical mechanical polishing; and cleaning the wafer by using a chemical cleaning solution, wherein the concentration of the chemical cleaning solution is 0.4-0.8%. The method in the invention can effectively avoid the wafer surface from occurring pit-shaped defects, achieve better residue removal effect after chemical mechanical polishing and improve the reliability and stability of a semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

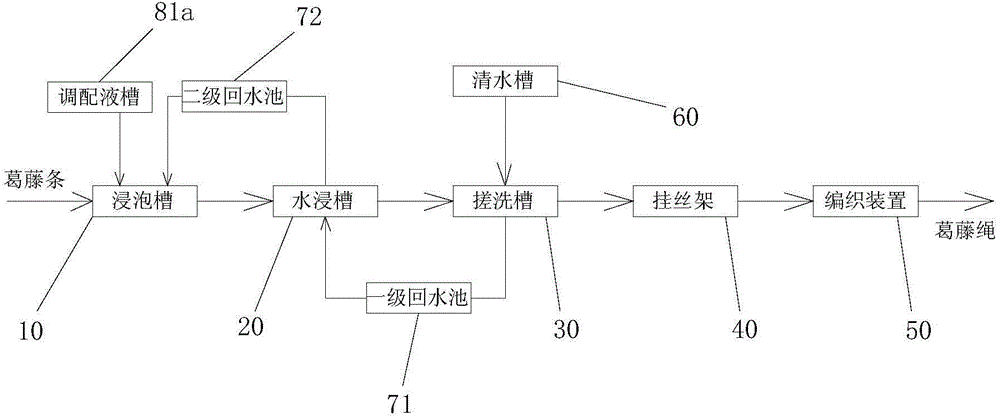

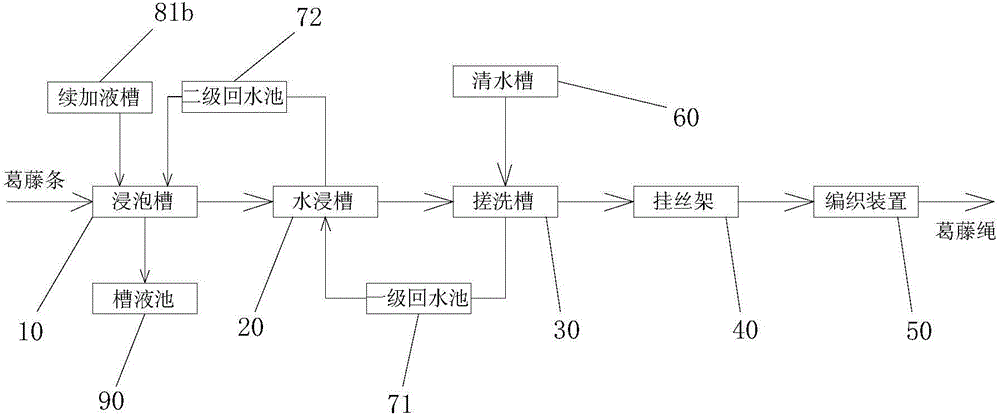

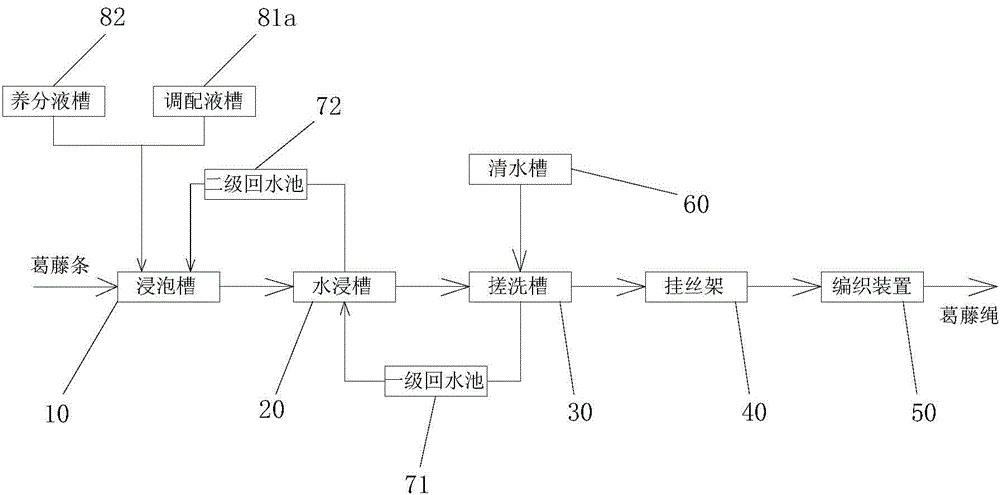

New process for preparing kudzu vine rope

ActiveCN104942925AImprove qualityHigh strengthCane mechanical workingReed/straw treatmentFiberBlack spot

The invention discloses a new process for preparing a kudzu vine rope. The new process comprises steps as follows: soaking kudzu vines, peeling the soaked kudzu vines, rubbing and washing peeled kudzu vine barks, soaking kudzu vine bark fiber in a wormwood extract liquid, dividing the soaked kudzu vine bark fiber, drying the divided kudzu vine bark fiber in the sun and weaving the divided kudzu vine bark fiber into the rope. Compared with a traditional process, the kudzu vine twined rope prepared with the technique has advantages as follows: a layer of pond silt is laid at the bottom of a soaking pond and is rich in flora capable of decomposing organic matters, the floras decompose colloid and other organic matters on the kudzu vine barks, the soaking time is shortened, the kudzu vine barks can be separated from lignin parts of the kudzu vines, and accordingly, follow-up peeling is facilitated; besides, the skin layer can be effectively decomposed due to decomposition of the organic matters, no black spots are left on the left kudzu vine fiber through follow-up rubbing and washing, and the quality of the kudzu wine fiber is improved.

Owner:中知永慧知识产权运营(烟台)有限公司

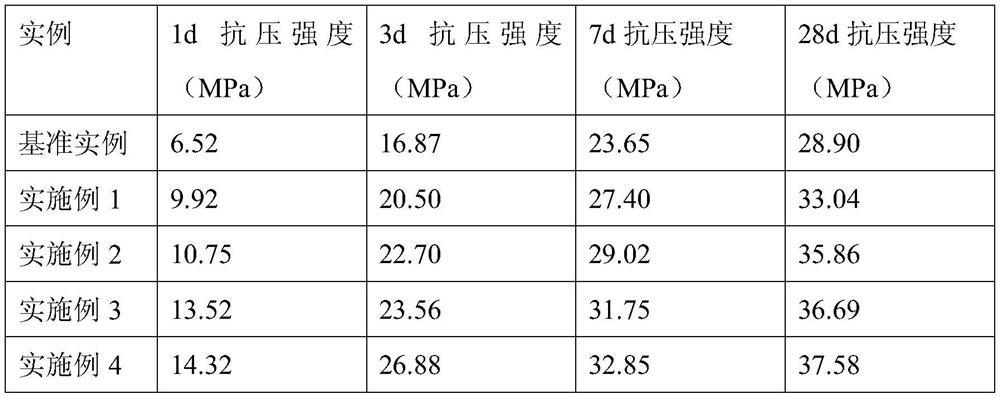

Preparation method of modified recycled coarse aggregate

The invention discloses a preparation method of modified recycled coarse aggregate. The preparation method comprises the following steps of: soaking a recycled coarse aggregate obtained by crushing and screening waste concrete in clear water, cleaning and airing the recycled coarse aggregate; fully soaking the recycled coarse aggregate into a silicon slag emulsion, adding limestone powder into thesilicon slag emulsion, performing continuous stirring, and uniformly mixing the limestone powder with the silicon slag emulsion; and further performing slow stirring for a period of time, fishing outthe recycled coarse aggregate, and naturally draining the recycled coarse aggregate to obtain the modified recycled coarse aggregate. The silicon slag emulsion is a non-layered mixed solution obtained by ultrasonically dispersing acidic silicon slag particles with recovered zirconium in water uniformly. The silicon slag emulsion is utilized to modify the recycled coarse aggregate, and therefore,the moisture absorption of the recycled coarse aggregate can be reduced, and the water absorptivity of the recycled coarse aggregate can be lowered; meanwhile, when the modified recycled coarse aggregate is used for preparing recycled concrete, the early strength and the mechanical property of the concrete are improved. The method is simple in operation process and low in cost, and has very high economic value and application value.

Owner:山东鲁桥建材有限公司

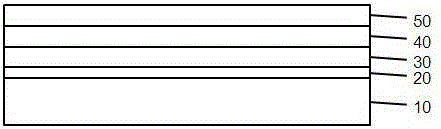

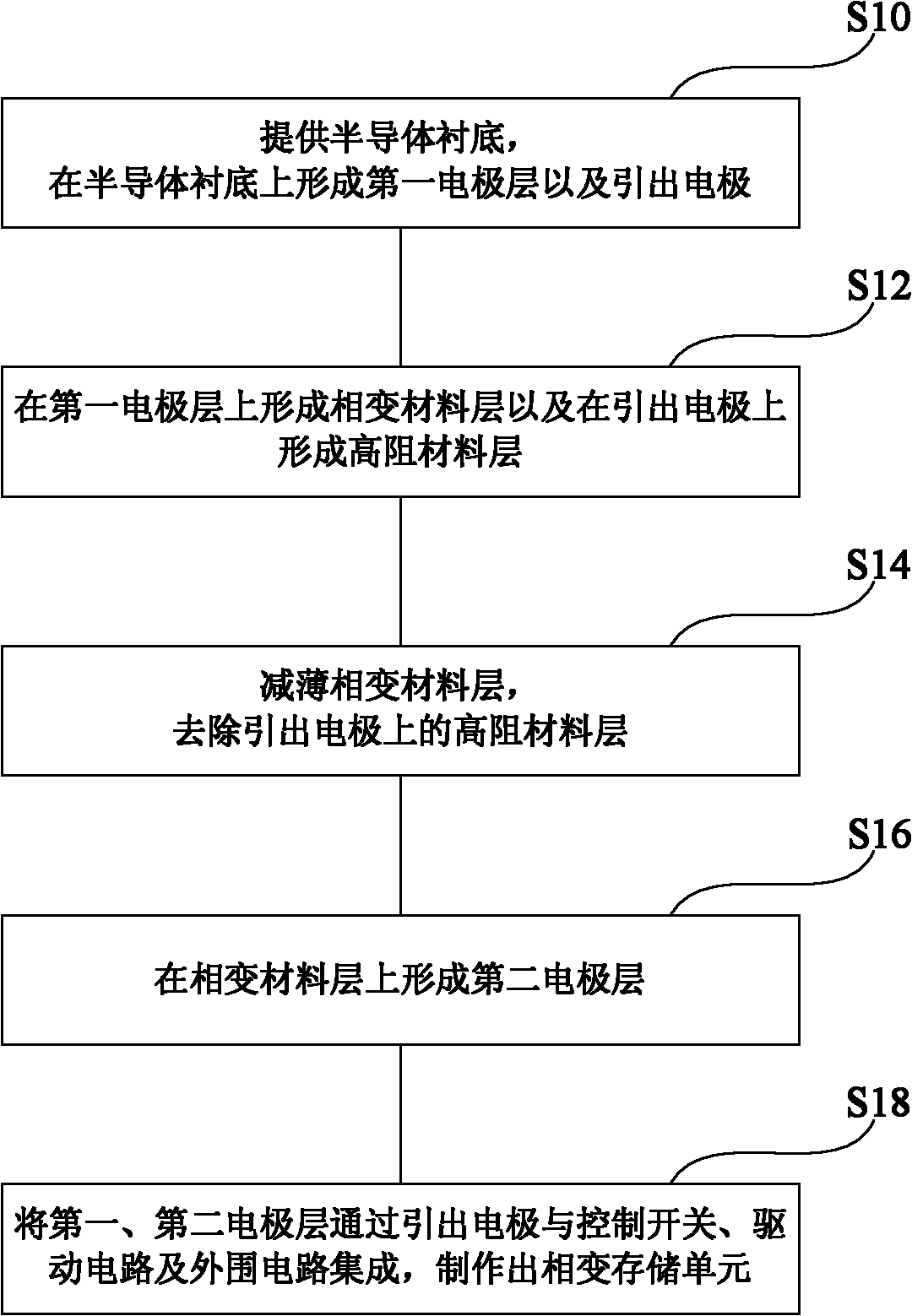

Phase change memory cell and producing method thereof

ActiveCN102593350AIncrease storage capacityImprove yieldSolid-state devicesDigital storageHigh resistancePhase-change memory

The invention provides a phase change memory cell and a producing method thereof, the phase change memory cell comprises a semiconductor substrate, a first electrode layer, a phase-change material layer, a second electrode layer, an extraction electrode and a high-resistance material layer, wherein the high-resistance material layer is used for preventing the phase-change material layer from being excessively corroded in the process of chemical mechanical polishing, the resistance of the high-resistance material layer is at least ten times of or above that of the phase-change material layer, the phase-change material layer can be prevented from being excessively corroded in the process of chemical mechanical polishing and the memory performance and yield of the phase change memory cell are increased.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

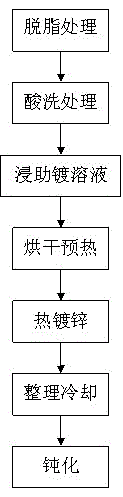

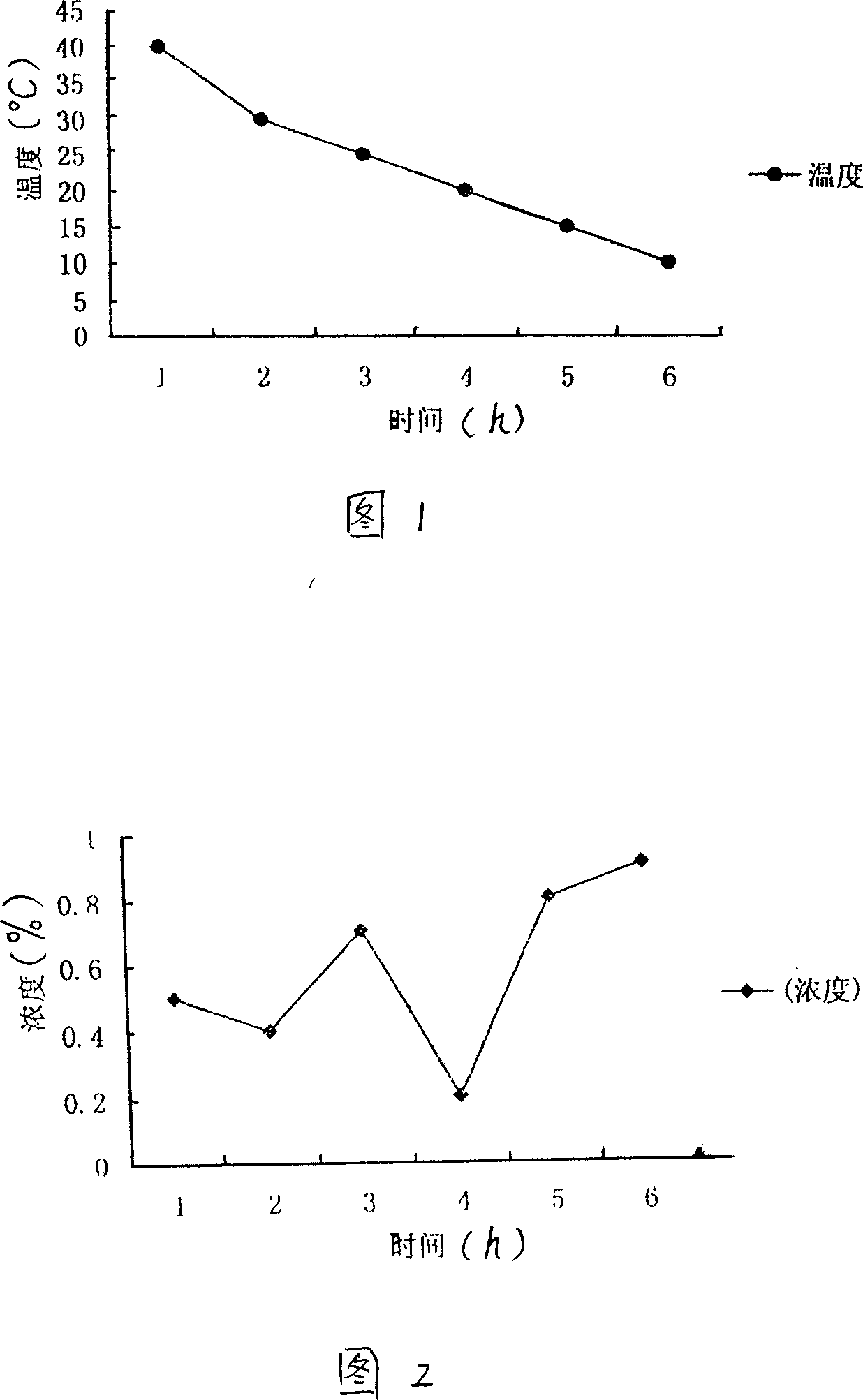

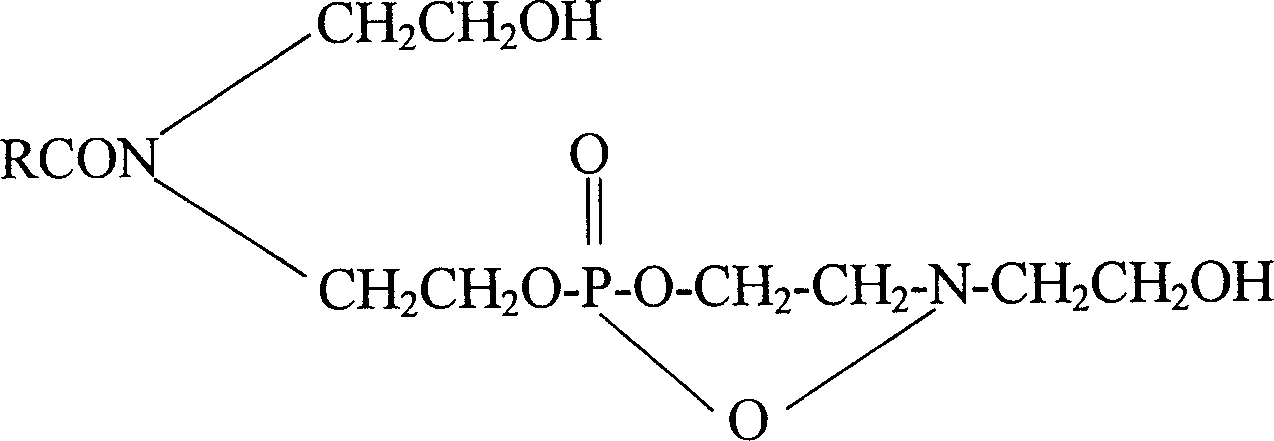

Surface galvanizing technology for guide hook of drop-out fuse

InactiveCN102912274AAvoid excessive corrosionImprove surface activityHot-dipping/immersion processesEvaporationEngineering

The invention discloses a surface galvanizing technology for a guide hook of a drop-out fuse, comprising the following steps: 1) ungrease treatment; 2) cleanup acid treatment; 3) plating solubilizing assistant immersion; 4) drying prewarming; 5) hot galvanizing; 6) finishing cooling; and 7) passivating. According to the technology, a corrosion inhibitor is added to acid cleaning liquor so that the over corrosion when the guide hook is acid-cleaned can be prevented and the hydrogen absorption amount of an iron substrate is reduced; a small amount of glycerin is added to plating solubilizing assistant so that the activity of the surface of the guide hook can be promoted and the evaporation of the plating solubilizing assistant is reduced; and tiny metallic aluminium is added to galvanizing flux so that the flowing of the galvanizing flux can be strengthened, the over thickness of a cladding layer is prevented and the appearance of the cladding layer is improved. Through the technology, the guide hook of the drop-out fuse can achieve the cladding layer with good uniformity; the cladding layer is not easy to drop out and has good tenacity, elasticity, abrasion resistance and corrosion resistance; and the cladding layer is incapable of becoming rusty under outdoor conditions.

Owner:CHANGSHU QIANGSHENG PUNCHING

Non-corrosive steel pickle acid catalyst and process for preparing the same

InactiveCN1970147AReduce dosageIncrease profitOrganic-compounds/hydrides/coordination-complexes catalystsComplexonsCarboxylic salt

It relates to nitrate hydrofluoric acid for washing stainless steel surface oxide skins. It aims to solve the acid mist generated in the process of acid pickling stainless oxidization layer through nitrate or hydrogen fluoride, made of aliphatic alcohol polyvinyl ether 80-220%., alkylamino carboxylate surfactant 60-180%., sodium benzoate 10-60%., complexon 2-30%. and water for the rest with their percentage by weight. Heating the mixture of material to the temperature 50-80 DEG C and blend evenly. It can prohibit acid mist in acid pickling, speeding up the elimination of metal oxidization layer, avoiding corrosion to the metal, reducing acid consumption with improved acid application efficiency.

Owner:北京长航伟业环保科技有限公司

Aluminum veneer processing process

InactiveCN109440121AGood weather resistanceImprove corrosion resistanceMetallic material coating processesWeather resistancePre washing

The invention relates to an aluminum veneer processing process and belongs to the technical field of aluminum veneer building decoration materials. The aluminum veneer processing process comprises thesteps that sheet metal processing is conducted, and an aluminum veneer is prewashed in the sheet metal processing process; and the aluminum veneer after sheet metal processing is sequentially subjected to acid pickling, passivation and spraying, wherein alkaline washing liquid is adopted during pre-washing and chromate-free passivation liquid is adopted during passivation. The process has the effects that the process is simple, environmentally friendly and safe, and the aluminum veneer obtained by processing is stable in quality and good in chemical corrosion resistance and weather resistance.

Owner:成都四吉达新材料科技有限公司

Chemical deplating composition of nickel-copper alloy layer for circuit board and deplating method thereof

The invention discloses a chemical deplating composition of a nickel-copper alloy layer for a circuit board and a deplating method thereof. The deplating composition comprises 50-80g / L of sodium 3-nitrobenzene sulfonate, 10-20g / L of cyclohexane-diamine-tetraacetic acid, 2-5g / L of octyl hydroximic acid, 5-10g / L of ammonia water and water, wherein the pH value is 7.2-7.5. The deplating method comprises the following steps: (1) successively dissolving the component sin water to obtain an aqueous solution, then adding ammonia water, and controlling the pH value of a deplating solution at 7.2-7.5;(2) soaking a circuit board of a PBC / Sn / NiCu structure in the deplating solution prepared in the step (1);(3) taking the circuit board in the step (2) out and ultrasonically cleaning the circuit boardwith water and drying the same; (4) soaking the surface of the circuit board in the step (3) in a formic acid aqueous solution; and (5) taking the surface of the circuit board in the step (3) out, and ultrasonically cleaning the circuit board with water and drying the same. A metal tin layer is unlikely to be corroded in the deplating process, no harmful gas is generated, and the environmental pollution is reduced; the cost is lowered, the process is simple, and actual production is facilitated; and the chemical deplating composition is clear to deplate and good in effect.

Owner:深圳市天熙科技开发有限公司

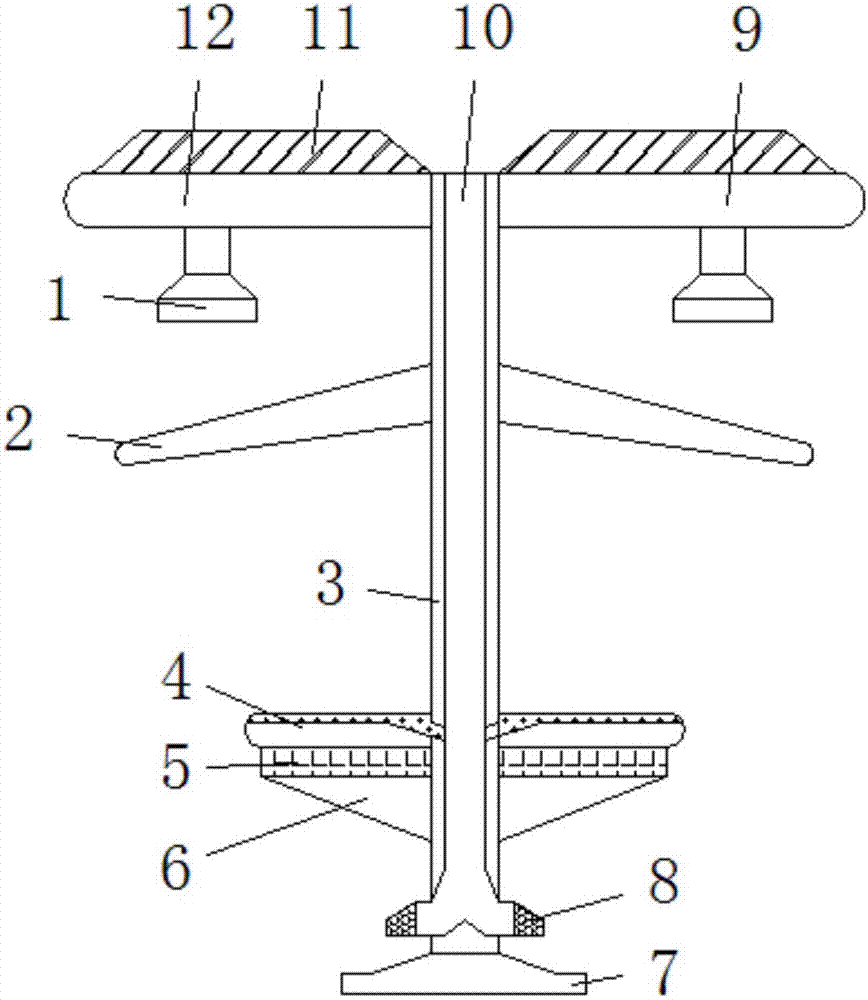

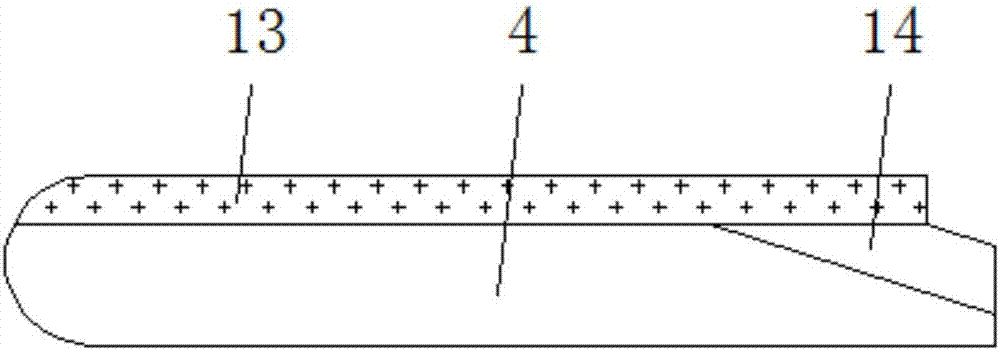

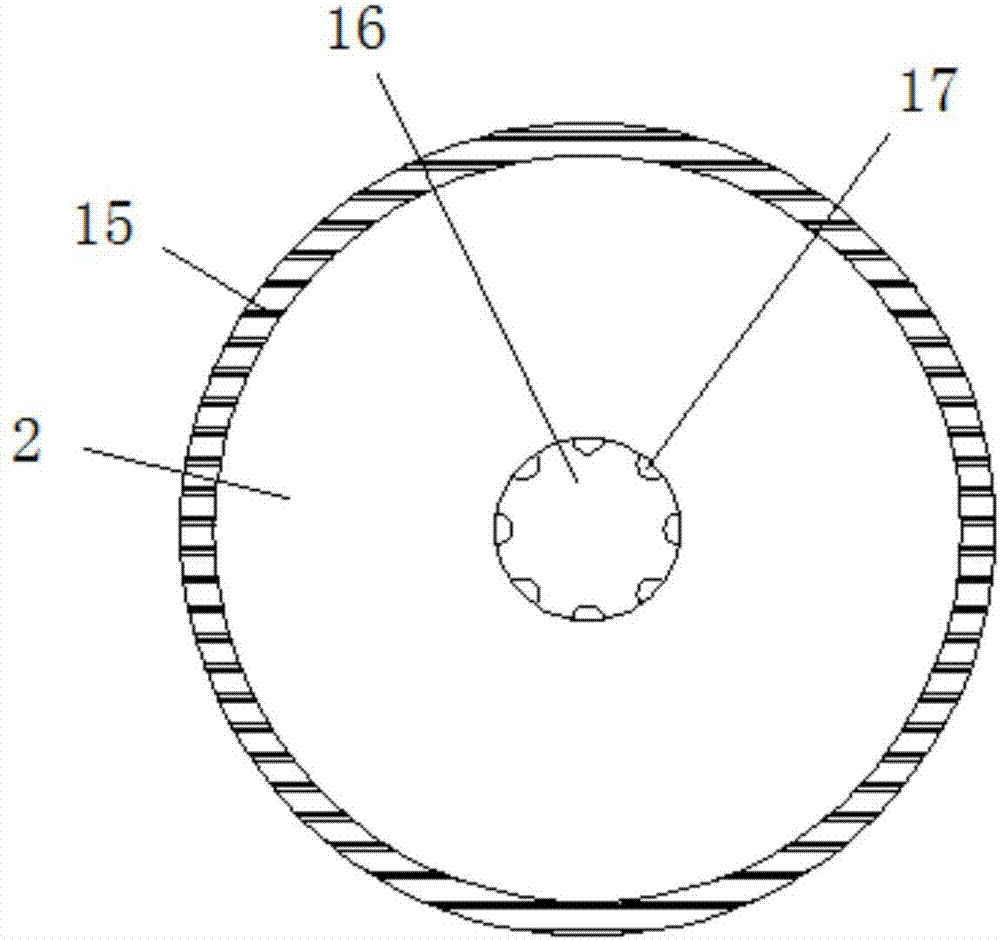

Rainproof campus road illumination street lamp with adjustable height

InactiveCN107489948ARelieve pressureExtended service lifeMechanical apparatusLighting support devicesEngineering

The invention discloses a campus road lighting street lamp capable of preventing rain and adjusting height, which comprises a support column, a first bracket and a second bracket are welded on the top of the support column, and a first bracket and a second bracket are welded on the bottom of the first bracket and the second bracket. Lighting lamps, the top of the first bracket and the second bracket are provided with a waterproof layer, the support column is buckled with the ceiling through the positioning rod in the clamping hole, and the outer surface of the ceiling is provided with a soft leather layer, and the support column An aqueduct is arranged inside, and a filter screen is provided at the bottom of the aqueduct, seats are welded on both sides of the support column, and a hollow layer is provided on the upper surface of the seat, and the hollow layer passes through the guide tube and the guide in the support column. The water pipe is connected, the bottom of the seat is provided with an elastic plate, and the bottom of the elastic plate is provided with reinforcing ribs, and the bottom of the support column is welded with a base. In the present invention, the overall structure of the street lamp is simple and reasonable in design, has many functions, and has relatively low wear and tear on the joints, thus having strong practicability.

Owner:弘毅天承知识产权股份有限公司

Fixture and etching method for one-sided area etching

PendingCN109244031AEasy dischargeImprove flatnessSemiconductor/solid-state device manufacturingFinal product manufactureWater bathsEtching

The invention relates to a fixture and an etching method for one-sided area etching. The fixture comprises an upper part of the fixture, an upper end of the fixture is open, and a bottom part is provided with a through hole; A slide is positioned below the upper part of the jig; An O-ring group positioned between the upper part of the jig and the carrier sheet and positioned below the through hole; The O-ring group comprises an outer O-ring for preventing the external water bath solution from entering and an inner O-ring for placing an etched chip inside the O-ring group and preventing the etching liquid from etching out; A clamping device for clamping the upper part of the clamping device and the carrier sheet. Further may include a pressure balancing ring, a magnetic rotor, a surface protective film, and the like. The invention realizes the single-side corrosion facing upward, facilitates the discharge of corrosion gas, can carry out reliable corrosion on part of the single-side areaof the chip, protects other areas from being affected, and can be stable and reliable under the condition of corrosion penetration.

Owner:PEKING UNIV

Spray valve control system of spray tower

ActiveCN102133502AAvoid excessive corrosionAvoid corrosion-free phenomenaOperating means/releasing devices for valvesUsing liquid separation agentAutomatic balancing valvesProgrammable logic controller

The invention relates to a spray valve control system of a spray tower. The spray valve control system of the spray tower comprises a water spraying electromagnetic valve, a gas spraying electromagnetic valve, a booster pump, a pressure gauge, a flow meter, an automatic regulating valve and a programmable logic controller (PLC), wherein at least two groups of electromagnetic valves (11, 12) whichare controlled by the PLC control water spraying and gas spraying; and a circulation control module is designed in the PLC to make each group of electromagnetic valves (11, 12) serve as the first group of valves sequentially to control the operation of spray valves. The system can send out an instruction automatically according to a preset time value to indicate that the electromagnetic valves control each spray valve to operate alternately for spraying and cooling, so that over-corrosion of the spray valve on a side and the wall of the spray tower is avoided; moreover, the PLC can change theratio of a water pressure to a gas pressure automatically, so that an atomization effect is better.

Owner:SNTO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com