Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Avoid over corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning agent and cleaning method for air conditioner

InactiveCN101475878AImprove heating efficiencyImprove cooling efficiencyNon-ionic surface-active compoundsFlush cleaningStrong acidsHigh pressure water

The invention discloses a detergent and a cleaning method for a complete air-conditioner, which not only can uniformly and completely remove dirt but also cannot strongly corrupt components and parts such as aluminum, copper and stainless steel, are time-saving and labor saving, safe and reliable, and pollution-free, and have low cost. Raw materials of the detergent are at least two compositions of citric acid, inorganic weak acid and inorganic strong acid; a non-ionic surfactant or a non-ionic surfactant is mixed with an anionic surfactant; and the detergent comprises an oxygen solvent, an acid corrosion inhibitor, and the balance being water. The cleaning method comprises: disassembling a motor and a fan, and taking off the motor and the fan for independent cleaning; preparing the detergent into an aqueous solution according to the proportion of between 10 and 15 percent, hanging the complete air-conditioner after disassembly of the motor and the fan into a cleaning tank, soaking the complete air-conditioner for 30 minutes at normal temperature, and starting ultrasonic waves to clean for 10 to 30 minutes; placing the complete air-conditioner into a washing tank, and using a high-pressure water gun to spray the surface and the inside of the air-conditioner; and using hot blast to dry the air-conditioner at a temperature of 80 DEG C.

Owner:DALIAN SANDAAOKE CHEM

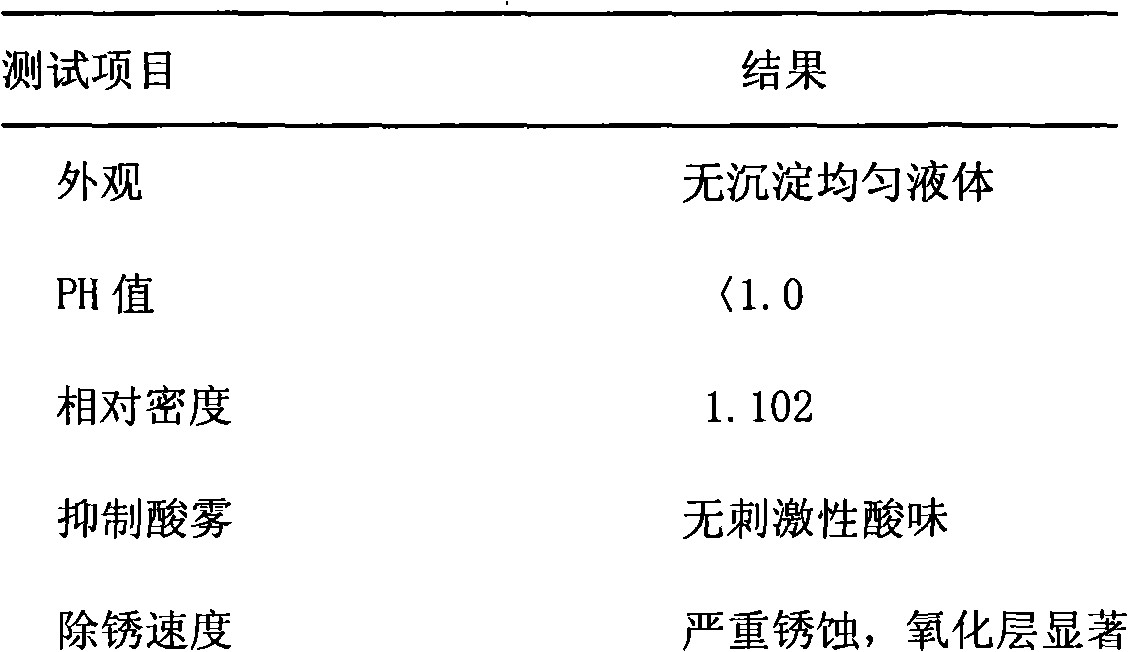

Acid-wash additive for iron and steel

The invention discloses an acid-wash additive for iron and steel. Every 4000g of the acid-wash additive is prepared from 200-250g of accelerator-oxalic acid or citric acid, 900-1000g of phosphoric acid, 200-250g of anionic surfactant-sodium lauryl sulfate, 150-200g of corrosion inhibitor-urotropine, 150-200g of mist inhibitor-nonylphenol polyethenoxy ether and the balance of water. The acid-wash additive is prepared by the following steps: evenly mixing phosphoric acid, anionic surfactant and water, adding the rest of components, and dissolving by stirring. The FSD-7001 acid-wash additive can further increase the derusting speed of hydrochloric acid, prevent iron and steel workpieces from generating over etching, reduce the acid consumption, inhibit acid mist, and enable the acid liquor to have certain oil removal function.

Owner:CHONGQING NORMAL UNIVERSITY

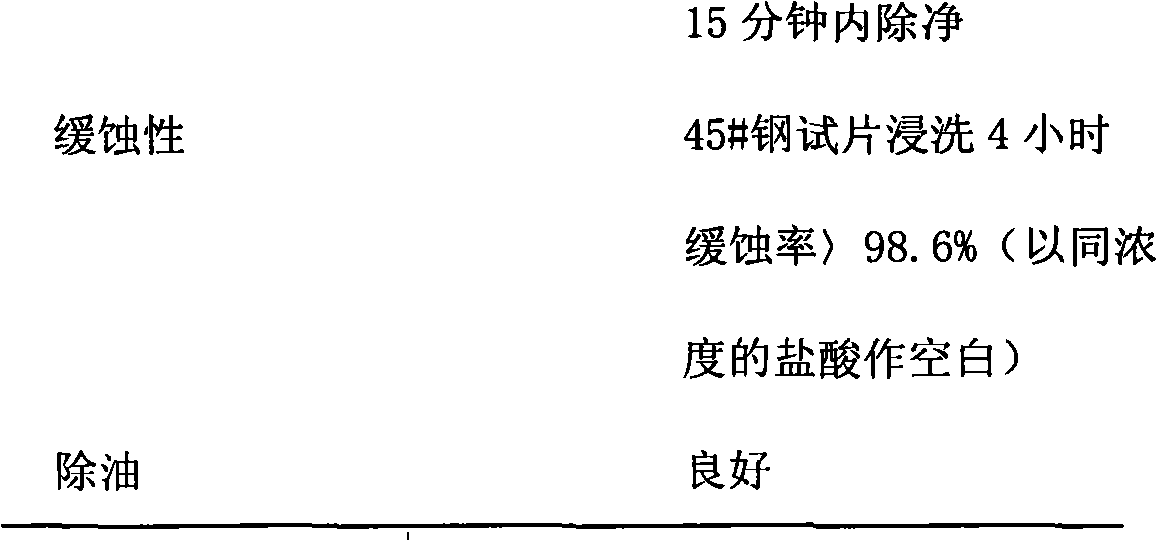

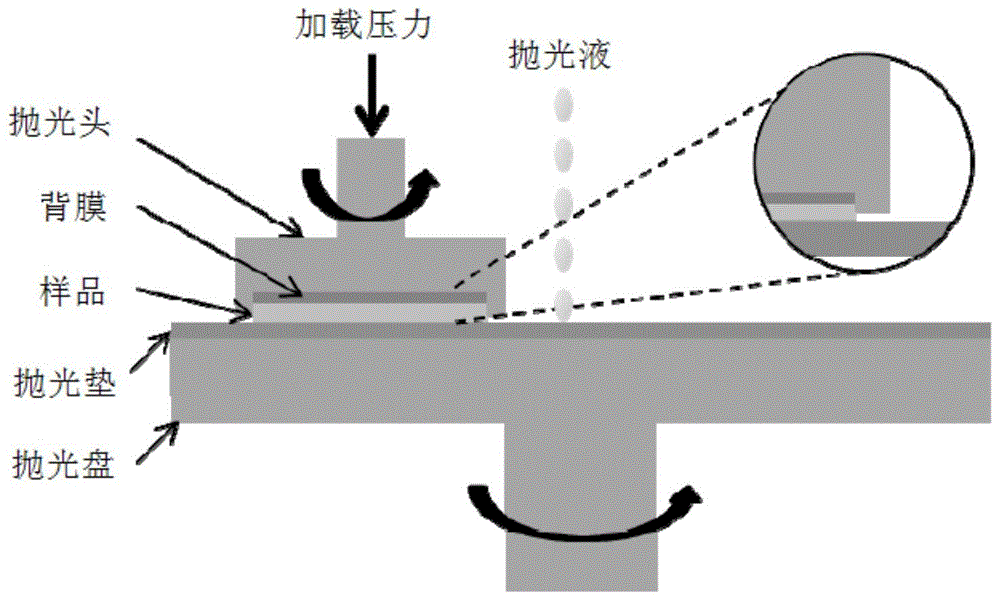

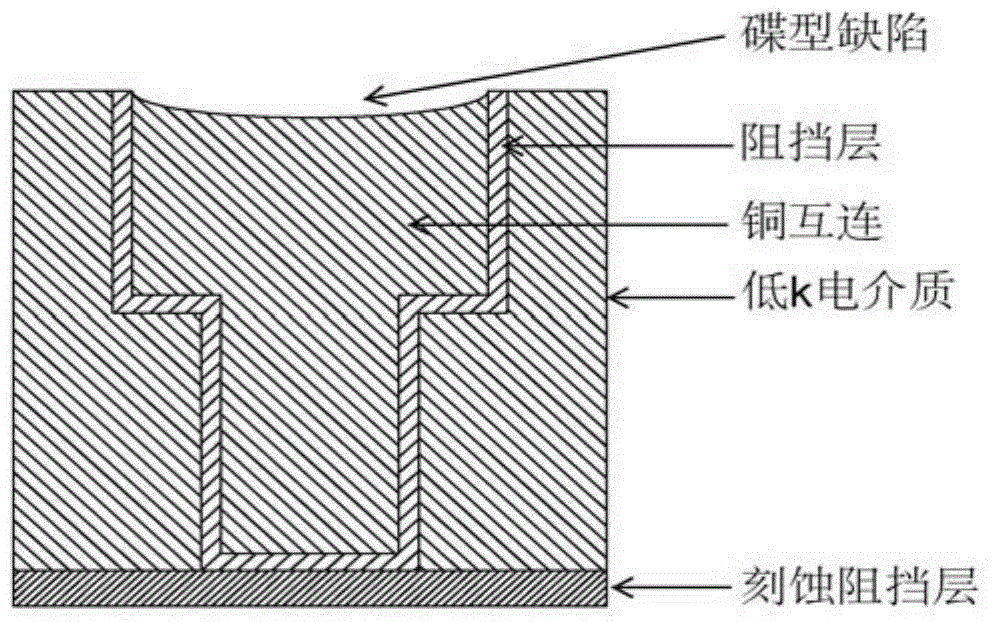

Polishing solution for chemically and mechanically polishing cobalt barrier layer structure and applications thereof

ActiveCN104830235AReduced removal rateAdjustable removal rateSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesCopperCobalt

The invention discloses a polishing solution for chemically and mechanically polishing a cobalt barrier layer structure and applications thereof. The polishing solution comprises the following components in percentage by weight: 0.01 to 20 wt% of grinding particles, 0.01 to 10 wt% of oxidant, 0.01 to 10 wt% of metal complexing agent, 0.005 to 5 wt% of metal corrosion inhibitor, 0.001 to 1 wt% of surfactant, and the balance being water. The polishing solution can form a layer of protective passivation film on the surface of cobalt and copper so as to prevent over-corrosion during the polishing process, can reduce the removal rates of cobalt and copper materials, and obtains the removal rate selectivity of an adjustable material.

Owner:TSINGHUA UNIV

Stainless steel surface scale removal method and pickling solution adopted by same

The invention discloses a stainless steel surface scale removal method and a pickling solution adopted by the same. The pickling solution is a water solution composed of 100-300 ml / L dilute sulfuric acid, 1-5 g / L auxiliary acid, 1-5 g / L surfactant, 1-5 g / L brightening agent and 1-5 g / L corrosion inhibitor. The auxiliary acid is one of citric acid, oxalic acid, nicotinic acid and phytic acid. The surfactant is coconut oil fatty acid and / or nonylphenol polyethenoxy ether. The brightening agent is sodium hexametaphosphate or ethylenediamine tetraacetic acid. The corrosion inhibitor is one of sulfosalicylic acid, thiocarbamide, urotropine and urea. The pickling solution is environment-friendly, can prevent the stainless steel base from over corrosion, and especially can simultaneously remove grease on the stainless steel surface.

Owner:JIANGSU UNIV OF TECH

Copper cleaning agent and preparation method thereof

The invention discloses a copper cleaning agent and a preparation method thereof. The copper cleaning agent disclosed by the invention consists of an inorganic acid, an organic acid, a surfactant, a penetrating agent, an emulsifier, a defoaming agent, a complexing agent and water. The inorganic acid and the organic acid are compounded, the hazards to health of cleaning workers caused by individual use of the inorganic acid in the traditional cleaning agent are avoided, over etching of a copper workpiece is also avoided, the copper cleaning agent is an environmental-friendly cleaning agent and has a certain oiliness, an effect of cleaning dirt such as oil attached to the surface of a copper part is improved by using the cleaning agent, the cleaning agent solution is acidic, and the oxide skin on the surface of the copper part can be well removed. The cleaning agent prepared by the invention is simple in using method, the copper part only needs to be soaked at normal temperature for 2-5 minutes so as to be cleaned, no greasy dirt residue is left on the cleaned copper part, the color of the surface of the copper part is the copper base color, and the cleaning effect is obvious. The copper cleaning agent disclosed by the invention is simple in preparation method, low in cost and obvious in effect and is suitable for industrial production and application.

Owner:PINGGAO GRP +1

Method of raising binding force of chemical coating on the surface of NdFeB permanent magnet

ActiveCN1847451AEvenly degreasingGood degreasing effectLiquid/solution decomposition chemical coatingUltrasonic assistedCavitation

The present invention provides method of raising binding force of chemical coating on the surface of NdFeB permanent magnet. The NdFeB permanent magnet is pre-coated in alkaline plating solution under ultrasonic action, and by means of the activation, cavitation and stirring of ultrasonic wave, one homogeneous and compact initial deposited layer is formed on the surface of the magnet, so as to raise the binding force of chemical nickel-base coating on the surface of the magnet obviously and reduce pores in the coating. The present invention also provides the technological process including deoiling and pickling to activate before plating, the ultrasonic pre-plating and the conventional chemical plating. The formed coating has high corrosion resistance, raised binding to the substrate and perfect protection on the NdFeB permanent magnet.

Owner:ZHEJIANG UNIV

Alkaline cleaner for removing simple substance mercury in natural gas separator and cleaning technique thereof

InactiveCN101671606AReduce concentrationNo concentration surgeOrganic detergent compounding agentsNon-ionic surface-active compoundsSodium phosphatesPhosphoric acid

The invention discloses an alkaline cleaner for removing simple substance mercury in a natural gas separator and a cleaning technique thereof, which can thoroughly remove residual paraffin in the separator, converts the simple substance mercury into non-volatile compound, avoids corrosion for carbon steel and stainless steel, and has the advantages of low cost and no pollution. The alkaline cleaner contains the raw materials by weight percent: at least two of 1-40% of sodium sulfide, 0.1-15% of sodium polysulfide and 1-35% of sodium thiosulfate, at least one of 0.1-10% of sodium nitrate, sodium phosphate and sodium sulfate, at least one of 0.1-15% of sulfuric acid and phosphoric acid, 0.5-20% of non-ionic surface active agent, 0.5-10% of anion surface active agent, 0.5-15% of oxygen-containing solvent, 0.1-10% of inhibiter and less than or equal to 90% of water; and the pH value is more than 10.0.

Owner:DALIAN SANDAAOKE CHEM

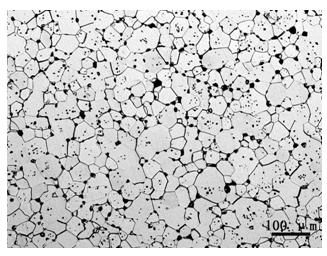

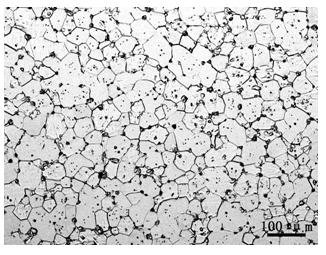

Method for observing metallographic structure of molybdenum-niobium alloy

InactiveCN102419275AGrinding enoughAvoid over corrosionPreparing sample for investigationHydrofluoric acidCrystallography

The invention discloses a method for observing a metallographic structure of a molybdenum-niobium alloy. The method is characterized by comprising the following steps: after grinding a sample on a grinding machine and then polishing the sample on a polishing machine, carrying out attrition on the observed surface of the sample by using a mixed solution of potassium ferricyanides and sodium hydroxides firstly; then, eroding the sample by using a reagent containing sulfuric acid, nitric acid, hydrochloric acid and hydrofluoric acid, carrying out metallographic structure observation on the sample. By using the method disclosed by the invention, the metallographic structure of a molybdenum-niobium alloy can be observed clearly. The method is easy to operate without using any special devices.

Owner:WESTERN METAL MATERIAL

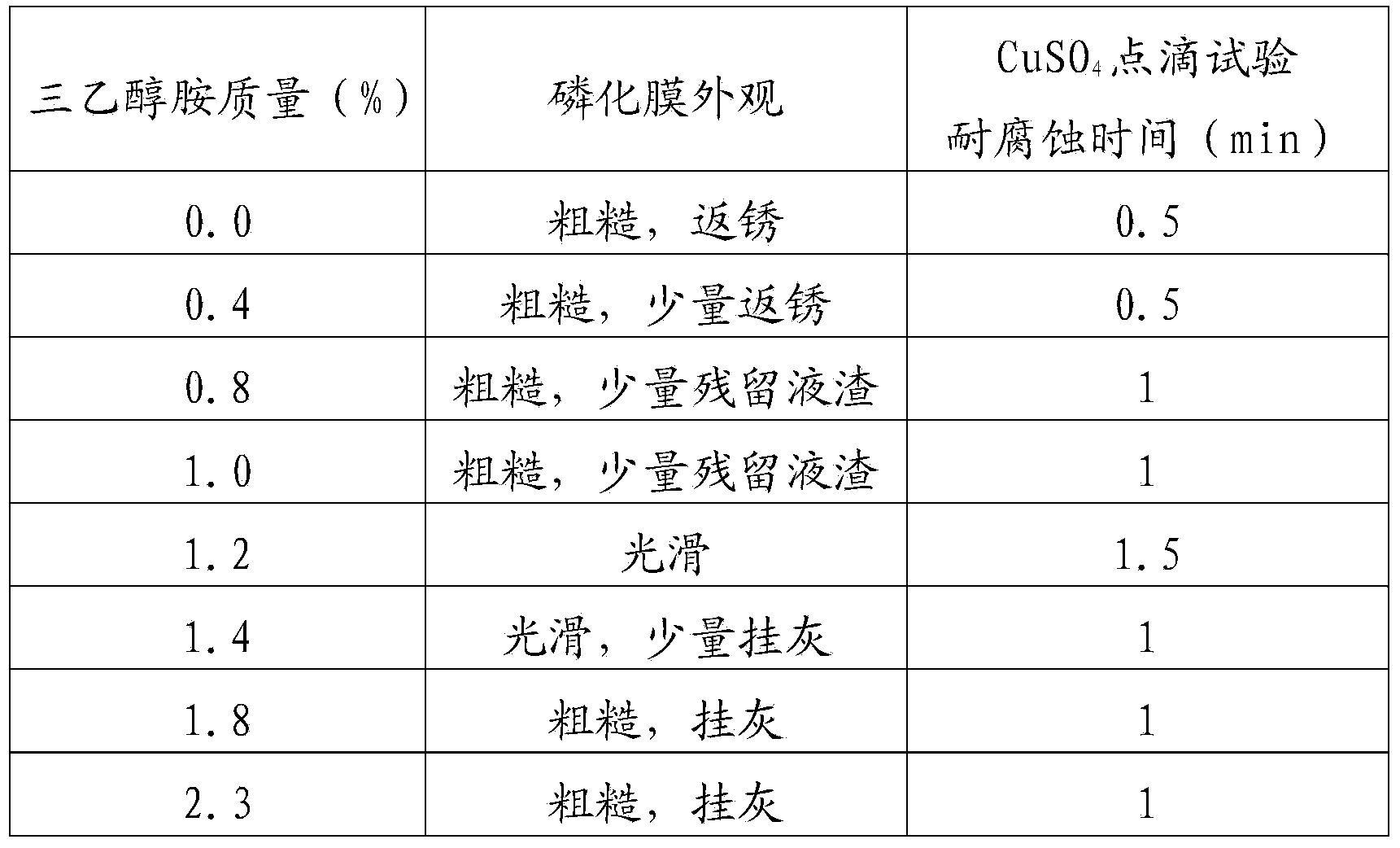

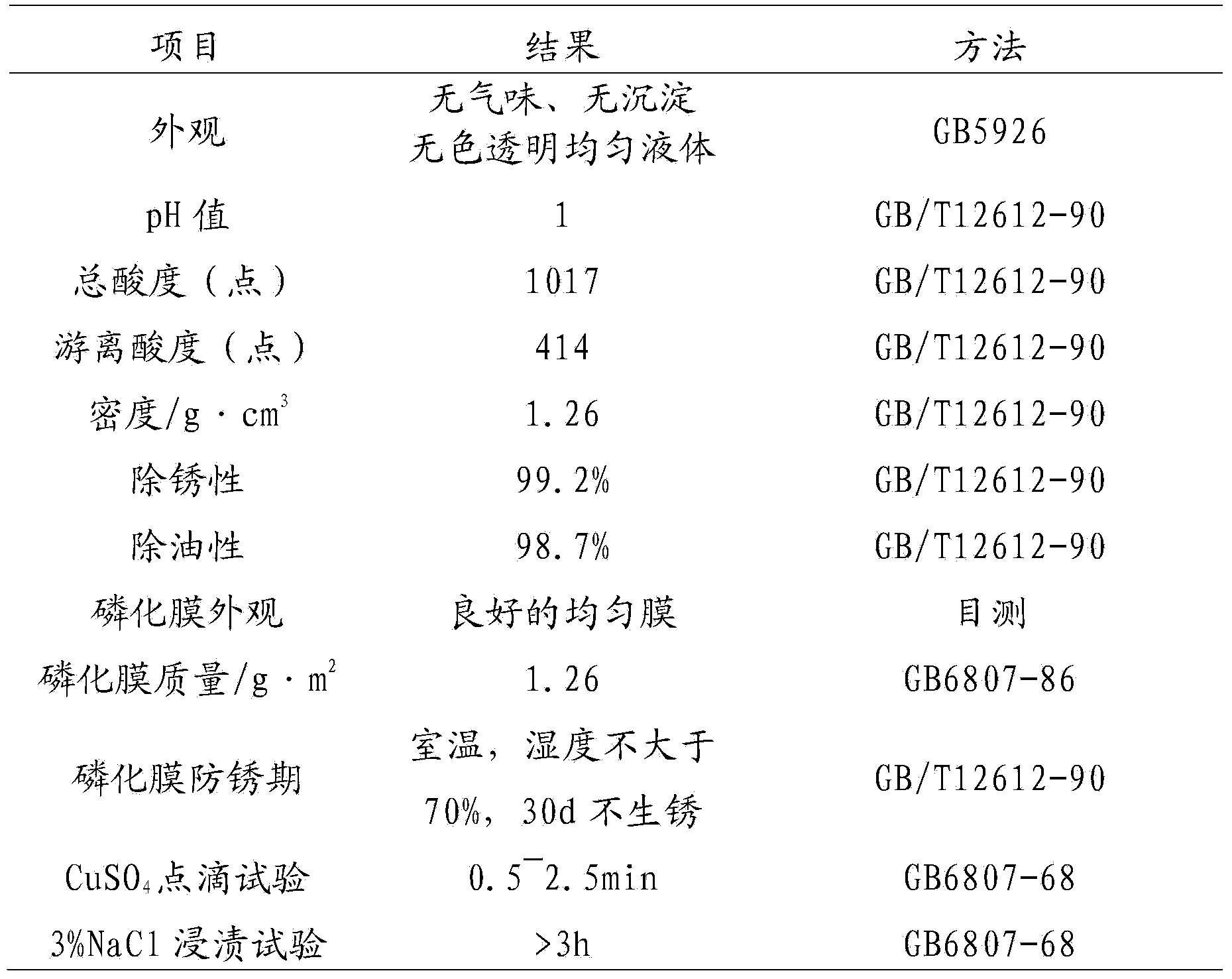

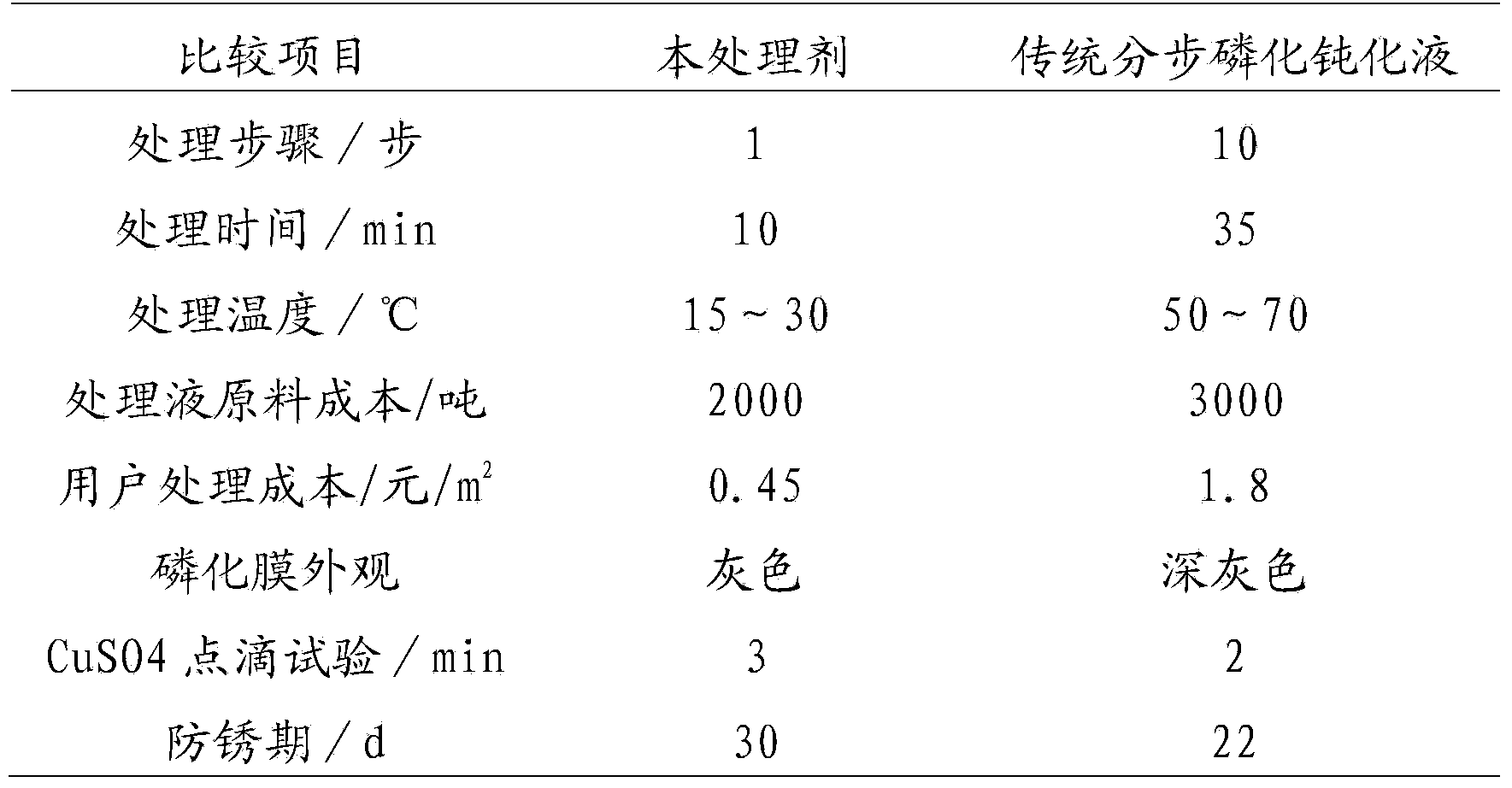

Comprehensive treatment agent and use method thereof

InactiveCN103436872AAvoid time costReduce processing costsMetallic material coating processesThioureaPhosphate

The present invention relates to a comprehensive treatment agent, which comprises, by mass, 25.0-30.0% of phosphoric acid, 1.0-3.0% of zinc oxide, 0.1-0.5% of sodium molybdate, 4.0-7.0% of zinc dihydrogen phosphate, 0.3-1.2% of potassium chlorate, 0.3-1.2% of a surfactant, 0.0-2.3% of triethanolamine, 0.8-2.3% of citric acid, 0.1-0.3% of thiourea, and 58.0-62.6% of water. According to the present invention, the treatment agent can be recycled, a treatment cost is low, and pollution on the environment can not be generated.

Owner:谢俊磊

Environmentally-friendly chemical deplating agent for nickel plating and deplating method

The invention relates to an environmentally-friendly chemical deplating agent for a nickel plating and a deplating method. The deplating agent comprises the components of 30 g / L to 100 g / L of sulfuric acid, 30 g / L to 140 g / L of oxalic acid, 10 g / L to 30 g / L of sodium citrate, 10 g / L to 60 g / L of sodium acetate, 15 g / L to 60 g / L of sodium gluconate, and the balance being water. According to the environmentally-friendly chemical deplating agent, oxalic acid is added based on sulfuric acid, acidity of oxalic acid is not high, and overetching of the nickel plating can be prevented; oxalic acid can provide hydrogen ions used for corroding the plating, and the deplating purpose of the nickel plating can be achieved through only a relatively small amount of sulfuric acid; deplating speed is high, efficiency is high, a deplated stainless steel matrix is smooth in surface, overetching is avoided, and follow-up reutilization and processing are not affected; and oxalate and nickel ions generate nickel oxalate sediment through complexing, nickel is directly sedimented and separated from the system, the follow-up step of recycling nickel metal from deplating waste water is eliminated, nickel oxalate can be directly recycled, and utilization is convenient.

Owner:佛山市南博旺环保科技有限公司

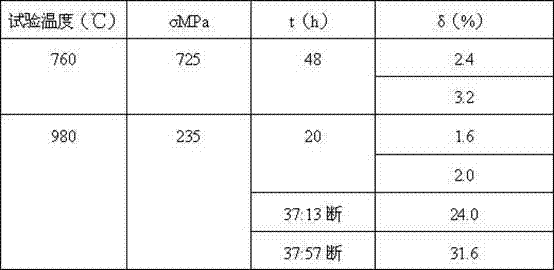

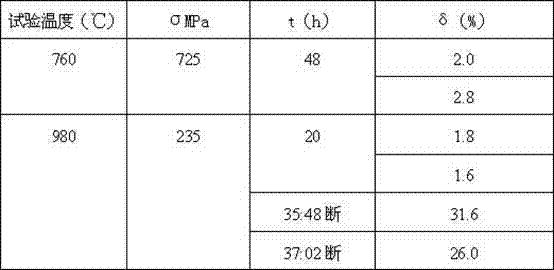

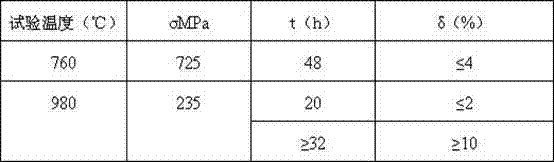

Method for repairing NiCrAlYSi coating on DZ125 blade surface

ActiveCN102965623AGuaranteed to completely removeAvoid over corrosionVacuum evaporation coatingSputtering coatingEtchingPerformance index

The invention belongs to the field of surface treatment, and particularly a method for repairing an NiCrAlYSi coating on a DZ125 blade surface. The method comprises the following steps: removing the original NiCrAlYSi coating on the blade in a coating removal tank solution, treating the blade with a wool felt wheel bonded with 180-mesh corundum until no megascopic coating residue is left on the blade surface, plating a new NiCrAlYSi coating with a vacuum arc plating device for 110-130 minutes, and finally, carrying out heat treatment on the blade in a vacuum heat treatment furnace. The blade subjected to coating repair has the advantages of good use effect and stable property and state; surface over etching, fluoroscopy, mechanical properties and other performance indexes can achieve the design requirements; and the blade repaired through the coating by utilizing the method provided by the invention has the advantages of low production cost, operation convenience and wide application prospects.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Hot galvanizing process

InactiveCN105734476AAvoid over corrosionAvoid destructionHot-dipping/immersion processesThioureaPhosphate

The invention discloses a hot galvanizing process. The hot galvanizing process is characterized in that thiourea with concentration being 0.12% is added during pickling, wherein a picking temperature is 50 DEG C, so that a workpiece can be prevented from being over-etched, and hydrogen absorption capacity of ferro matrix can be reduced; an ultrasonic cleaning agent with concentration being 7.5% is added during ultrasonic cleaning, so that greasy dirt and corrosion on the surface of a workpiece can be quickly removed; the ultrasonic cleaning agent is trichloro ethylene which does not contain phosphate, is harmless to aquatic life, is harmless to a human body and is free of stimulation on skin; the cooling comprises the following two steps: a first step, slow cooling, wherein a cooling speed is 10 DEG C / S, and the workpiece is cooled to a temperature of 650 DEG C; and a second step, quick cooling, wherein the workpiece is cooled by a cooling fan, and is cooled to a temperature of 445 DEG C, so that the structure of the workpiece can be prevented from being damaged; pure aluminum with concentration being 0.02% is added into a zinc pot before galvanizing, so that mobility, at a relatively low temperature, of a hot galvanizing solution is improved, a coating is prevented from being thickened, and the appearance of the coating is improved; a bearing produced by adopting the method has the advantages of corrosion resistance, great bonding strength of a galvanized coating and long usage time, is great in market potential and is wide in prospect.

Owner:徐开文

Paint remover and preparation method thereof, and paint removing method

InactiveCN111334115AAvoid over corrosionEfficient removalChemical paints/ink removersPolymer scienceActive agent

The invention relates to the field of paint removers, and discloses a paint remover and a preparation method thereof, and a paint removing method. The paint remover is prepared from the following components in parts by mass: 20 to 80 parts of ether, 10 to 60 parts of alcohol, 1 to 40 parts of inorganic alkali, 0.1 to 10 parts of a volatile inhibitor, 0.1 to 10 parts of a corrosion inhibitor, 0.1 to 5 parts of a surfactant and 0.1 to 4 parts of a thickening agent. The preparation method of the paint remover comprises the following steps: mixing the inorganic alkali, the ether, the alcohol, thevolatile inhibitor, the corrosion inhibitor, the surfactant and the thickening agent, and uniformly stirring to obtain the paint remover. According to the invention, the paint remover is low in toxicity, environmentally friendly, high in paint removing speed and good in paint removing effect, can avoid corrosion on metal base materials, improve the rust resistance of iron materials, improve the painting adhesive force of iron materials and effectively remove phenolic aldehyde paint films, alkyd paint films, nitro paint films, polyurethane paint films, epoxy resin paint films, water-based paintfilms and electrostatic powder paint films.

Owner:广东东明新材科技有限公司

Multifunctional antirust corrosion-inhibiting agent

The present invention relates to a multifunctional preparation for rust prevention and corrosion inhibition, which is prepared by the following method: 1) first add 597g of water into a 1000ml beaker, then add 217g of metal corrosion inhibitor, and stir for 3-4 hours at room temperature; 2) add 83g of borate coupling agent, stirred at room temperature for 1-1.5 hours; 3) Finally, 103g of titanate coupling agent was added, stirred for 2-3 hours to obtain the antirust and corrosion inhibitor. The antirust performance of the present invention is carried out according to the antirust test standard, and there is no rust on the inner metal surface within 24 hours, and there is no change on the surface. After using the present invention, the paint adhesion is significantly enhanced. According to the cross-cut test standard of GB / T 9286-1998 paint and varnish paint film, the paint film adhesion grade is 0 grade. The invention has excellent corrosion inhibition function, and the pure hydrochloric acid is added in a ratio of 0.3-0.5%, which can effectively prevent metal over-corrosion.

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

Stainless steel electrochemical polishing liquid and polishing process

The invention discloses stainless steel electrochemical polishing liquid and a polishing process, and relates to the technical field of surface electrochemical polishing of stainless steel equipment or products, in particular to the stainless steel electrochemical polishing liquid and the polishing process. The stainless steel electrochemical polishing liquid comprises compositions including, by weight, 15%-25% of sulfuric acid, 20%-35% of citric acid, 3%-10% of ethylene glycol, 1%-3% of ethylene diamine tetraacetic acid, 0.1%-0.5% of polyvinylpyrrolidone and the balance water. According to the stainless steel electrochemical polishing liquid and the polishing process, the sulfuric acid is a strong inorganic acid, has good dispersibility, can be completely ionized in the solution, helps toimprove the conductivity, dispersing ability and anode current efficiency of the polishing liquid and uniformly polishes the surface of the stainless steel; the citric acid has low acidity and high viscosity to prevent corrosion of the stainless steel; and the ethylene glycol is absorbed on the surface of the anode, formation of a diffusion layer is promoted, a film can be formed on the surface of the stainless steel together with citric acid to prevent over-corrosion of the stainless steel, and the polished stainless steel surface is bright and meticulous, and the reflectivity is greater than 98%.

Owner:SHANGHAI GUOSHUN IND EQUIP

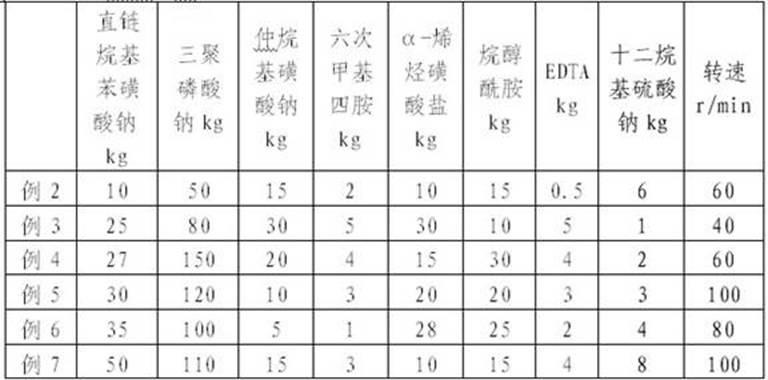

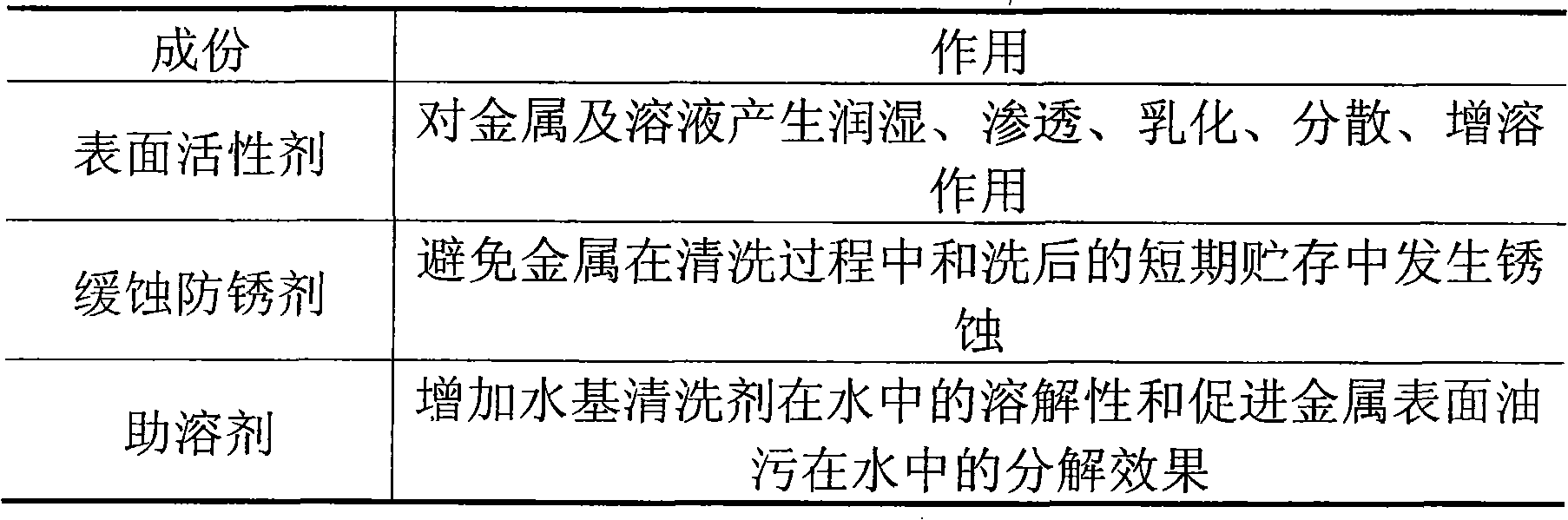

Acidic normal temperature degreasing agent and preparation method thereof

The invention discloses an acidic normal temperature degreasing agent and a preparation method thereof. The degreasing agent comprises the following components and contents (g / L): 20-30 g / L of LAS (Linear Alkylbenzene Sulphonic Acid), 10-20 g / L of SAS (Secondary Alkyl Sulfonate), 80-120 g / L of sodium tripolyphosphate, 2-3 g / L of hexamethylene tetramine, 10-20 g / L of AOS (Alpha-Olefin Sulfonate), 5-15 g / L of alkanol amide, 0.5-2 g / L of EDTA (Ethylene Diamine Tetraacetic Acid) and 2-5 g / L of lauryl sodium sulfate. When in preparing, the method comprises the following steps of: heating purified water of 1 / 3 weight of the required preparation amount to about 60 DEG C; pouring into a stirring kettle; respectively adding the materials to the stirring kettle according to proportion to be stirred and dissolved under the condition of normal temperature and normal pressure and the rotating speed of 40-100r / min; and then adding the purified water to the required amount, and stirring adequately and uniformly. The degreasing agent is characterized in that oil is washed with acid in one step; the surface of a workpiece is not corroded even if the dipping time of the workpiece is long; and because lots of foams are on the tank liquor surface, the volatilization of an acid liquor can be inhibited, and the environmental pollution and the damage to a human body are reduced.

Owner:HUBEI DE MEI TECH

Alkaline chemical milling machining and polishing method for aluminum alloy

The invention discloses an alkaline chemical milling machining and polishing method for aluminum alloy. The method comprises the steps of chemical degreasing, alkaline corrosion treating, deoxidation treating, protection glue applying, drying, curing, carving, alkaline chemical milling machining, polishing treating, cleaning and drying. According to the method, a bright and smooth surface can be obtained on the surface of 2,000-series aluminum alloy, a protection film capable of effectively preventing over corrosion can be formed on the surface of a substrate after chemical milling machining and polishing treatment is conducted, and the surface is not liable to be oxidized after being cleaned. A polishing solution is easy and convenient to prepare, low in cost, environmentally friendly and capable of preventing over corrosion.

Owner:NANCHANG HANGKONG UNIVERSITY

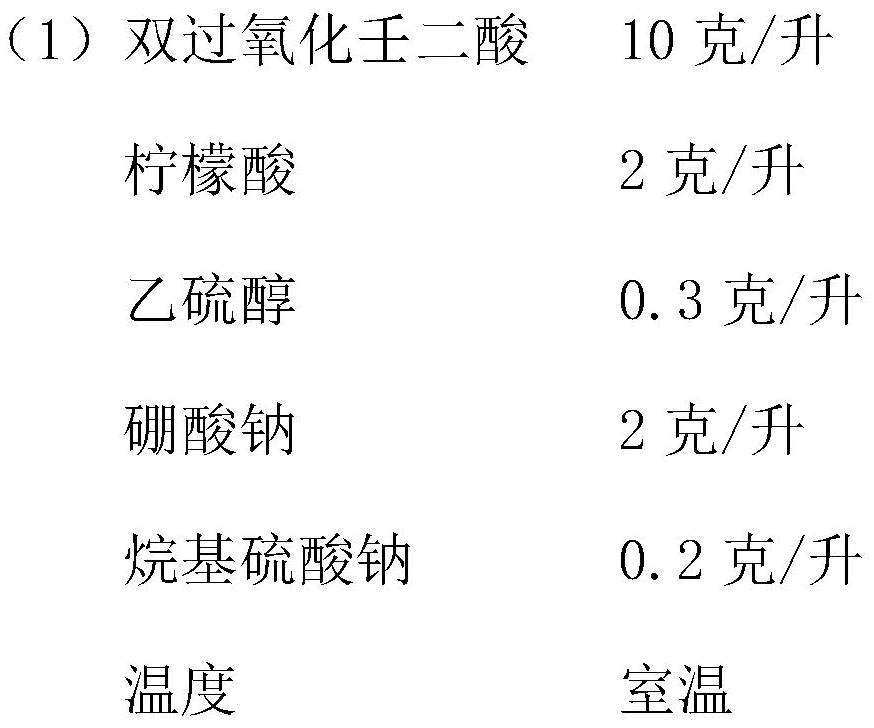

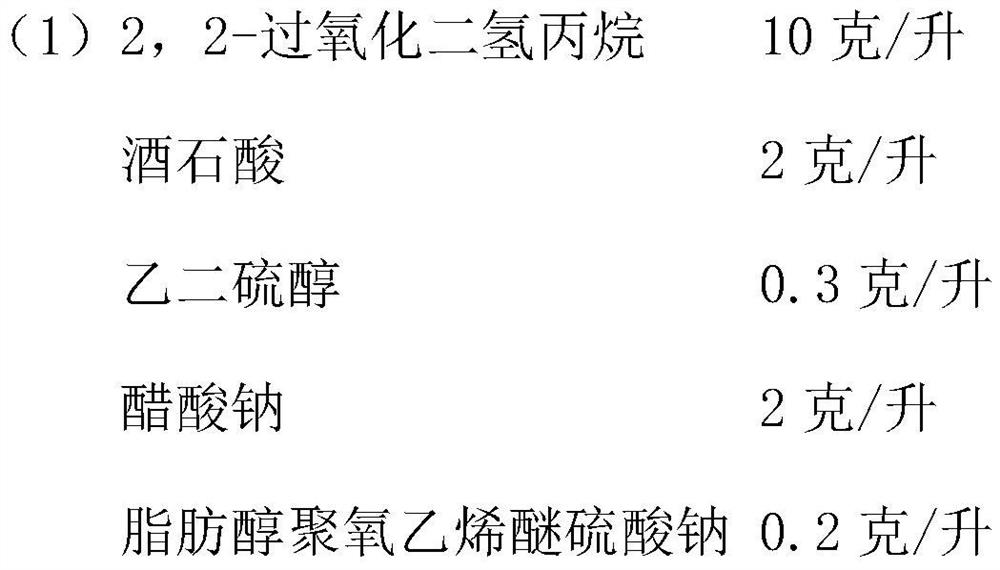

Novel environment-friendly ash removing agent for aluminum alloy and preparation method thereof

The invention discloses a novel environment-friendly ash removing agent for an aluminum alloy and a preparation method thereof. The ash removing agent comprises the following components including, by weight part, 5-15 grams per liter of organic peroxide, 1-3 grams per liter of organic acid complexing agent, 0.2-0.5 gram per liter of organic corrosion inhibitor, 2-3 grams per liter of PH buffering agent and 0.2-0.3 gram per liter of surface active agent. According to the novel environment-friendly ash removing agent for the aluminum alloy and the preparation method thereof, the ash removing agent is used for removing ash hanging to the aluminum alloy after alkaline corrosion and chemical polishing, the ash removing speed is high, the phenomenon of over etching is avoided, metal salt, phosphorus, fluorine and benzene are not contained, the environment-friendly performance is good, no poisonous or pernicious gas is generated in the ash removing process, and the ash removing agent is friendly to environment, and beneficial for protecting body health of operators.

Owner:江门市优博科技有限公司

A kind of environment-friendly chemical stripping agent and stripping method for nickel coating

The invention relates to an environmentally-friendly chemical deplating agent for a nickel plating and a deplating method. The deplating agent comprises the components of 30 g / L to 100 g / L of sulfuric acid, 30 g / L to 140 g / L of oxalic acid, 10 g / L to 30 g / L of sodium citrate, 10 g / L to 60 g / L of sodium acetate, 15 g / L to 60 g / L of sodium gluconate, and the balance being water. According to the environmentally-friendly chemical deplating agent, oxalic acid is added based on sulfuric acid, acidity of oxalic acid is not high, and overetching of the nickel plating can be prevented; oxalic acid can provide hydrogen ions used for corroding the plating, and the deplating purpose of the nickel plating can be achieved through only a relatively small amount of sulfuric acid; deplating speed is high, efficiency is high, a deplated stainless steel matrix is smooth in surface, overetching is avoided, and follow-up reutilization and processing are not affected; and oxalate and nickel ions generate nickel oxalate sediment through complexing, nickel is directly sedimented and separated from the system, the follow-up step of recycling nickel metal from deplating waste water is eliminated, nickel oxalate can be directly recycled, and utilization is convenient.

Owner:佛山市南博旺环保科技有限公司

Copper detergent

The invention discloses a copper detergent which is composed of the following raw materials: 15-20 parts of metatitanic acid, 15-20 parts of thiosulfuric acid, 15-20 parts of phosphorous acid, 20-25 parts of fluoboric acid, 8-10 parts of zinc hydroxide, 5-10 parts of aluminum sulfate, 15-18 parts of phosphoric acid, 5-10 parts of tartaric acid, 8-10 parts of oxalic acid, 3-5 parts of cocooctyl phenol polyethenoxy ether, 5-6 parts of fatty alcohol polyethenoxy ether, 5-8 parts of isoalcohol polyethenoxy ether, 4-5 parts of diethylene glycol aether, 5-7 parts of glycol ether acetate, 6-8 parts of propylene glycol methyl ether acetate, 6-8 parts of emulsified silicone oil, 8-10 parts of polydimethylsiloxane, 6-8 parts of glycerol, 3-5 parts of ethylene glycol monophenyl ether, 4-5 parts of sodium alginate, 5-6 parts of ammonium citrate and 200-250 parts of deionized water. The copper detergent lowers the consumption of three industrial strong acids, lowers the health hazard to the operating personnel and avoids generating over etching on the copper substrate. After being cleaned by the copper detergent and flushed with distilled water, the copper part has the advantages of uniformly distributed surface water film and no oil stain residue.

Owner:张慧玲

Cleaning agent and cleaning method for air conditioner

InactiveCN101475878BAvoid over corrosionLow costNon-ionic surface-active compoundsFlush cleaningStrong acidsHigh pressure water

The present invention discloses a detergent and a cleaning method for a complete air-conditioner, which not only can uniformly and completely remove dirt but also cannot strongly corrupt components and parts such as aluminum, copper and stainless steel, are time-saving and labor saving, safe and reliable, and pollution-free, and have low cost. Raw materials of the detergent are at least two compositions of citric acid, inorganic weak acid and inorganic strong acid; a non-ionic surfactant or a non-ionic surfactant is mixed with an anionic surfactant; and the detergent comprises an oxygen solvent, an acid corrosion inhibitor, and the balance being water. The cleaning method comprises: disassembling a motor and a fan, and taking off the motor and the fan for independent cleaning; preparing the detergent into an aqueous solution according to the proportion of between 10 and 15 percent, hanging the complete air-conditioner after disassembly of the motor and the fan into a cleaning tank, soaking the complete air-conditioner for 30 minutes at normal temperature, and starting ultrasonic waves to clean for 10 to 30 minutes; placing the complete air-conditioner into a washing tank, and using a high-pressure water gun to spray the surface and the inside of the air-conditioner; and using hot blast to dry the air-conditioner at a temperature of 80 DEG C.

Owner:DALIAN SANDAAOKE CHEM

Surface cleaning agent for sensor zinc-plating shell

The invention discloses a surface cleaning agent for a sensor zinc-plating shell. The surface cleaning agent mainly comprises XP-80, TX-10, phenanthroline, phytic acid, sodium salicylate, a citric acid corrosion inhibitor, hydrochloric acid, a hydrochloric acid fog inhibitor and water, wherein the hydrochloric acid fog inhibitor comprises the following components in percentage by weight: 8-18% of a corrosion inhibitor, 4-8% of a fog inhibitor, 8-15% of a surfactant and the balance of water. By adopting the surface cleaning agent for the sensor zinc-plating shell disclosed by the invention, over-corrosion and acid fog formation can be inhibited, the consumption of materials and hydrochloric acid can be saved, the service life of hydrochloric acid can be prolonged, and environmental protection can be achieved. In addition, the invention also provides a surface cleaning agent for a sensor zinc-plating shell. By adopting the surface cleaning agent for the sensor zinc-plating shell, the cleaning time can be shortened, and the corrosion can be reduced. Meanwhile, by adopting the surface cleaning agent for the sensor zinc-plating shell, an anti-rust layer can also be formed on the cleaned metal surface so as to prevent the cleaned metal surface from rusting again.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Pretreatment method for plating or chemically plating tungsten alloy and application thereof

ActiveCN105420699AUniform removalImprove antioxidant capacityLiquid/solution decomposition chemical coatingPretreatment methodChrome plating

The invention provides a pretreatment method for plating or chemically plating tungsten alloy and a chrome plating method for the tungsten alloy. According to the pretreatment method for plating or chemically plating the tungsten alloy, the pretreatment method of chemical degreasing, strong corrosion and nickel preplating is adopted, and an appropriate solution formula and technological parameters are selected; under the condition that a base body is not corroded, oil on the surface of the tungsten alloy is removed, an oxide film and a natural passive film are removed uniformly, and an excellent base body surface is obtained; in addition, a compact nickel layer is formed on the surface of the tungsten alloy through an appropriate preplating solution and technological parameters, the follow-up obtained binding force of a plating layer is increased, and the properties such as high binding force, abrasion resistance and oxidation resistance of chrome or other metal are ensured; the pretreatment method is stable, not only suitable for the chrome plating treatment of the tungsten alloy material, but also suitable for other plating pretreatment and chemical plating pretreatment of the tungsten alloy material; the plating layer is obtained after plating, and the phenomena of peeling and shedding of the plating layer are not existed.

Owner:天津航空机电有限公司

Galvanizing technology for combination intensity of galvanizing layer and base material

InactiveCN104762579APrevents defects that are easy to fall offGuaranteed adhesionHot-dipping/immersion processesSulfurTetramine

The invention discloses a galvanizing technology for combination intensity of a galvanizing layer and a base material, which is used for anticorrosion processing of surface of a photovoltaic flat rack. The technology comprises the steps of cleaning, drying, galvanizing and cooling in order, and the cleaning step comprises the steps of degreasing, examining, pickling and washing in order, pickling temperature scope is between 30-35 DEG C, a pickle containing hydrogen chloride, hexamethylene tetramine and a corrosion inhibitor is used for cleaning the photovoltaic flat rack; the corrosion inhibitor contains a nitrogen compound-containing corrosion inhibitor and a sulfur compound-containing corrosion inhibitor; an assistant leaching step is provided between the drying step and galvanizing step, the assistant leaching is characterized in that the photovoltaic flat rack is immersed into a plating auxiliary for 5-8 minutes, the temperature of the plating auxiliary is between 50-57 DEG C, the plating auxiliary contains zinc chloride and ammonium chloride, the mass ratio of zinc chloride to ammonium chloride is between 1 and 4 to 1 and 10, and the plating auxiliary also contains glycerin. According to the invention, the technology route is simple, and the galvanizing layer bonding strength is good.

Owner:CHENGDU ZHENZHONG ELECTRIC

Washing agent for electrical copper braided wire

InactiveCN104831294AStrong anti-tarnish abilityImprove shelf life and service lifeCitrate sodiumChemistry

The invention provides a washing agent for electrical copper braided wire. The washing agent comprises the following chemical components in percentage by weight: 20 to 25% of scale and corrosion inhibitor, 1 to 5% of sodium tripolyphosphate, 0.5 to 3% of sodium citrate, 2 to 5% of trichloroethane, 10 to 20% of polyacrylic acid, 15 to 30% of phosphoric acid, 10 to 18% of fatty acid glyceride, 5 to 12% of osmotic agent, 3 to 5% of emulsifier, 2 to 6% of antifoaming agent, and the balance being water. The washing agent is nontoxic and environment-friendly, can effectively wash off the copper scales on the surface of electrical copper braided wires after oxidation, and can form a protective film on the surface of electrical copper braided wires after washing, because the film is uniform and compact and is hard to peel off, the electrical copper braided wire has a very good performance on preventing fading and oxidation therefore, the preservation time and service life of electrical copper braided wire are both prolonged, and the production cost is reduced.

Owner:丰城市华丰金属制品有限责任公司

Alkaline cleaning agent and cleaning process for removing elemental mercury in natural gas separator

InactiveCN101671606BReduce concentrationNo concentration surgeOrganic detergent compounding agentsNon-ionic surface-active compoundsO-Phosphoric AcidSodium phosphates

The invention discloses a low-cost and non-polluting method for removing the residual paraffin in the separator, converting elemental mercury into a non-volatile compound, and avoiding corrosion of carbon steel and stainless steel. Mercury alkaline cleaning agent and cleaning process. The raw materials and weight percentages are as follows: at least two of sodium sulfide, sodium polysulfide and sodium thiosulfate, wherein sodium sulfide is 1-40%, sodium polysulfide is 0.1-15%, and sodium thiosulfate is 1-35%; At least one of sodium nitrate, sodium phosphate, and sodium sulfate, the content of which is 0.1-10%; one of sulfuric acid and phosphoric acid, the content of which is 0.1-15%; nonionic surfactant 0.5-20%; anionic surface active agent Active agent 0.5-10%; oxygen-containing solvent 0.5-15%; corrosion inhibitor 0.1-10%; water less than or equal to 90%; pH value greater than 10.0.

Owner:DALIAN SANDAAOKE CHEM

Photovoltaic plate frame corrosion resistance treatment method

InactiveCN104831205AImprove galvanizing qualityImprove mechanical propertiesHot-dipping/immersion processesWater basedAcid washing

The present invention discloses a photovoltaic plate frame corrosion resistance treatment method, which is used for surface corrosion resistance treatment on a photovoltaic plate frame and sequentially comprises washing, drying, hot zinc plating, and cooling, wherein the washing step sequentially comprises degreasing, inspection, acid washing, and water washing, the degreasing step is adopting a water-based metal degreaser to carry out an oil removing treatment on the photovoltaic plate frame surface, the hot zinc plating step comprises heating a zinc liquid to a temperature of 455-480 DEG C, placing the photovoltaic plate frame into the zinc liquid, maintaining for 1-1.5 min, and taking out, the zinc liquid contains 0.07-0.1% by mass of aluminum, and the leaching assisting step is set between the drying step and the hot zinc plating step. According to the present invention, the process route is simple, and the photovoltaic plate frame surface corrosion resistance quality is easily achieved.

Owner:SICHUAN HEDING ENVIRONMENTAL PROTECTION ENG

Method of raising binding force of chemical coating on the surface of NdFeB permanent magnet

ActiveCN100427642CEasy to removeHigh catalytic activityLiquid/solution decomposition chemical coatingUltrasonic assistedCavitation

The present invention provides method of raising binding force of chemical coating on the surface of NdFeB permanent magnet. The NdFeB permanent magnet is pre-coated in alkaline plating solution under ultrasonic action, and by means of the activation, cavitation and stirring of ultrasonic wave, one homogeneous and compact initial deposited layer is formed on the surface of the magnet, so as to raise the binding force of chemical nickel-base coating on the surface of the magnet obviously and reduce pores in the coating. The present invention also provides the technological process including deoiling and pickling to activate before plating, the ultrasonic pre-plating and the conventional chemical plating. The formed coating has high corrosion resistance, raised binding to the substrate and perfect protection on the NdFeB permanent magnet.

Owner:ZHEJIANG UNIV

Treatment process before plating environment-friendly copper alloy

InactiveCN101619476AAvoid over corrosionMeet environmental protection requirementsLiquid/solution decomposition chemical coatingIonOxide

The invention discloses a treatment process before plating an environment-friendly copper alloy. The treatment process comprises the following four steps: (i) using a water-based cleaning agent to deoil; (ii) rinsing the copper alloy in cold water; (iii) ultrasonically immersing the copper alloy in phytic acid; and (iv) ultrasonically rinsing the copper alloy in deionized water. The invention adopts the phytic acid for the ultrasonic using treatment process before plating the copper alloy, not only can thoroughly remove an oxide film on the surface of a basal body of a plating article and activates the basal body, but also can avoid over eroding the basal body of the plating article, achieve the environmental-protection requirement in aspects of operation environment, sewage drain, and the like and greatly decrease the production cost.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Air conditioner aluminum fin weak alkaline cleaner and cleaning method

InactiveCN107988613AEvenly and thoroughlyImprove heating efficiencyCleaning methodsSurface-active agents

The invention discloses an air conditioner aluminum fin weak alkaline cleaner which can evenly and thoroughly remove dirt, cannot generate high corrosion on aluminum fins, saves time and labor, and islow in cost, safe, reliable and free of pollution. The air conditioner aluminum fin weak alkaline cleaner comprises raw materials including, by mass percent, 1%-5% of citric acid, 0.1%-15% of sodiummetasilicate pentahydrate, 0.1%-5% of sodium carbonate, 0.1%-10% of sodium gluconate, 0.5%-20% of a non-ionic surface active agent, 0.5%-10% of a cationic surface active agent, 0.5%-15% of an oxygen bearing solvent and the balance water; and the pH value is 10.0-10.5. The cleaning method includes the following steps that the aluminum fins on an air conditioner in a train are detached; the cleaneris prepared into an aqueous solution according to the mass percent being 10%-15%, the detached aluminum fins are hoisted into a cleaning tank, soaking is carried out for 30 min at the normal temperature, ultrasonic cleaning is started to last for 10 min-30 min; the aluminum fins of the air conditioner are placed into a washing tank, a water torch is used for spraying and cleaning the surfaces of gaps of the aluminum fins of the air conditioner; and the aluminum fins are placed to be dried.

Owner:DALIAN SANDAAOKE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com