Phase change memory cell and producing method thereof

A technology of phase change storage and manufacturing method, which is applied in the field of phase change storage unit introducing high-resistance materials and its production, which can solve problems such as failure and performance degradation of phase change storage unit, so as to avoid excessive corrosion, improve storage performance and finished products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

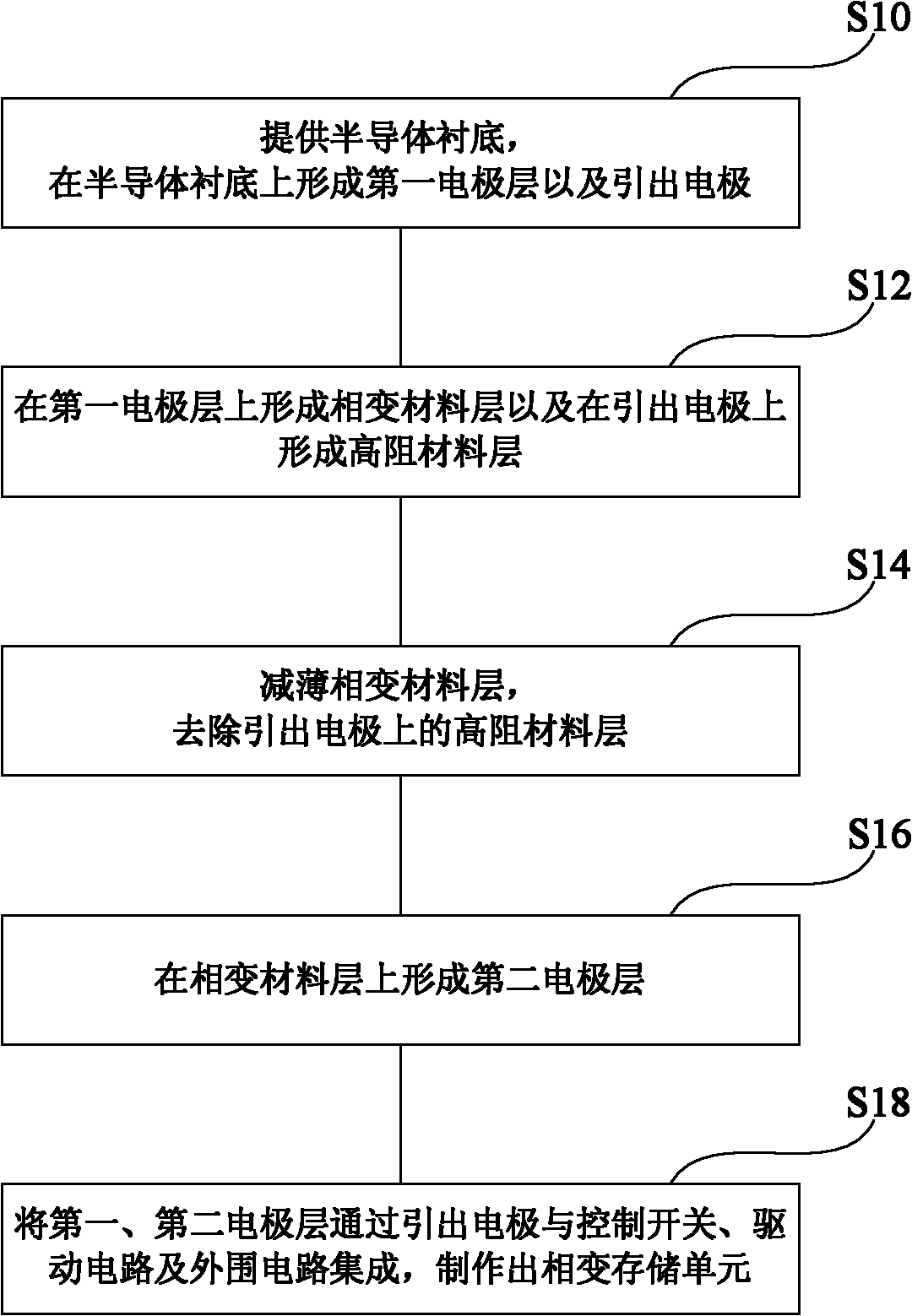

[0027] see figure 2 , which shows a schematic flow chart of the first embodiment of the manufacturing method of the phase-change memory cell provided by the present invention. like figure 2 As shown, the preparation method includes the following steps:

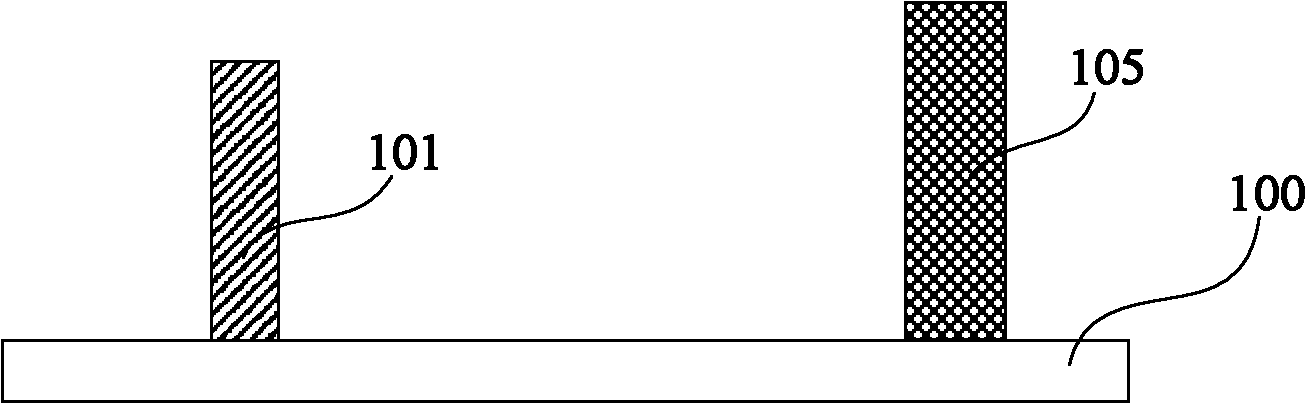

[0028] S10, providing a semiconductor substrate, forming a first electrode layer and an extraction electrode on the semiconductor substrate;

[0029] S12, forming a phase-change material layer on the first electrode layer and forming a high-resistance material layer on the extraction electrode;

[0030] S14, thinning the phase change material layer, and removing the high resistance material layer on the extraction electrode;

[0031] S16, forming a second electrode layer on the phase change material layer;

[0032] S18, integrating the first and second electrode layers with the control switch, drive circuit and peripheral circuits through the lead-out electrodes to manufacture a phase-change memory unit.

[0033] The co...

no. 2 example

[0053] see Figure 9 , which shows a schematic flow chart of the first embodiment of the manufacturing method of the phase-change memory cell provided by the present invention. like Figure 9 As shown, the preparation method includes the following steps:

[0054] S20, providing a semiconductor substrate, forming a first electrode layer and an extraction electrode on the semiconductor substrate;

[0055] S22, forming a high resistance material layer on the first electrode layer;

[0056] S24, forming a phase change material layer on the high resistance material layer and performing thinning treatment;

[0057] S26, forming a second electrode layer on the phase change material layer;

[0058] S28 , integrating the first and second electrode layers with the control switch, drive circuit and peripheral circuits through the lead-out electrodes to manufacture a phase-change memory unit.

[0059] The content of the present invention will be described in detail below in conjuncti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com